Method for predicting working condition and service life stage of vehicle lithium ion battery based on summer climate

A technology for lithium-ion batteries and vehicles. It is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables. It can solve the problems of increasing economic costs and delaying the development cycle of complete vehicles, and achieves the goal of reducing economic costs and shortening life test time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by way of examples.

[0026] Taking a certain ternary lithium-ion battery system as an example, the sample information is shown in Table 1.

[0027] Table 1 Basic information table of battery system samples

[0028]

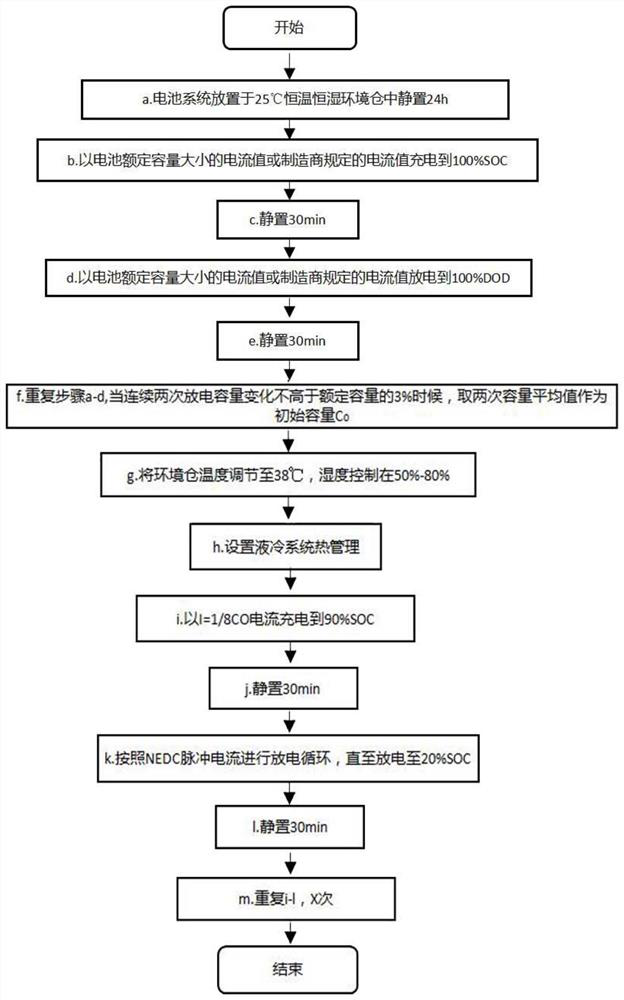

[0029] According to technical scheme of the present invention, carry out typical implementation steps and result as follows:

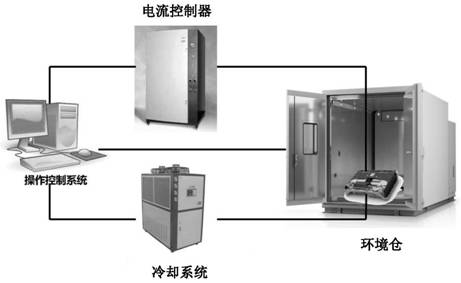

[0030] a) Place the battery system in a GIANT FORCE brand ETH-1000-40-CP-SD environmental chamber at 25°C for 24 hours to allow the temperature of each monomer in the system to reach equilibrium;

[0031] b) Use the Bitrode brand FTF2-500 / 100-750 current controller to charge the battery to 100% SOC with a rated capacity of 228A;

[0032] c) Stand still for 30 minutes;

[0033] d) Use the Bitrode brand FTF2-500 / 100-750 current controller to discharge the battery with a rated capacity of 228A to 100% DOD cut-off condition;

[0034] e) Stand still for 30 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com