Preparation method of vinyl collagen microsphere/polyamide fiber composite material

A technology based on collagen and polyamide fibers, which is applied in the directions of light/infrared/X-ray fiber processing, fiber processing, fiber type, etc., which can solve the problems of unsatisfactory moisture permeability, poor moisture absorption and moisture permeability, and stuffy wearing. , to achieve the effect of resource utilization, improving moisture permeability and long functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

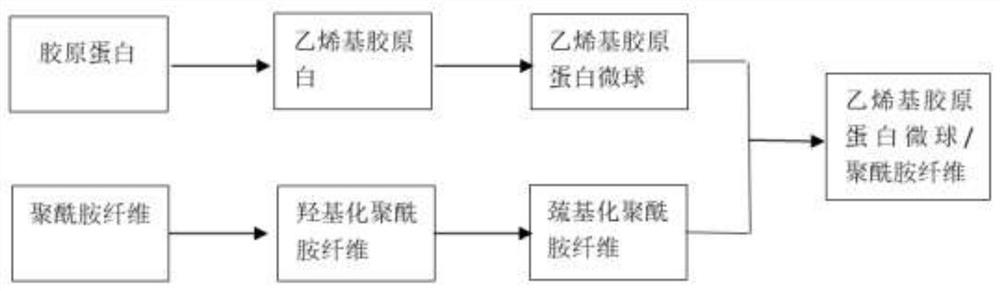

[0039] The invention provides a kind of preparation method of vinyl collagen microsphere / polyamide fiber composite material, such as figure 1 As shown, the specific steps are as follows:

[0040] Step 1, methacrylic anhydride modifies collagen to obtain vinyl collagen; then emulsifies and cross-links vinyl collagen to obtain vinyl collagen microspheres;

[0041] Step 1 is specifically implemented according to the following steps:

[0042] Step 1.1, Preparation of Vinyl Collagen

[0043] Add a certain amount of collagen and phosphate buffer solution into the Erlenmeyer flask, then place the Erlenmeyer flask in a constant temperature magnetic stirrer at 70°C, heat and stir until the collagen is completely dissolved, then lower the temperature of the constant temperature magnetic stirrer After 20 minutes, add a certain amount of methacrylic anhydride to the Erlenmeyer flask to react for 2 hours. The amount of methacrylic anhydride added is 3 / 500 of the volume of the phosphate buf...

Embodiment 1

[0066] The preparation method of vinyl collagen microsphere / polyamide fiber composite material is specifically implemented according to the following steps:

[0067] Step 1, modifying collagen with methacrylic anhydride to obtain vinyl collagen; then emulsifying and crosslinking vinyl collagen to obtain vinyl collagen microspheres;

[0068] Step 1 is specifically implemented according to the following steps:

[0069] Step 1.1, Preparation of Vinyl Collagen

[0070] Add a certain amount of collagen and phosphate buffer solution into the Erlenmeyer flask, then place the Erlenmeyer flask in a constant temperature magnetic stirrer at 70°C, heat and stir until the collagen is completely dissolved, then lower the temperature of the constant temperature magnetic stirrer After 20 minutes, add a certain amount of methacrylic anhydride to the Erlenmeyer flask to react for 2 hours. The amount of methacrylic anhydride added is 3 / 500 of the volume of the phosphate buffer solution. Dialyze...

Embodiment 2

[0084] The preparation method of vinyl collagen microsphere / polyamide fiber composite material is specifically implemented according to the following steps:

[0085] Step 1, methacrylic anhydride modifies collagen to obtain vinyl collagen; then emulsifies and cross-links vinyl collagen to obtain vinyl collagen microspheres;

[0086] Step 1 is specifically implemented according to the following steps:

[0087] Step 1.1, Preparation of Vinyl Collagen

[0088] Add a certain amount of collagen and phosphate buffer solution into the Erlenmeyer flask, then place the Erlenmeyer flask in a constant temperature magnetic stirrer at 70°C, heat and stir until the collagen is completely dissolved, then lower the temperature of the constant temperature magnetic stirrer After 20 minutes, add a certain amount of methacrylic anhydride to the Erlenmeyer flask to react for 2 hours. The amount of methacrylic anhydride added is 3 / 500 of the volume of the phosphate buffer solution. Dialyze for 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com