Method for measuring surface tension coefficient of liquid by injecting liquid into round tank

A technology of liquid surface tension and circular grooves, applied in the direction of surface tension analysis, etc., can solve the problems of inaccurate measurement of liquid column height, liquid surface curvature, and low measurement accuracy, and achieve low measurement cost, small error, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

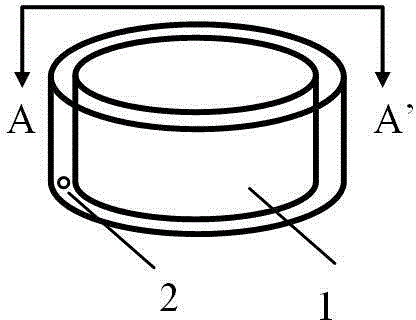

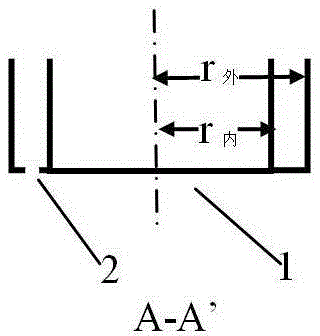

[0011] The circular groove 1 is composed of two cylinders with the same central axis and a common sealing bottom plate. The outer side of the inner cylinder, the inner side of the outer cylinder and the upper part of the sealing bottom plate form the space of the circular groove 1. There is a small hole 2 on the sealing bottom plate of the circular groove 1, and the small hole 2 is a through hole; the circular groove 1 is placed on a table (the table has a horizontal bubble, and the base has a level adjustment device), and the small hole 2 is in the Place a measuring cup under the small hole 2, take a certain amount of liquid and pour it into the circular groove 1. Let the volume of the liquid be Q1. The amount of the liquid should ensure that there is liquid dripping from the bottom of the small hole 2. , stand still until there is no liquid dripping below the small hole 2, read the volume Q2 of the liquid dripping from the small hole 2 in the measuring cup from the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com