Seamless steel tube welding lengthways cocked piece rubbing wear reduction device

A technology of friction and wear and seamless steel pipes, which is applied in the field of high-temperature hot slag cooling heat energy recovery, can solve problems such as poor adaptability of coal types, energy waste environment, serious maintenance problems, etc. even gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

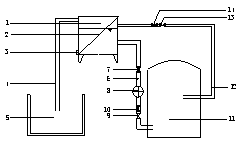

[0008] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

[0009] like figure 1 As shown in the figure, a seamless steel pipe welded vertical warping piece reducing friction and wear equipment and its process method belong to the technical field of high-temperature hot slag cooling heat energy recovery, including a hot slag storage pool 5, a temperature-adjusting and cooling pool 11, and a hot slag storage pool. The feed pipe 4 is connected, the other end of the feed pipe 4 is connected to the vacuum feeder 1, the two ends of the discharge pipe 6 and the circulation pipe 12 are respectively connected to the fermentation tank 11 and the vacuum feeder 1, and a centrifugal pump is installed on the discharge pipe 8. When the centrifugal pump 8 is turned on, the liquid will be sucked into the vacuum feeder 1 from the hot slag storage tank 5, and the liquid will be filtered through the filter 2 to filter the large solid particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com