Rapid service life testing device and method applied to precision speed reducer

A precision reducer and life testing technology, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve problems such as long life testing cycle and affecting product development and testing, shorten the research and development process, reduce Life test time, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

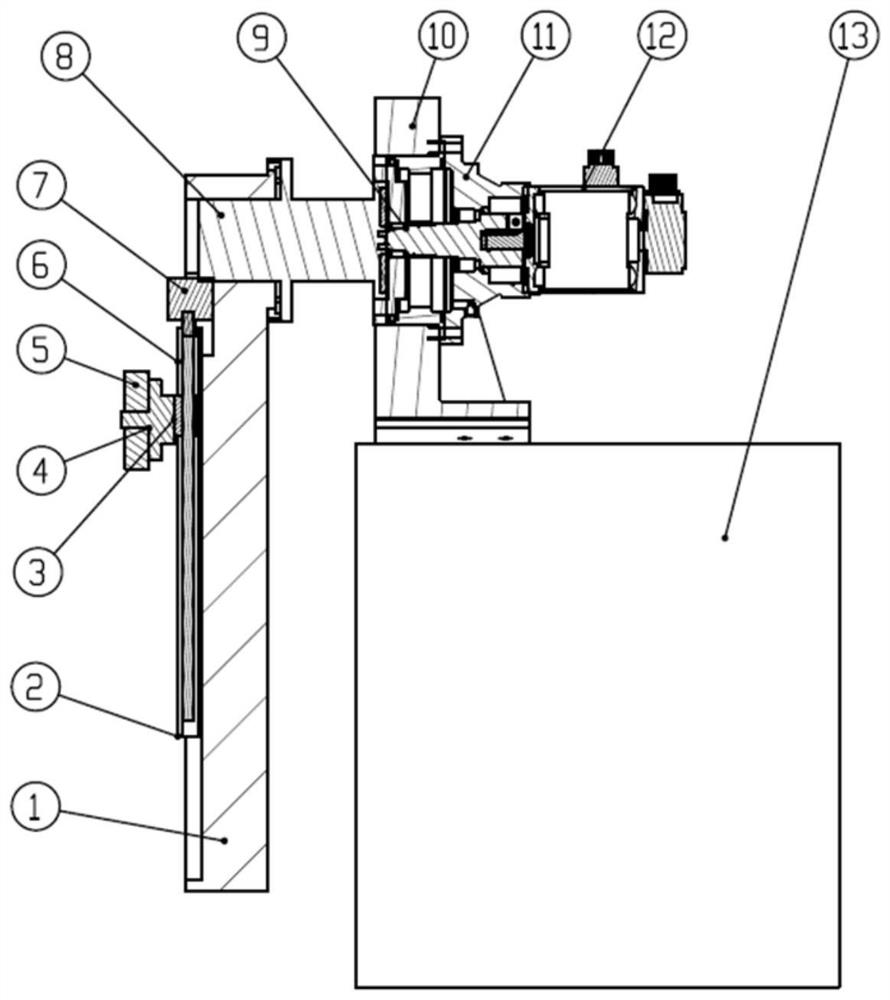

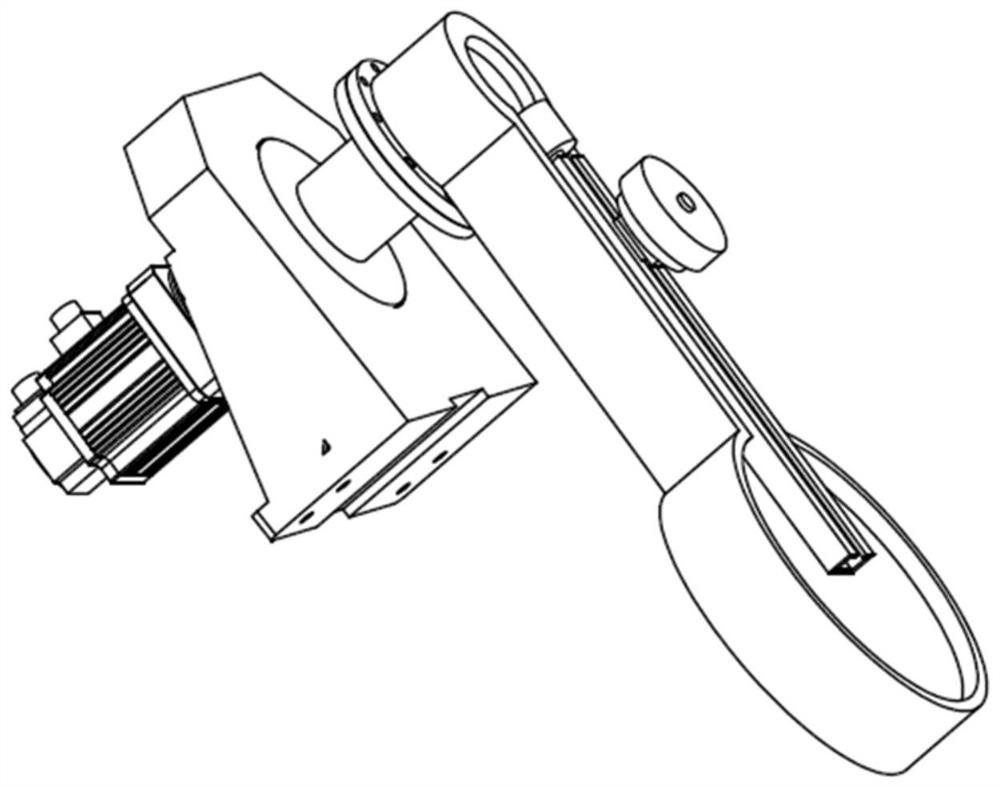

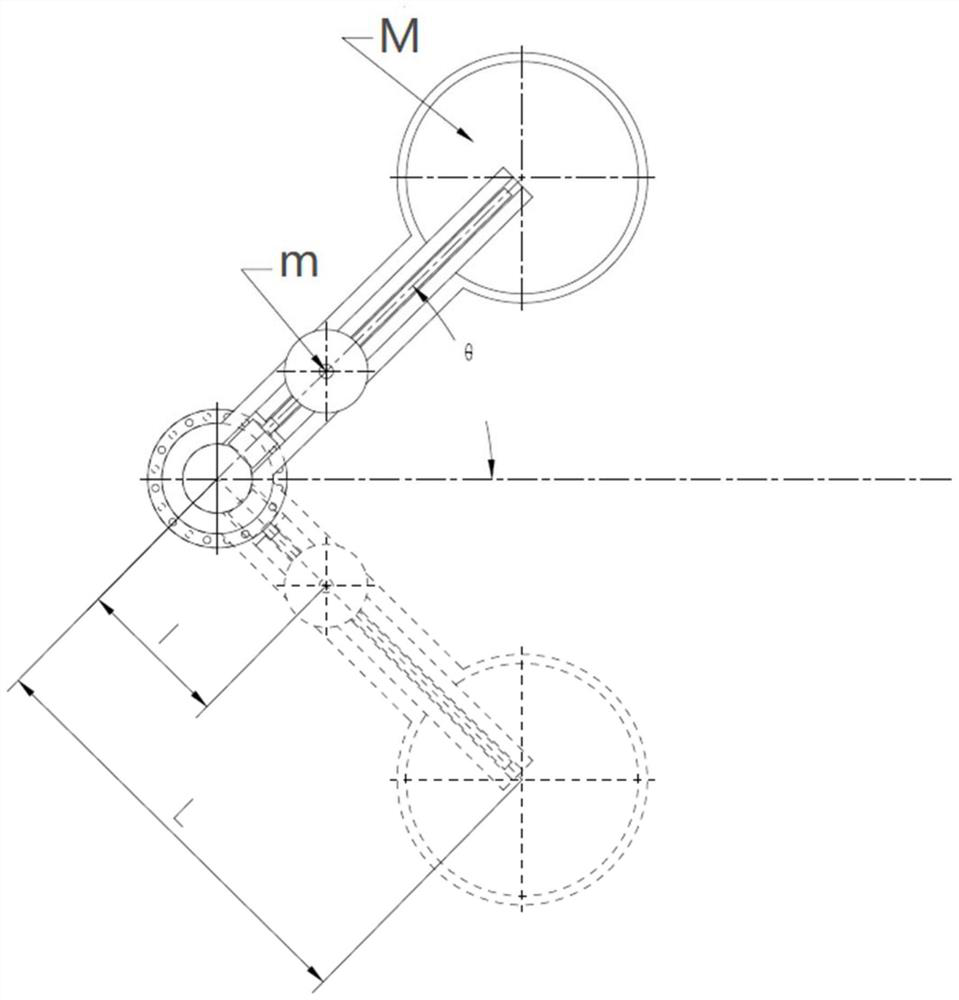

[0030] A rapid life test device applied to precision reducers, such as figure 1 and figure 2 As shown, including the precision reducer 9 to be tested, the input end and the output end of the precision reducer 9 are respectively connected to the drive motor 12 and the swing arm 1, and under the drive of the drive motor 12, the input end of the precision reducer 9 rotates, and then The output end of the precision reducer 9 drives the swing arm 1 to swing; the swing arm 1 is provided with a slide rail 2, a driving device and a slide block 3, the slide block 3 is slidably installed in the slide rail 2, and a counterweight block is installed on the slide block 3 5. The driving device cooperates with the sliding block 3 and the sliding rail 2 , and the sliding block 3 slides along the sliding rail 2 under the action of the driving device, thereby driving the counterweight 5 to move on the swing arm 1 .

[0031] A rapid life test method applied to precision reducers, specifically: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com