Method for catalytically synthesizing diisooctyl dodecanedioate base oil by solid superacid

A technology of diisooctyl dodecanedioate and solid super acid, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

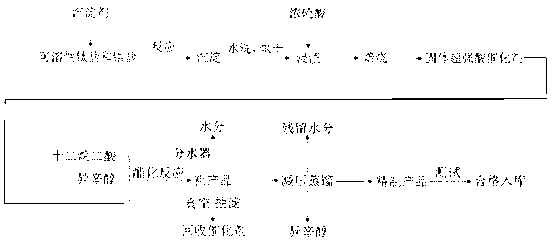

[0018] like figure 1 Show a kind of embodiment of the present invention with solid superacid catalyzed synthesis of di-isooctyl dodecanedioate base oil, comprising the following steps:

[0019] A. Preparation of solid superacid SO by precipitation and impregnation method 4 2- / ZrO 2 -TiO 2 Catalyst: Mix soluble titanium salt and soluble zirconium salt according to the molar ratio (1-10): 1, add the precipitant dropwise until the pH of the mixture reaches 5-14, wash the precipitate with water to neutral, dry and grind into powder, immersed in sulfuric acid or sulfate solution for 0.5-24 h, filtered and dried, and then calcined at 50-700 °C for 0.5-24 h, and finally the solid superacid SO 4 2- / ZrO 2 -TiO 2 catalyst;

[0020] B. Synthesis of base oil: using solid super acid SO 4 2- / ZrO 2 -TiO 2 As a catalyst, mix dodecanedioic acid and isooctyl alcohol in a molar ratio of 1: (1-10), catalyze the reaction at 50-200 °C for 0.5-16 h, vacuum filter out the catalyst, an...

Embodiment 1

[0022] Example 1: Add 4.7837g 99% zirconium oxychloride and 16.2353 g 98% titanium tetrachloride in a 500ml three-necked flask, shake until completely dissolved, add 25% ammonia water dropwise until the pH reaches 8-10, and obtain white Precipitate, wash the precipitate with water until neutral, dry and grind into powder, and then in 0.5 mol / L H 2 SO 4 The solid superacid SO 4 2- / ZrO 2 -TiO 2 Catalyst, seal the catalyst and place it in a desiccator for later use. Add 108.9753 g of 99% dodecanedioic acid, 199.3317 g of 98% isooctyl alcohol and 1.65 g of solid superacid catalyst to a 500 ml three-necked flask in turn, add 26.5 ml of distilled water to the water separator, and react the reaction solution at 140 °C After 7 hours, the catalyst was vacuum filtered after cooling, and the filtrate was the crude product; after the crude product was distilled under reduced pressure at 30-300 °C, a high-purity di-isooctyl dodecanedioate product was obtained. After testing, the puri...

Embodiment 2

[0023] Example 2: Add 4.8627g 99% zirconium oxychloride and 30.3318 g 98% butyl titanate to a 500ml three-neck flask, shake until completely dissolved, add 28% ammonia water dropwise until the pH reaches 8-10, and obtain white Precipitate, wash the precipitate with water to neutral, dry and grind into powder, and then in 0.4 mol / L H 2 SO 4 Immersed in the solution for 6 h, dried by suction filtration, and roasted in a muffle furnace at 550 °C for 4 h to obtain the solid superacid SO 4 2- / ZrO 2 -TiO 2 Catalyst, seal the catalyst and place it in a desiccator for later use. Add 116.3132 g of 99% dodecanedioic acid, 205.5325 g of 98% isooctyl alcohol and 2 g of solid superacid catalyst to a 500 ml three-neck flask in turn, add 26.5 ml of distilled water to the water separator, and react the reaction solution at 170 °C After 5 hours, the catalyst was vacuum filtered after cooling, and the filtrate was the crude product; after the crude product was distilled under reduced pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com