Wave-absorbing biomimetic composite material and preparation method

A biomimetic composite material and technology of biomimetic materials are applied in the field of wave absorbing biomimetic composite materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

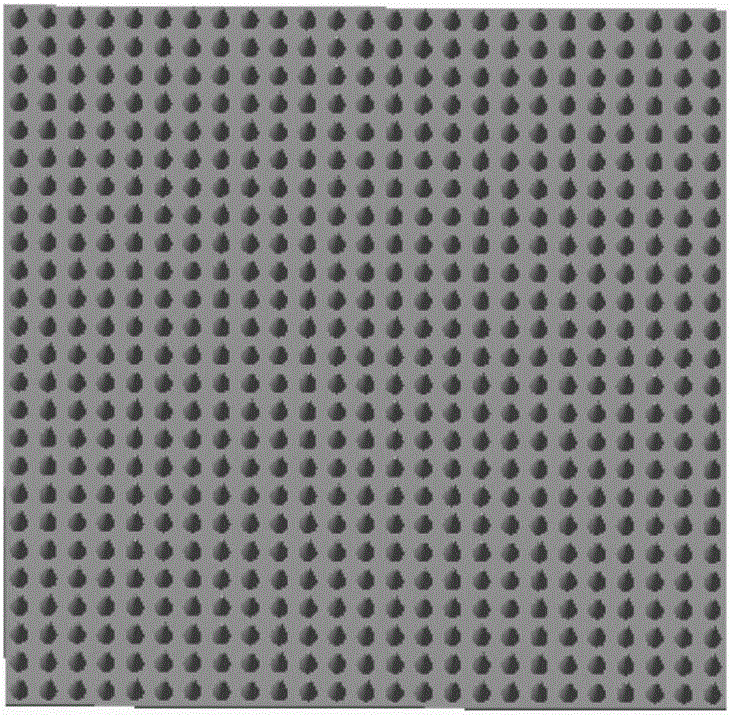

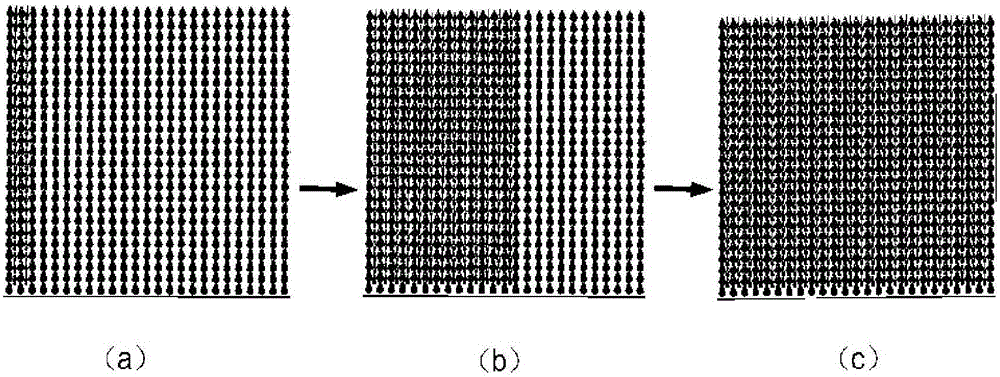

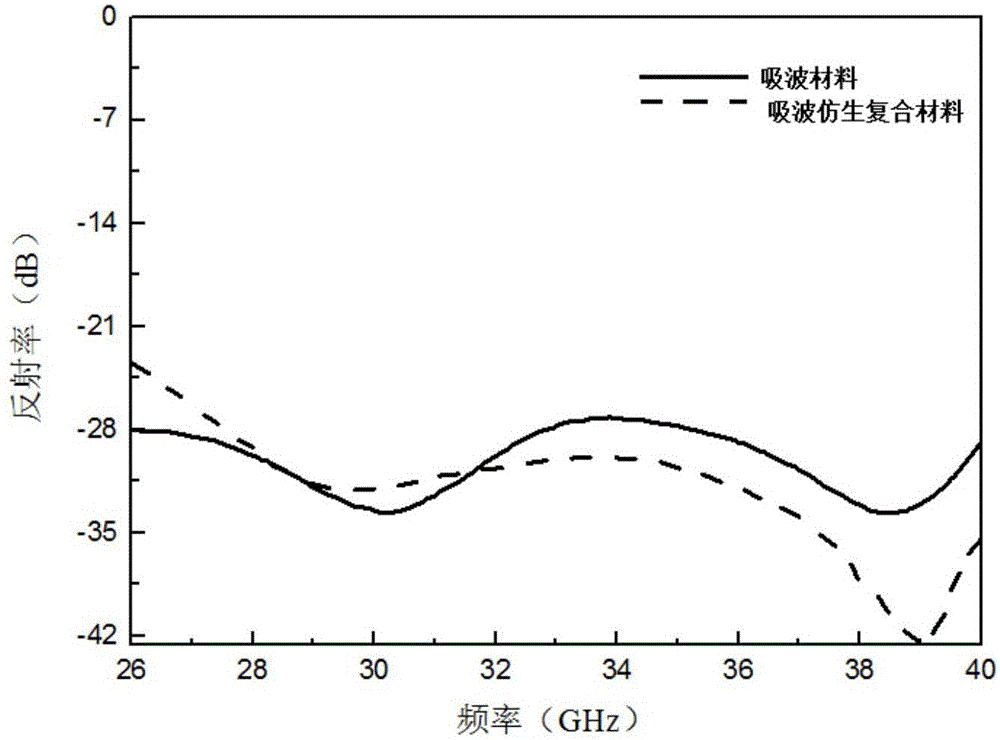

Image

Examples

Embodiment 1

[0037] (1) Weigh the raw materials of each component in parts by weight, add 1 part of polyvinyl alcohol water-soluble polymer into 250 mL of deionized water to dissolve to make a polyvinyl alcohol solution;

[0038] (2) Dissolve 1 part of lithium chloride, 2 parts of L-malic acid, 5 parts of acetic acid, 2 parts of chromium oxide green in the above polyvinyl alcohol solution, and undergo cross-linking reaction for 5 hours at a temperature of 60°C , Made into casting film liquid;

[0039] (3) Take out the casting liquid in step (2), put it in an oven and heat it to 80℃ for 1 hour to promote the cross-linking of polyvinyl alcohol, then evacuate and defoam and spread it on the customized board, vacuum and defoam. Including: putting the casting solution in a suction filter flask or vacuum oven to evacuate, then place it at room temperature and let it stand in a sealed state for 18h;

[0040] (4) Heat the customized board in a constant temperature and humidity box at a temperature of 40...

Embodiment 2

[0046] (1) Weigh the raw materials of each component in parts by weight, and add 4 parts of polyvinyl alcohol water-soluble polymer into 250 mL of deionized water to dissolve to make a polyvinyl alcohol solution;

[0047] (2) Dissolve 3 parts of lithium chloride, 6 parts of L-malic acid, 5.5 parts of acetic acid, 4 parts of chromium oxide green in the above polyvinyl alcohol solution, and undergo a cross-linking reaction for 5.5 hours at a temperature of 75°C , Made into casting film liquid;

[0048] (3) Take out the casting liquid in step (2), put it in an oven and heat it to 90℃ for 1.2h to promote the cross-linking of polyvinyl alcohol, then evacuate and defoam, then lay it flat on the custom board, and defoam by vacuum It specifically includes: putting the casting solution in a suction filter flask or a vacuum oven to evacuate, and then place it at room temperature to seal and stand for 21 hours;

[0049] (4) Heat the customized board in a constant temperature and humidity box a...

Embodiment 3

[0055] (1) Weigh the raw materials of each component in parts by weight, and add 8 parts of polyvinyl alcohol water-soluble polymer into 250 mL of deionized water to dissolve to make a polyvinyl alcohol solution;

[0056] (2) Dissolve 7 parts of lithium chloride, 9 parts of L-malic acid, 6 parts of acetic acid, and 6 parts of chromium oxide green in the above polyvinyl alcohol solution, and undergo a crosslinking reaction for 6 hours at a temperature of 90°C , Made into casting film liquid;

[0057] (3) Take out the casting liquid in step (2), put it in an oven and heat it to 100°C for 1.5h to promote the crosslinking of polyvinyl alcohol, then evacuate and defoam, then lay it flat on the customized board, and defoam by vacuum It specifically includes: placing the casting solution in a suction filter flask or a vacuum oven to evacuate, and then place it at room temperature to seal and stand for 24 hours;

[0058] (4) Heat the customized board in a constant temperature and humidity b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com