A method for preparing cotton pulp used for high-strength filter paper

A cotton pulp, high-strength technology, applied in the field of pulp manufacturing, can solve the problems of filter cleaning ability decline, moisture absorption performance and strength influence, automobile engine failure, etc., to achieve the effect of ensuring hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

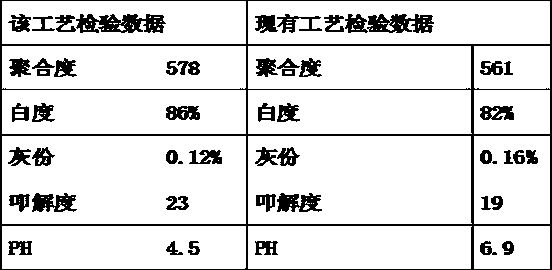

Image

Examples

Embodiment 1

[0035] Embodiment 1, a kind of preparation method of cotton pulp for high-strength filter paper, comprises the following steps:

[0036] A. Cotton opening:

[0037] With the air-dried pulp 2640Kg / ball or the absolute-dried pulp 2401Kg / ball as the basic unit, it is manually separated according to the requirements of the feeding thickness ≤ 10cm and put into the cotton opener. The feeding time of each basic unit is ≥ 30min, and then two series of seven The roller opener and three five-roller openers in series are all turned on, so that the pulp output by the opener passes through in sequence;

[0038] The frequency of the opening fan on the opener is set to 50 Hz / min, and cotton linters are used for air-dried pulp or absolute-dried pulp.

[0039] B. Alkali

[0040] Prepare alkali solution with the standard of 9600L / ball (relative to air-dried pulp 2640Kg / ball or absolute dry pulp 2401Kg / ball);

[0041] The concentration of NaOH in the alkali solution is 39g / L, and the tempera...

Embodiment 2

[0064] Embodiment 2, a kind of preparation method of cotton pulp for high-strength filter paper, comprises the following steps:

[0065] A. Cotton opening:

[0066] With the air-dried pulp 2650Kg / ball or the absolute-dried pulp 2411Kg / ball as the basic unit, it is manually separated according to the requirements of the feeding thickness ≤ 10cm and put into the cotton opener. The feeding time of each basic unit is ≥ 30 minutes, and then two series-connected The seven-roller opener and three five-roller openers in series are all turned on, so that the pulp output by the opener passes through in sequence;

[0067] The frequency of the opening fan on the opener is set to 50 Hz / min, and cotton linters are used for air-dried pulp or absolute-dried pulp.

[0068] B. Alkali

[0069] Prepare alkali solution with the standard of 9600L / ball (relative to air-dried pulp 2650Kg / ball or absolute dry pulp 2411Kg / ball);

[0070] The concentration of NaOH in the alkali solution is 40g / L, and...

Embodiment 3

[0093] Embodiment 3, a kind of preparation method of cotton pulp for high-strength filter paper, comprises the following steps:

[0094] A. Cotton opening:

[0095] With the air-dried pulp 2660Kg / ball or the absolute-dried pulp 2421Kg / ball as the basic unit, it is manually separated according to the requirements of the feeding thickness ≤ 10cm and put into the cotton opener. The feeding time of each basic unit is ≥ 30min, and then two series-connected seven The roller opener and three five-roller openers in series are all turned on, so that the pulp output by the opener passes through in sequence;

[0096] The frequency of the opening fan on the opener is set to 50 Hz / min, and cotton linters are used for air-dried pulp or absolute-dried pulp.

[0097] B. Alkali

[0098] Prepare alkali solution with the standard of 9600L / ball (relative to air-dried pulp 2660Kg / ball or absolute dry pulp 2421Kg / ball);

[0099] The concentration of NaOH in the alkali solution is 41g / L, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com