Soakage device capable of reinforcing supporting strength and capillary action

A technology of capillary action and support strength, applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve problems such as increasing weight, weakening structural stability, and sharply reducing heat dissipation efficiency, to achieve enhanced support strength, The effect of improving structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

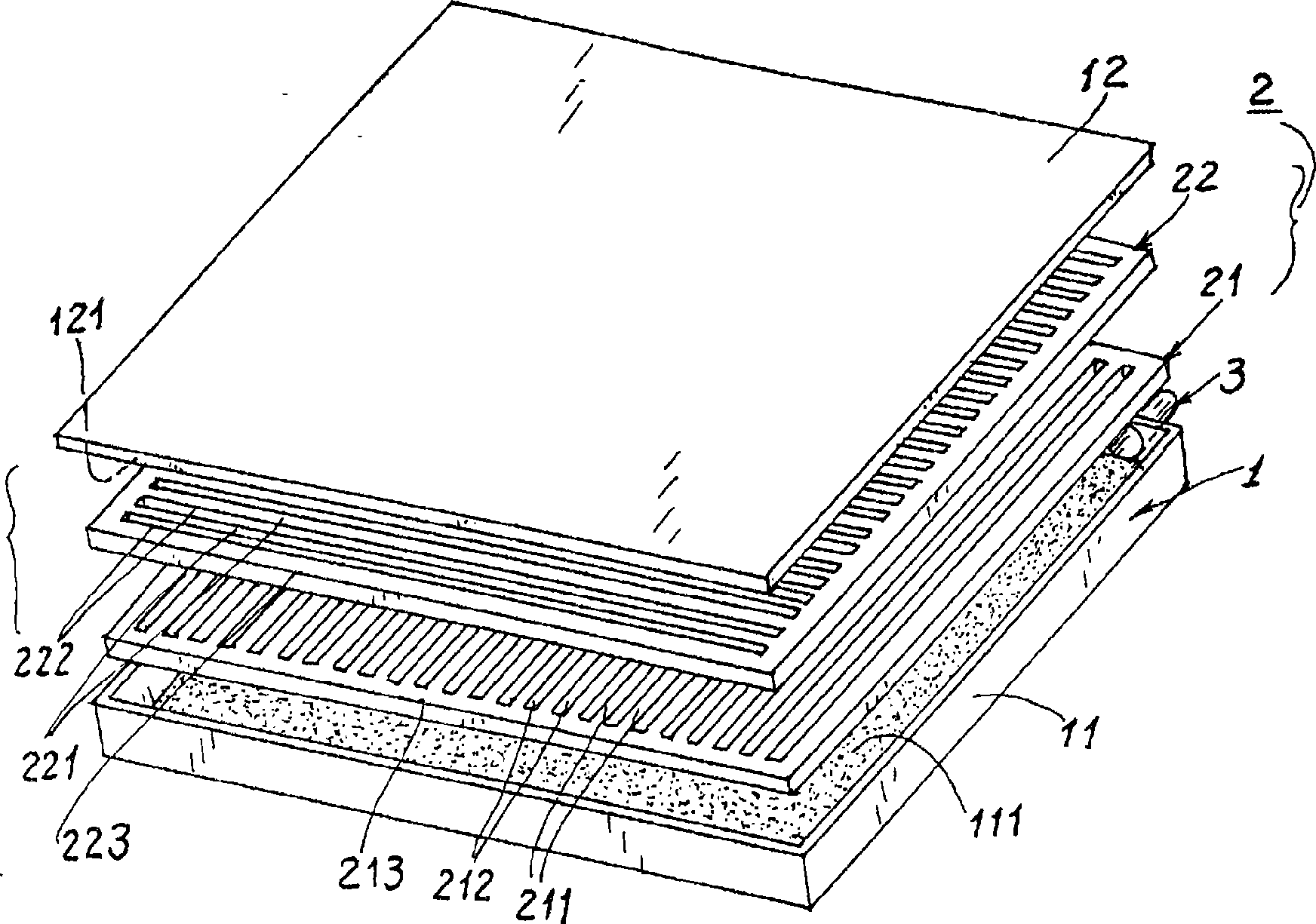

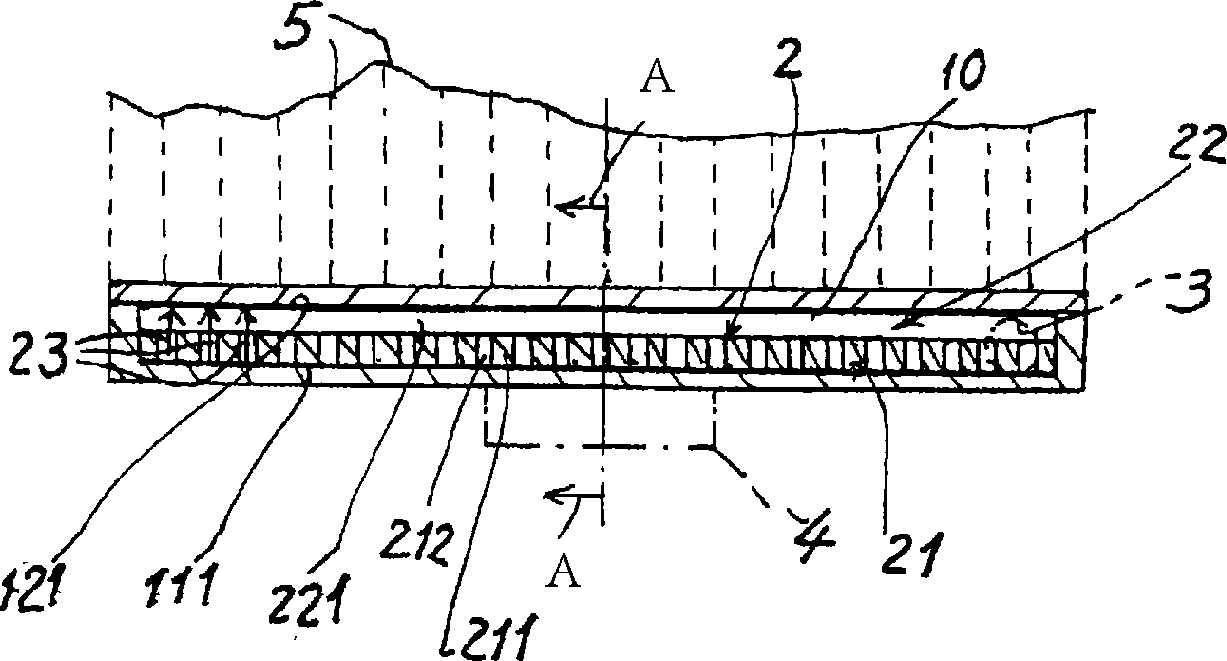

[0037] refer to Figure 2 to Figure 4 , the heat spreader of the present invention (thermal spreader) comprises: casing 1 defines steam chamber or vapor chamber (vapor chamber) 10 in it, fills into the evaporable working fluid after vacuumizing; And reticular intersecting capillary structure 2 is located in the steam chamber 10 of the housing.

[0038] The casing 1 can be made of materials such as metal with good thermal conductivity, and includes: a first casing cover 11 and a second casing cover 12 . The second casing 12 covers the first cover 11 and defines a steam chamber 10 between the first and second cover 11 , 12 .

[0039] Capillary thin layers 111, 121 can be connected to the inside of each of the shell covers 11, 12, and the capillary thin layers 111, 121 are selected from: metal (such as copper) mesh, sintered film, powder metallurgy thin layer, and other capillary thin layers . The thin capillary layers 111 , 121 can be welded, glued, and other connection metho...

no. 2 example

[0056] The second embodiment of the present invention is shown in Figure 5 Among them, the reticular intersecting capillary structure 2 "two-in-one" the aforementioned vertical grid plate 21 and horizontal grid plate 22, that is, the vertical grid bar 211 and the longitudinal capillary hole 212 are formed at the lower part of the frame body 20, and the Horizontal grid strips 221 and transverse capillary holes 222 are formed on the upper part to simplify the manufacturing and installation procedures. The fluid connecting pipe 3 directly passes through the frame body 20 and communicates with the capillary holes.

no. 3 example

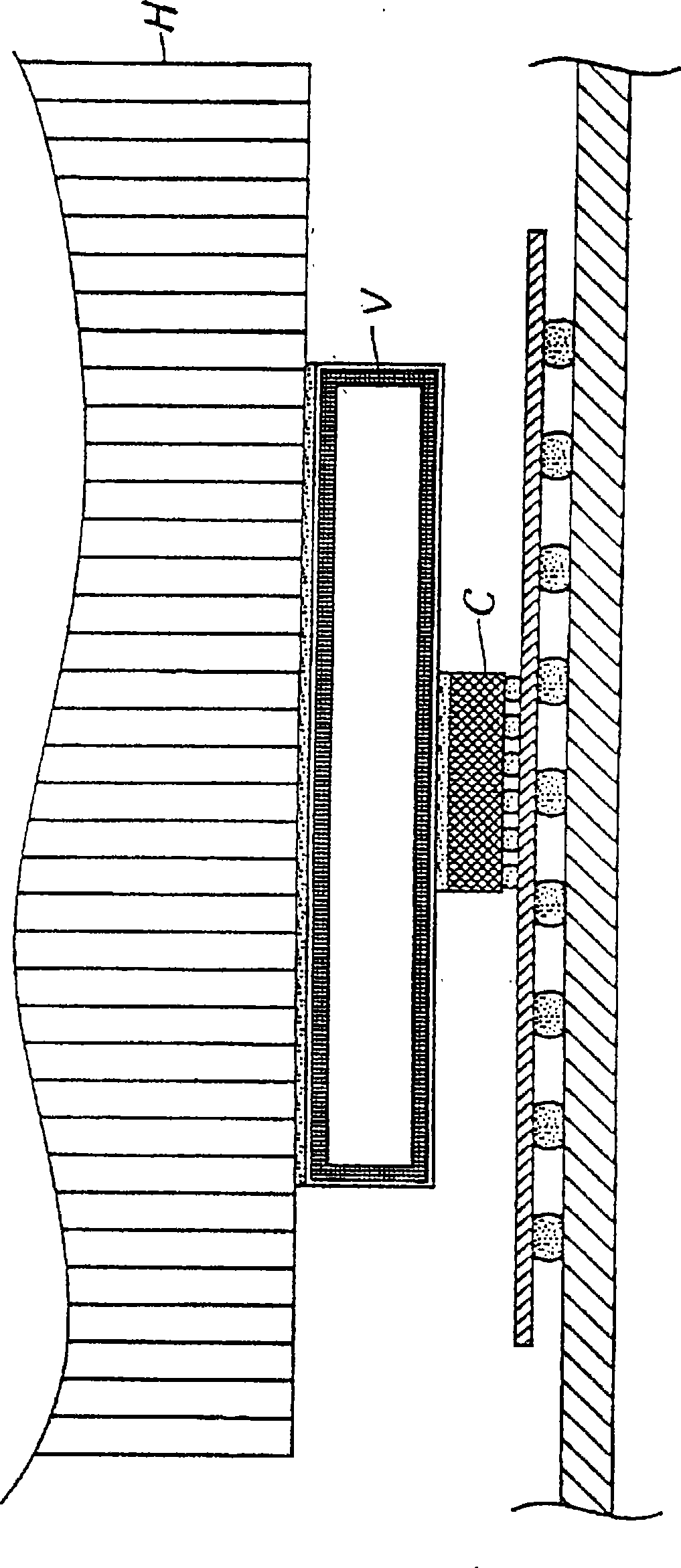

[0058] Such as Figure 6 As shown, the vertical and horizontal grids 21, 22 are respectively surrounded by the frame body 20 to define the evaporation chamber 10 in the vertical grid plate 21 and the horizontal grid plate 22, and the frame body 20 doubles as the shell of the heat equalizing device of the present invention The body 1, that is, the casing 1 combined by the first and second casing covers 11, 12 is eliminated, and the fluid connection 3 is in fluid communication with the evaporation chamber 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com