Antibacterial cotton cloth and preparation method

A cotton cloth and solution technology, which is applied in the processing of textile materials, textile and papermaking, liquid/gas/steam textile processing, etc., can solve the problems of low bonding fastness and poor washing resistance, etc. The effect of high permeability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

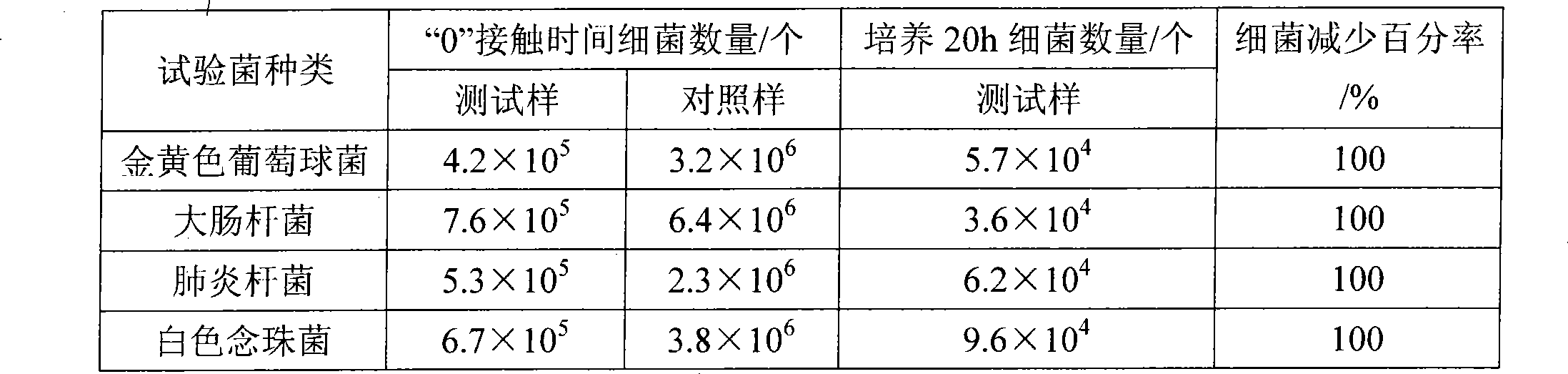

Image

Examples

Embodiment 1

[0026] An antibacterial cotton cloth made by the following method:

[0027] (1) Take 2% silver-loaded hydroxyapatite, 0.1% sodium hexametaphosphate, 5% chitin, and 0.05% citric acid according to mass percentage, and add water to 100% to make a solution;

[0028] (2) Put the medical absorbent cotton cloth into the solution prepared in step (1) for padding, padding twice, with a rolling margin of 100%, pre-baking at 90°C for 2 minutes, and then baking at 150°C for 3 minutes to make Antibacterial cotton cloth.

[0029] The silver-loaded hydroxyapatite was prepared in Example 5.

Embodiment 2

[0031] An antibacterial cotton cloth made by the following method:

[0032] (1) Take 1% of silver-loaded hydroxyapatite, 0.2% of sodium hexametaphosphate, 8% of chitin, and 0.1% of citric acid according to mass percentage, and add water to 100% to make a solution;

[0033] (2) Put the medical absorbent cotton cloth into the solution prepared in step (1) for padding, padding once, with a rolling margin of 90%, pre-baking at 80°C for 1 min, and then baking at 130°C for 4 min to make Antibacterial cotton cloth.

[0034] The silver-loaded hydroxyapatite was prepared in Example 6.

Embodiment 3

[0036] An antibacterial cotton cloth made by the following method:

[0037] (1) Take 3% silver-loaded hydroxyapatite, 0.05% sodium hexametaphosphate, 6% chitin, 0.02% citric acid according to mass percentage, and add water to 100% to make a solution;

[0038] (2) Put the medical absorbent cotton cloth into the solution prepared in step (1) for padding, padding twice, with a rolling margin of 60%, pre-baking at 100°C for 3 minutes, and then baking at 170°C for 1 minute to make Antibacterial cotton cloth.

[0039] The silver-loaded hydroxyapatite was prepared in Example 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com