Windproof warm-keeping composite garment fabric

A technology for fabrics and clothing, which is applied in the field of windproof and warm-keeping composite clothing fabrics, which can solve the problems of decreased air permeability and moisture permeability of fabrics, the inability of airflow to pass directly, and many pores on the surface of fabrics, etc., to achieve large capillary action, extended contact range, and good water repellency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

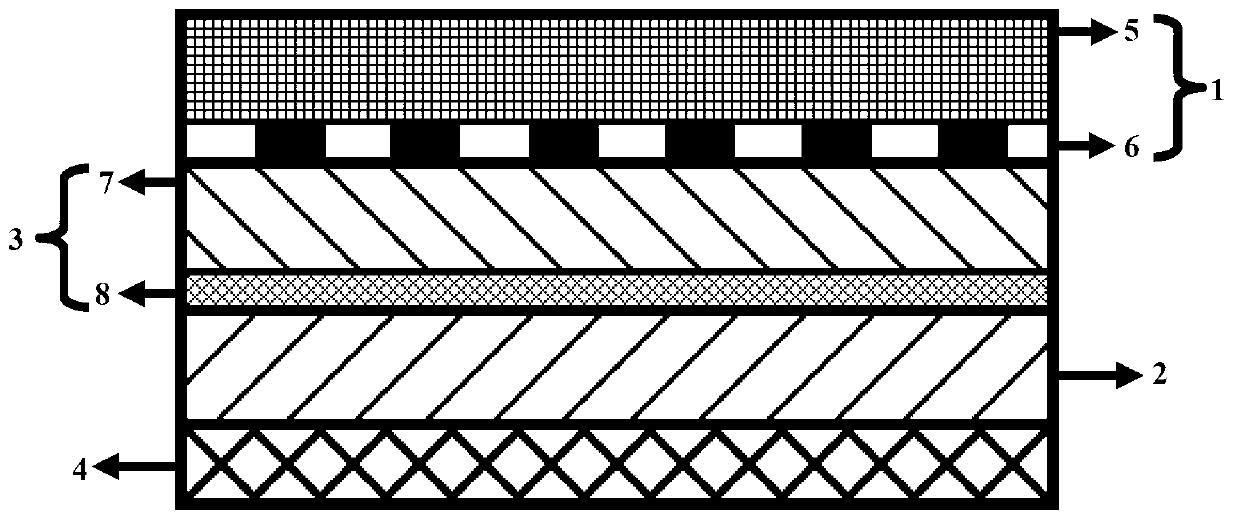

[0025] Such as figure 1 As shown, the present invention is a windproof and warm-keeping composite clothing fabric. In order to achieve better windproof performance, warmth retention and moisture permeability, a preferred embodiment is that the composite clothing fabric sequentially includes a windproof, waterproof and moisture-permeable outer layer from outside to inside. 1. Far-infrared thermal insulation layer 3. Moisture-wicking inner layer 2 and mesh lining 4. Four layers.

Embodiment 2

[0027] On the basis of Example 1, in order to achieve a better windproof effect in the present invention, reduce the air permeability of the fabric, and increase the moisture permeability, a preferred embodiment is that the windproof, waterproof, and moisture-permeable outer layer 1 is made of a high-density base The cloth 5 and the polytetrafluoroethylene microporous membrane 6 are laminated and compounded by an adhesive, and the other parts are exactly the same as in Example 1.

Embodiment 3

[0029] On the basis of Example 2, in order to reduce the weight of the fabric and increase the capillary action of the fabric in the present invention, so that the fabric is light and comfortable to wear, a preferred embodiment is that the moisture-wicking and sweat-wicking inner layer 2 has good moisture-conducting properties. The hollow polypropylene fiber and the polypropylene fiber with special-shaped cross-section are made, and the yarn count of the polypropylene fiber is 45s, and the other parts are exactly the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com