Material composites made of a moulded part made of transparent or translucent, dyeable plastic thermoplastic moulding compositions

A composite, molded product technology for layered products, thin material handling, transportation and packaging, which solves problems such as lens cleaning cycles that are not specified in detail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2、3 and 5

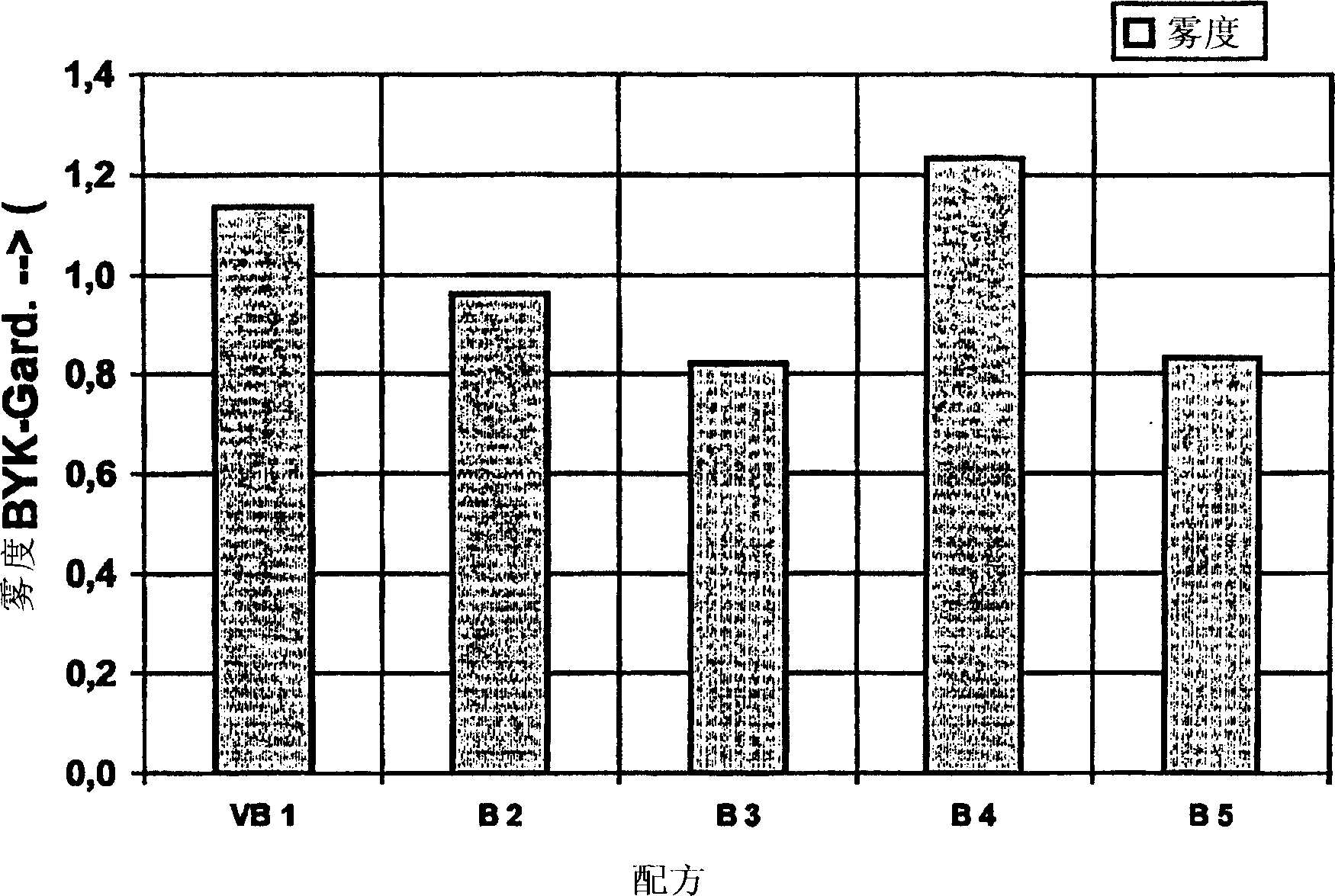

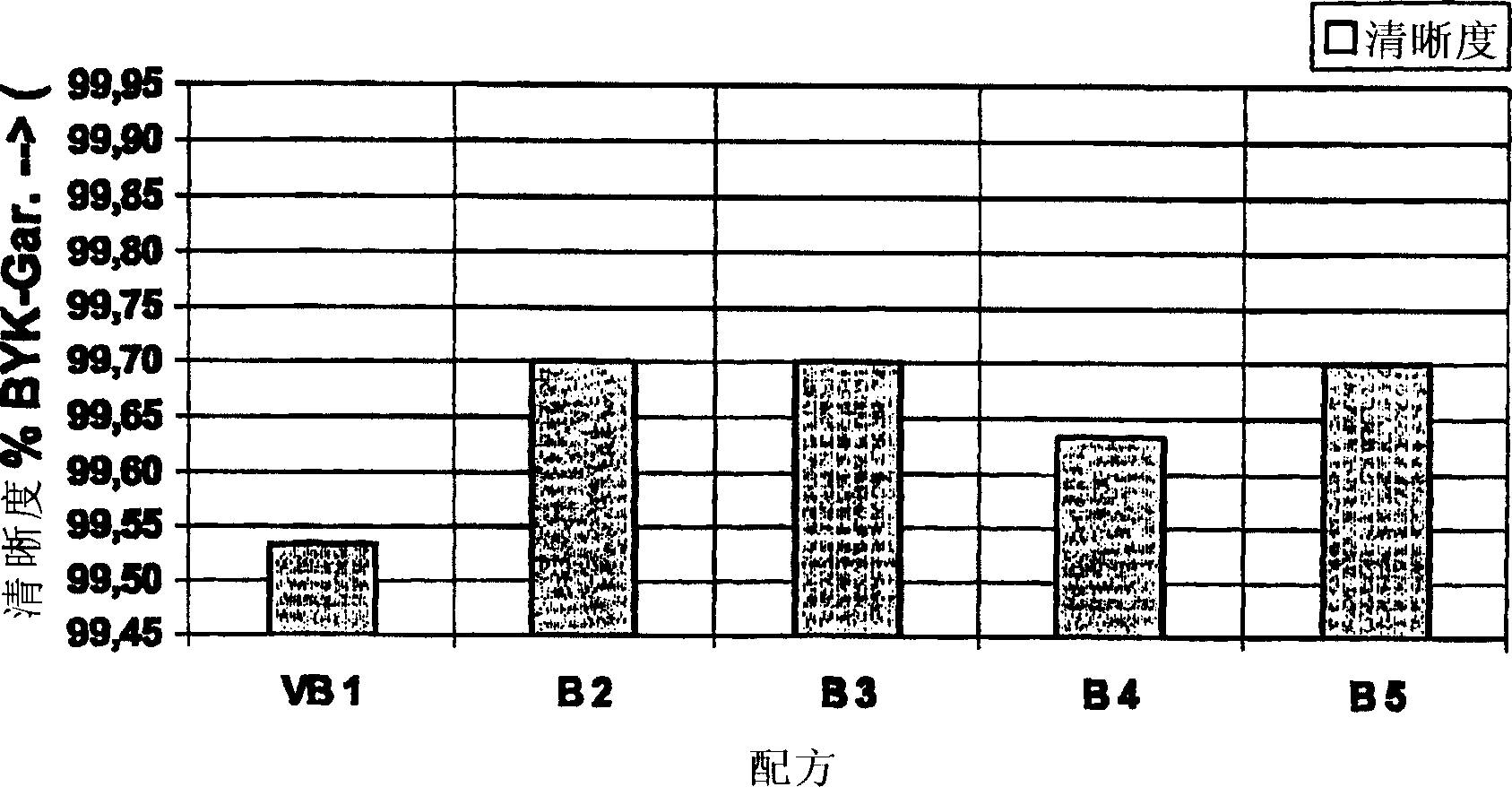

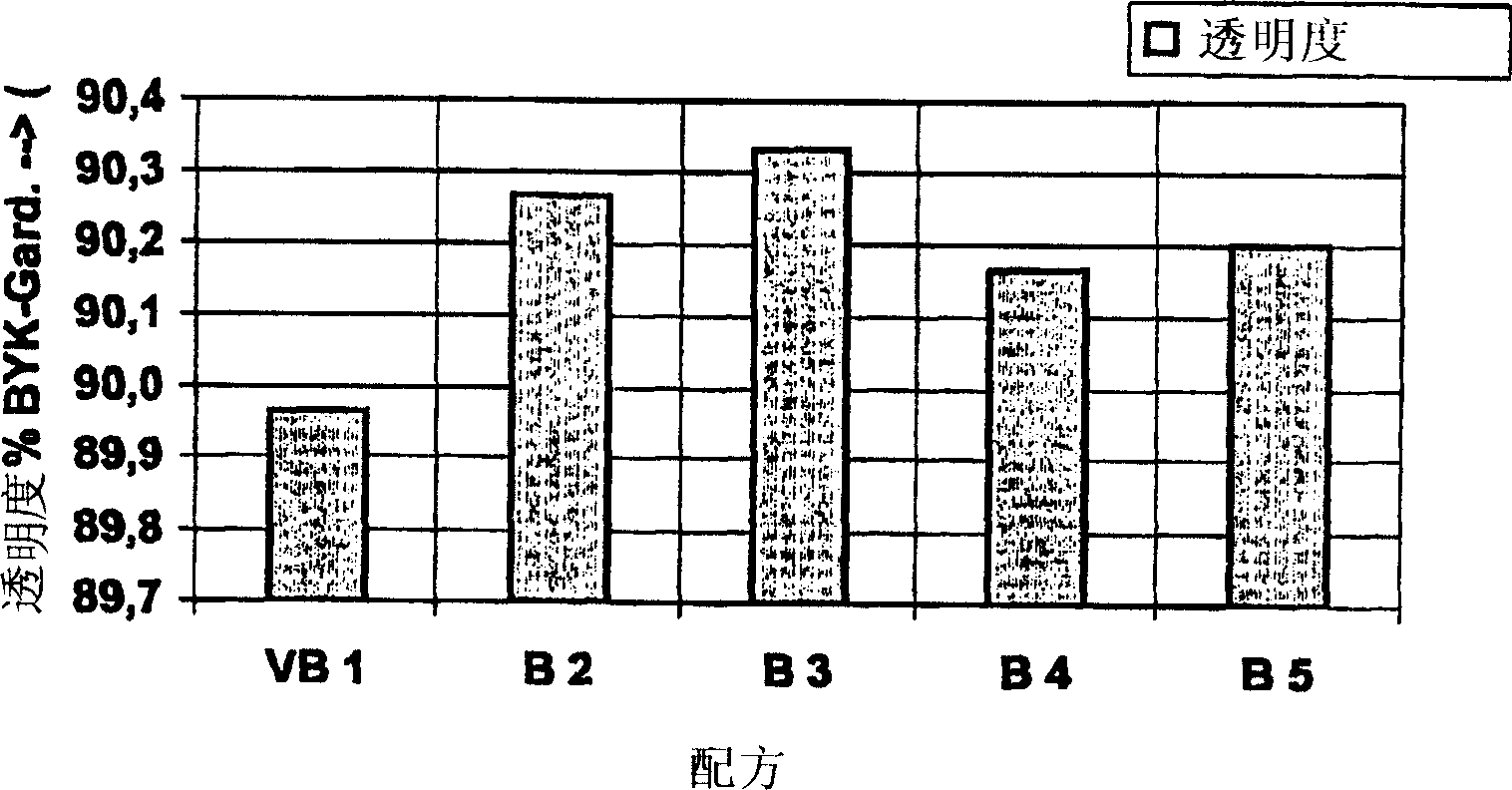

[0247] Examples 2, 3 and 5 (according to the invention); Comparative Example 4

[0248] Several lubricants were added to the particle mixture of Example 1, which was subsequently extruded, pelletized, dried to a moisture content below 0.06% and processed in the same manner into test lenses. In Examples 2-5, the UV protection up to 400 nm is 99.8%.

Embodiment 2

[0249] Example 2: +0.05% paraffin oil (HTNP) (liquid)

Embodiment 3

[0250] Example 3: +0.10% paraffin oil (HTNP) (liquid)

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com