Short-flow pretreatment processing method for cotton blending woven fabric

A processing method and short-process technology, which is applied in the field of printing and dyeing, can solve the problems of fabric strength damage, long processing process, and complicated process, and achieve the effects of improving production efficiency, reducing production costs, and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

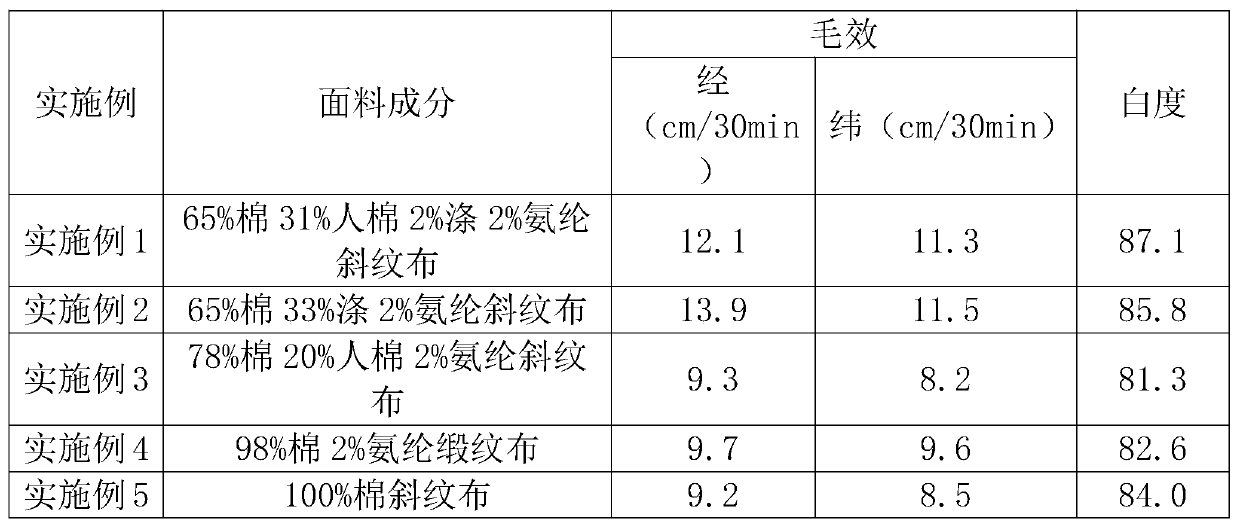

Embodiment 1

[0025] This example provides a short-process pre-processing method for cotton, rayon, polyester and spandex blended woven fabrics. The blended woven fabric used is 65% cotton 31% rayon 2% polyester 2% spandex twill. The treatment process is followed by padding cold pile liquid (rolling residual rate 100%, two dip two rolling), cold pile (cold pile at room temperature for 24 hours), first washing, padding steaming liquid (rolling residual rate 100% , Two soaking and two rolling), steaming, second washing and drying 7 steps. Specific steps are as follows:

[0026] (1) Pad cold pile liquid:

[0027] The preparation of cold reactor liquid: add 25g / L of caustic soda, 20g / L of scouring enzyme, 3g / L of complexing agent, 28g / L of 50% hydrogen peroxide, and 10g / L of hydrogen peroxide stabilizer into the trough. The scouring penetrant is 5g / L. After each ingredient is added, it needs to be stirred evenly to prepare a cold pile liquid. The fabric to be treated is dipped into the cold pile...

Embodiment 2

[0041] This example provides a short-process pre-processing method for cotton, polyester and spandex blended woven fabrics. The blended woven fabric used is 65% cotton 33% polyester 2% spandex twill fabric. The short-process pre-treatment process is followed by padding. Cold pile liquid (rolling residual rate 100%, two dip two rolling), cold pile (cold pile at room temperature for 24 hours), the first water washing, pad steaming liquid (rolling residual rate 100%, two dip two rolling), 7 steps of steaming, second washing and drying. Specific steps are as follows:

[0042] (1) Pad cold pile liquid:

[0043] The preparation of cold reactor liquid: add 25g / L of caustic soda, 20g / L of scouring enzyme, 3g / L of complexing agent, 28g / L of 50% hydrogen peroxide, and 10g / L of hydrogen peroxide stabilizer into the trough. The scouring penetrant is 5g / L. After each ingredient is added, it needs to be stirred evenly to prepare a cold pile liquid. The fabric to be treated is dipped into the...

Embodiment 3

[0057] This example provides a short-process pre-treatment method for cotton, rayon and spandex blended woven fabrics. The blended woven fabric used is 78% cotton, 20% rayon, 2% spandex twill, and its short-process pre-treatment process passes through Pad cold pile liquid (rolling residual rate 100%, two dip two rolling), cold pile (cold pile at room temperature for 24 hours), the first water washing, pad steaming liquid (rolling residual rate 100%, two dip two rolling) ), steaming, second washing and drying 7 steps. Specific steps are as follows:

[0058] (1) Pad cold pile liquid:

[0059] The preparation of cold reactor liquid: add 25g / L of caustic soda, 25g / L of scouring enzyme, 3g / L of complexing agent, 28g / L of 50% hydrogen peroxide, and 10g / L of hydrogen peroxide stabilizer into the trough. The scouring penetrant is 5g / L. After each ingredient is added, it needs to be stirred evenly to prepare a cold pile liquid. The fabric to be treated is dipped into the cold pile solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com