Piston cylinder sleeve

A piston cylinder liner and piston technology, which is applied to cylinders, cylinder heads, engine components, etc., can solve the problems of uneven distribution of lubricating oil, reduced service life of pistons and piston liners, dry friction between pistons and cylinder liners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

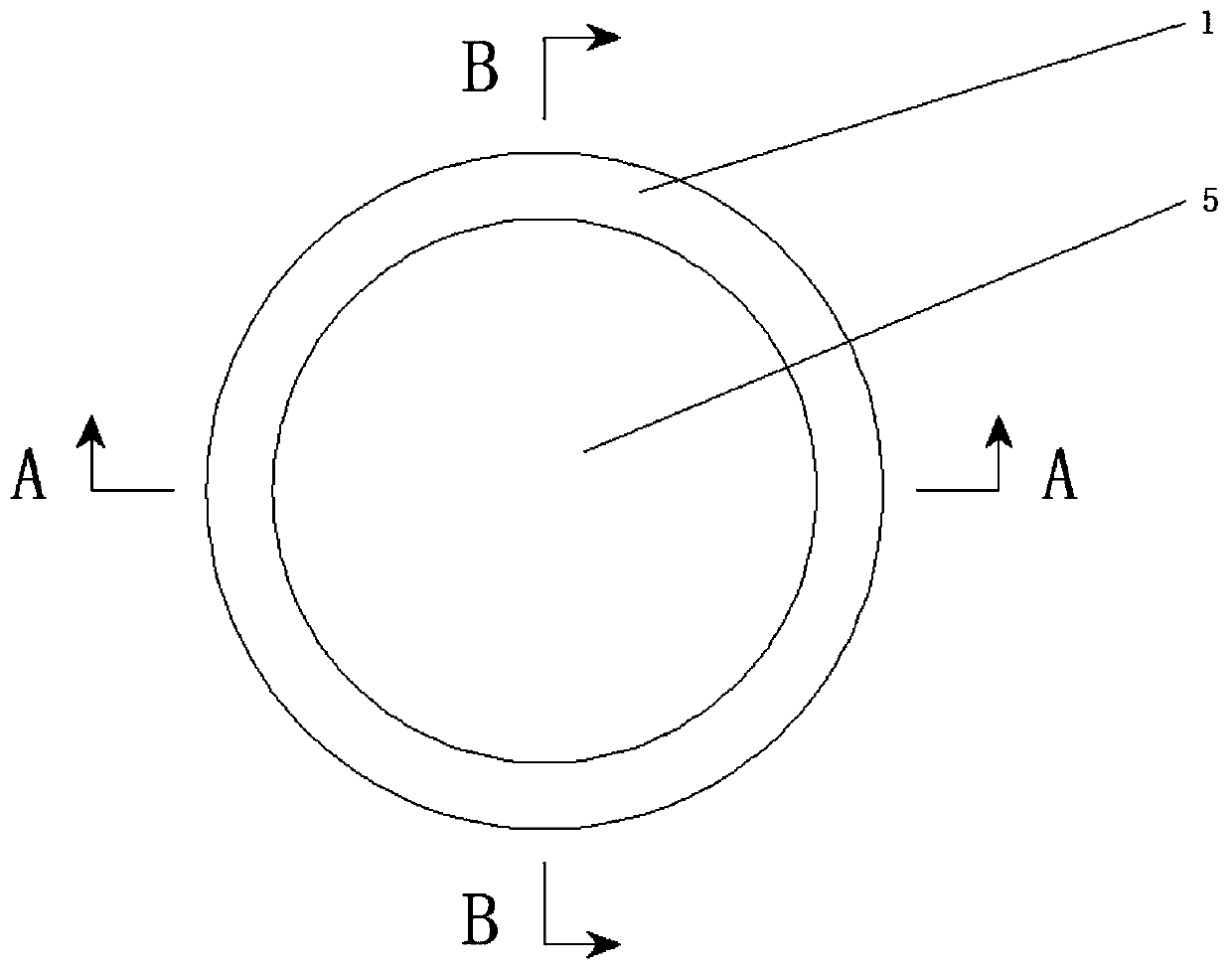

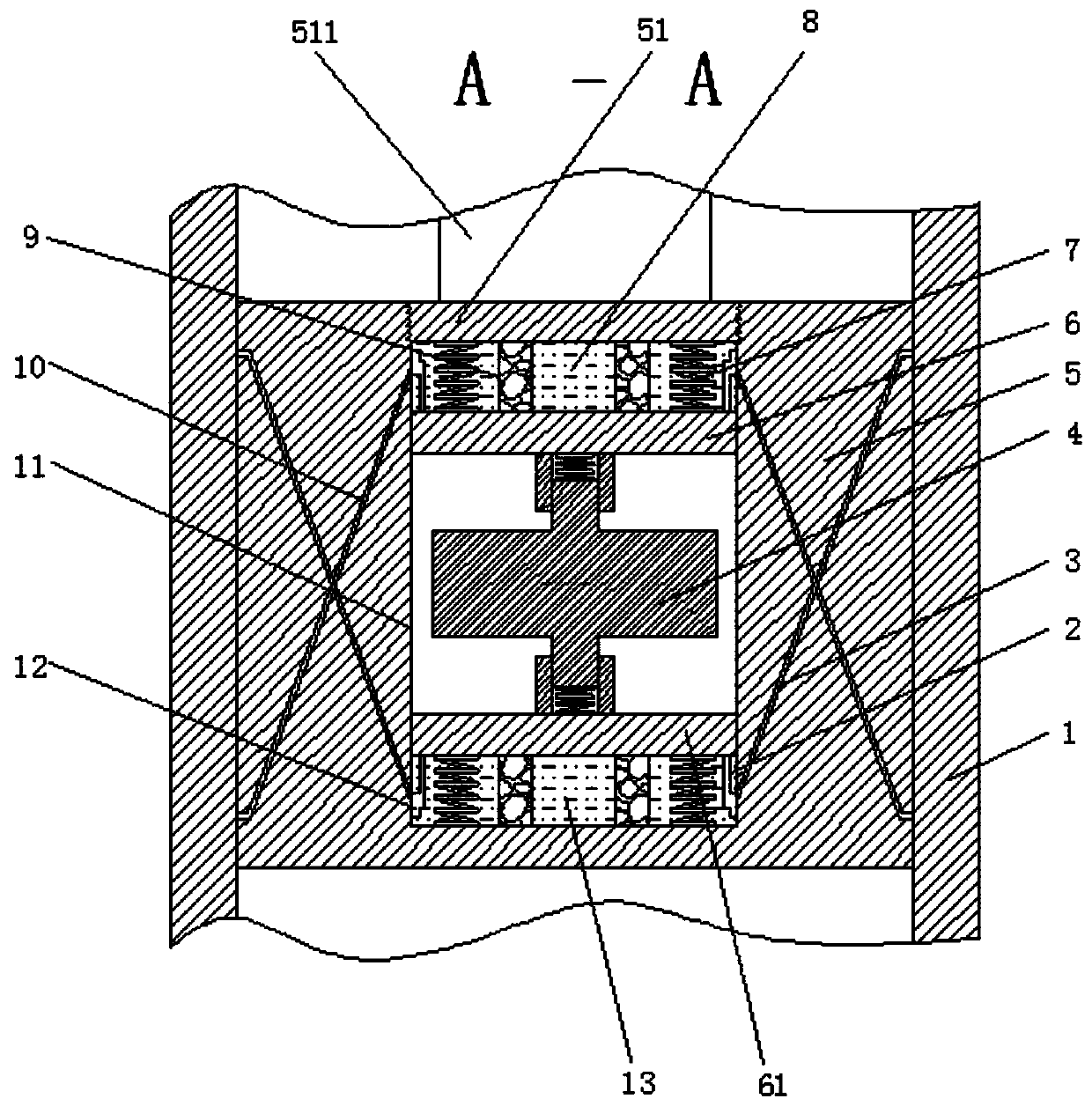

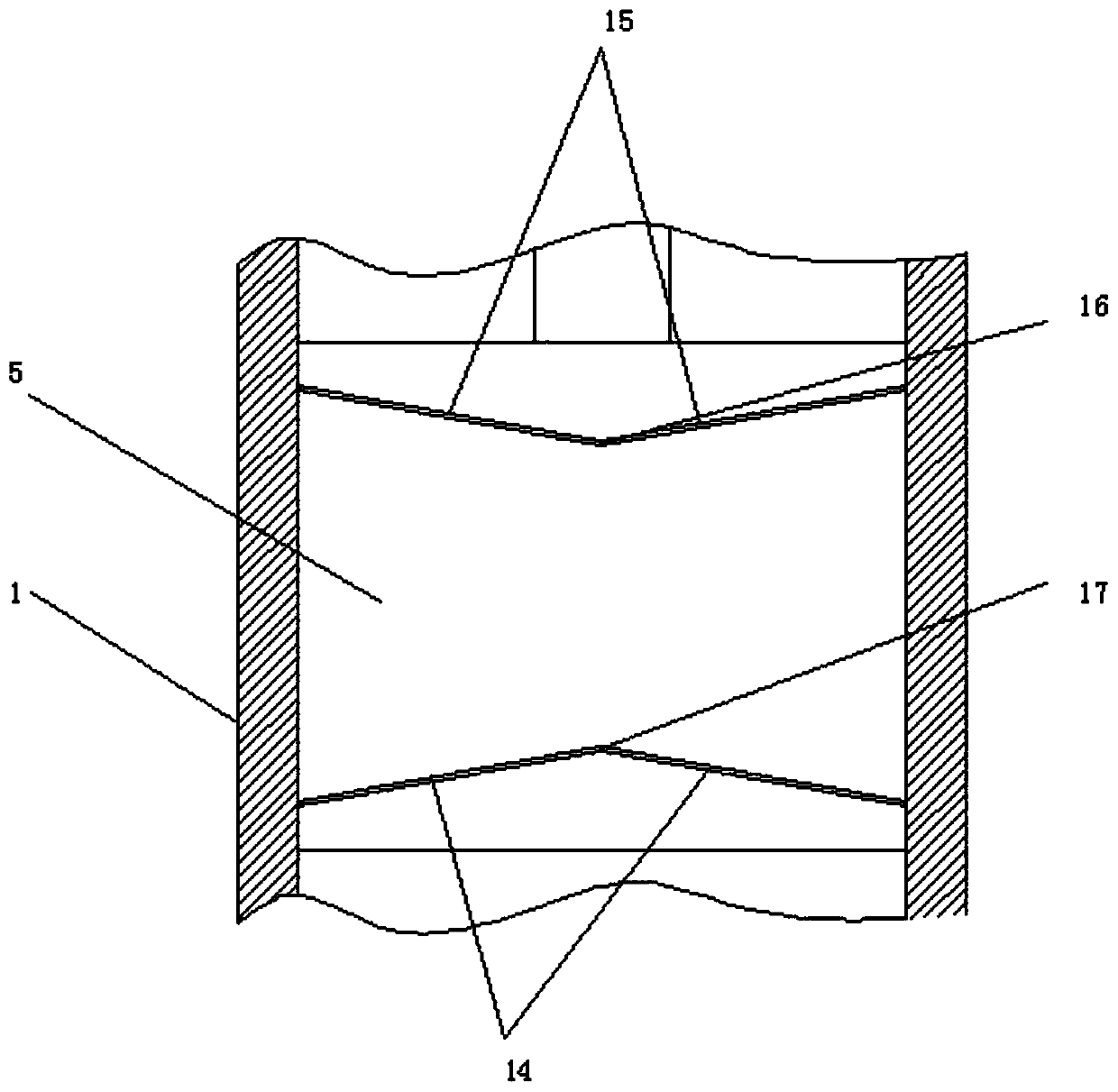

[0033] Such as Figure 1-10 A piston cylinder liner shown includes a cylinder liner 1, and also includes a piston 5 slidably arranged inside the cylinder liner 1. The outer walls of both sides of the top of the piston 5 are provided with positive eight-shaped oil delivery grooves 15, and the two The two ends of a positive figure-of-sight oil delivery groove 15 communicate with each other, the outer sidewalls of both sides of the bottom of the piston 5 are provided with an inverted figure-of-sight oil delivery groove 14, and the two ends of the two inverted figure-of-sight oil delivery grooves 14 Connected to each other, the middle position inside the piston 5 is provided with a sealing chamber 11, and the inner two ends of the sealing chamber 11 are respectively slidingly provided with a sealing piston plate 6 and a sealing piston plate 2 61, and a sealing piston plate 6 and a sealing piston plate 2 61 A piston chamber 1 8 and a piston chamber 2 13 are respectively arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com