Double-high burner

A burner and auxiliary combustion technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of low average furnace temperature, high flue gas temperature, large furnace temperature difference, etc., and achieve a balanced vaporization heating rate, smoke The effect of low gas temperature and small furnace temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

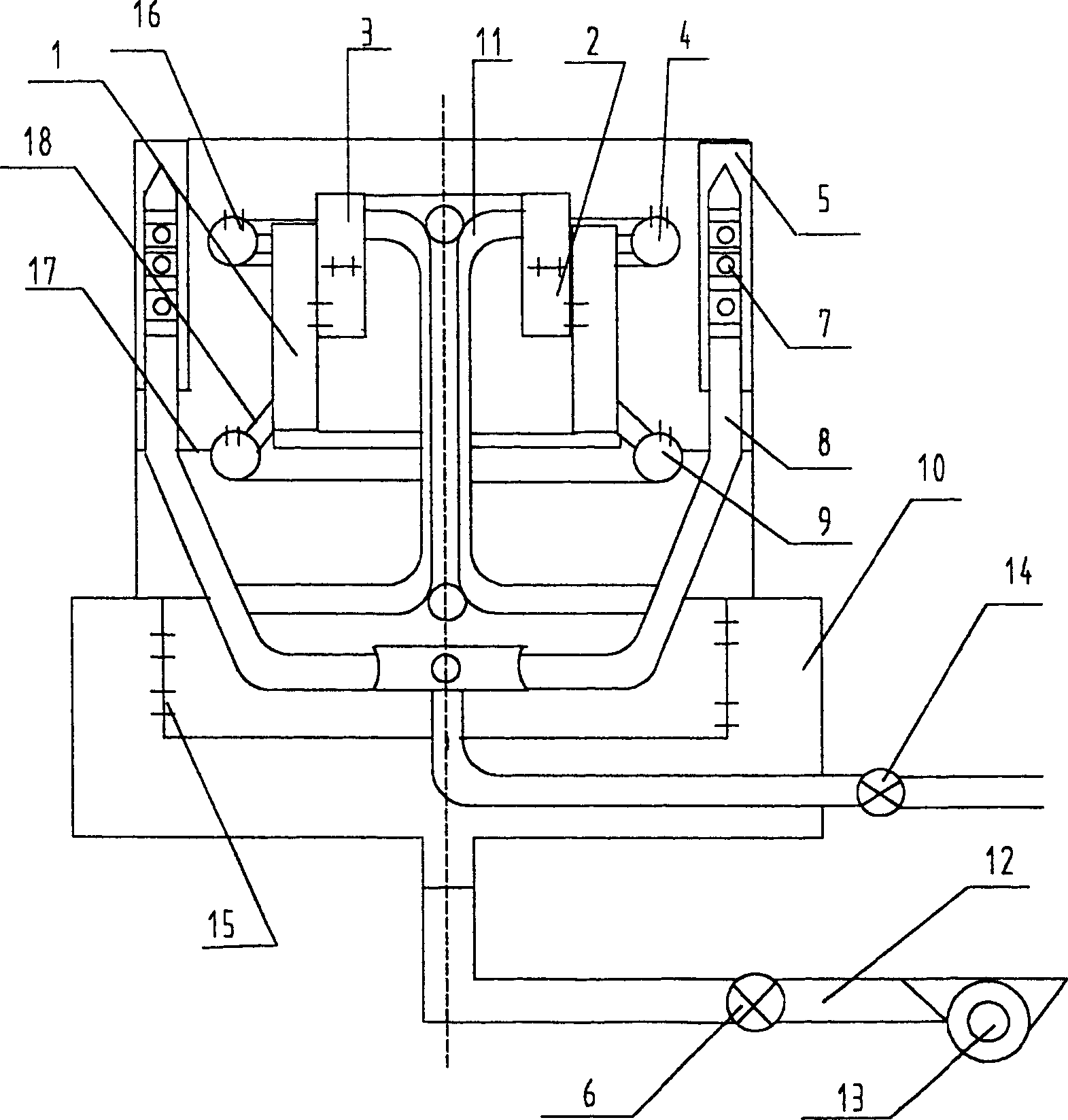

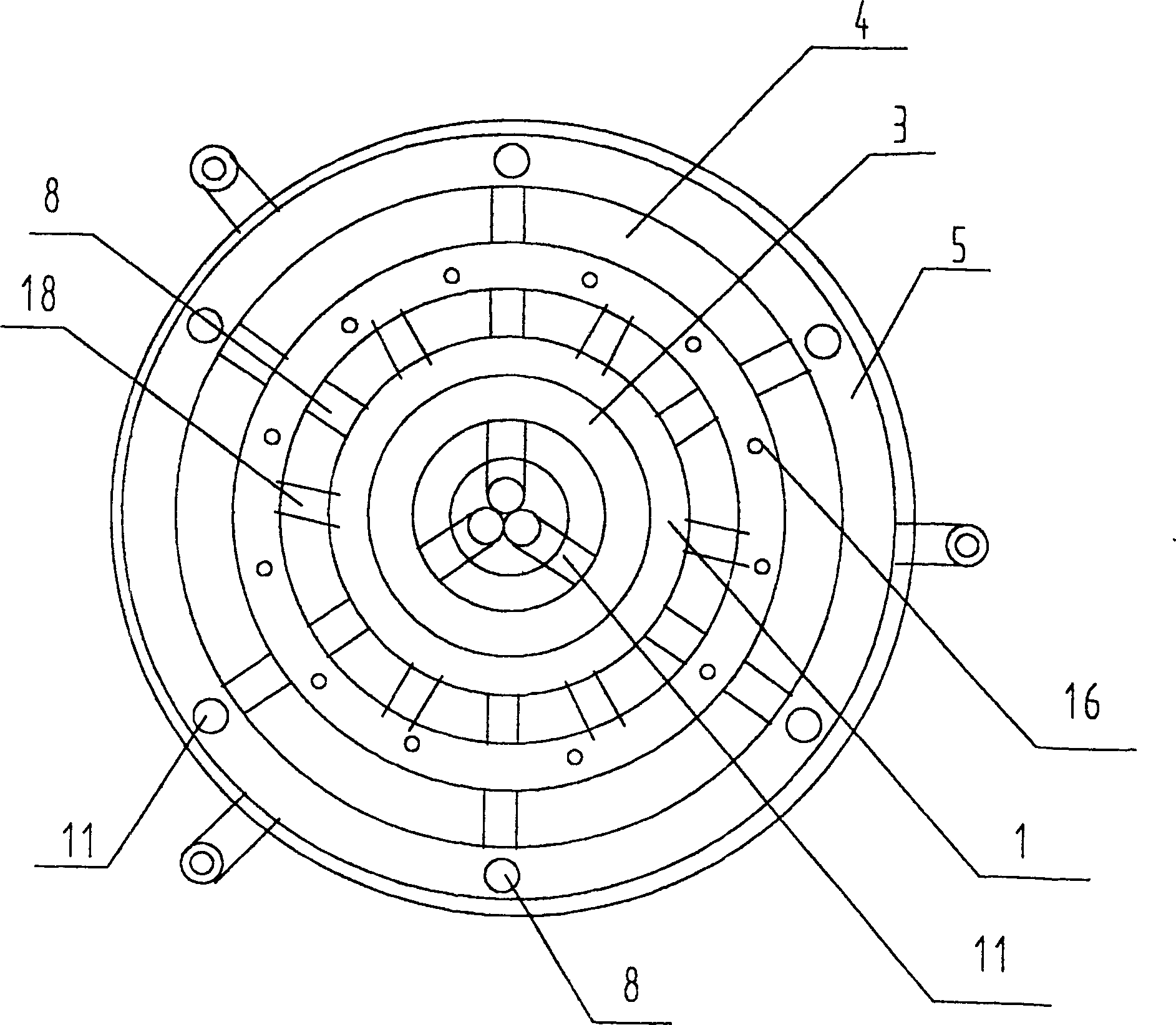

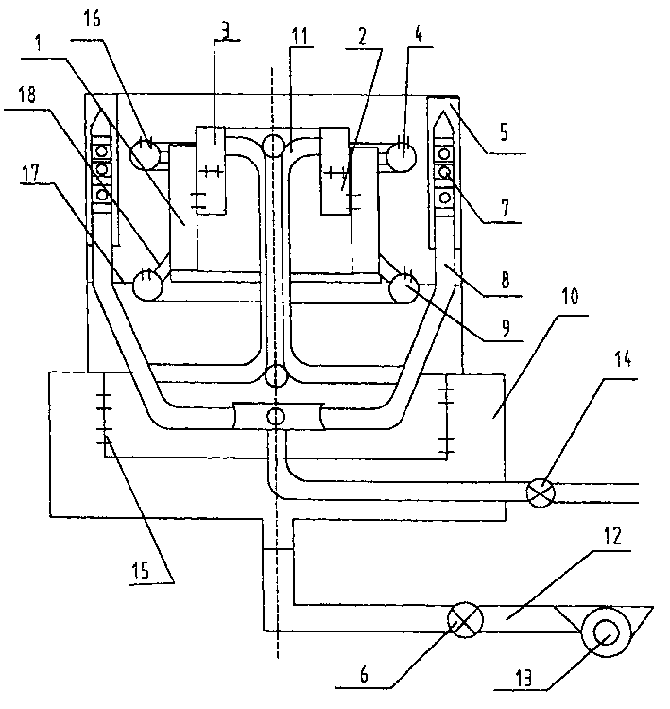

[0013] Such as figure 1 , figure 2 As shown, the double-height burner of the present invention includes three parts: an air supply part, a fuel supply part and a vaporization heating combustion part.

[0014] The structure of the fuel supply part wherein is as follows: the end portion of the claw-shaped fuel delivery pipe 8 that opens upward is provided with the aperture 7 that sprays around, and purpose is to make the liquid or gaseous fuel that enters preheating vaporization chamber 5 evenly distribute. The end periphery of the fuel delivery pipe 8 is sealed with a preheating vaporization chamber 5, and the other end of the fuel delivery pipe 8 is combined and then connected to the fuel tank through a control switch 14; Angle is 120 ° of tube bundles, such a structure can make the fuel evenly enter the preheating vaporization chamber 5;

[0015] The structure of the vaporization heating and combustion part is as follows: the upper end of the delivery pipe 11 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com