Method for measuring surface tension coefficient of liquid through liquid drainage of semi-spherical shell

A liquid surface tension and liquid measurement technology, applied in the direction of surface tension analysis, etc., can solve the problems of inaccurate measurement of liquid column height, low measurement accuracy, and difficult coordinate values, and achieve a simple structure, low cost, and high cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

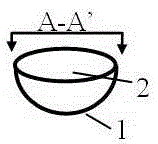

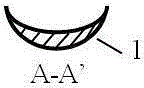

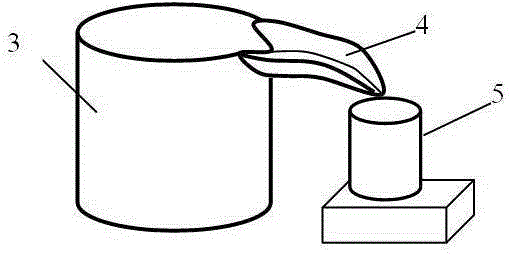

[0008] A hemispherical shell 1, the radius of the outer spherical shell is R, because it is a hemispherical shell, that is, the outer radius of the circle where the opening 2 of the hemispherical shell is located is R, the bottom of the hemispherical shell 1 is thick and the upper end is thin, and the deformation occurs inside the hemispherical shell , the outside is a standard spherical shape, such as figure 2 As shown, that is, its center of gravity shifts to the bottom of the hemispherical shell 1; the average density of the hemispherical shell 1 is the mass m of the hemispherical shell 1 and the volume of the spherical gap (hemispherical volume) enclosed by the outside of the hemispherical shell 1 is 2πR 3 / 3 divided, average density=m / (2πR 3 / 3), the average density of the hemispherical shell 1 is less than the density of the liquid, and the optimal value is 0.5-0.8 times the liquid density, because the liquid density changes greatly with the temperature change, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com