Heat pipe

A heat pipe and heat conductor technology, applied in the field of heat pipes, can solve the problems of small contact area between the tubular heat pipe and the heat source, not suitable for heat dissipation of small electronic products, damage to the internal structure of the heat pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings.

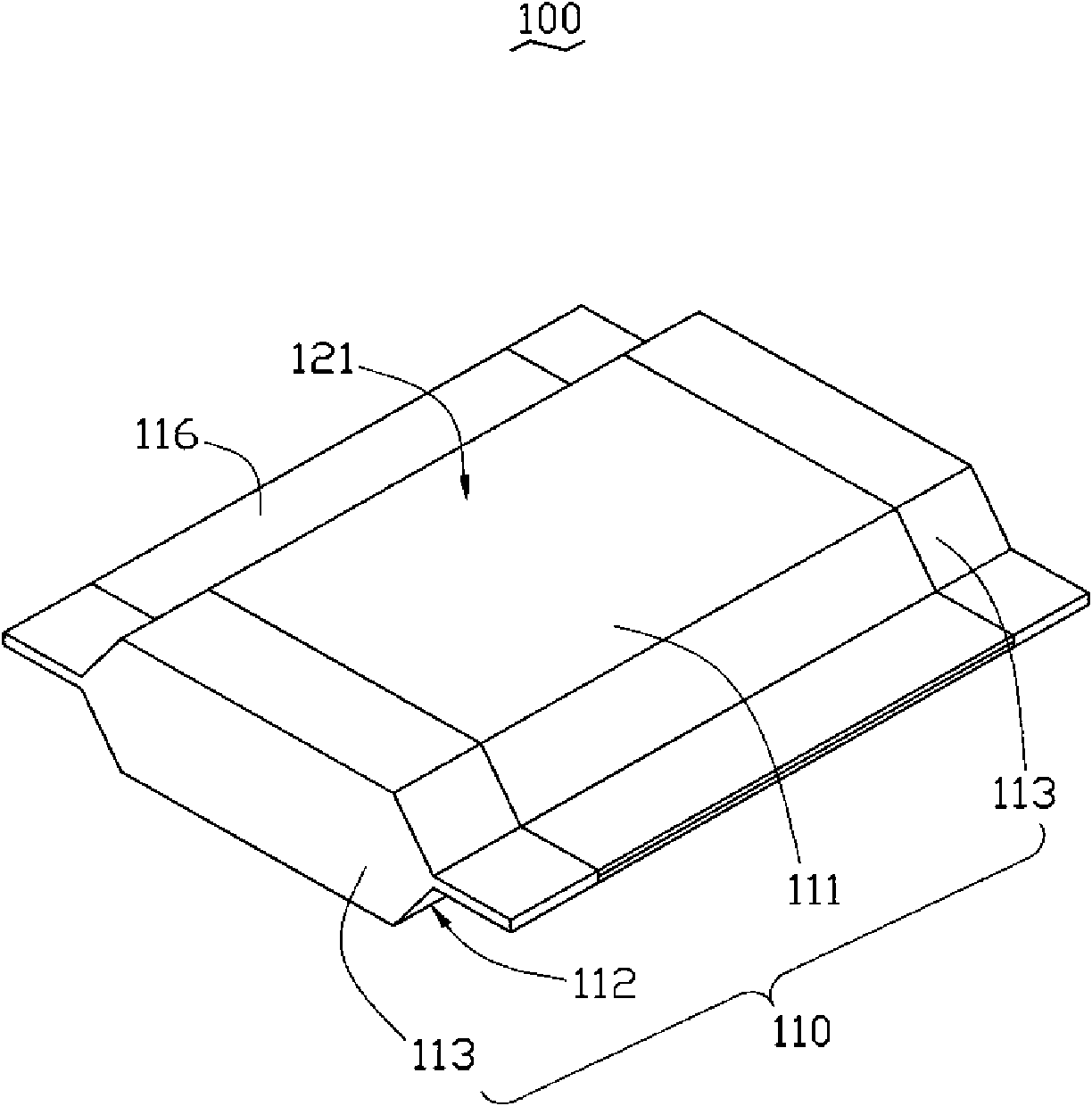

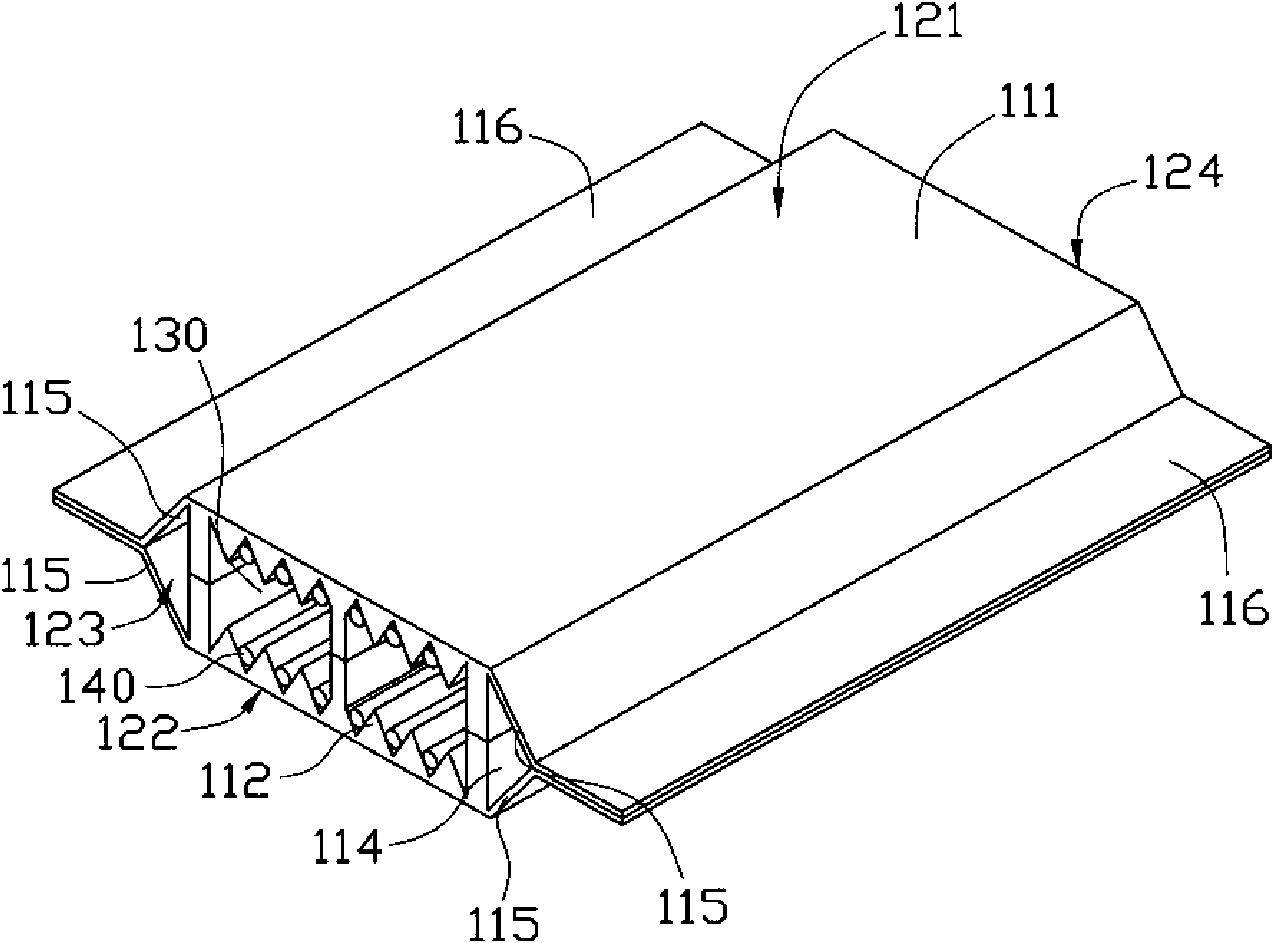

[0010] see figure 1 and figure 2 , is the heat pipe 100 provided by the present invention, which includes a heat conductor 110 , a working fluid (not shown) and a carbon nanotube array 140 .

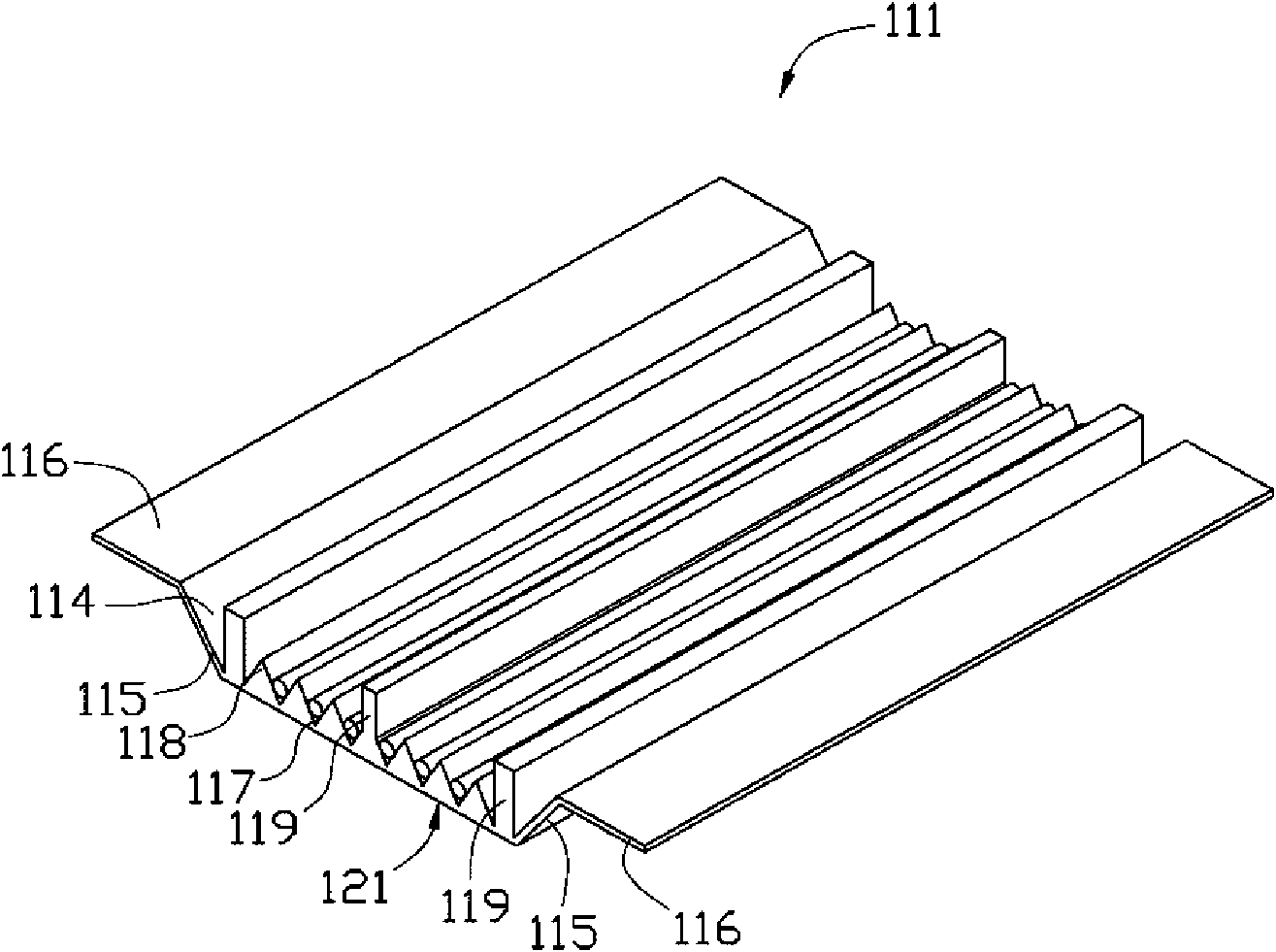

[0011] see figure 1 and figure 2 , the heat conductor 110 is made of metal copper with good thermal conductivity, and includes a first metal cover 111 , a second metal cover 112 , and two third metal covers 113 . A groove 114 is formed in the middle of the first metal cover 111 and the second metal cover 112. The groove 114 of the first metal cover 111 is composed of a flat bottom 121 and two opposite sides 115. The groove 114 of the second metal cover 112 is composed of a flat bottom 122 and two opposite sides 115 , and two thin metal flanges 116 extend outward from the two opposite sides 115 of the groove 114 . The side of the first metal cover 111 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com