Method for measuring surface tension coefficient of liquid through discharging liquid by hollow cylinder

A liquid surface tension, hollow cylinder technology, applied in the direction of surface tension analysis, etc., can solve the problems of inaccurate measurement of liquid column height, low measurement accuracy, and difficult coordinate values, and achieve simple structure, low cost, and high cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

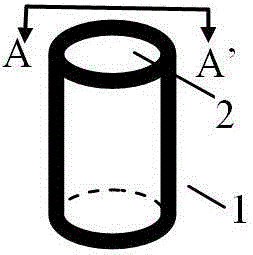

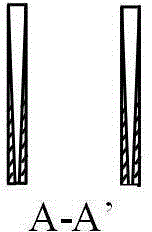

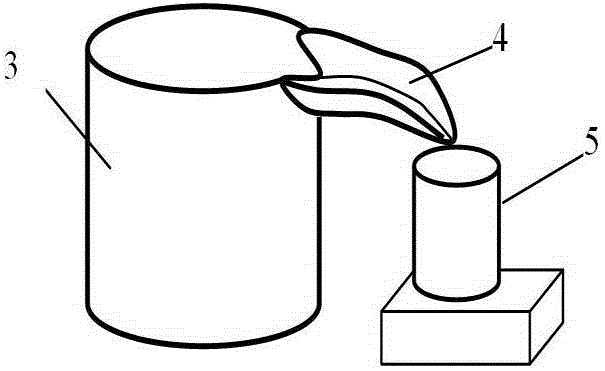

[0008] A hollow cylinder 1 consisting of two inner and outer cylinders with a common central axis, the inner diameter of the inner cylinder is D 内 , radius R 内 =D 内 / 2, the outer diameter of the outer cylinder is D 外 , radius R 外 =D 外 / 2, there is a cavity between the two cylinders, the upper and lower ends of the cavity are sealed, the hollow cylinder 1 has a thicker lower end and a thinner upper end (the deformation occurs in the cavity, and the standard cylindrical shape outside the cavity ),Such as figure 2 As shown, that is, its center of gravity shifts to the lower end of the hollow cylinder 1, the thickness of the material at the lower end is 2-5 times thicker than that of the upper end material, and an inverted triangular cavity (upper end) is formed in the longitudinal sectional view of the hollow cylinder 1 is the base of the triangle, and the lower end is the vertex of the triangle), such as figure 2 As shown; because the thickness of the wall material at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com