Equipment for reducing frictional wear by welding omni-bearing fins in seamless steel tubes

A friction and wear, seamless steel pipe technology, applied in heat exchange equipment, lighting and heating equipment, tubular components, etc., can solve the problems of cinder physical waste heat can not be effectively recovered, the number of boiler equipment is large, energy waste environment and other problems, to avoid entanglement , The water side gap is uniform, and the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

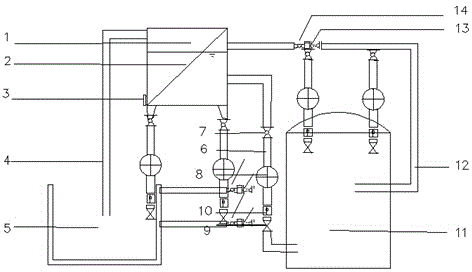

[0019] A device for reducing friction and wear by welding omni-directional warping pieces of seamless steel pipes, comprising a hot slag storage pool 5 and a temperature-adjusting and cooling pool 11, characterized in that: the hot slag storage pool 5 is connected with a feed pipe 4, and the feed pipe 4 The other end is connected to the vacuum feeder 1, the two ends of the discharge pipe 6 and the circulation pipe 12 are respectively connected to the fermentation tank 9 and the vacuum feeder 1, and the discharge pipe 6 is equipped with a centrifugal pump 8.

Embodiment 2

[0021] Example 2 as figure 1 As shown, it is improved on the basis of Example 1. Every time the ash particles hit the heating surface, tiny metal shavings will be peeled off, and the tube wall of the heating surface will become thinner, resulting in a reduction in the strength of the heating surface, and the pipe will The wear of the ash on the pipe wall is divided into the impact wear of the normal component force and the friction wear of the tangential component force. The amount of wear is proportional to the square of the fluid velocity. It is mainly due to the rolling friction and wear of slag in the pipe wall.

Embodiment 3

[0023] Example 3 as figure 1 As shown, it is improved on the basis of Example 1, its described hot slag storage tank 5 is connected with feed pipe 4, the other end of feed pipe 4 is connected with vacuum feeder 1, discharge pipe 6, Both ends of the circulation pipe 12 are respectively connected to the fermentation tank 9 and the vacuum feeder 1, and a centrifugal pump 8 is installed on the discharge pipe 6. When the centrifugal pump 8 is running, the liquid will be sucked into the vacuum feeder 1 from the hot slag storage tank 5 , when the centrifugal pump 8 is turned on, the liquid will be sucked from the hot slag storage tank 5 into the vacuum feeder 1, and the liquid will be filtered by the filter 2, and the large solid particles will be filtered on the left side of the filter 2, and the residue will be filtered after a period of time It can be manually discharged from the inspection hole 3, and the gate valve 13 of the circulation pipe 12 is closed, and the liquid in the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com