Shape prediction method of extrusion type 3D printing bio-ink extrusion filament

A bio-ink, 3D printing technology, applied in 3D modeling, geometric CAD, image data processing, etc., can solve the problem of lack of extrusion 3D printing bio-ink extrusion filament shape prediction method, etc., and achieve high prediction accuracy. , high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

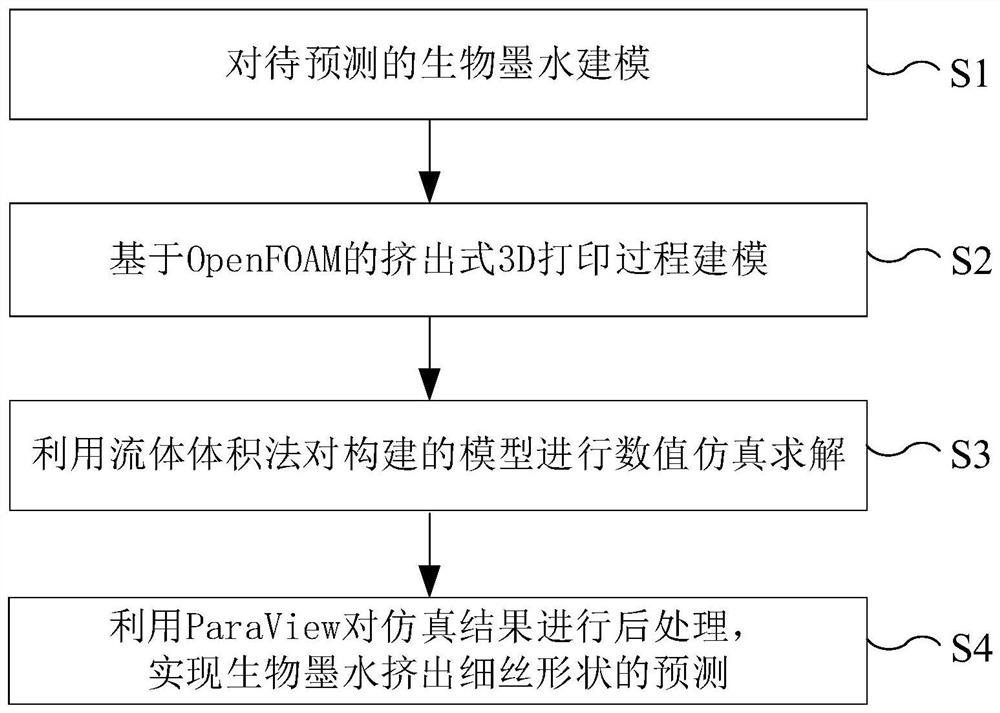

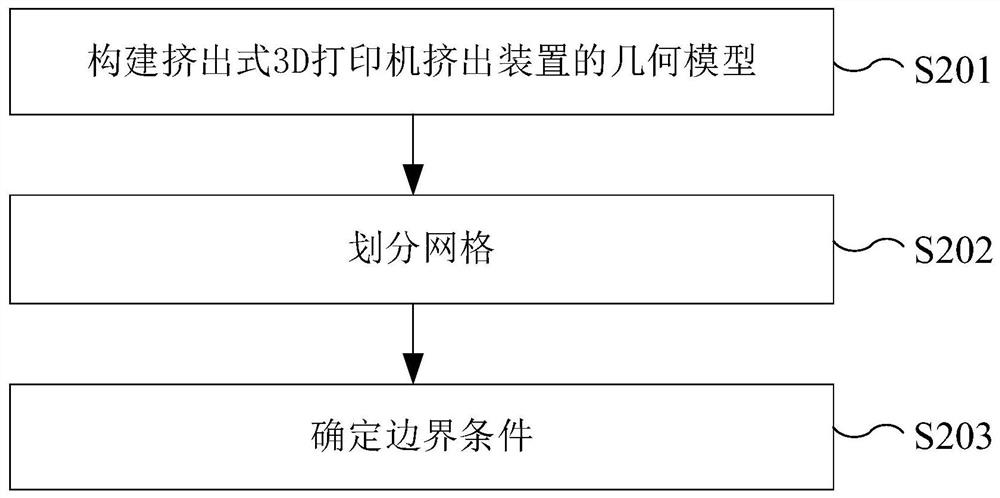

[0050] Such as figure 1 As shown, the shape prediction method of the extruded 3D printing bio-ink extruded filament of the application is used to predict the shape of a certain cellulose bio-ink extruded filament, and its specific implementation steps are as follows:

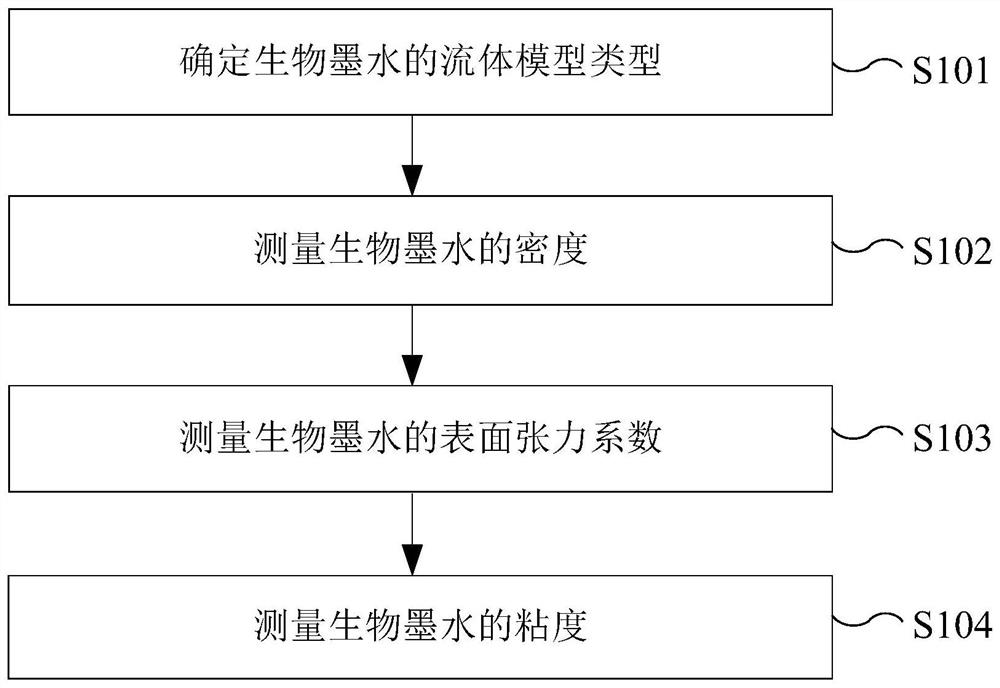

[0051] S1. Bioink modeling to be predicted, such as figure 2 As shown, the specific steps are:

[0052] S101. Determine the fluid model type of the bio-ink;

[0053] Based on the following three reasons:

[0054] Reason 1: In the extrusion 3D printing process, the pressure on the bio-ink is stable, so it is an incompressible fluid;

[0055] Reason 2: The printing process is carried out at room temperature without heating or cooling, and the entire printing process can be regarded as an adiabatic process, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com