Design method of refining slag system for removing magnesium aluminate spinel inclusions

A technology of magnesium aluminum spinel, design method, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A plant produces aluminum deoxidation steel, using magnesium treatment in the absence of refining process, and generates inclusions mainly magnesium aluminum spinel. The main component of refinement is Al 2 O 3 -CAO-SIO 2 .

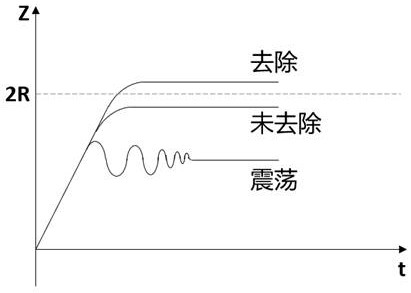

[0078] The relationship between the inclination z and time t is calculated by the following formula (1) - (8).

[0079] (1)

[0080] among them, Driving force, N; R The radius of inclusions, M; G is gravity acceleration, 9.81m / s 2 ; For fluid density, kg / m 3 ; - For the density of inclusions, kg / m 3 ;

[0081] (2)

[0082] among them, Feature viscosity, Pa • S; For the upper floating speed, m / s of the inclusions; F d The floating force of the inclusions is being treated by fluid drag, n; re is the number of conjunction of inclusions;

[0083] (3)

[0084] among them, F m In addition to quality, N; Acceleration, m / s for inclusive exercise 2 ;

[0085] (4)

[0086] among them, Interfacial resistance, n; In the interface, J; Z is...

Embodiment 2

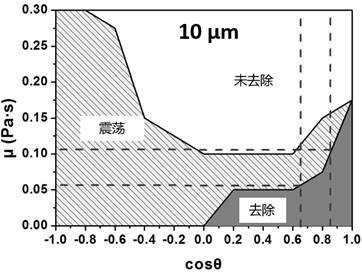

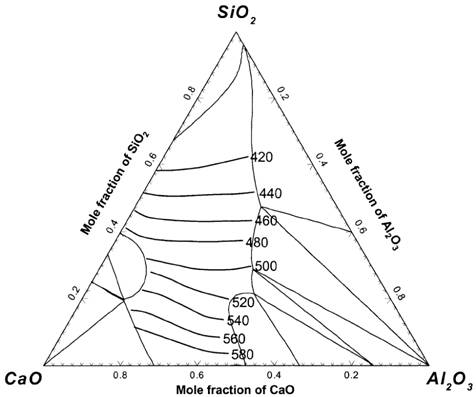

[0109] With the same process conditions as in Example 1, the refined slag system is capable of absorbing a magnesium-aluminum spinel clutter having a radius greater than 10 μm, according to figure 2 The selected slag system has a range of less than 0.12 Pa • s, steel-slag clamp three-phase moisture angle cosine value COS θ is greater than 0.7, calculated that the surface tension coefficient of the corresponding refinement is less than 0.53 n / m. The first finishing slag component group corresponding to the viscosity corresponding to the FACTSAGE software is used as 20-35% Al. 2 O 3 , 55-60% Cao, 10-15% SiO 2 , According to the three-dimensional surface tension equivalent map ( image 3 ) The corresponding first finiterating slag component composition and the second fine-absorbing system component group becomes 10-40% alone. 2 O 3 , 50-80% Cao, 0-15% SiO 2 . Take the first refining residue component composition and the second fine scorpion system composition composition correspon...

Embodiment 3

[0111] The same algorithm as in Example 1 was used.

[0112] A plant produces low carbon steel, aluminum-magnesium composite oxygen in the refining process, and generates inclusions mainly magnesium aluminum spinel. The main component of refinement is Al 2 O 3 -CAO binary slag system. The size of the predetermined inclusions is 15 μm, and the inclusion to remove the physical properties of the inclusion by dynamic force analysis model. Figure 5 Indicated. The selected viscosity range is less than 0.09 Pa • S, steel-slag clamp three-phase moisture angle cosine value COSθ is 0.65-0.85, calculated that the surface tension coefficient of the corresponding refinement is from 0.55 to 0.8 N / m. The first fine scorpion component group corresponding to the slag-resistant viscosity was used to calculate or query the slag-induced viscosity. According to Al 2 O 3 -CAO dual residue surface tension characteristics, using equations (13) and (14) to calculate ingredients and surface tension rela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com