Design method of refining slag system for removal of magnesium aluminum spinel inclusions

A technology of magnesium aluminum spinel, design method, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A factory produces aluminum-deoxidized molten steel, which is treated with magnesium in the late stage of the refining process, and the inclusions are mainly magnesium-aluminum spinel. The main component of refining slag is Al 2 o 3 -CaO-SiO 2 .

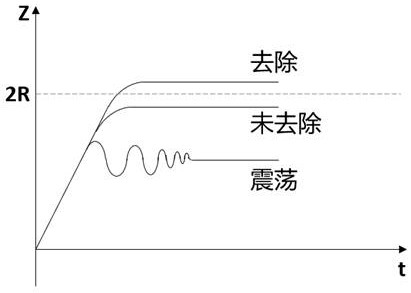

[0078] The relationship between the inclusion displacement Z and the time t is calculated by the following formulas (1)-(8).

[0079] (1)

[0080] in, is the driving force on the inclusion, N; R is the radius of the inclusion, m; G is the acceleration due to gravity, 9.81m / s 2 ; is fluid density, kg / m 3 ; ——inclusion density, kg / m 3 ;

[0081] (2)

[0082] in, is the characteristic viscosity of the fluid, Pa·s; is the floating speed of inclusions, m / s; F d is the fluid drag force on the uplift of the inclusions, N; Re is the Reynolds number of the uplift of the inclusions;

[0083] (3)

[0084] in, F m is the additional mass force, N; is the acceleration during the movement of inclusions, m / s ...

Embodiment 2

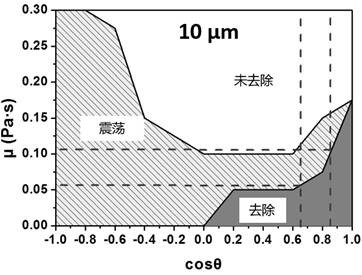

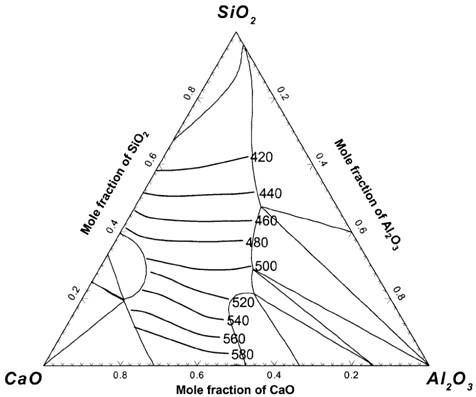

[0109] The same process conditions as in Example 1, the refining slag system is required to be able to absorb magnesium-aluminum spinel inclusions with a radius greater than 10 μm, according to figure 2 , the viscosity range of the selected slag system is less than 0.12 Pa•s, the cosine value of the three-phase wetting angle cosθ of steel-slag inclusions is greater than 0.7, and the calculated surface tension coefficient of the corresponding refining slag is less than 0.53 N / m. The composition of the first refining slag system corresponding to the viscosity calculated by FactSage software is 20-35%Al 2 o 3 , 55-60%CaO, 10-15%SiO 2 , according to the equivalent diagram of the surface tension of the ternary system ( image 3 ) The composition of the first refining slag system and the composition of the second refining slag system corresponding to the surface tension coefficient are 10-40%Al 2 o 3 , 50-80%CaO, 0-15%SiO 2 . The ratio (mass fraction) of the slag-based compos...

Embodiment 3

[0111] The same algorithm as in Embodiment 1 is used.

[0112] A factory produces low-carbon steel. In the refining process, aluminum-magnesium composite deoxidation is used, and the inclusions are mainly magnesium-aluminum spinel. The main component of refining slag is Al 2 o 3 -CaO binary slag system. The upper limit of the size of the predetermined inclusions is 15 μm, and the advantageous area diagram of the inclusion removal physical properties is obtained through the calculation of the dynamic force analysis model, as shown in Figure 5 shown. The selected viscosity range is less than 0.09 Pa•s, the cosine value of the three-phase wetting angle cosθ of steel-slag inclusions is in the range of 0.65-0.85, and the calculated surface tension coefficient corresponding to the refining slag is 0.55-0.8 N / m. Use the FactSage thermodynamic database software to calculate or query the slag atlas to obtain the composition of the first refining slag system corresponding to the vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com