Single way jet gas reflux type burner

A technology of injectors and burners, applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of high CO and NOx content, incomplete combustion, unstable combustion, etc., and achieve low CO and NOx content, vaporization heating speed Balanced, volume-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

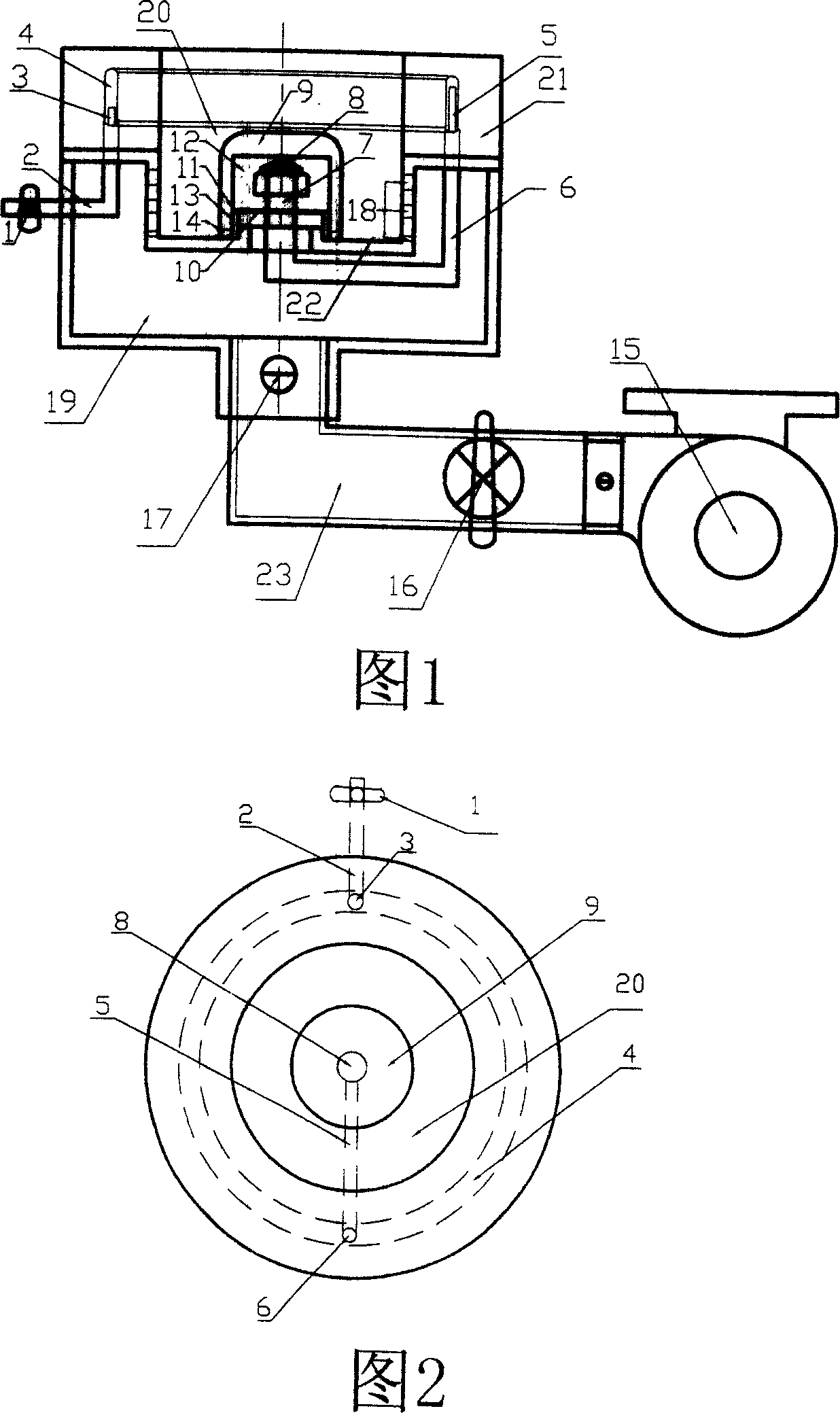

[0019] See Figure 1 and Figure 2: A one-way injection gas return burner, which includes a gas supply system, a fuel supply system and a high-temperature heating vaporization system, and its fuel supply system includes a fuel control valve 1, a fuel delivery pipe 2 and a single A pilot injector 3, the liquid inlet end of the control valve 1 is connected to the liquid fuel tank, and the liquid outlet is connected to the fuel conveyor 2, and a one-way pilot injector 3 is arranged on the end of the fuel conveyor 2;

[0020] The high-temperature heating vaporization system consists of two parts: the hollow-core annular waste heat pre-vaporizer device and the high-temperature vaporizer device:

[0021] The structure of the hollow annular waste heat pre-evaporator device is as follows: the one-way flow injector 3 is directly sealed and installed in the cavity from the corresponding position on the bottom periphery of the hollow annular waste heat pre-evaporator 4, and the hollow annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com