Polyolefin microporous membrane and preparation method thereof

A technology of polyolefin microporous membrane and microporous membrane, which is applied in the direction of electrical components, electrochemical generators, circuits, etc., can solve the problem of low surface tension coefficient, failure to meet the requirements of use, and inability to effectively increase the surface tension coefficient, etc. problems, to achieve the effect of improving the surface tension coefficient, ensuring safety and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a polyolefin microporous membrane, which includes the following steps:

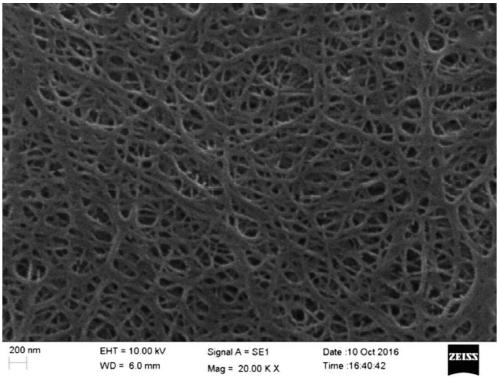

[0029] (1) The polyolefin resin and diluent are melted and blended in a twin-screw extruder, extruded from the die, and the cast sheet is cooled by the casting roll, and then biaxially stretched, extracted, and dried to prepare Microporous membrane A;

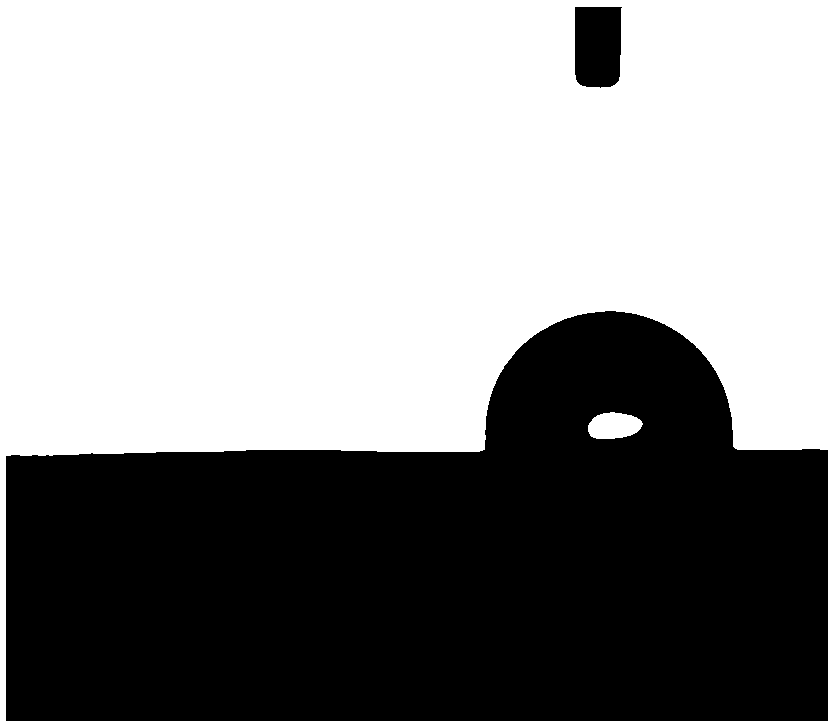

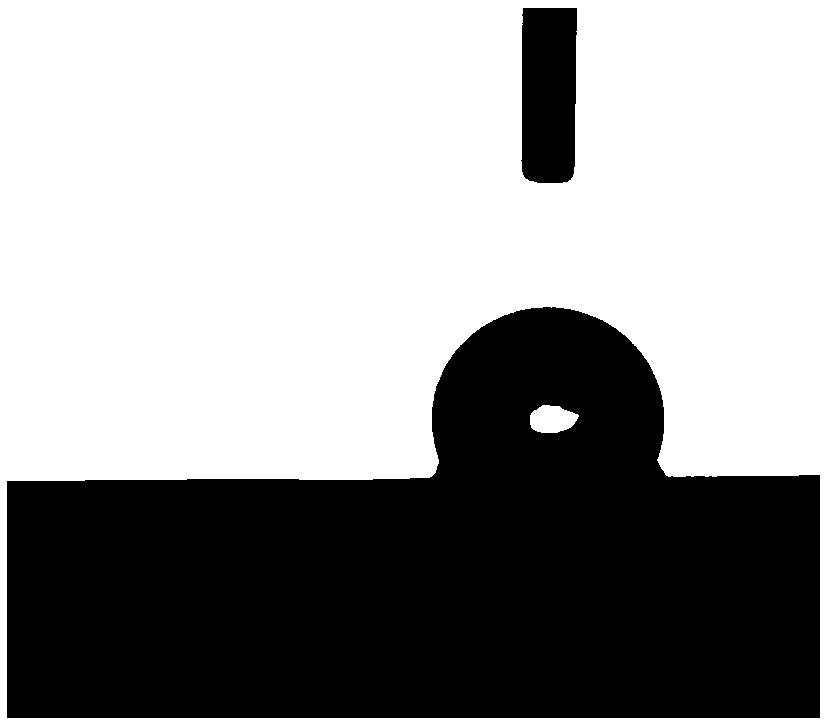

[0030] (2) In the presence of the photosensitizer, use a low-pressure mercury lamp to irradiate the surface of the microporous membrane A to obtain the microporous membrane B;

[0031] (3) The microporous membrane B is subjected to transverse heat setting treatment to obtain the microporous membrane C;

[0032] (4) The microporous film C is corona treated with a corona treatment machine to obtain a polyolefin microporous film.

[0033] Preferably, the weight ratio of the polyolefin resin to the diluent is 1:1-9, and more preferably, the weight ratio of the polyolefin resin to the diluent is 1:2-6.

[0034] Prefera...

Embodiment 1

[0045] (1) UHMWPE with a weight ratio of 1:3 (average molecular weight of 2×10 6 ) And paraffin oil are melted and blended in a twin-screw extruder at an extrusion temperature of 190℃, extruded from a die, and the cast sheet is cooled by a casting roll at a temperature of 40°C, and the cast sheet is biaxially stretched , Where the stretching ratio is longitudinal × transverse = 5 × 7 times, and then subjected to extraction post-drying treatment in heptane at 25°C to obtain microporous membrane A;

[0046] (2) In the presence of benzophenone, the surface of the microporous membrane A is irradiated with ultraviolet light with a wavelength of 254nm generated by a low-pressure mercury lamp for 1 min to obtain microporous membrane B, where the gap between the low-pressure mercury lamp and the microporous membrane A Is 200mm;

[0047] (3) The microporous film B was heat-set at a rate of 1.2 in a transverse stretching oven at 140°C to obtain the microporous film C;

[0048] (4) The micropo...

Embodiment 2

[0050] (1) UHMWPE with a weight ratio of 1:2 (average molecular weight of 3×10 5 ) And diisobutyl adipate are melted and blended in a twin-screw extruder with an extrusion temperature of 160°C, extruded from a die, and the cast sheet is cooled by a casting roll at a temperature of 10°C, and the cast sheet Perform biaxial stretching, where the stretching ratio is longitudinal × transverse = 3 × 5 times, and then perform extraction and post-drying treatment in acetone at 15° C. to obtain microporous membrane A;

[0051] (2) In the presence of benzophenone, irradiate the surface of the microporous membrane A with ultraviolet light with a wavelength of 180nm generated by a low-pressure mercury lamp for 2 minutes to obtain microporous membrane B. The gap between the low-pressure mercury lamp and the microporous membrane A Is 100mm;

[0052] (3) The microporous film B is heat-set at a rate of 1 in a transverse stretching oven at 100°C to obtain the microporous film C;

[0053] (4) The mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com