Polyester resin for engineering machinery

A technology of polyester resin and construction machinery, applied in the field of polyester resin, can solve the problem that the resin does not have thick coating and is not suitable, and achieve the effect of unchanged performance, excellent mechanical properties and flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

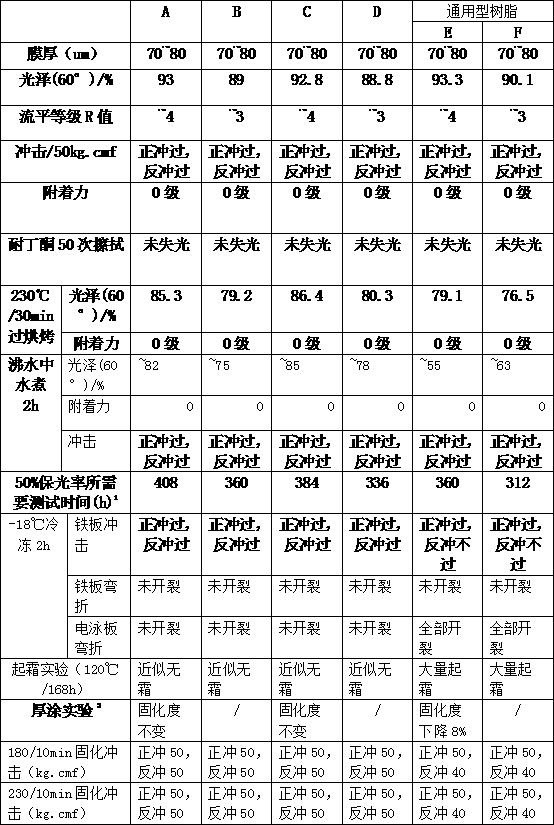

[0017] A~D in Table 1 are the primary properties of the embodiments of the present invention and their corresponding polyester resins.

[0018] Preparation method: In a 5-liter glass reactor, put the polyols, branching agents, aromatic acids and appropriate amount of catalysts in the formulas of each example in Table 1 into the reactor at the same time, and slowly heat up to 235-255 C in a nitrogen atmosphere. After the system is clarified, take a sample to detect the acid value (AV) reaches 5-15 (unit: mgKOH / g resin, the same below), add secondary acidolysis agents such as IPA, ADA, CHDA and FCC, and maintain the temperature at 235-250 Acid decapping was carried out at ℃. After the acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com