Long-life prediction method for laser optical components

A technology of optical components and prediction methods, which is applied in optical instrument testing, machine/structural component testing, instruments, etc., can solve problems such as accelerated life testing, and achieve the effect of improving test efficiency and shortening life test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

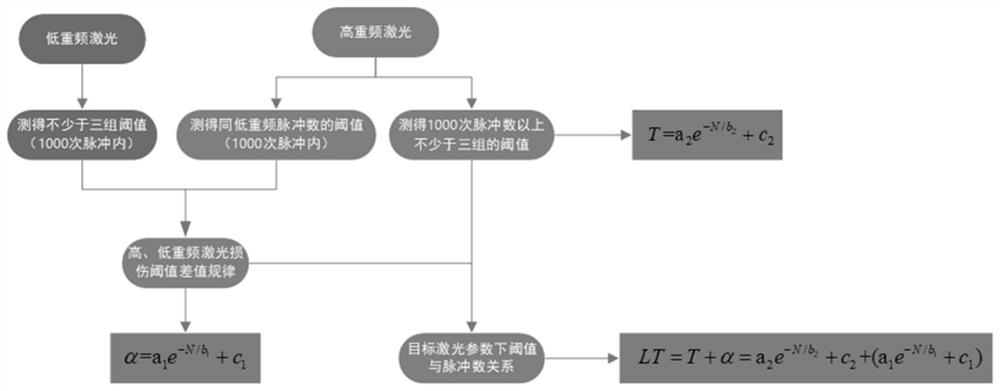

Method used

Image

Examples

Embodiment

[0033] For a typical 355nm reflective film element (the stacking formula of the film is Sub|(LH)^40 4L|Air, where the L layer is SiO 2 , the H layer is Al 2 o 3 ) to carry out the life test process of laser damage threshold as follows:

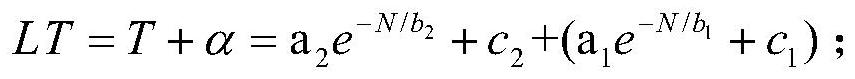

[0034] Firstly, select the test points whose pulse times are within 1000 from the four groups of 1, 10, 100, and 1000. The repetition rate of the low repetition rate laser used is 1 Hz, and the repetition rate of the high repetition rate laser is 60 Hz. Through 1-on-1 and S-on-1 test methods, the threshold value of 355nm thin film components under low repetition frequency laser is 22.3J / cm 2 (1-on-1), 21.2J / cm 2 (10-on-1), 20.6J / cm 2 (100-on-1), 20.4J / cm 2 (1000-on-1). Through 1-on-1 and S-on-1 test methods, the threshold value of 355nm thin film components under high repetition frequency laser is 20.5J / cm 2 (1-on-1), 19.5J / cm 2 (10-on-1), 19.0J / cm 2 (100-on-1), 18.8J / cm 2 (1000-on-1). Bring the relationship between the threshold d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com