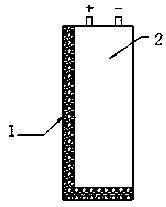

Profile of elastic silica aerogel for lithium ion power batteries of new energy vehicles

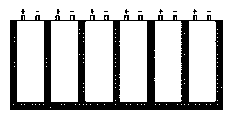

A new energy vehicle, silicon dioxide technology, applied in the direction of electrical components, battery pack components, secondary batteries, etc., can solve the problems of thermal runaway of peripheral batteries, sudden increase in heat production, hidden safety hazards, etc., to improve reliability and Safety, the effect of slowing down the transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of silica sol liquid includes adding 100~120ml of coagulant into 800~1000ml of solvent and stirring evenly, then adding 160~180ml of methyltrimethoxysilane and 90~120ml of silicon source, stirring evenly, Add 150-170ml of gel accelerator and stir again to obtain a silica sol liquid. The rotation speed of uniformly stirring the solution is 50~300 rpm.

[0030] The silicon source includes one or more of dimethyldimethoxysilane, ethyl orthosilicate, ethyl silicate and silicic acid; the gel accelerator is 1,2-propylene oxide, and the coagulant is ten Hexaalkyltrimethylammonium chloride or octadecyltrimethylammonium chloride; the solvent is dilute hydrochloric acid solution with a concentration of 1.5×10-5mol / ml-3×10-5mol / ml.

[0031] When adding a gel accelerator to the sol liquid, a flame retardant is also added, preferably an environmentally friendly halogen-free flame retardant, and the sol liquid is aged in the mold to form a wet gel, and the sol...

Embodiment 1

[0034] Embodiment 1: The manufacture method of elastic silica airgel special-shaped part 1: the cetyltrimethylammonium chloride of 100ml is added to the hydrochloric acid solvent that 800ml concentration is 1.5 * 10-5mol / ml and stir evenly, The stirring speed is 50 rev / min, then add 160ml of methyltrimethoxysilane and 90ml of dimethyldimethoxysilane, stir evenly to form a sol, the stirring speed is 50 rev / min, add 150ml of 1,2- Propylene oxide, stir again to form a sol, the stirring speed is 50 rpm, pour the sol into the mold, age the gel in an oven at a temperature of 30 degrees Celsius, and then perform two solvent replacements, and the solvent replacement is taken out every 12 hours The mould, replace the solvent precipitated by the wet gel with alcohol, and get a block wet gel after the solvent is fully replaced, and dry it in an oven at a low temperature to dry gel. Elastic Silica Airgel Shaped Part 1 .

Embodiment 2

[0035]Embodiment 2: the manufacture method of elastic silica airgel special-shaped part 1: the octadecyltrimethylammonium chloride of 110ml is added to the hydrochloric acid solvent that 900ml concentration is 2 * 10-5mol / ml and stir evenly, The stirring speed is 180 rpm, then add 170ml of methyl trimethoxysilane and 110ml of ethyl orthosilicate, stir evenly to form a sol, the stirring speed is 175 rpm, add 160ml of 1,2-propylene oxide , Stir again to form a sol, the stirring speed is 170 rpm, pour the sol into the mold, age the gel in an oven at a temperature of 45 degrees Celsius, and then perform three solvent replacements. The solvent replacement is to take out the mold every 12 hours and use alcohol Substitute the solvent precipitated from the wet gel, and get a massive wet gel after the solvent is fully replaced, and dry it in a microwave oven or oven at a low temperature to dry gel, the oven temperature is 48 degrees Celsius, and the microwave heating and drying method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com