Imbibition chip, imbibition core and plate type integrated hot pipe

A technology of integrated heat pipe and liquid-absorbing core, which is applied in the field of heat transfer, mass transfer and heat dissipation, can solve the problems of dryness, small gap between sheets, and poor ability of integrated heat pipe to transport condensate, so as to reduce product cost, improve mechanical performance, and improve The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

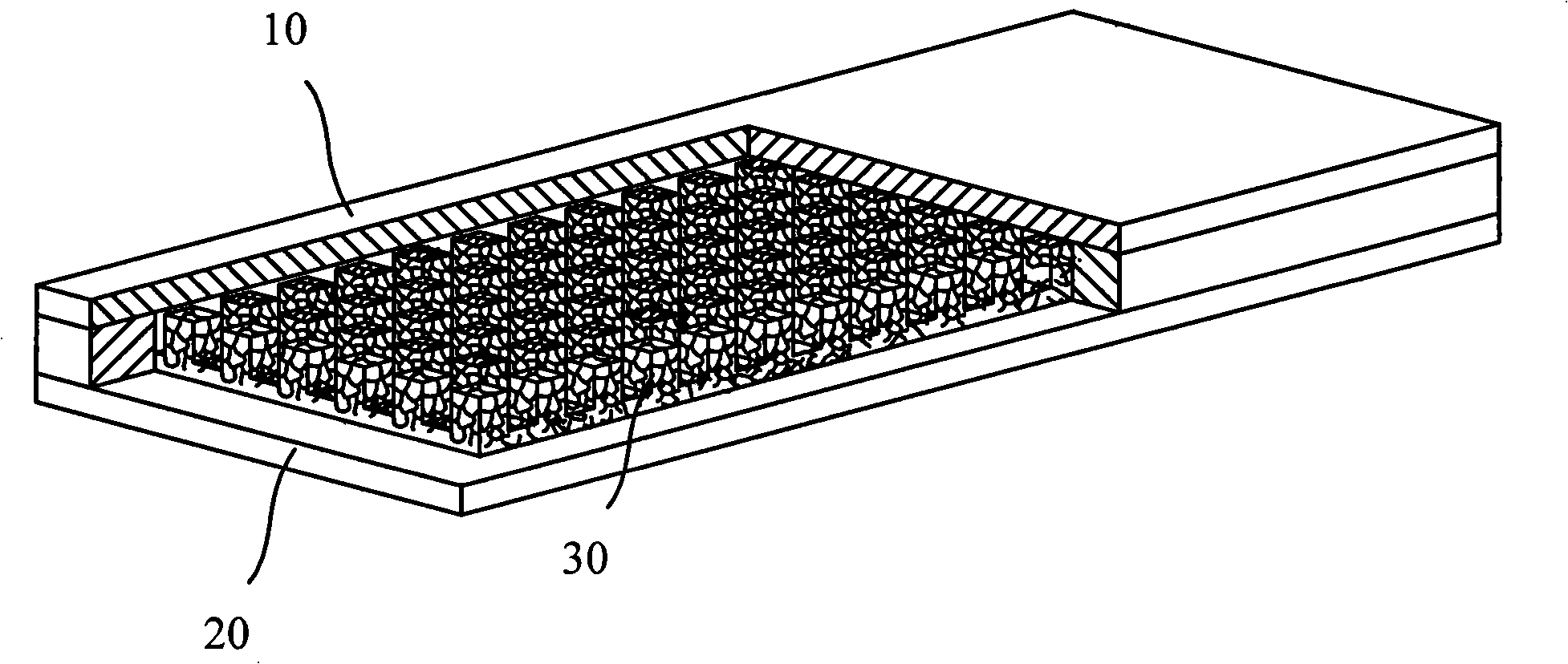

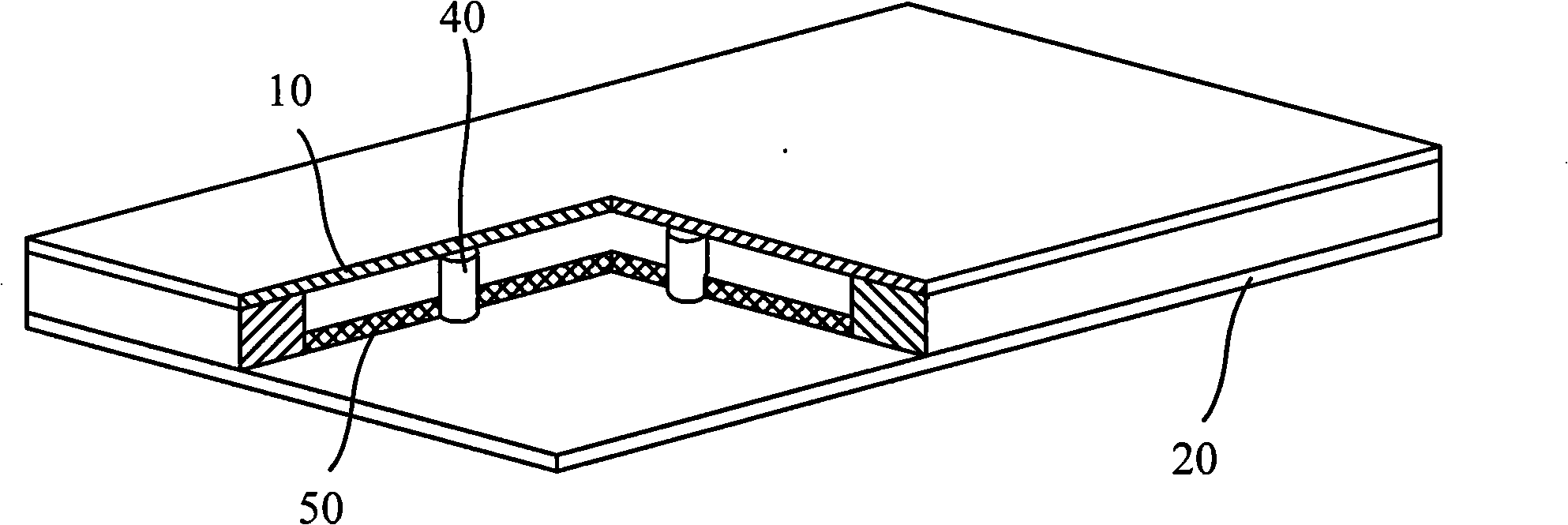

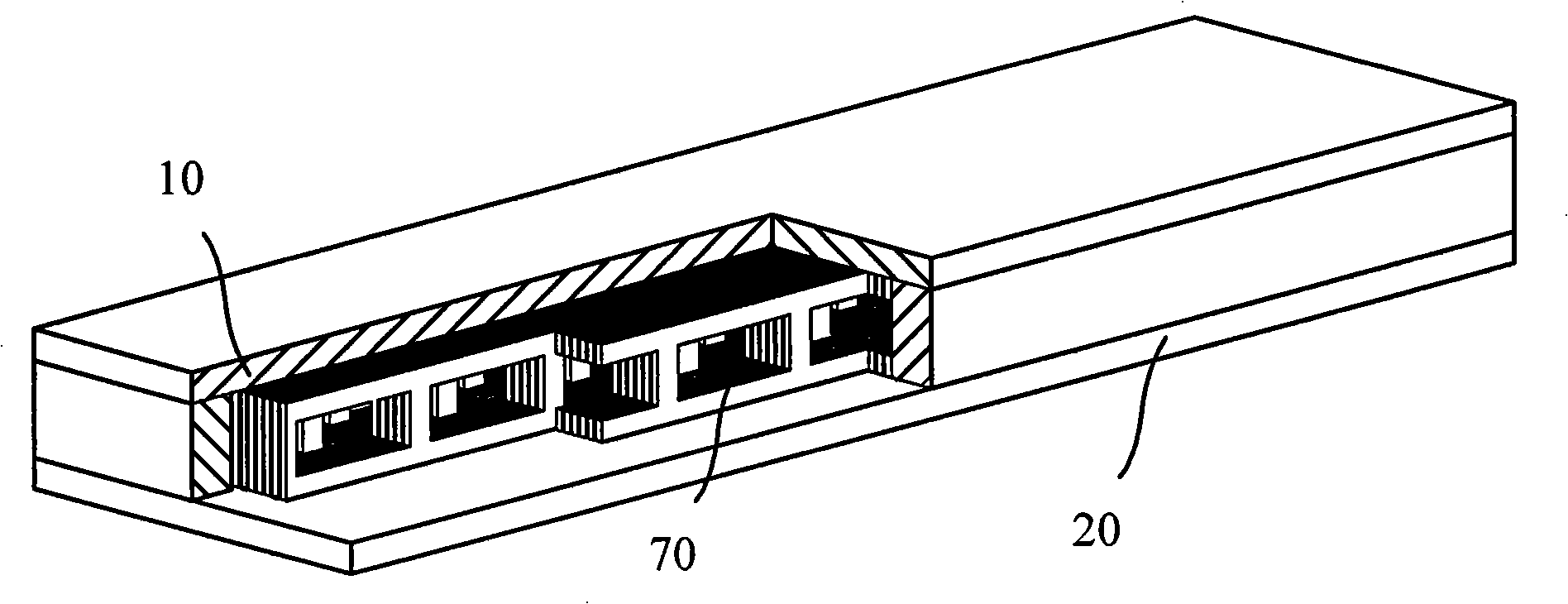

[0030] The liquid-absorbing chip of the present invention is used to be arranged in an integrated heat pipe to form a liquid-absorbing core with capillary capacity, and the liquid-absorbing chip is specifically a metal sheet used for horizontal stacking and brazing connection to form a liquid-absorbing core; and the metal sheet There are holes for guiding the return flow of condensate. There may be various shapes and layouts of the holes on the metal sheet, which will be introduced through examples below.

[0031] Liquid-absorbing chip embodiment one

[0032] Such as Figure 4 Shown is a schematic structural diagram of a specific embodiment 1 of the liquid-absorbing chip of the present invention. In this embodiment, the metal sheet is rectangular, and a plurality of holes 1 for guiding the reflux of condensate are arranged on it in a matrix shape. The shape is elongated, specifically a rectangle with rounded corners at both ends. Moreover, the strip-shaped holes 1 can be ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com