Low-temperature curing type epoxy group acrylic acid transparent powder coating and preparation method thereof

A technology of epoxy-based acrylic and powder coatings, applied in powder coatings, coatings, etc., can solve the problems of poor transparency, no introduction of weather resistance and corrosion resistance, no introduction of acrylic resin epoxy equivalent, etc., to achieve increased results Density, solution to yellowing, good anti-copper acceleration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

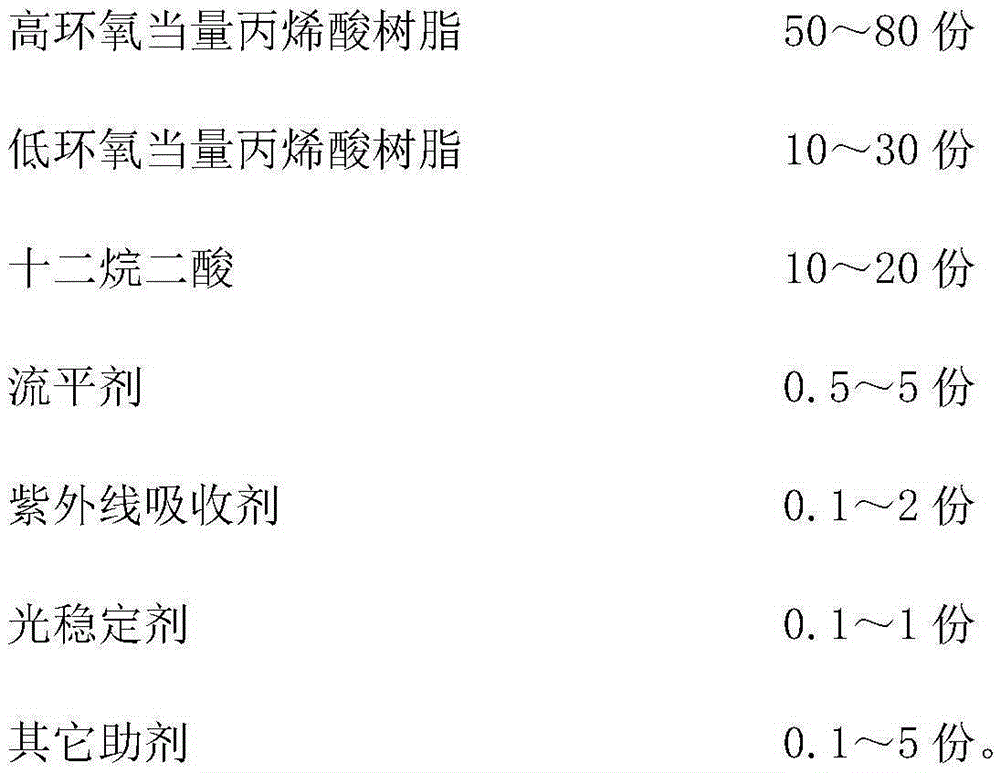

[0051] A low-temperature curing type epoxy acrylic transparent powder coating, the low temperature curing type epoxy acrylic transparent powder coating of this embodiment, its component and weight ratio are:

[0052]

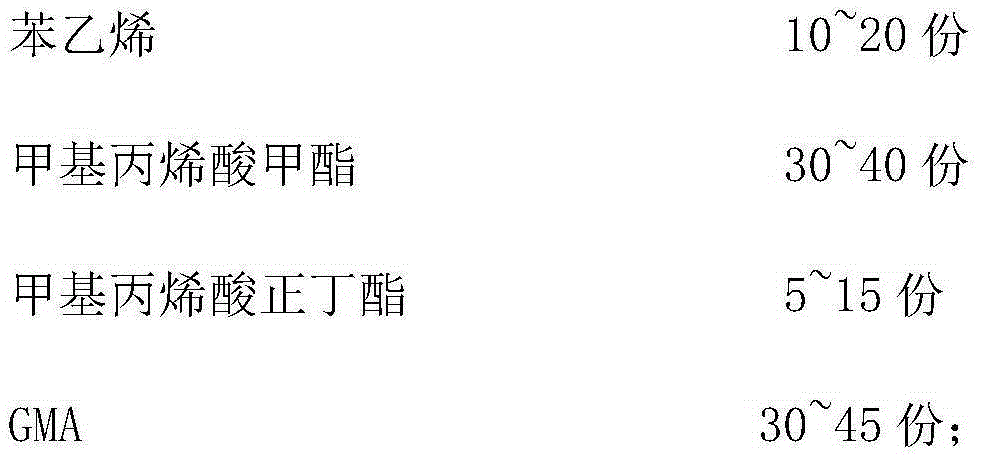

[0053] in,

[0054] The high epoxy equivalent acrylic resin modified by ultrafine titanium dioxide has an epoxy equivalent of 500 to 700 g / eq, which is obtained by modifying the high epoxy equivalent acrylic resin with ultrafine titanium dioxide modified by KH-550 silane coupling agent , the preparation method is as follows:

[0055] (1) Preparation of modified ultrafine titanium dioxide: Weigh 1 part of ultrafine titanium dioxide (particle size 100-300nm), add 20 parts of isopropanol, and use an ultrasonic instrument at room temperature for 30 minutes to obtain a uniform suspension, then add 0.02 parts The coupling agent was ultrasonicated for 3 minutes, then stirred at a constant temperature of 90°C for 3 minutes, and then centrifuged to obtain KH-550 modi...

Embodiment 2

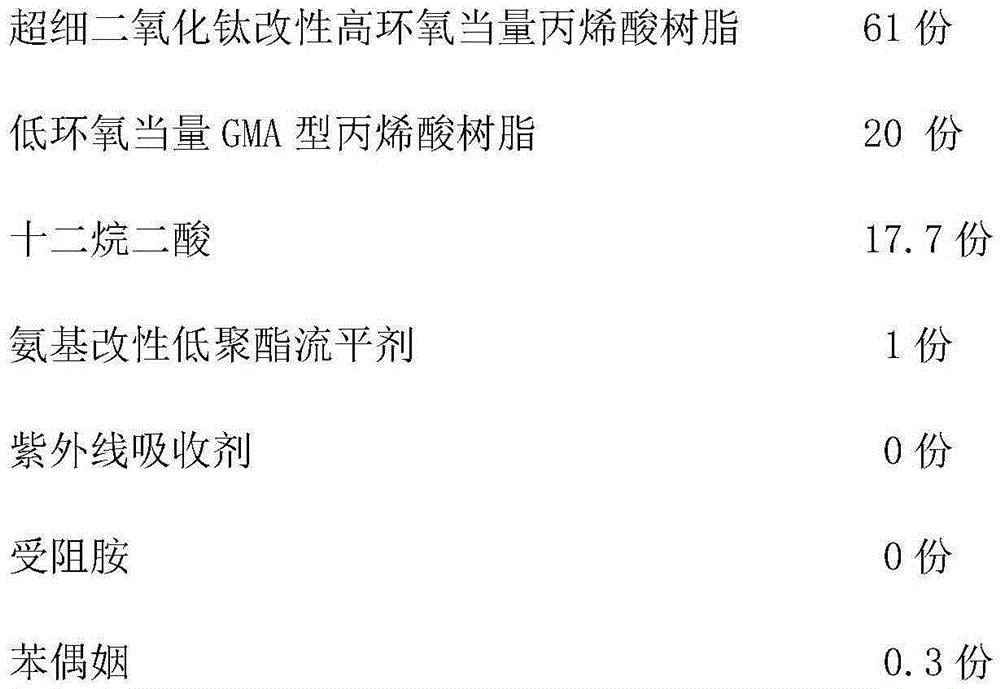

[0069] A low-temperature curing type epoxy acrylic transparent powder coating, the low temperature curing type epoxy acrylic transparent powder coating of this embodiment, its component and weight ratio are:

[0070]

[0071] in,

[0072] The high epoxy equivalent acrylic resin modified by ultrafine titanium dioxide has an epoxy equivalent of 500 to 700 g / eq, which is obtained by modifying the high epoxy equivalent acrylic resin with ultrafine titanium dioxide modified by KH-550 silane coupling agent , the preparation method is as follows:

[0073] (1) Preparation of modified ultrafine titanium dioxide: Weigh 1 part of ultrafine titanium dioxide (particle size 100-300nm), add 20 parts of isopropanol, and use an ultrasonic instrument at room temperature for 30 minutes to obtain a uniform suspension, then add 0.04 parts The coupling agent was ultrasonicated for 3 minutes, then stirred at a constant temperature of 80°C for 3 minutes, and then centrifuged to obtain KH-550 modi...

Embodiment 3

[0085] A low-temperature curing type epoxy acrylic transparent powder coating, the low temperature curing type epoxy acrylic transparent powder coating of this embodiment, its component and weight ratio are:

[0086]

[0087] in,

[0088] The high epoxy equivalent acrylic resin modified by ultrafine titanium dioxide has an epoxy equivalent of 500 to 700 g / eq, which is obtained by modifying the high epoxy equivalent acrylic resin with ultrafine titanium dioxide modified by KH-570 silane coupling agent , the preparation method is as follows:

[0089] (1) Preparation of modified ultrafine titanium dioxide: Weigh 1 part of ultrafine titanium dioxide (particle size 100-600nm), add 20 parts of isopropanol, and use an ultrasonic instrument at room temperature for 30 minutes to obtain a uniform suspension, then add 0.04 parts The coupling agent was ultrasonicated for 3 minutes, then stirred at a constant temperature of 80°C for 4 minutes, and then centrifuged to obtain KH-570 modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com