Adhesion method for improving adhesion performance of carbon nanotube dry glue

A carbon nanotube and carbon nanotube array technology, which is applied in the field of carbon nanotube dry glue material preparation, can solve the problems of limited improvement of adhesion strength, failure to achieve ultra-high adhesion strength, etc., and achieves increased adhesion strength, Excellent adhesion strength, the effect of improving adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

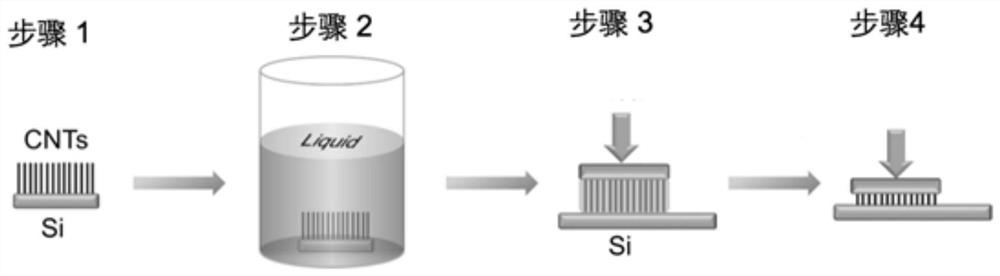

[0047] The adhesion method for improving the adhesion performance of carbon nanotube dry adhesive provided by the embodiment 1 of the present invention mainly includes the following steps:

[0048] (1) Use magnetron sputtering (PVD) to plate an alumina buffer layer and iron catalyst on the surface of a single-sided polished silicon wafer. The alumina buffer layer is sputtered by radio frequency reactive sputtering, and high-purity argon gas 12sccm (standard ml / Minutes), high-purity oxygen 3sccm, sputtering power of 200W, reaction time of 10min; iron catalyst adopts DC sputtering, high-purity argon gas 12sccm, sputtering power of 20W, and sputtering time of 30s. The thickness of the finally prepared alumina buffer layer is 10 nm, and the thickness of the iron catalyst is 4 nm.

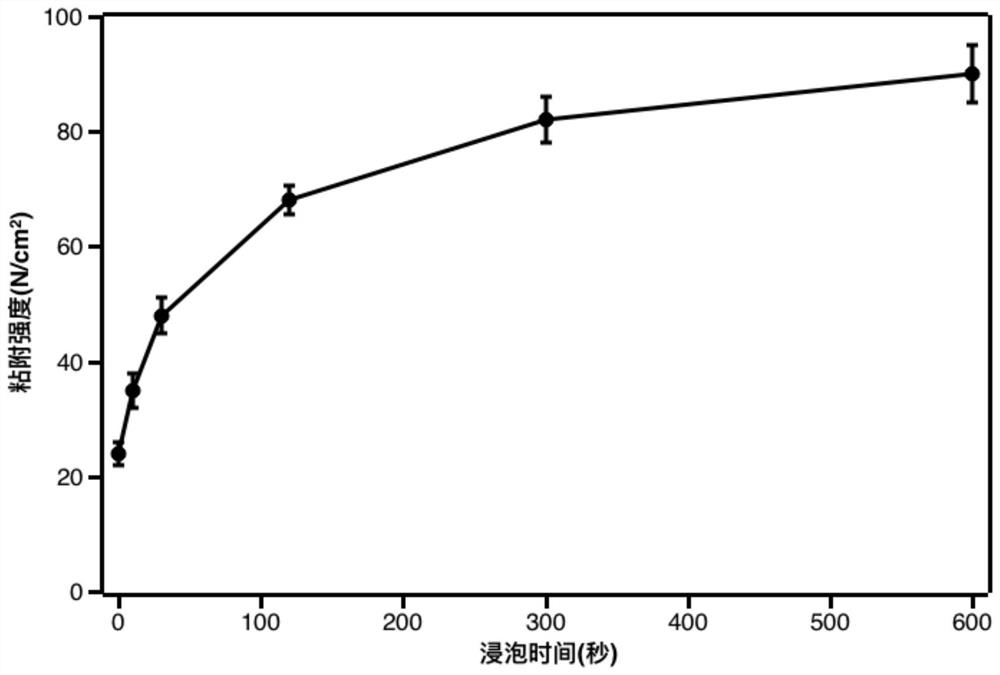

[0049] (2) The carbon nanotube array is prepared by the "Super growth" water assisted chemical vapor deposition method ("Super growth" water assisted CVD), wherein the tube furnace has a diameter of 1 inch,...

Embodiment 2

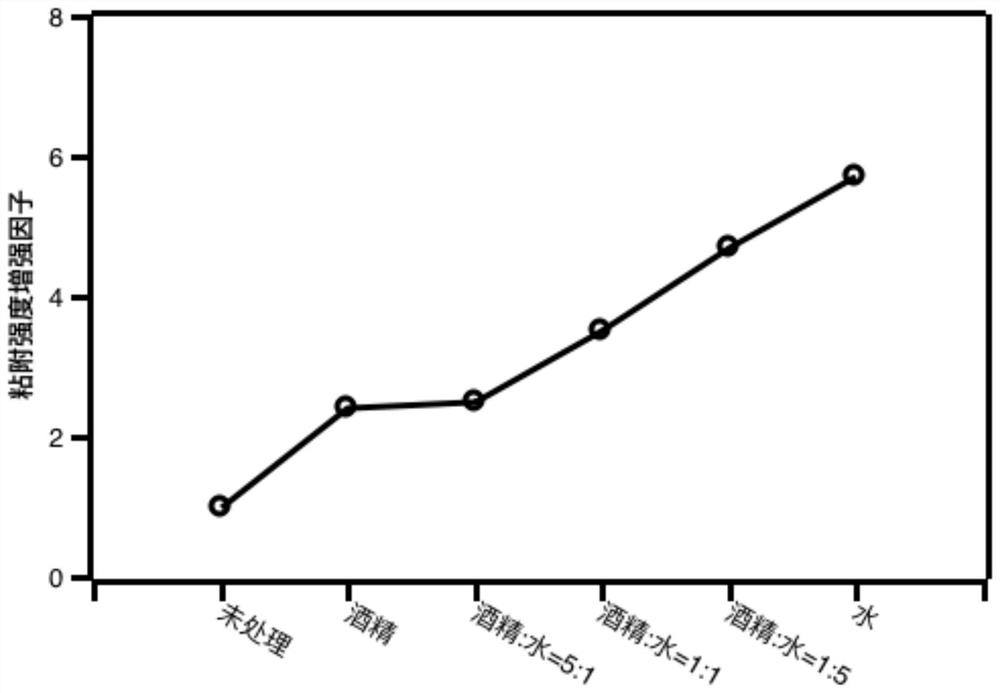

[0055] The adhesion method for improving the adhesion performance of carbon nanotube dry glue provided by the embodiment 2 of the present invention is basically the same as that of the embodiment 1, except that the treatment liquid environment in step (3) is changed from deionized water to ethanol solution, and ethanol treatment The adhesion strength enhancement factor of the carbon nanotube array after figure 2 Shown from figure 2 It can be seen that the enhancement factor of the carbon nanotube array after ethanol treatment is 2.6.

Embodiment 3

[0057] The adhesion method for improving the adhesion performance of the carbon nanotube dry glue provided by the embodiment 3 of the present invention is basically the same as that of the embodiment 1, except that the treatment liquid environment in step (3) is changed from deionized water to ethanol and deionized water. The resulting mixed solution (the volume ratio of ethanol to deionized water is 5:1), the adhesion strength enhancement factor of the carbon nanotube array after liquid treatment is as figure 2 Shown, since figure 2 It can be seen that the enhancement factor of the carbon nano array after liquid treatment is 2.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com