Method for evaluating probability of liquid leakage of electronic atomizer

An electronic atomizer and atomizing liquid technology, applied in the application, tobacco, smoker's products, etc., can solve the problems of uncertain evaluation results, long debugging time, strong subjectivity in evaluating atomizers, etc., and shorten the research and development process. , the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

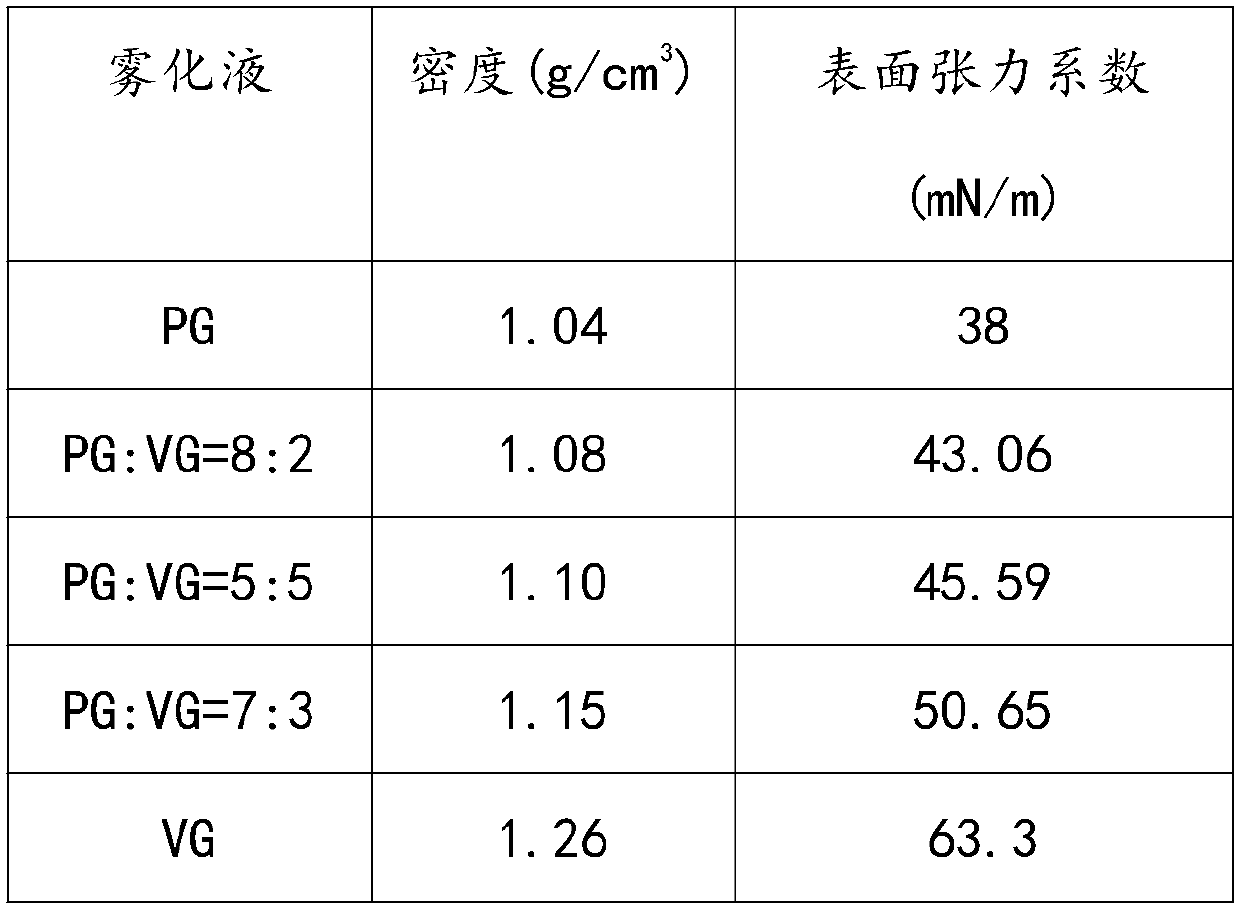

[0048] Atomizer 1, the volume of the oil tank is small, and the amount of smoke is limited. It is suitable for women or for medical atomization. The atomizer liquid is a common liquid in the market, that is, PG:VG=8:2, and its density and tension coefficient See Table 1.

[0049] A Determine the parameters: ①The volume of the oil storage tank: 0.1cm 3; ② The circumference of the contact surface between the oil-conducting cotton / rope and the atomized liquid: 10mm; ③ The circumference of the contact surface between the oil-repelling cotton and the atomized liquid: 0; The oil tank is annular, D 1 =8.5mm,D 2 =6mm, l=πD=3.145*(8.5+6)=45.60mm;

[0050] B force analysis:

[0051] ①Gravity: The gravity direction of the atomized liquid is always vertical and downward, which is recorded as "-", according to the gravity formula:

[0052] G=-m·g=-ρ·v·g=-1.085g / cm 3 *0.1cm 3 *9.8N / kg=-1.063mN

[0053] ② Surface tension of atomized liquid and oil storage tank: Surface tension is the...

Embodiment example 2

[0064] Choose atomizer product 2. This atomizer is a neutral electronic atomizer. The volume of the e-liquid tank is medium. It is suitable for medical atomization. The atomizer liquid is pure PG with low density and viscosity. Its density and tension coefficient See Table 1.

[0065] A Determine the parameters: ①The volume of the oil storage tank: 0.46cm 3 ; ② The circumference of the contact surface between the oil-conducting cotton / rope and the atomized liquid: 10mm; ③ The circumference of the contact surface between the oil-repelling cotton and the atomized liquid: 0; The oil tank is annular, D 1 =8.75mm,D 2 =6mm, l=πD=3.145*(8.75+6)=46.39mm;

[0066] B force analysis:

[0067] ①Gravity: The gravity direction of the atomized liquid is always vertical and downward, which is recorded as "-", according to the gravity formula

[0068] G=-m·g=-ρ·v·g=-1.04g / cm 3 *0.46cm 3 *9.8N / kg=-4.69mN;

[0069] ② Surface tension of atomized liquid and oil storage tank: Surface tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com