A high-efficiency and energy-saving kiln tube-type vaporization equipment and its control method

A high-efficiency energy-saving and control method technology, applied in the combustion method, liquid fuel supply/distribution, combustion type, etc., can solve the problems of high safety accident rate, unstable heat transfer oil quality, unstable gas supply pressure, etc., to achieve energy saving Good effect, good vaporization effect, stable pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

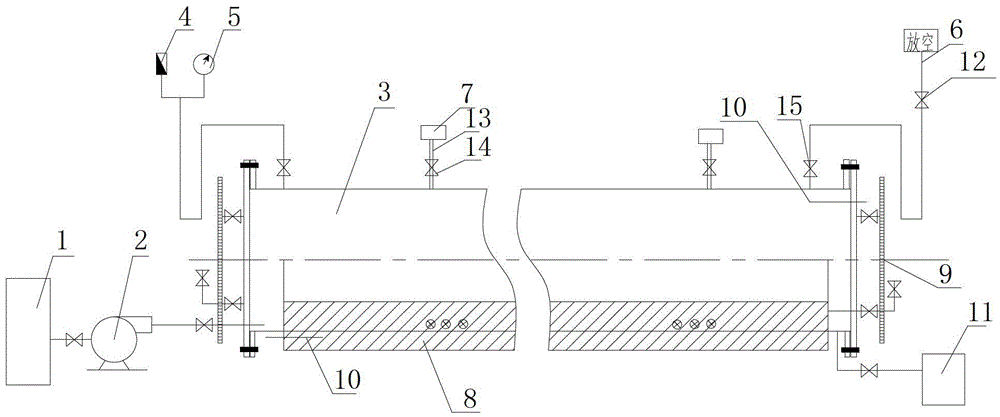

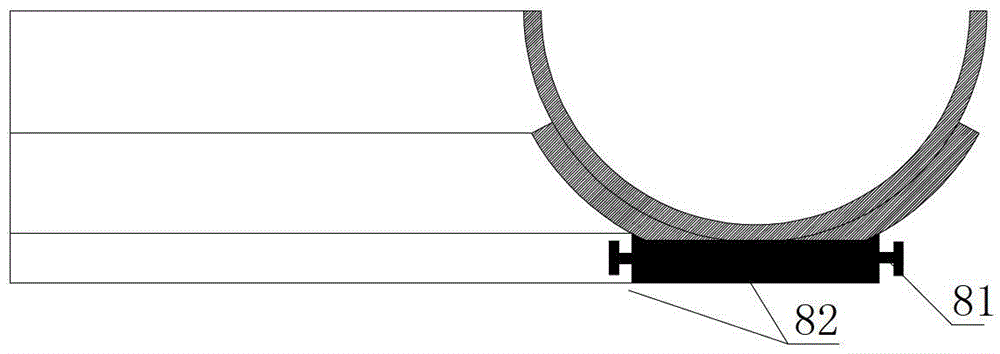

[0043] The high-efficiency energy-saving kiln tubular vaporization equipment of this embodiment has a structure such as figure 1 As shown, the liquid storage tank 1 is included, and the liquid storage tank 1 is connected with a group of series or parallel vaporization pipes 3 through a liquid feeding pipe provided with a high-pressure liquid feeding pump 2. The upper part of the vaporization pipe 3 is provided with a vaporization chamber, and the lower part is provided with a vaporization chamber. Liquid chamber; the upper part of the vaporization pipe 3 is connected with a pressure sensor 4, an electric contact vacuum pressure gauge 5, an overpressure vent pipe 6 and a set of burners 7, and the lower part is provided with an electric heating base 8 that fits with the bottom; the vaporization pipe 3 The two ends are closed, and the two ends are respectively equipped with a liquid level gauge 9 connected with the vaporization pipe 3 (the liquid level gauge 9 has a liquid level s...

Embodiment 2

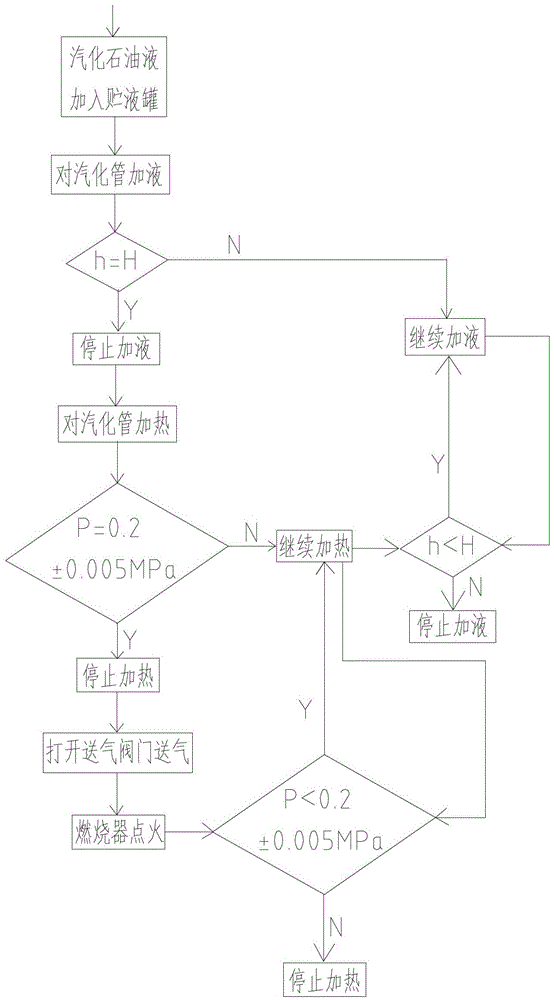

[0054] The high-efficiency energy-saving kiln tubular vaporization equipment of this embodiment differs from the first embodiment in that the vaporization pipe 3 has a diameter of 300 cm and a length of 1250 cm, which is applied to a calcining kiln, and the corresponding electric heating base 8 has the same size , during work, the purchased raw materials are first added with additives according to the physical and chemical properties of the vaporized petroleum liquid to prepare vaporized petroleum liquid, and the vaporized petroleum liquid is added to the liquid storage tank 1, and the vaporized petroleum liquid in the vaporization pipe 3 is set by programming the digital display instrument. Add liquid level H, check whether the indicator lights are normal. After everything is normal, the control unit of the automatic control cabinet starts the high-pressure liquid pump 2, and adds the vaporized petroleum liquid in the liquid storage tank 1 to the vaporization pipe 3 at normal t...

Embodiment 3

[0056]The difference between this embodiment and the first embodiment is that the vaporization pipe 3 has a diameter of 200 cm and a length of 1000 cm, which is used in an annealing furnace, and the corresponding electric heating base 8 has the same size, and is used in a boiler or an aluminum melting furnace. When working, add additives to the purchased raw materials according to the physical and chemical properties of the vaporized petroleum liquid to prepare vaporized petroleum liquid, and add the vaporized petroleum liquid to the liquid storage tank 1, and set the liquid addition of the vaporized petroleum liquid in the vaporization pipe 3 by programming the digital display instrument Liquid level H, check whether the indicator lights are normal. After everything is normal, the control unit of the automatic control cabinet starts the high-pressure liquid filling pump 2, and adds the vaporized petroleum liquid in the liquid storage tank 1 to the vaporization pipe 3 at normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com