Method for measuring liquid surface tension by using transparent glass tube with scale marks

A liquid surface tension, transparent glass tube technology, applied in surface tension analysis and other directions, can solve the problems of difficulty, inaccurate measurement of liquid column height, and low measurement accuracy, and achieve clear surface phenomena, low measurement costs, and simple methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

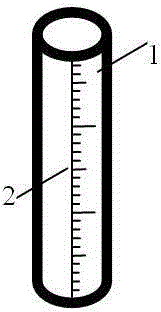

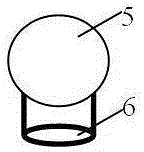

[0008] A transparent glass tube 1, the tube wall is thicker than 2 mm, it is recommended to be 2-5 mm, and there is a millimeter scale 2 on the outside of the transparent glass tube 1 along the axis direction (length direction) of the transparent glass tube 1 , the 0 scale line of the millimeter scale 2 is located at one end of the transparent glass tube 1, that is, the 0 scale line of the millimeter scale 2 is flush with the plane of one end of the transparent glass tube 1; The structure of the earball is the same, and it is composed of the airbag 5 and the airbag port 6, but the outer diameter of the airbag port 6 of the earwashing ball is basically the same as that of the transparent glass tube 1. Through the elasticity of the earwashing ball, the airbag port 6 is tightly covered with the transparent glass tube 1 Seal one end of the transparent glass tube 1 at the end where the 0 scale of the millimeter scale 2 is located, and extend the other end of the transparent glass tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com