Aluminum foil for power battery and preparation process of aluminum foil

A technology of power battery and preparation process, which is applied in metal rolling and other directions, can solve the problems of low dyne value of aluminum foil and affect product quality, etc., and achieve the effect of large surface tension coefficient, reasonable proportion and beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

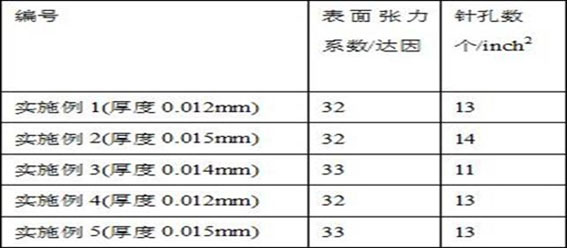

Examples

Embodiment 1

[0039] An aluminum foil for a power battery, the percentage by weight of each raw material in the aluminum foil is as follows: Si 0.05%, Fe 0.2%, Cu 0.2%, Mn 0.05%, Mg 0.05%, Zn 0.05%, Ti 0.01%, and the balance is Al.

[0040] The preparation process of the aluminum foil for the power battery comprises the following steps:

[0041] Step (1) Melting and casting: Weigh and mix each raw material according to the weight percentage, first smelt to obtain a melt, and then cast and roll the melt to form a 7mm thick cast-rolled coil; the smelting process includes melting, standing, refining, slag removal and deslagging After degassing, the hydrogen content of the melt is controlled below 0.10ml / 100gAl;

[0042] Step (2) First cold rolling: Cool the cast-rolled coil obtained in step (1) to room temperature, and then undergo the first cold rolling treatment to obtain a cold-rolled billet; the uncoiling tension of cold rolling is 20N / mm 2 , take-up tension is 30N / mm 2 , the rolling spe...

Embodiment 2

[0048] An aluminum foil for a power battery, the weight percentage of each raw material in the aluminum foil is as follows: Si 0.2%, Fe 0.7%, Cu 0.2%, Mn 0.05%, Mg 0.05%, Zn 0.05%, Ti 0.06%, and the balance is Al.

[0049] The preparation process of the aluminum foil for the power battery comprises the following steps:

[0050] Step (1) Melting and casting: Weigh and mix each raw material according to the weight percentage, first smelt to obtain a melt, and then cast and roll the melt to form a 7mm thick cast-rolled coil; the smelting process includes melting, standing, refining, slag removal and deslagging After degassing, the hydrogen content of the melt is controlled below 0.10 ml / 100gAl;

[0051] Step (2) First cold rolling: Cool the cast-rolled coil obtained in step (1) to room temperature, and then undergo the first cold rolling treatment to obtain a cold-rolled billet; the uncoiling tension of cold rolling is 25N / mm 2 , take-up tension is 35N / mm 2 , the rolling speed ...

Embodiment 3

[0057] An aluminum foil for a power battery, the weight percentage of each raw material in the aluminum foil is as follows: Si 0.1%, Fe 0.3%, Cu 0.2%, Mn 0.05%, Mg 0.05%, Zn 0.05%, Ti 0.02%, and the balance is Al.

[0058] The preparation process of the aluminum foil for the power battery comprises the following steps:

[0059] Step (1) Melting and casting: Weigh and mix each raw material according to the weight percentage, first smelt to obtain a melt, and then cast and roll the melt to form a 7mm thick cast-rolled coil; the smelting process includes melting, standing, refining, slag removal and deslagging After degassing, the hydrogen content of the melt is controlled below 0.10 ml / 100gAl;

[0060] Step (2) First cold rolling: Cool the cast-rolled coil obtained in step (1) to room temperature, and then undergo the first cold rolling treatment to obtain a cold-rolled billet; the uncoiling tension of cold rolling is 22N / mm 2 , take-up tension is 31N / mm 2 , the rolling speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com