Quick-acting vinegar brewing machine

A vinegar making machine and quick-acting technology, which is applied in the field of edible vinegar preparation, can solve the problems of large floor area, space-consuming, labor-intensive and time-consuming, etc., and achieve the effect of making up for the consumption and supplementing the consumption of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

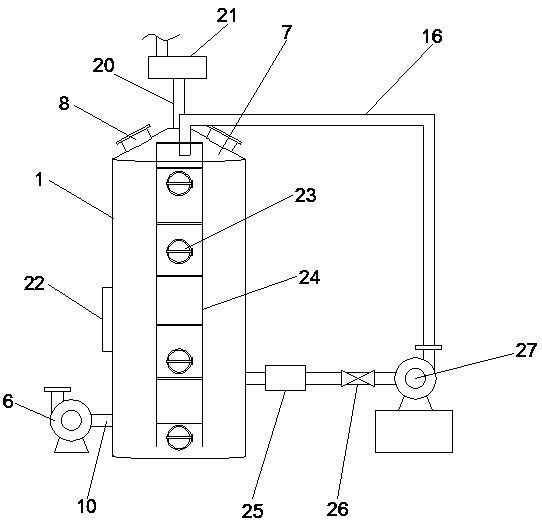

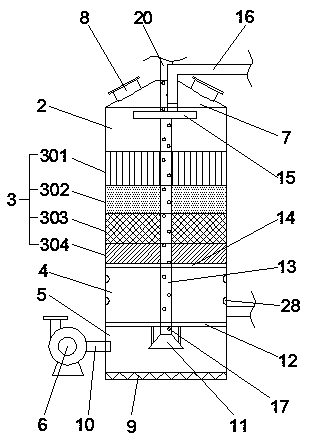

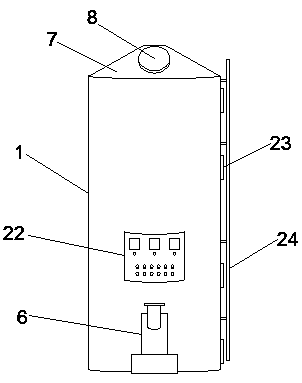

[0031] Such as figure 1 , figure 2 and Figure 4 As shown, a quick-acting vinegar brewing machine includes a vinegar brewing machine body 1, a heat conduction mechanism and a reflux mechanism. The top of the vinegar brewing machine body 1 is provided with a movable cover 7, and the vinegar brewing machine body 1 is sequentially provided with atomization zones from top to bottom. 2. Auxiliary material area 3, collection area 4 and heating area 5, a sieve plate 14 is arranged between the auxiliary material area 3 and the collection area 4, a partition plate 12 is arranged between the collection area 4 and the heating area 5, the sieve plate 14 and the separation The partitions 12 are all movably connected with the inner wall of the vinegar brewing machine body 1 . The heat conduction mechanism transports heat and air from the heating zone 5 to the atomization zone 2. The movable cover 7 is provided with a material delivery port 8. One end of the return mechanism communicates ...

Embodiment 2

[0036] Based on Embodiment 1, the heat conduction mechanism includes an air compressor 6 , a heat conduction pipe 13 and an exhaust pipe 20 . The heat pipe 13 is located in the main body 1 of the vinegar brewing machine, one end is located in the heating area 5, the other end is located in the atomization area 2, and communicates with the exhaust pipe 20 passing through the movable cover 7. The surface of the heat pipe 13 is covered with heat conduction holes 17.

[0037] In use, the air compressor pushes the air into the heating zone, and the heating zone heats the air to carry a certain amount of heat. Since the air compressor continuously pushes the air into the heating zone, the heated air in the heating zone enters from the heat pipe. Moving towards the atomization area, there are heat conduction holes on the heat pipe, so that the air can easily enter the collection area, auxiliary material area and atomization area, and the above three areas can be heated to maintain the...

Embodiment 3

[0040]Based on Example 2, an air distribution device 11 is provided at one end of the heat transfer pipe 13 located in the heating zone 5 .

[0041] In use, setting the air distribution device can effectively improve the efficiency of the heated air entering the heat pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com