Liquid surface tension coefficient measuring device based on optical fiber FP cavity

A liquid surface tension and measuring device technology, applied in the direction of surface tension analysis, etc., can solve the problems of low accuracy of measurement results, low reliability, and large amount of calculation, and achieve the effect of avoiding low accuracy, simple structure, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

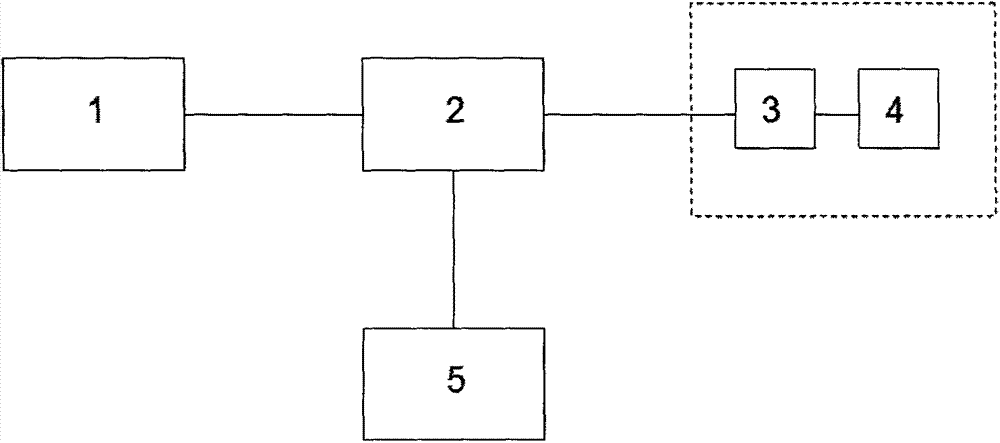

[0012] see figure 1 As shown, the optical fiber FP cavity liquid surface tension coefficient measurement device includes a wide-spectrum light source 1, an optical circulator 2, a liquid surface tension measurement sensor head composed of a fiber Bragg grating 3 and a hollow fiber 4, and a spectrum analyzer 5. The optical circulator 2 has three ports, wherein the input port is connected to the wide-spectrum light source 1, the output port is connected to any end of the fiber Bragg grating 3, the reflection port is connected to the spectrum analyzer 5, and the other port of the fiber Bragg grating 3 is connected to the air. Any end of the core fiber 4 is connected.

[0013] The working wavelength of the above-mentioned broadband light source is 1530nm-1570nm; the liquid surface tension measurement sensor head is composed of a fiber Bragg grating 3 and a hollow-core fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com