Flexible polymer waterproof coiled material and preparation method thereof

A flexible polymer and waterproof membrane technology, applied in chemical instruments and methods, flat products, layered products, etc., can solve the problems of poor polyurea or polyurethane, non-flat surface temperature conditions, dusty and sandy surfaces, etc. , to achieve the effect of ensuring moisture absorption performance, reducing weak points, and reducing the occurrence of adhesive surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

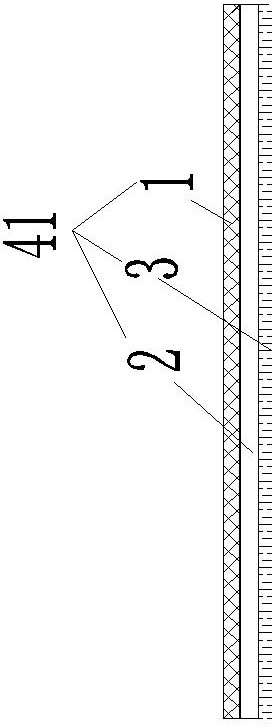

[0058]Example 1. Such asFigure 1-2 As shown, a flexible polymer waterproofing membrane includes a sprayed layer 4, a base layer, the base layer includes a 0.5mm PVC soft layer 2, and a polypropylene fiber with a mesh structure compounded on the top surface of the polyvinyl chloride soft layer 2 by hot pressing Non-woven fabric 3, thermo-compression compounded on the bottom surface of the PVC soft layer 2, the bottom surface of the polyester fabric 1; the spray layer 4 is sprayed on the top surface of the polypropylene non-woven fabric 3; the raw material of the spray layer 4 is polyurea, thickness Both are 1.0mm.

[0059]The polypropylene non-woven fabric 3 is a polypropylene spunbonded non-woven fabric.

[0060]The polypropylene non-woven fabric 3 is 40g / m2Of polypropylene spunbond non-woven fabric.

[0061]The polyester fabric 1 is a polyester filament hot-rolled non-woven fabric.

[0062]The polyester fabric 1 is a polyester filament hot-rolled non-woven fabric of 70g / m2Of polyester filament...

Embodiment 2

[0085]Example 2. The difference between this embodiment and embodiment 1 is that the polypropylene non-woven fabric 3 is 40g / m2Of polypropylene spunbond non-woven fabric. The thickness of the PVC soft layer 2 is 0.8 mm. The raw material of the spray coating 4 is polyurethane, and the thickness is 1.0 mm.

[0086]The polyester fabric 1 is a polyester filament hot-rolled non-woven fabric.

[0087]The polyester fabric 1 is a polyester filament hot-rolled non-woven fabric of 70g / m2Of polyester filament hot-rolled non-woven fabric.

[0088]The raw materials of the PVC soft layer 2 include the following components and contents by weight: 100 parts of polyvinyl chloride resin, 30 parts of diisononyl phthalate, 2 parts of DOTP softening plasticizer, 2 parts of OPE lubricant, 11 parts of dioctyl oxalate, 2 parts of epoxidized soybean oil, 1.5 parts of antimony trioxide, 0.10 parts of sodium pentachlorophenate, 0.05 parts of β-dodecyl thiopropionate pentaerythritol ester, liquid barium zinc compound s...

Embodiment 3

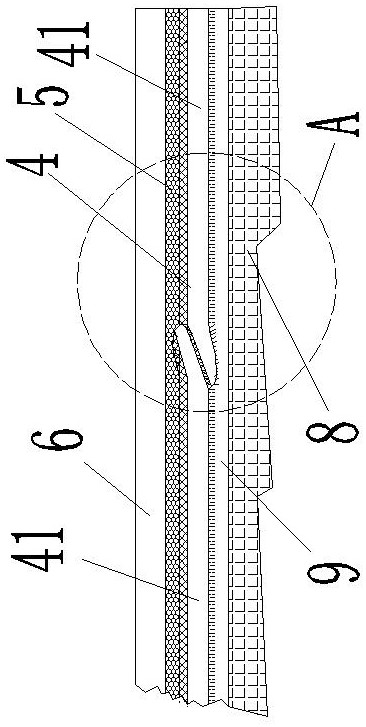

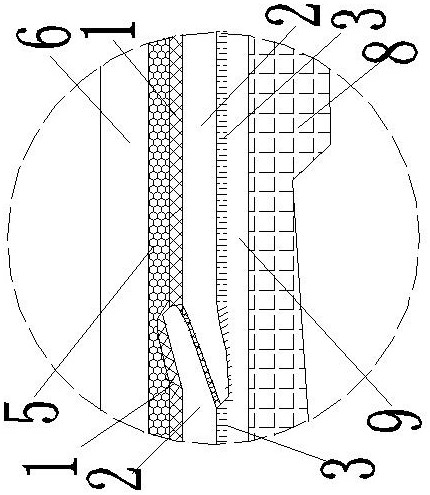

[0110]Example 3. The difference between this embodiment and embodiment 2 lies in:Figure 3-5As shown, the left side of the bottom surface of the PVC soft layer 2 is left with a lower lap area 21 without polyester fabric 1, and the right side of the top surface of the base layer is left with an upper side without polypropylene non-woven fabric 3. Overlap area 22. The spraying auxiliary coil includes a 0.8mm polyvinyl chloride soft layer 2, a polypropylene non-woven fabric with a mesh structure laminated on the top surface of the polyvinyl chloride soft layer 2 by hot pressing, and a polyvinyl chloride soft layer by hot pressing. 2 The bottom of the bottom surface is polyester cloth 1 with a wool surface.

[0111]Polypropylene non-woven fabric 3 is 50g / m2Of polypropylene spunbond non-woven fabric.

[0112]The polyester fabric 1 is a polyester filament hot-rolled non-woven fabric.

[0113]The polyester fabric 1 is polyester filament hot-rolled non-woven fabric, 90g / m2Of polyester filament hot-ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com