Dust suppressant as well as preparation method and application thereof

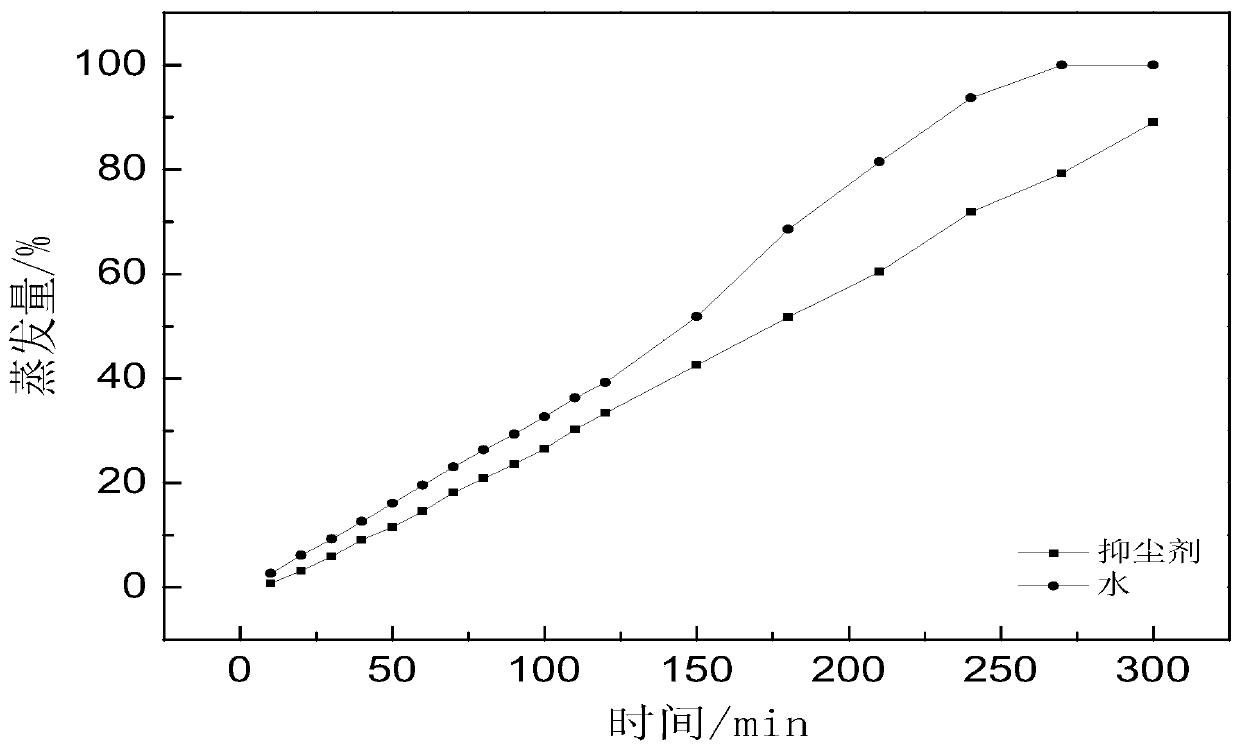

A dust suppressant and reaction technology, applied in the field of dust suppressant and its preparation, can solve the problems of easy cracking of the road surface, secondary dust on the road surface, and high cost, and achieve a low impact on the road environment, realize reuse and low use cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of dust suppressant, comprises the following steps:

[0021] Mix cellulase, water and straw, carry out enzymolysis reaction, add thickener or adhesive to obtain dust suppressant.

[0022] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

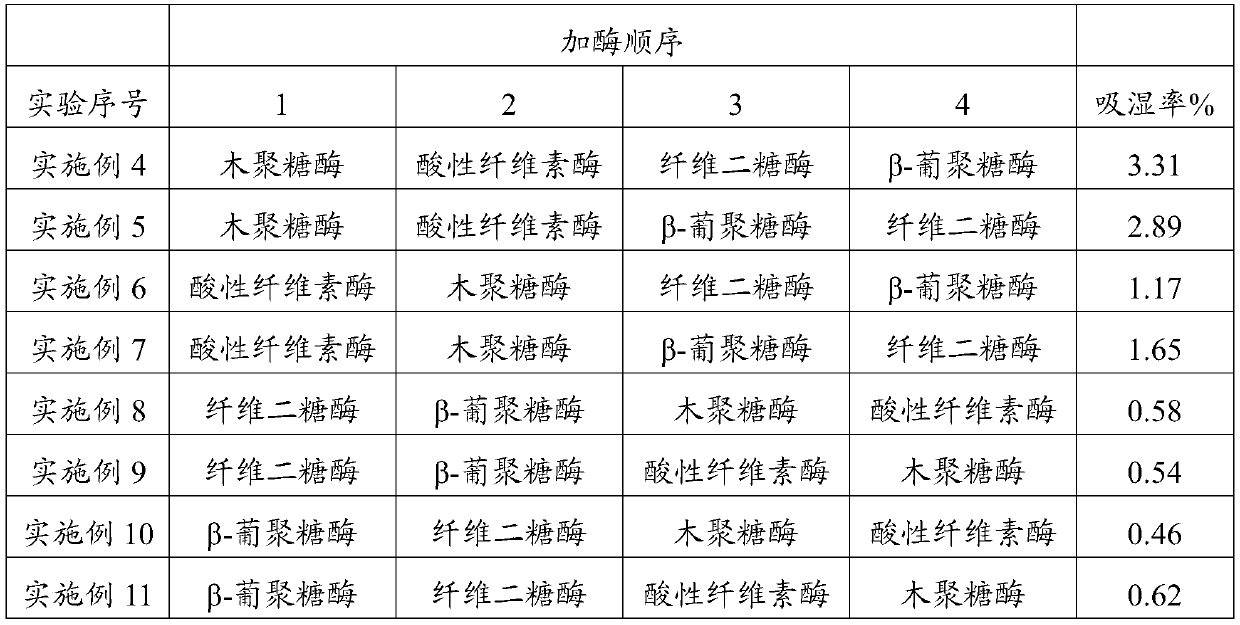

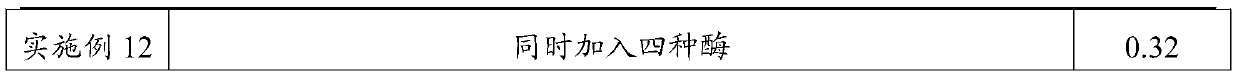

[0023] In the present invention, the cellulase preferably includes xylanase, acid cellulase, cellobiase and β-glucanase; the xylanase, acid cellulase, cellobiase The mass ratio to β-glucanase is preferably (1-4):(1-4):(1-4):(1-2), more preferably 3:3:3:1. In the present invention, the straw is preferably corn straw or sorghum straw; the particle size of the straw is preferably 1-2mm. In the present invention, the mass ratio of the cellulase, water and straw is preferably (0.01-2):(280-340):(5-10).

[0024] Before the mixing, the present invention preferably heats the water to 45-55° C., and adjus...

Embodiment 1

[0036] ①Crush the corn stalks with a pulverizer, the particle size of which is 1-2 mm, and set aside;

[0037] ② Mixing xylanase, acid cellulase, cellobiase and β-glucanase according to the mass ratio to prepare a compound enzyme, the mass ratio of the above four enzymes is 1:1:2:2;

[0038] ③ Use dilute hydrochloric acid and a pH meter to adjust the pH of 300 ml of water to 6.0, heat up to 50°C and keep it at a constant temperature;

[0039] ④Add 0.9g of the compound enzyme in ② into the water in ③ to activate. The activation time is 6 minutes to obtain an activated enzyme solution. During activation, stir to accelerate the dispersion and activation of the four enzymes;

[0040] ⑤Take 6g of ① crushed straw and put it into the above-mentioned activated enzyme solution, start the enzymatic hydrolysis reaction, the reaction time is 60min, then stop heating, add 0.3g of polyvinyl alcohol, ultrasonically stir the whole process, continue to stir for 20min after adding polyvinyl alc...

Embodiment 2

[0044] ①Crush the corn stalks with a pulverizer, the particle size of which is 1-2 mm, and set aside;

[0045] ② Mixing xylanase, acid cellulase, cellobiase and β-glucanase according to the mass ratio to prepare a compound enzyme, the mass ratio of the above four enzymes is 1:1:1:1;

[0046] ③ Use dilute hydrochloric acid and a pH meter to adjust the pH of 300 ml of water to 6.0, heat the water to 50°C and keep it at a constant temperature;

[0047] ④Add 0.9g of the compound enzyme in ② into the water in ③ to activate it. The activation time is 6 minutes to obtain an activated enzyme liquid. When the enzyme is activated, stir to accelerate the dispersion and activation of the four enzymes;

[0048] ⑤Take 6g of ① crushed straw and put it into the above-mentioned activated enzyme solution, start the enzymatic hydrolysis reaction, the reaction time is 60min, then stop heating, add 0.3g of polyvinyl alcohol, ultrasonically stir the whole process, continue to stir for 20min after a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com