Reliability calculation method for dual-redundancy brushless direct current motor control system

A brushed DC motor and control system technology, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as high cost and long time, and achieve the effect of reducing cost and shortening life test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

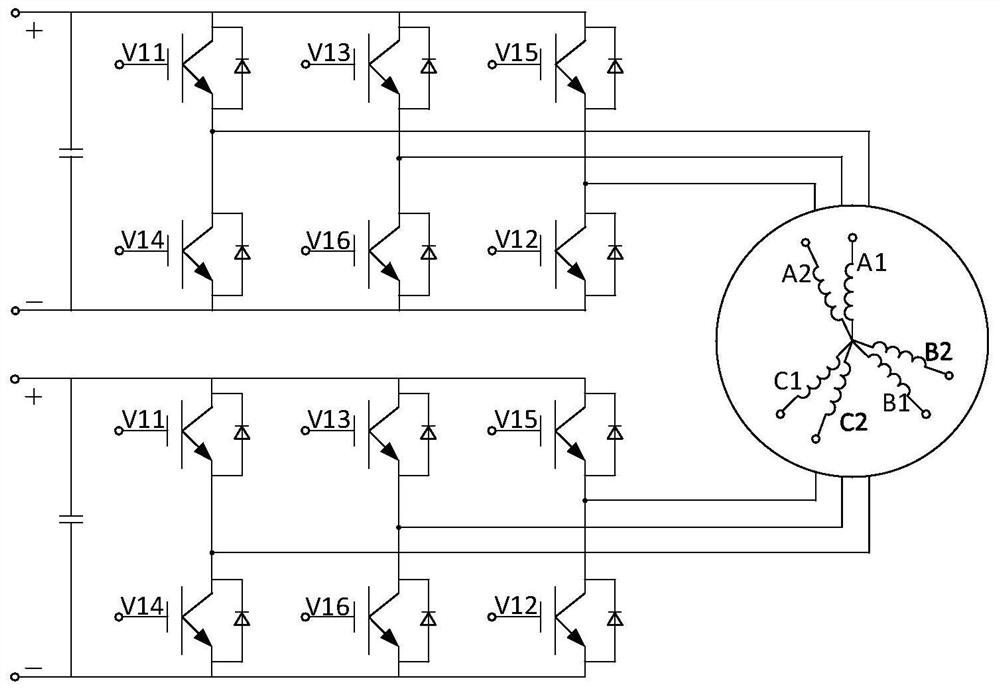

[0081] A dual-redundant brushless DC motor control system with a rated voltage of 270V and a rated speed of 1000r / min, the topology of its control circuit is as follows: figure 2 As shown, calculate the reliability of this type of motor after running for 18000 hours (about 2 years).

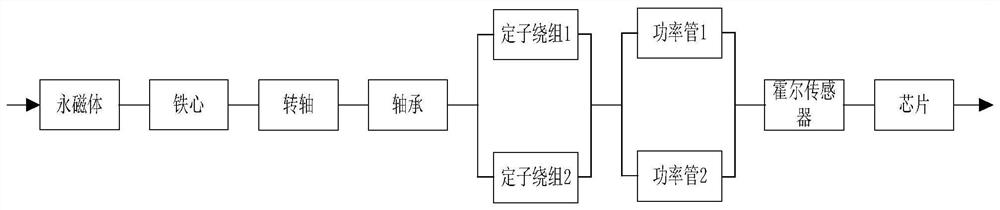

[0082] Step 1: The main faults of the dual redundant brushless DC motor control system are divided into winding faults, permanent magnet faults, Hall sensor faults, control chip faults, power tube faults and bearing faults.

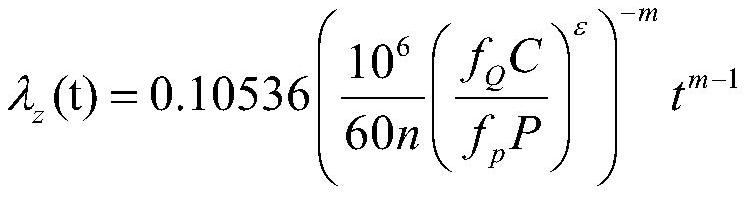

[0083] Step 2: Calculate the failure rate and reliability of the stator winding of the dual-redundancy brushless DC motor control system.

[0084] The failure rate of the first set of windings is: λ p11 =λ b1 π E1 π Q1 π K1 π C1

[0085] The failure rate of the second set of windings is: λ p12 =λ b1 π E1 π Q1 π K1 π C1

[0086] take lambda b1 =0.0205×10 -6 , π E1 = 2, π Q1 =0.6, π K1 = 1, π C1 = 1, the total reliability of the stator winding after workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com