Vapor-pressure-stabilized MO source device and vapor-pressure-stabilized MO source supply method

A vapor pressure, source device technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of reduced vapor pressure, reaction chamber pollution, solution instability, etc., to make up for consumption, vapor pressure The effect of stabilization and improvement of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

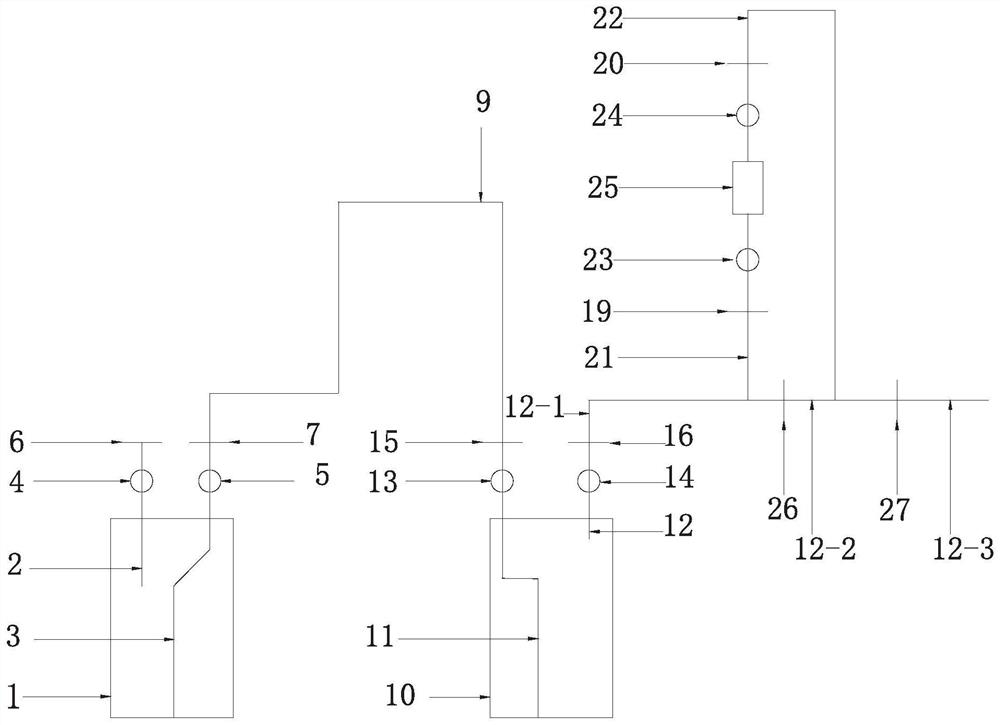

[0049] see figure 2 , a MO source device with stable vapor pressure, characterized in that it includes:

[0050] The first MO source supply unit is at least used for supplementing the MO source vapor to the second MO source supply unit with a solid MO source, so as to keep the MO source vapor pressure in the second MO source supply unit within a selected range ;

[0051] The second MO source supply unit is connected to the first MO source supply unit, and is at least used for providing the MO source vapor in the epitaxial growth device with the MO source solution;

[0052] The carrier gas buffer unit is connected to the second MO source supply unit, and is at least used to separate the solvent carried in the carrier gas output from the second MO source supply unit from the carrier gas, and to keep the solvent trapped in the carrier gas. in the carrier gas buffer unit;

[0053] a control unit, connected to the first MO source supply unit, the second MO source supply unit, a...

Embodiment 2

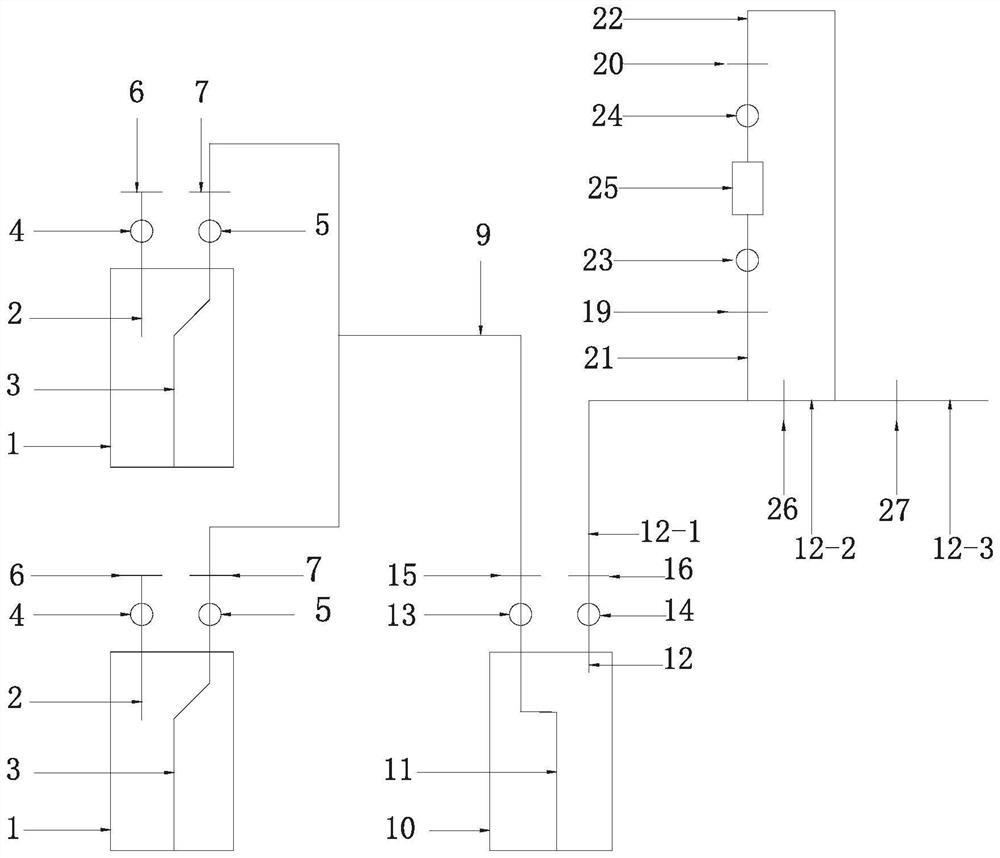

[0084] The structure of the MO source device with stable vapor pressure provided in this embodiment is basically the same as the structure of the MO source device with stable vapor pressure in Example 1, except that: image 3 As shown, the first MO source supply unit in the MO source device with stable vapor pressure in this embodiment includes two solid-state MO source accommodating mechanisms, the two solid-state MO source accommodating mechanisms have the same structure, and the two solid-state MO source accommodating mechanisms are The solid-state MO source accommodating mechanism is independently communicated with the second air inlet pipe 11 through the first air outlet pipe 3, so that when each solid-state MO source accommodating mechanism is replaced, the other solid-state MO source accommodating mechanism can work normally, and the solid-state MO source accommodating mechanism can work normally. The situation occurs when the epitaxial growth is interrupted due to repla...

Embodiment 3

[0089] The structure of the MO source device with stable vapor pressure provided in this embodiment is basically the same as the structure of the MO source device with stable vapor pressure in Embodiment 2, except that: Figure 4 As shown, the carrier gas buffer unit in the MO source device with stable vapor pressure in this embodiment includes two carrier gas buffer mechanisms, two sets of third gas inlet pipes 21 and third gas outlet pipes of the two carrier gas buffer mechanisms 22 are independently communicated with the second air outlet pipe 12, and the area between the third air inlet pipe 21, the third air outlet pipe 22 and the second air outlet pipe 12 is also provided with a seventh control valve 26. Solvent is still detected in the carrier gas processed by the first carrier gas buffer mechanism, and the corresponding control valve can be controlled to open the carrier gas to continue to pass through the next stage carrier gas buffer mechanism until the solvent in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com