Device for measuring liquid surface tension by pull-out method

A technology of liquid surface tension and liquid level, applied in the direction of surface tension analysis, etc., can solve the problems of slow measurement speed, liquid level fracture, small surface tension, etc., to reduce the difficulty of adjustment and improve the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

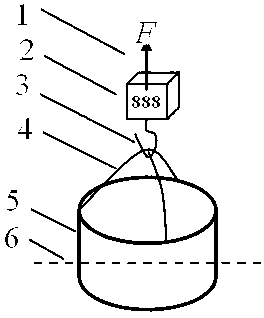

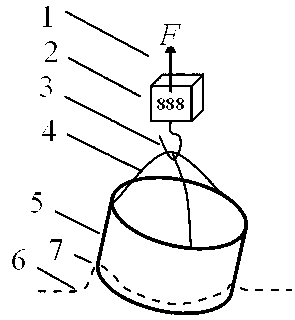

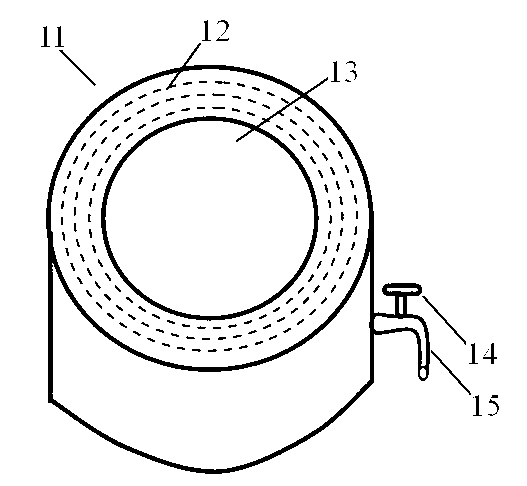

[0010] The principle of surface tension measurement by the pull-off method: the bottom edge of the suspension ring 5 for measuring surface tension is below the liquid surface 6, and there are three suspension wires 4 on the upper edge of the suspension ring 5. Since three points determine a plane, the three suspension wires 4 can be adjusted. Make the bottom edge of the suspension ring in a horizontal plane, in order to be able to adjust the suspension line 4, the suspension line 4 adopts a metal wire (called a suspension wire in CN01254339.X), the metal wire has a certain toughness, and can maintain its shape after bending. The suspension line 4 is suspended on the hook 3 of the tension sensor 2. Through the upward pulling force 1, the lifting ring is pulled upwards, the lifting ring is gradually separated from the liquid surface, the buoyancy decreases, and the gravity and surface tension increase. When the lifting ring is higher than the liquid level, the upward pulling force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com