Patents

Literature

52 results about "Muconic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

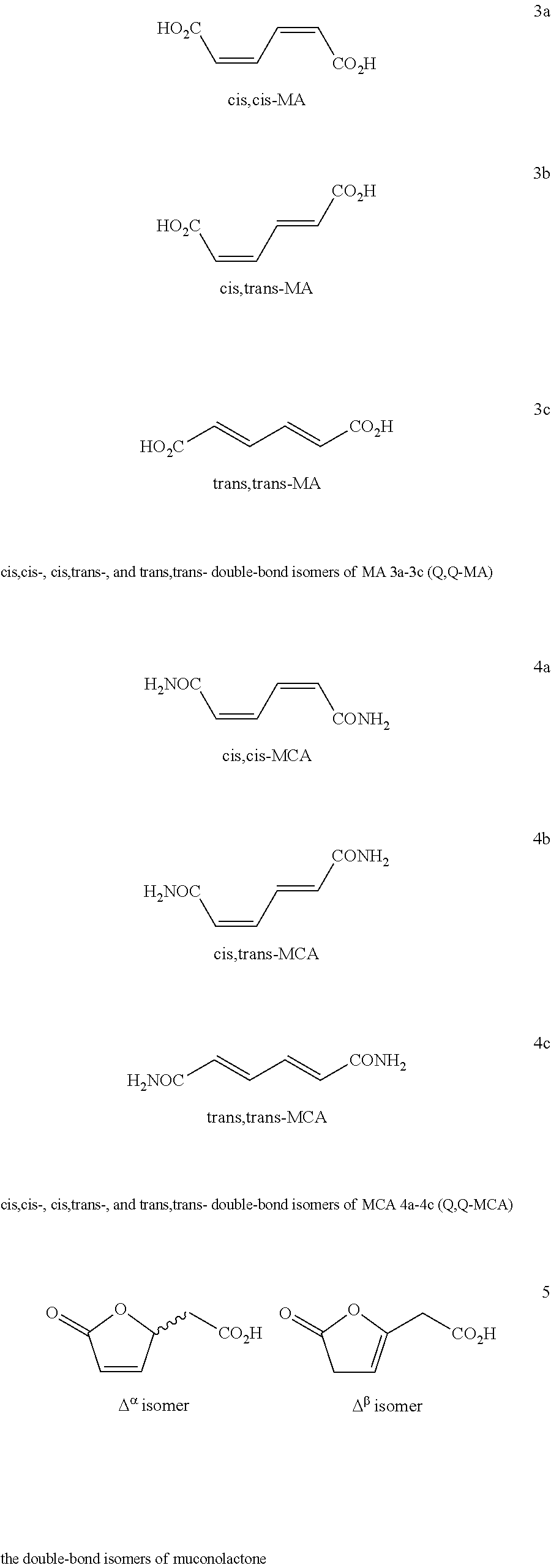

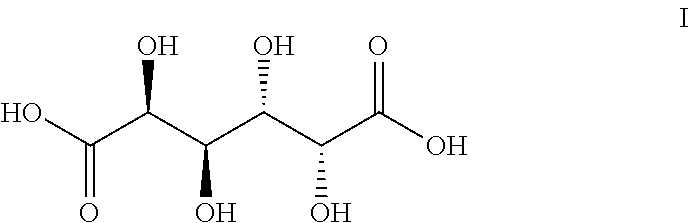

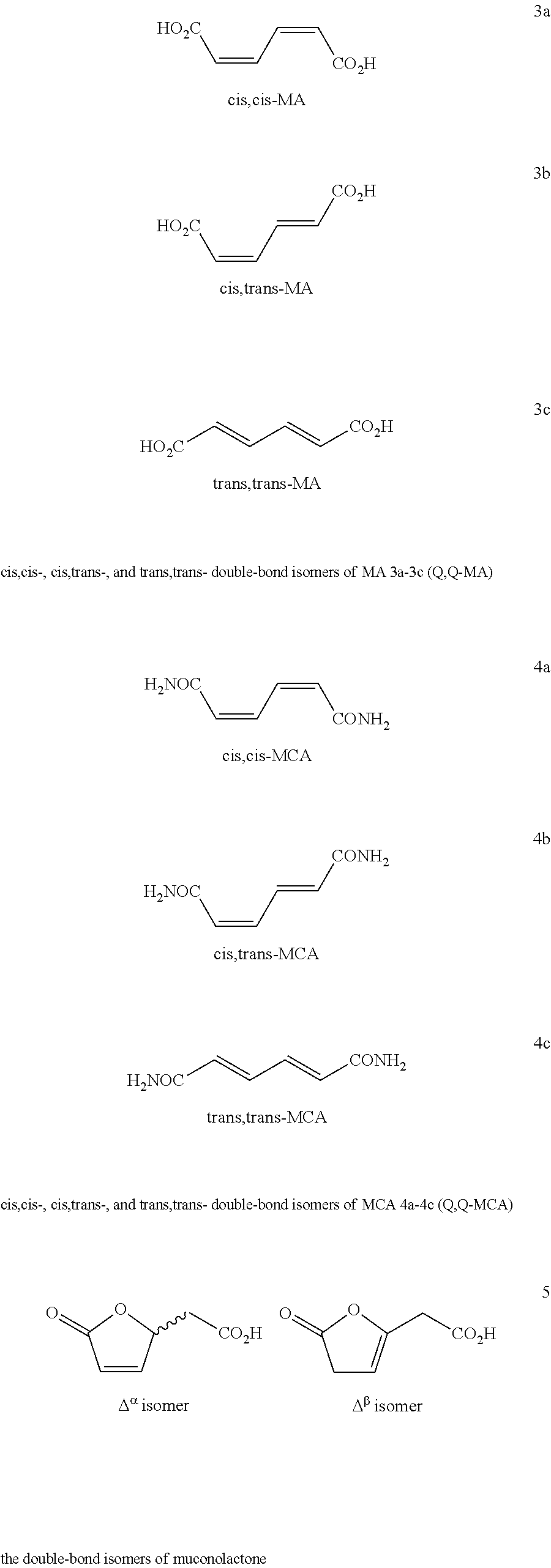

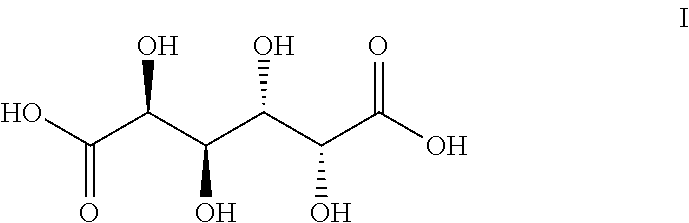

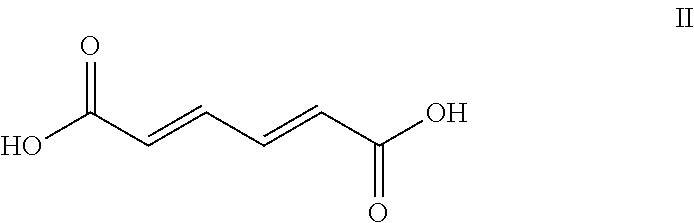

Muconic acid is a dicarboxylic acid. There are three isomeric forms designated trans,trans-muconic acid, cis,trans-muconic acid, and cis,cis-muconic acid which differ by the geometry around the double bonds.

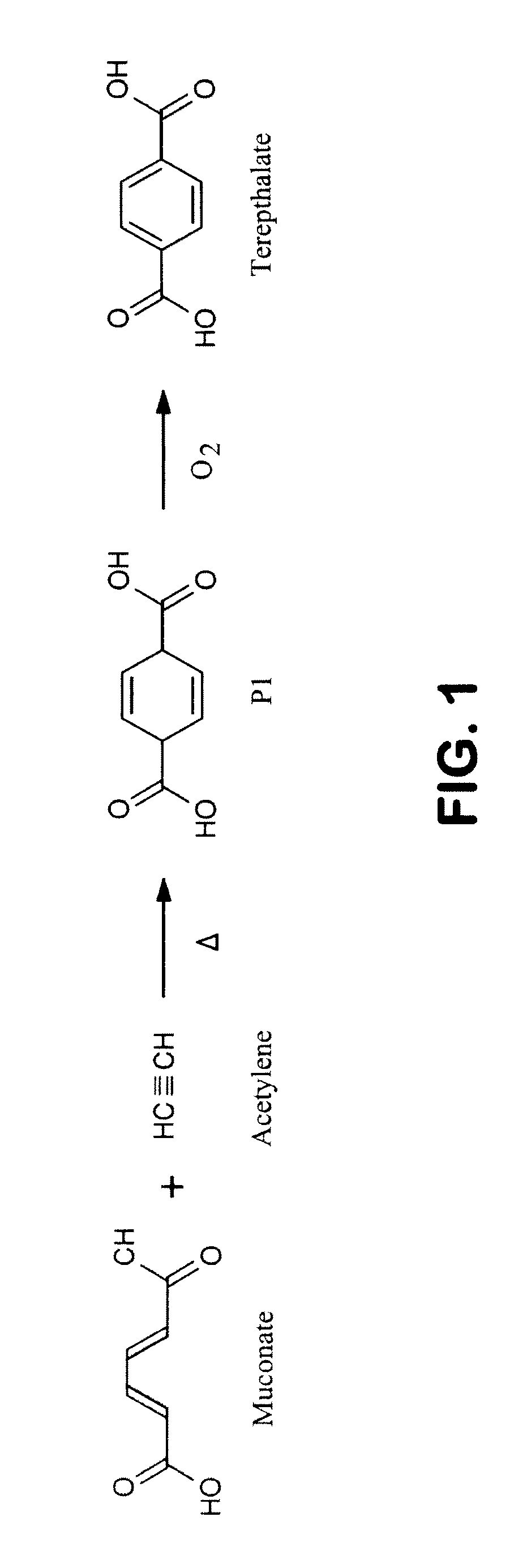

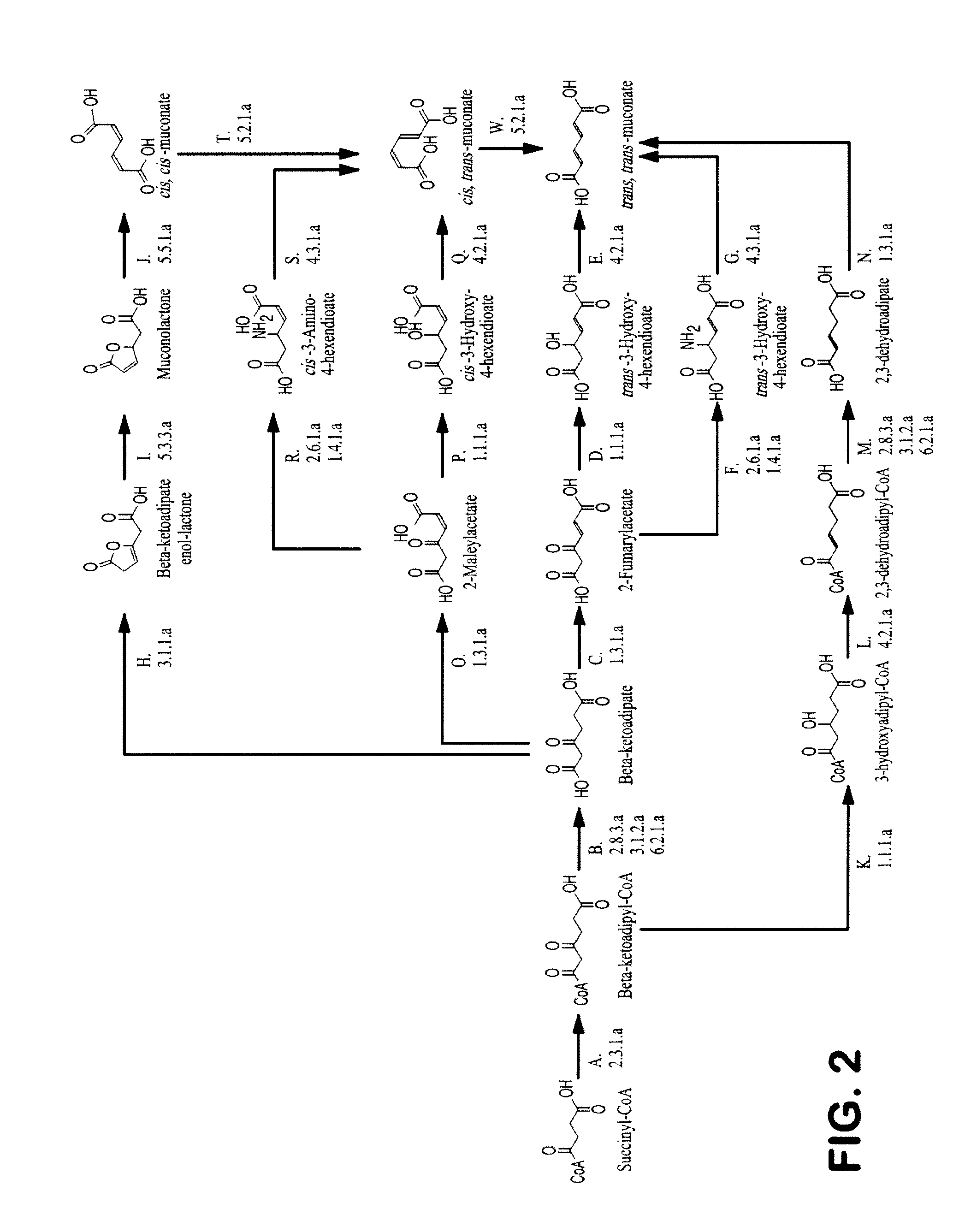

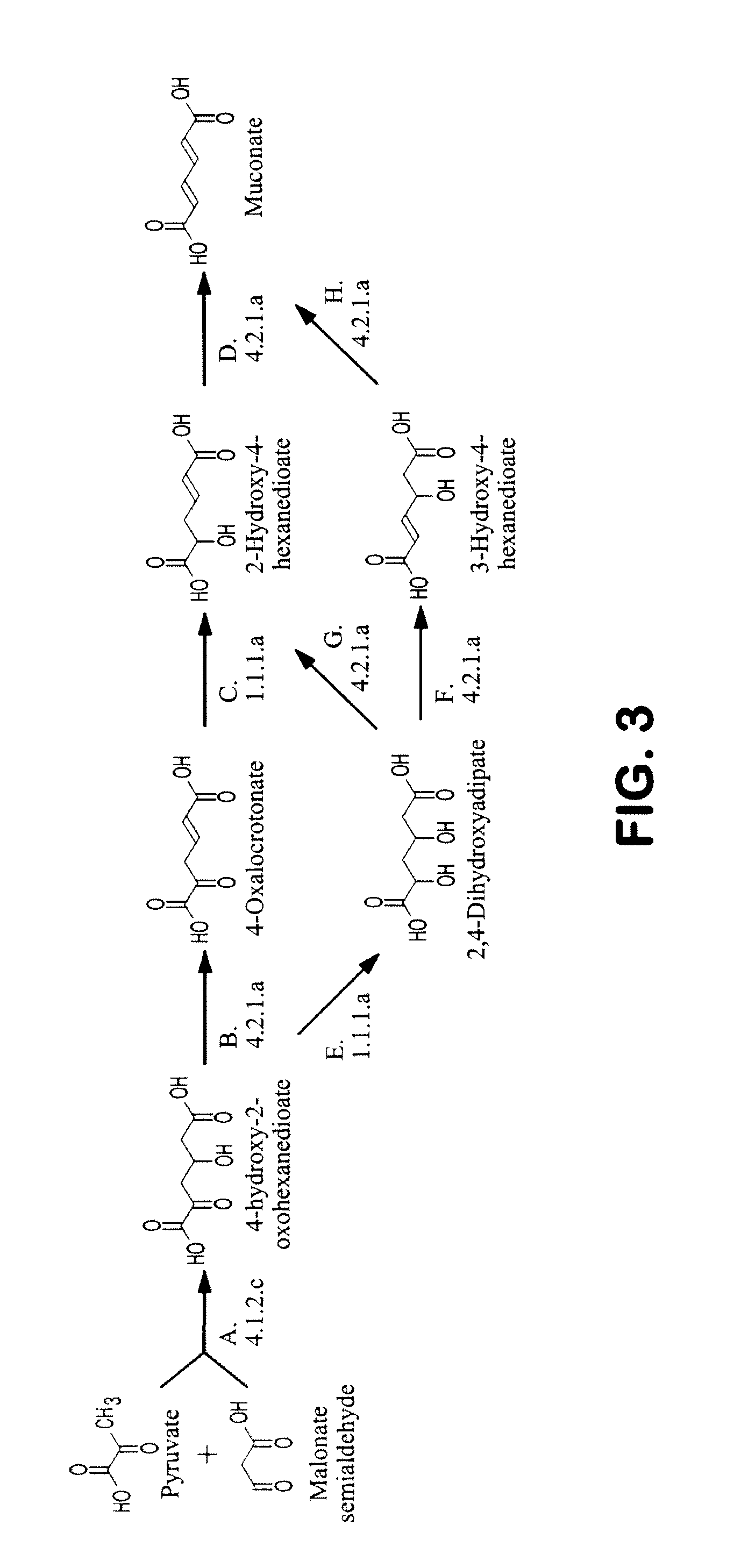

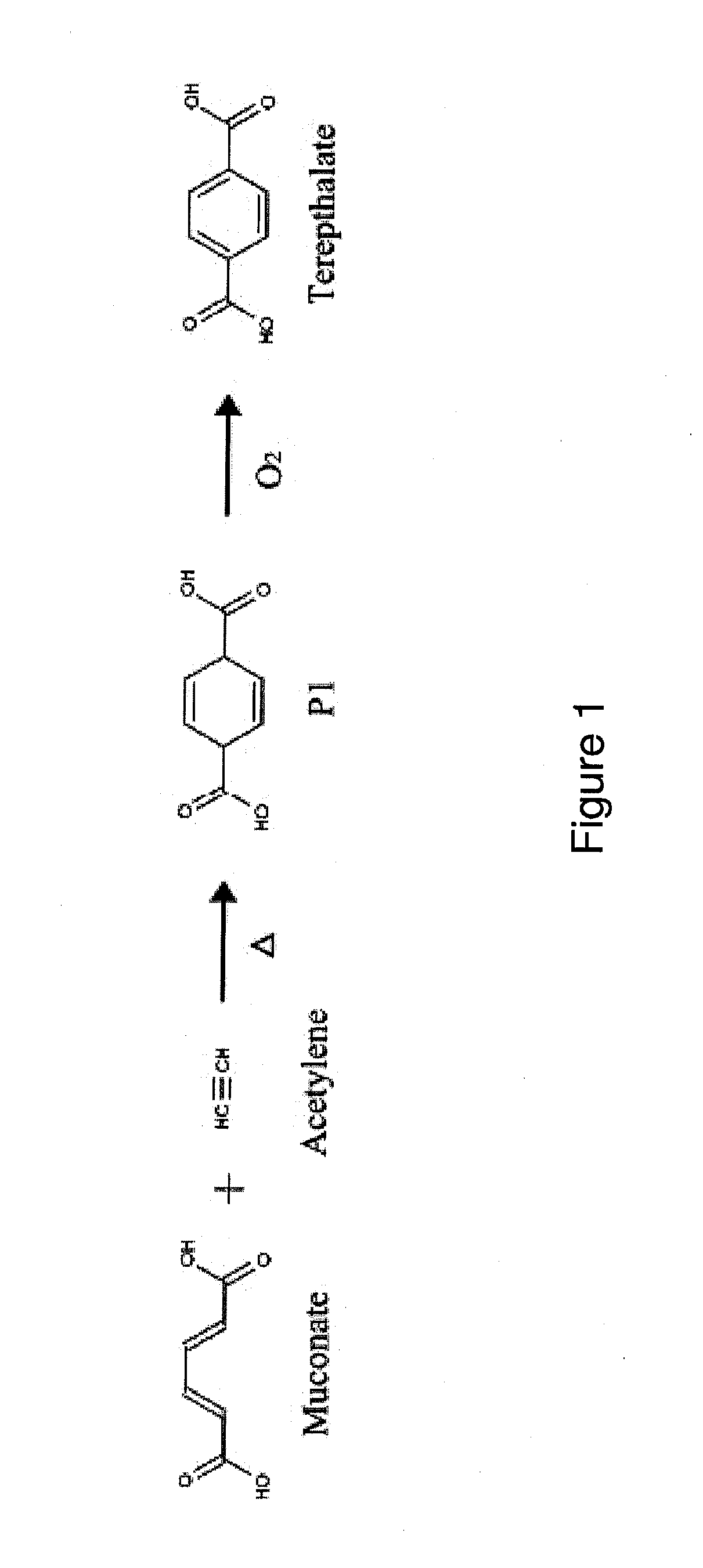

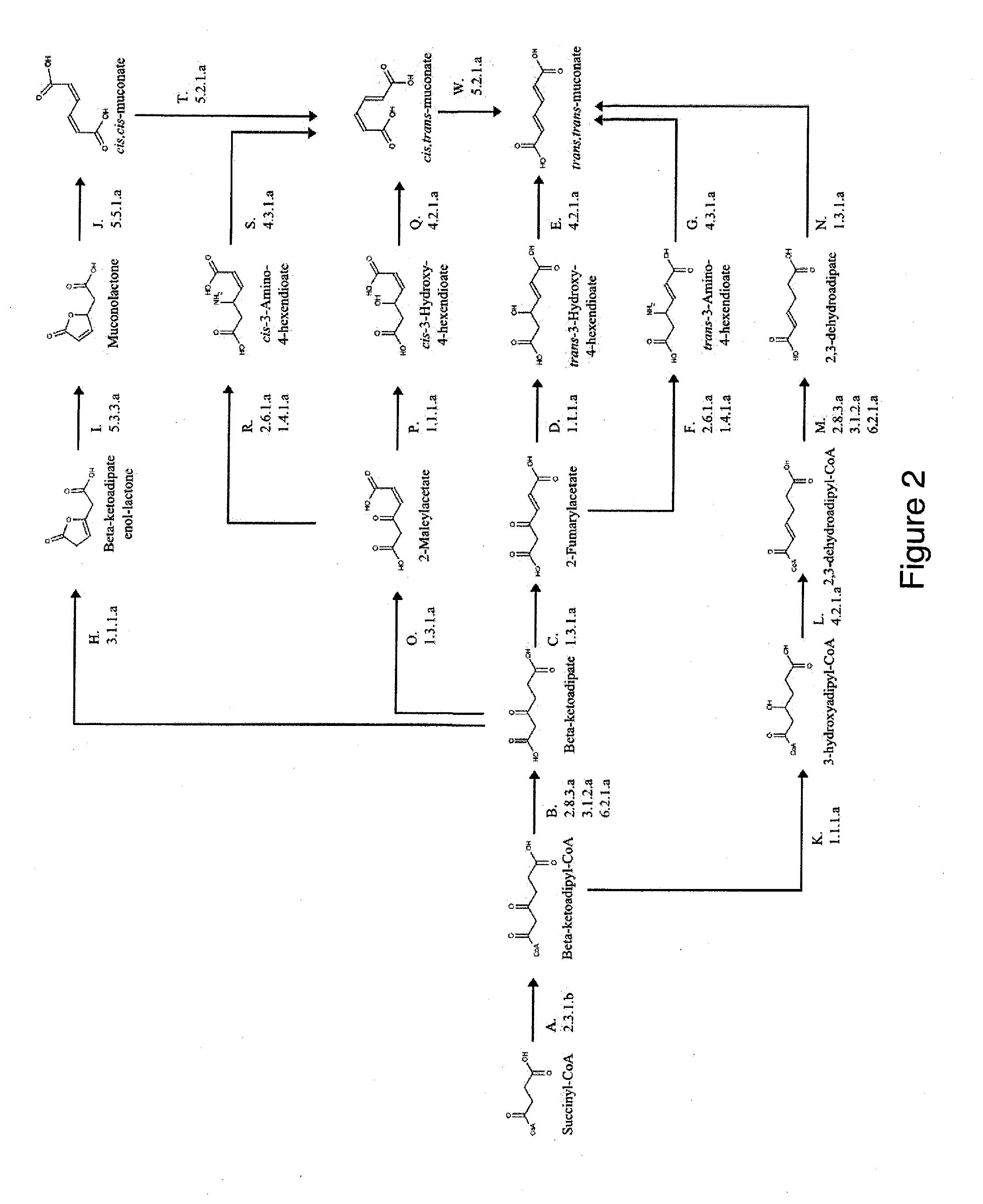

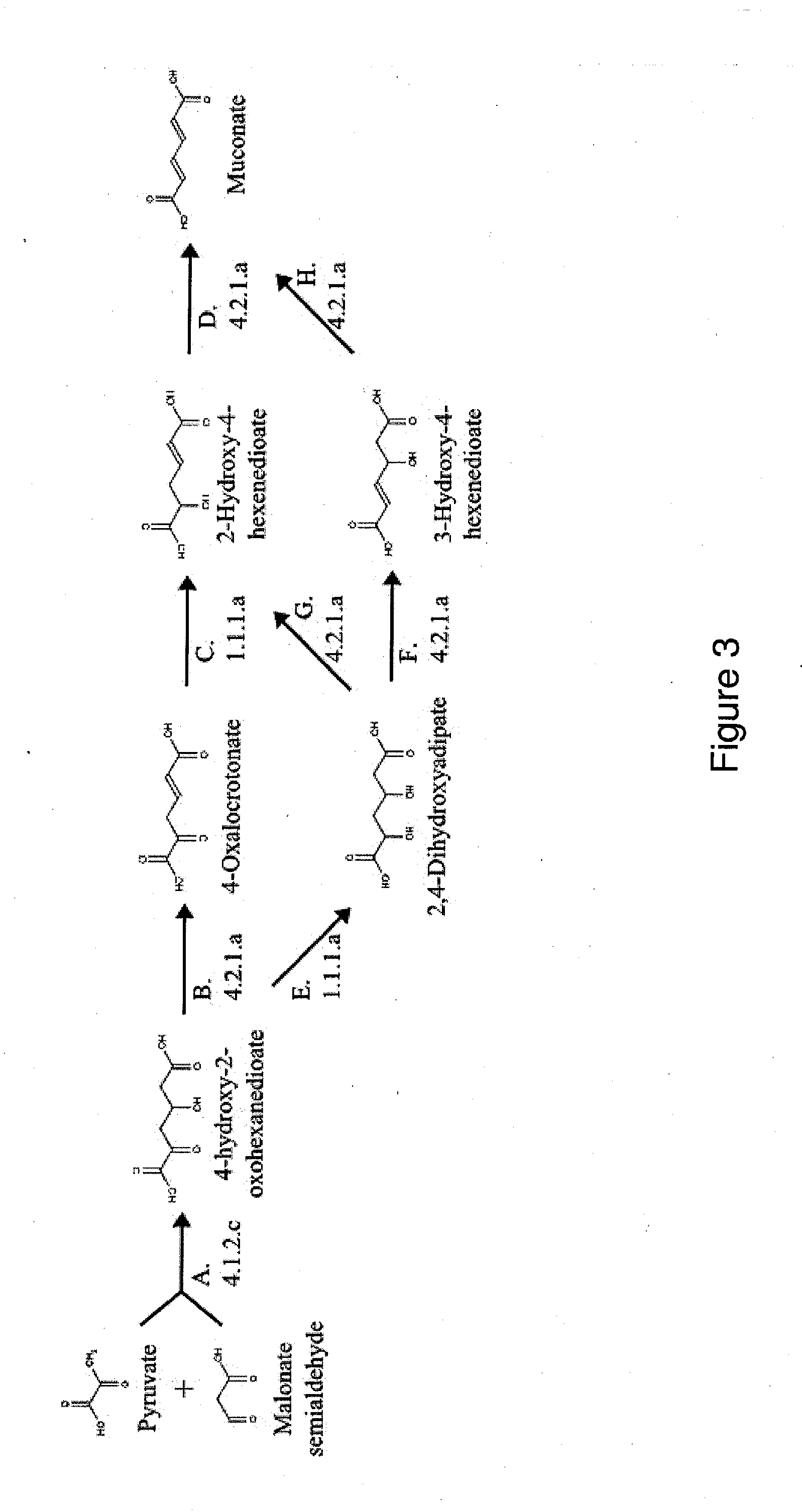

Semi-synthetic terephthalic acid via microorganisms that produce muconic acid

The invention provides a non-naturally occurring microbial organism having a muconate pathway having at least one exogenous nucleic acid encoding a muconate pathway enzyme expressed in a sufficient amount to produce muconate. The muconate pathway including an enzyme selected from the group consisting of a beta-ketothiolase, a beta-ketoadipyl-CoA hydrolase, a beta-ketoadipyl-CoA transferase, a beta-ketoadipyl-CoA ligase, a 2-fumarylacetate reductase, a 2-fumarylacetate dehydrogenase, a trans-3-hydroxy-4-hexendioate dehydratase, a 2-fumarylacetate aminotransferase, a 2-fumarylacetate aminating oxidoreductase, a trans-3-amino-4-hexenoate deaminase, a beta-ketoadipate enol-lactone hydrolase, a muconolactone isomerase, a muconate cycloisomerase, a beta-ketoadipyl-CoA dehydrogenase, a 3-hydroxyadipyl-CoA dehydratase, a 2,3-dehydroadipyl-CoA transferase, a 2,3-dehydroadipyl-CoA hydrolase, a 2,3-dehydroadipyl-CoA ligase, a muconate reductase, a 2-maleylacetate reductase, a 2-maleylacetate dehydrogenase, a cis-3-hydroxy-4-hexendioate dehydratase, a 2-maleylacetate aminoatransferase, a 2-maleylacetate aminating oxidoreductase, a cis-3-amino-4-hexendioate deaminase, and a muconate cis / trans isomerase. Other muconate pathway enzymes also are provided. Additionally provided are methods of producing muconate.

Owner:GENOMATICA INC

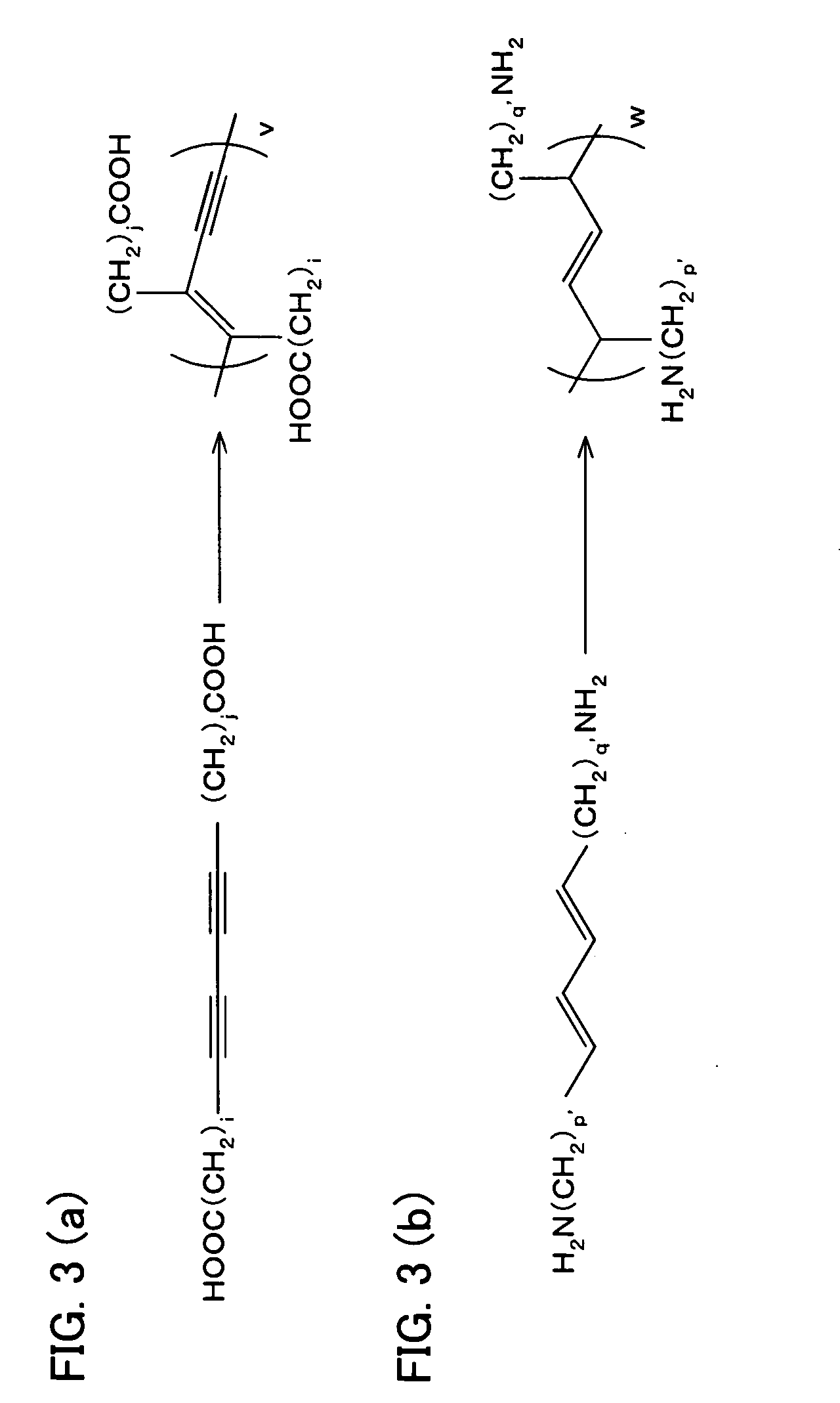

Methods for producing dodecanedioic acid and derivatives thereof

InactiveCN102498086AOrganic compound preparationCarboxylic acid esters preparationHexamethyldiamineMuconic acid

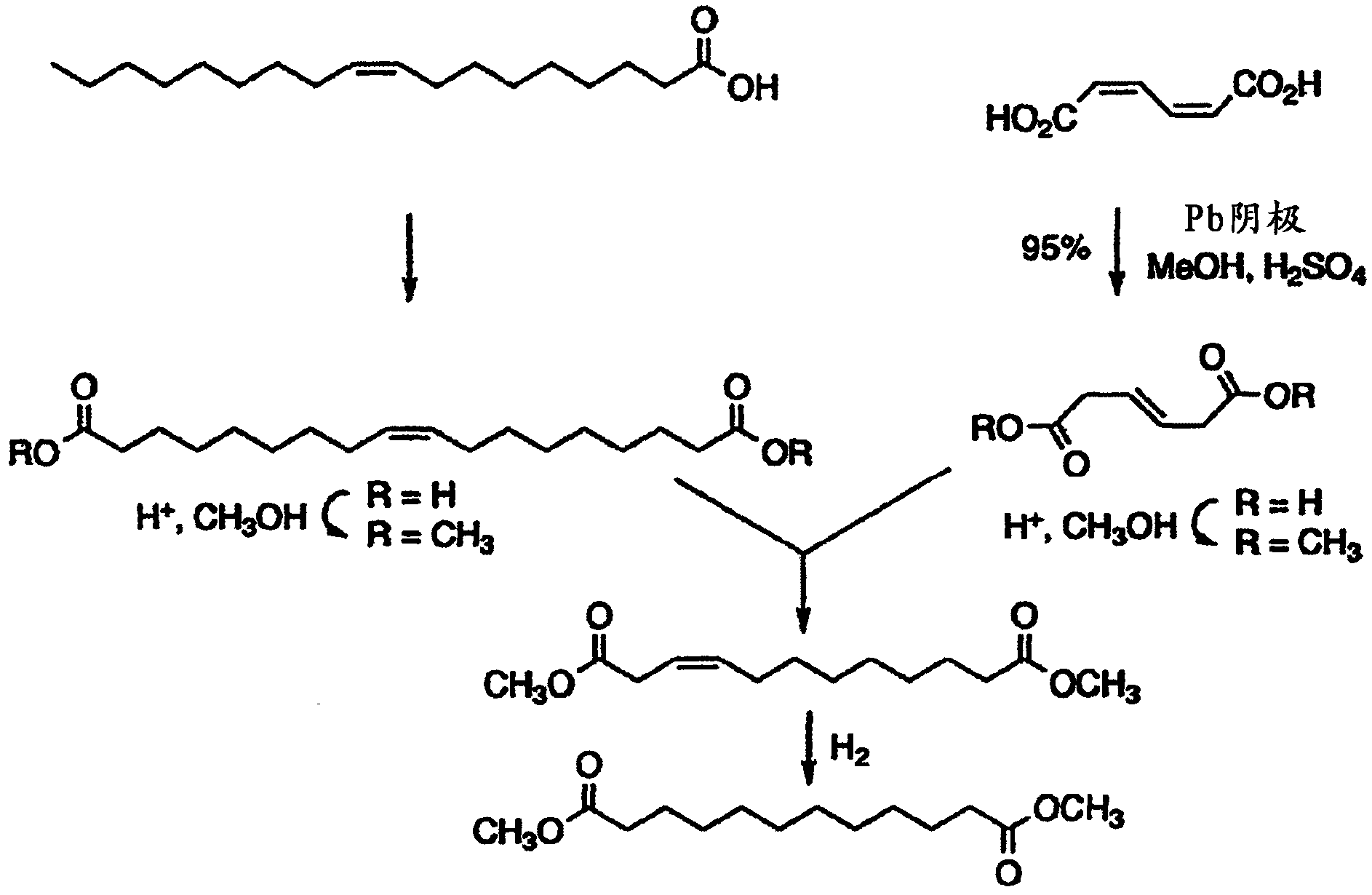

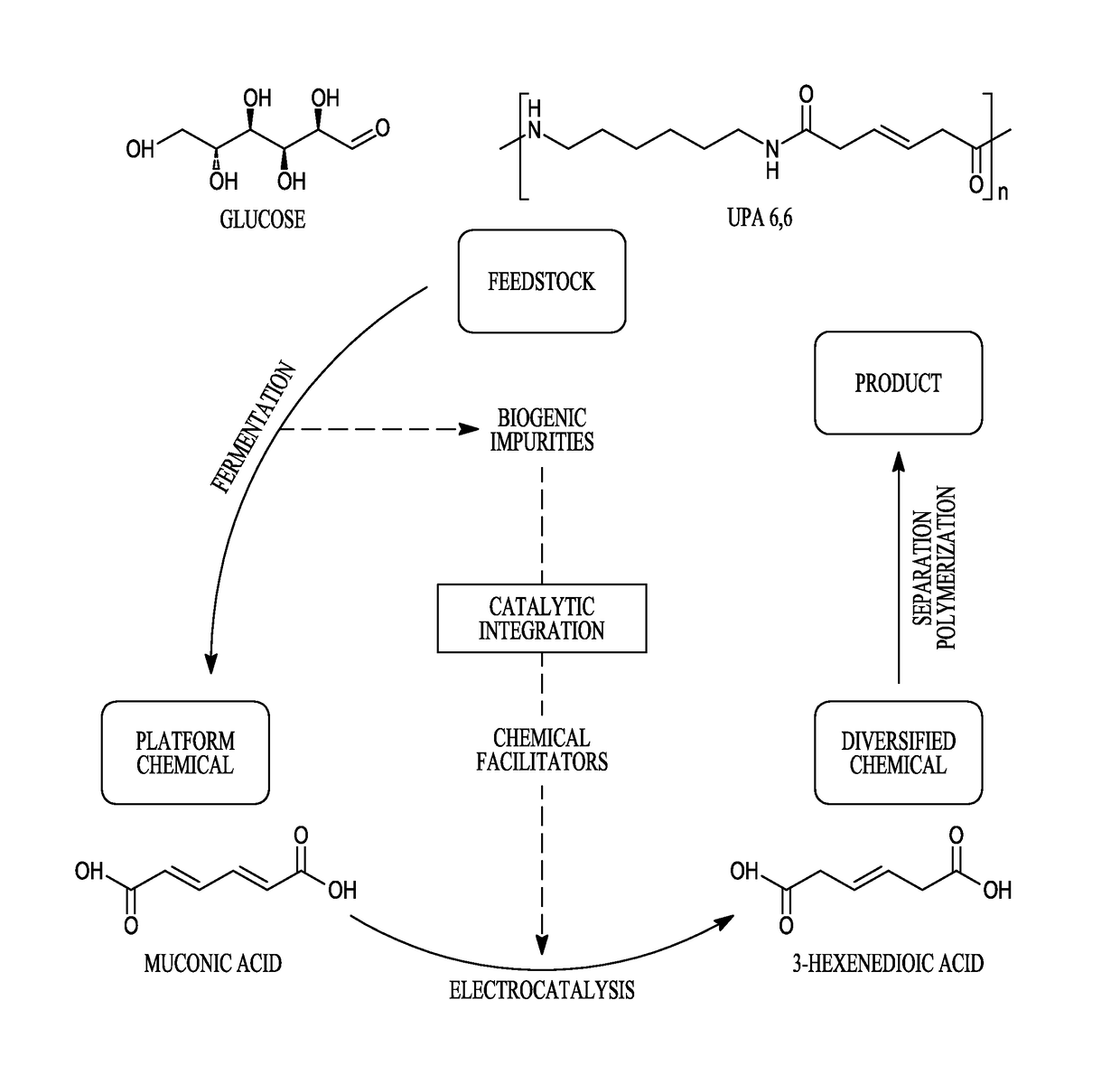

Methods for producing biosourced dodecanedioic acid and compositions comprising biosourced dodecanedioic acid are provided. In some embodiments, the method comprises first forming muconic acid biologically from a renewable carbon source, reducing the muconic acid to hexenedioic acid, and then reacting the hexenedioic acid with an unsaturated fatty acid, typically a Delta9 unsaturated fatty acid, in a metathesis reaction to produce dodecenedioic acid. Dodecenedioic acid is then reduced to dodecanedioic acid. Dodecanedioic acid is can be used to form polymers, such as polyamides. Examples of polyamides include nylon, such as nylon 6,12. Nylon 6,12 can be formed by reacting dodecanedioic acid with 1,6-hexamethylene diamine.

Owner:AMYRIS INC

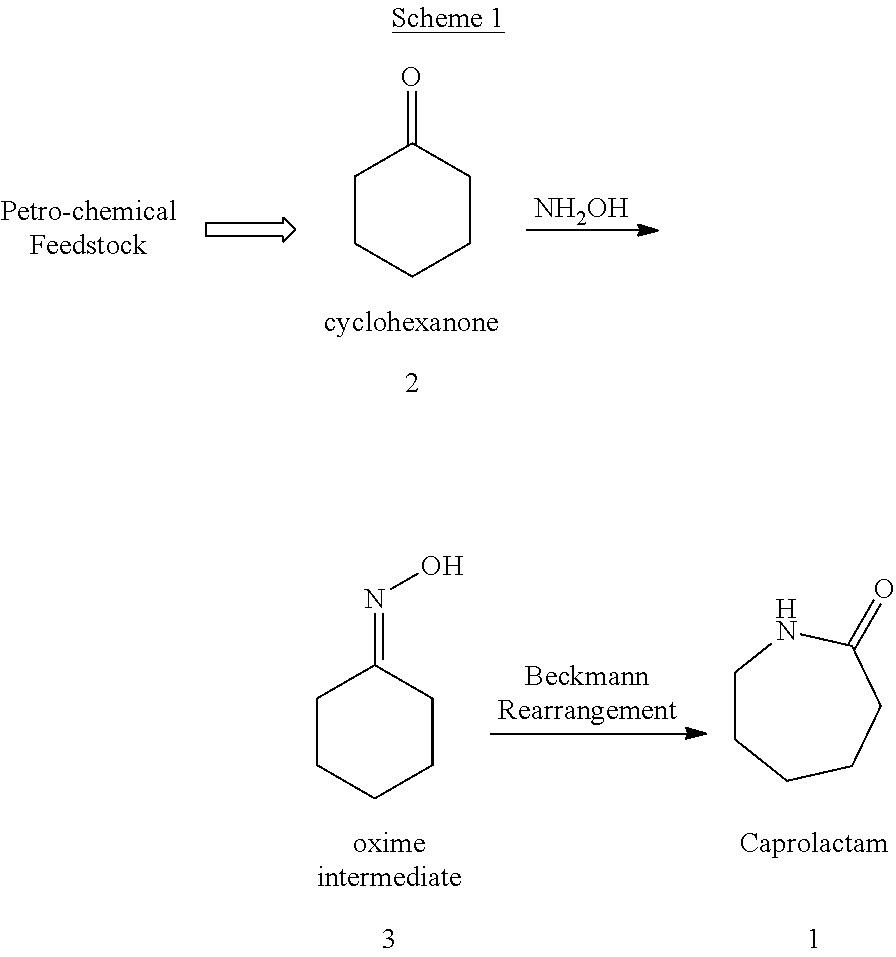

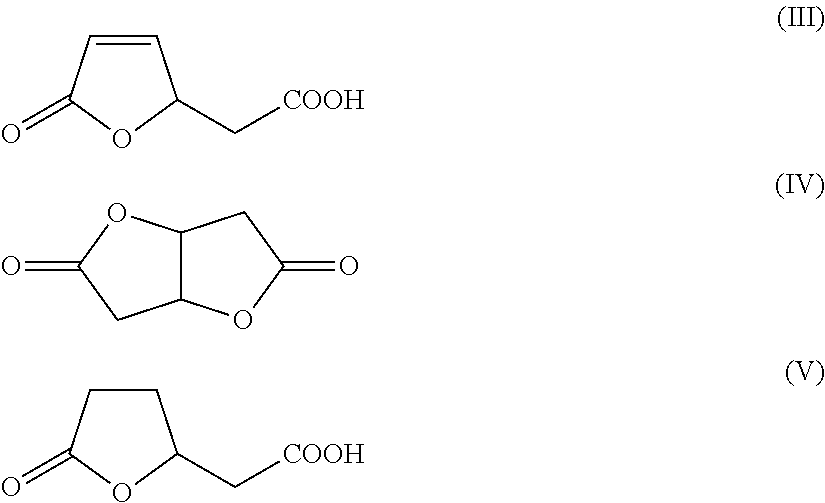

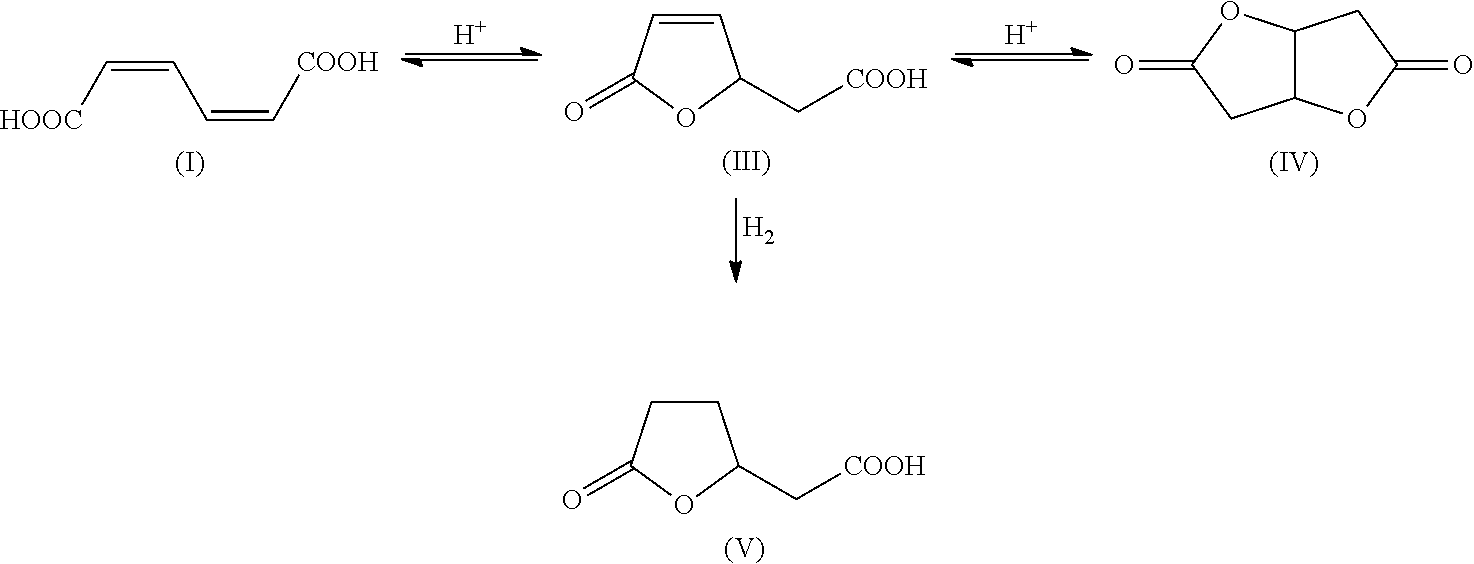

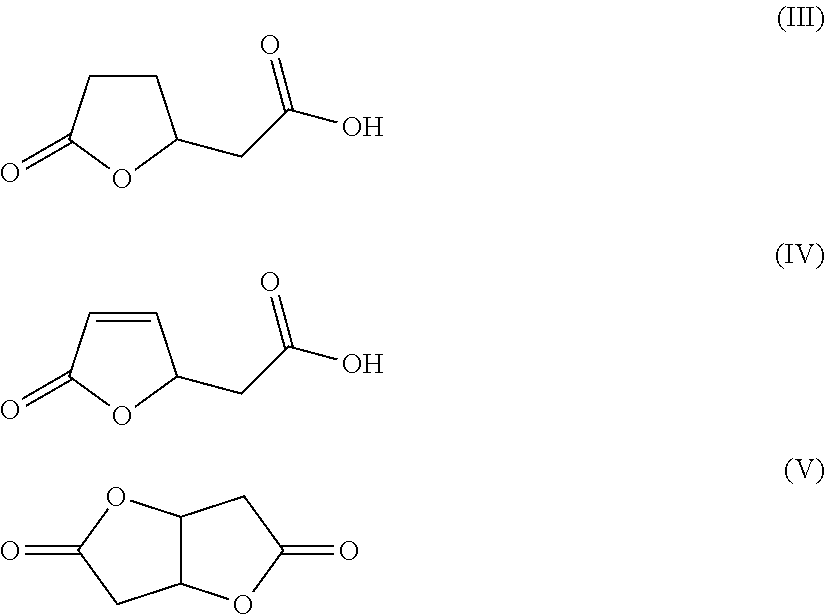

Process for Preparing Caprolactam and Polyamides Therefrom

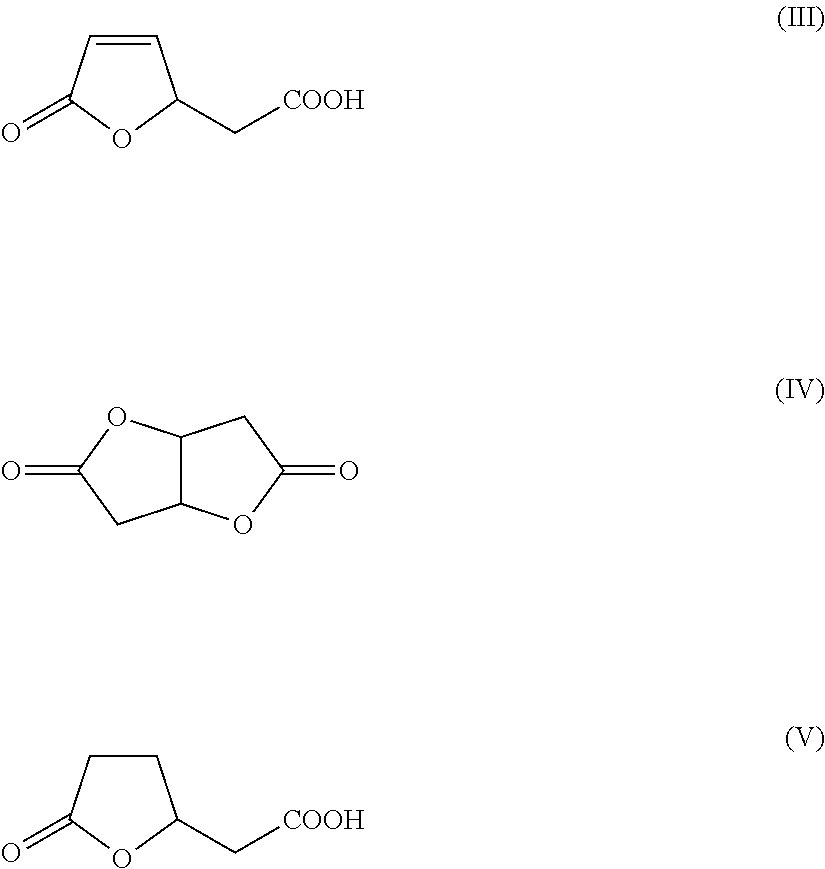

InactiveUS20130085255A1Reduce dependenceEasy to useLactams preparationOrganic compound preparationMuconic acidPolymer science

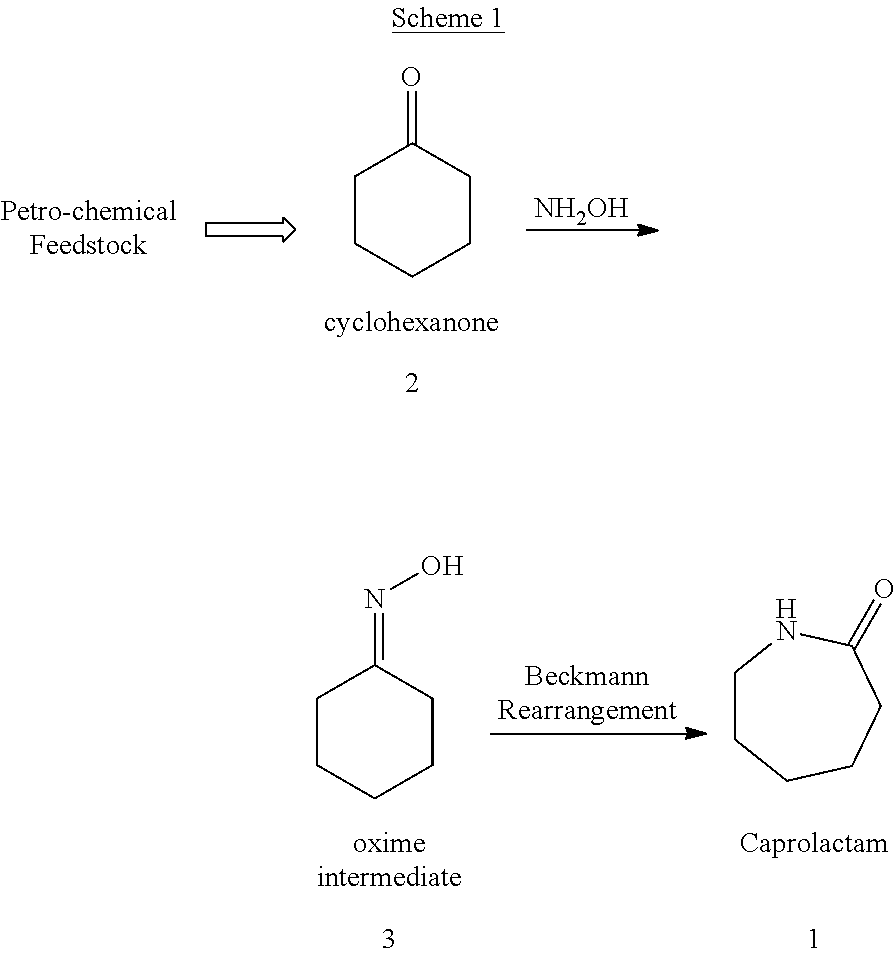

Provided herein are processes for preparing caprolactam from a starting material such as one or more of the cis,cis-, cis,trans- and trans,trans-double-bond isomers of muconamide, muconic acid ester, or muconic acid. The starting material, intermediates, and caprolactam prepared therefrom can contain carbon atoms derived from biomass containing detectable 14C content determined according to ASTM D6866 and optionally containing a 14C content up to 0.0000000001% (one part per trillion). Caprolactam so prepared can be used to make various polyamides.

Owner:AMYRIS INC

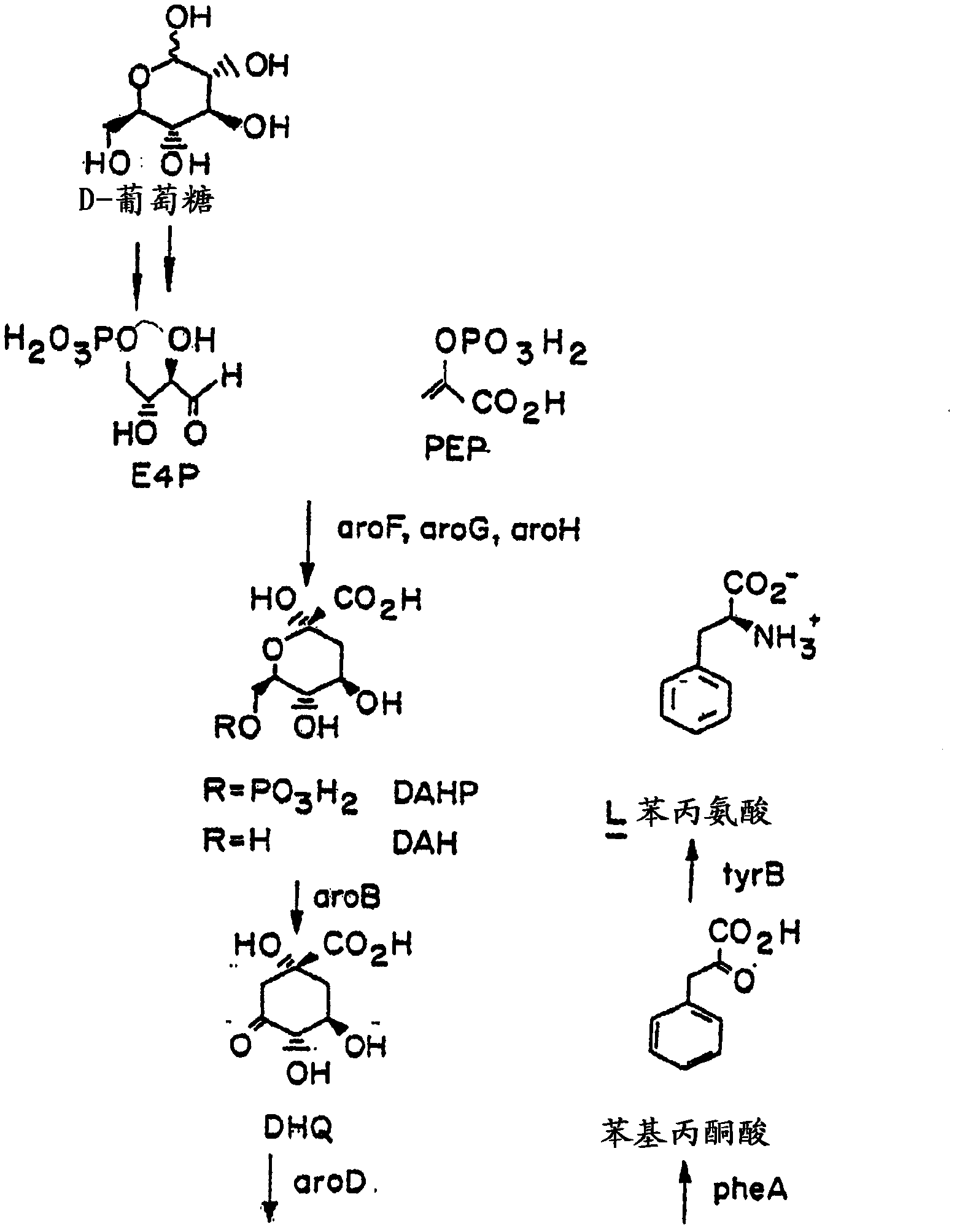

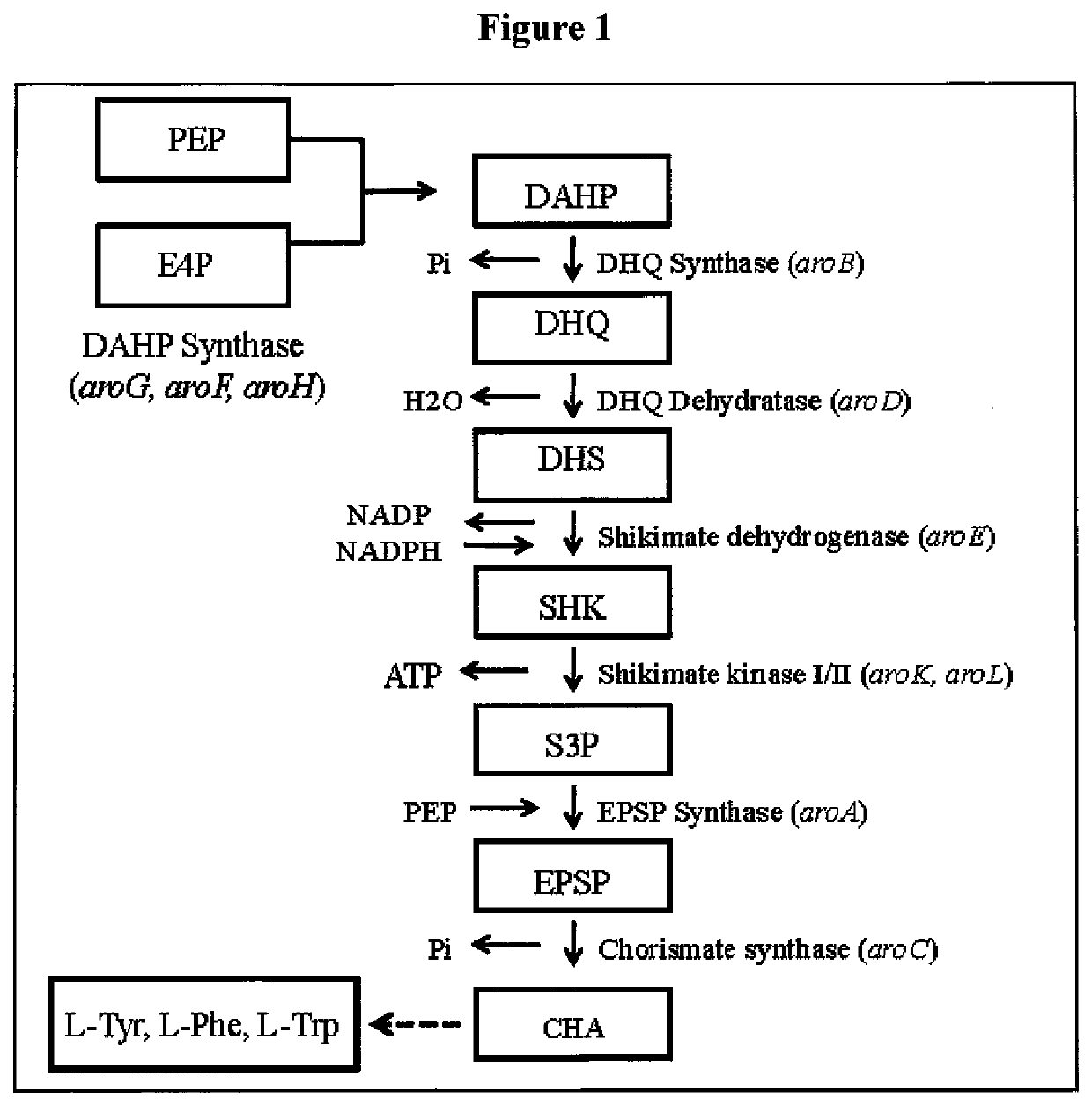

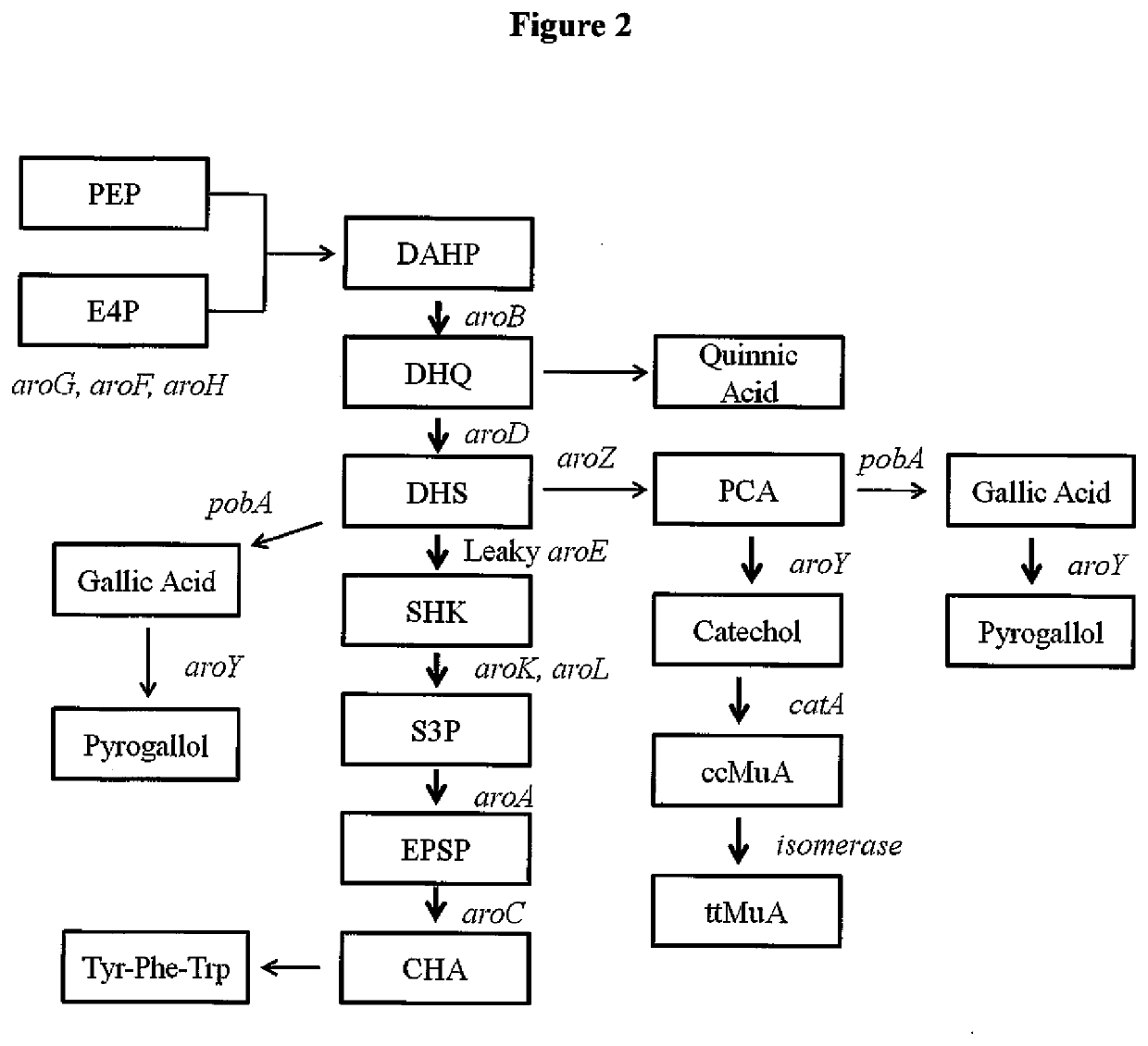

Escherichia coli for producing adipic acid precursor namely cis,cis-muconic acid and application of escherichia coli

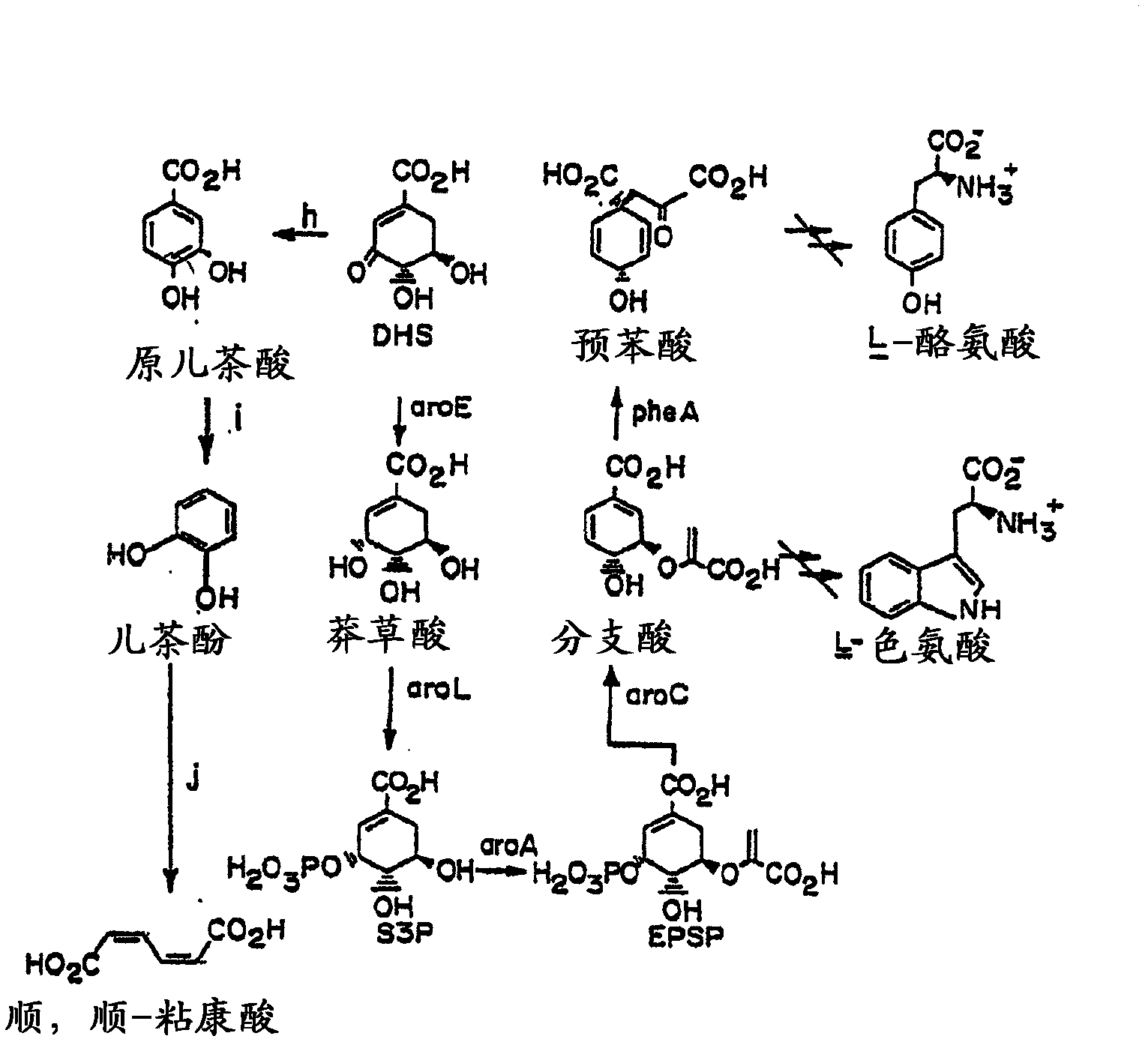

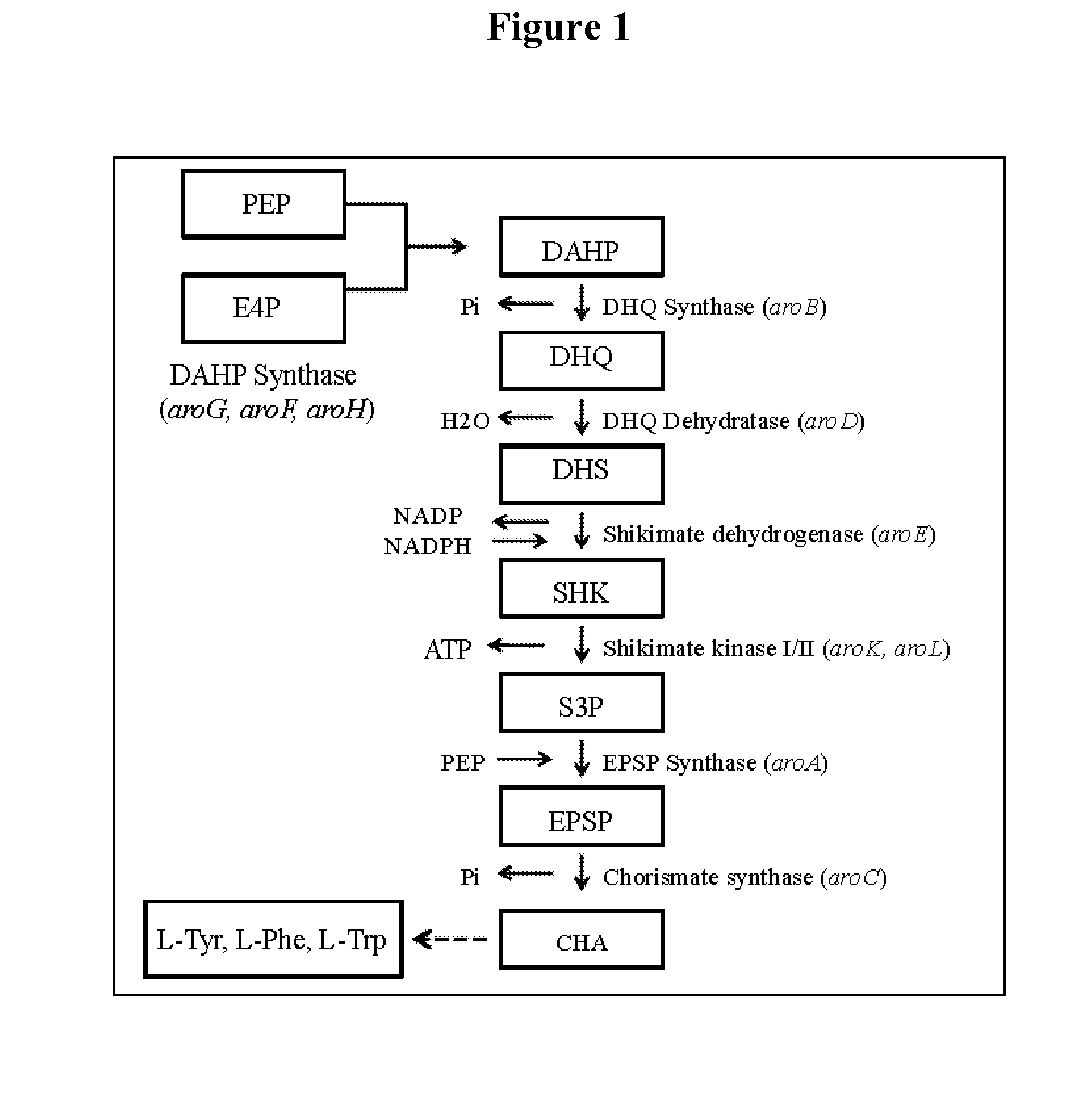

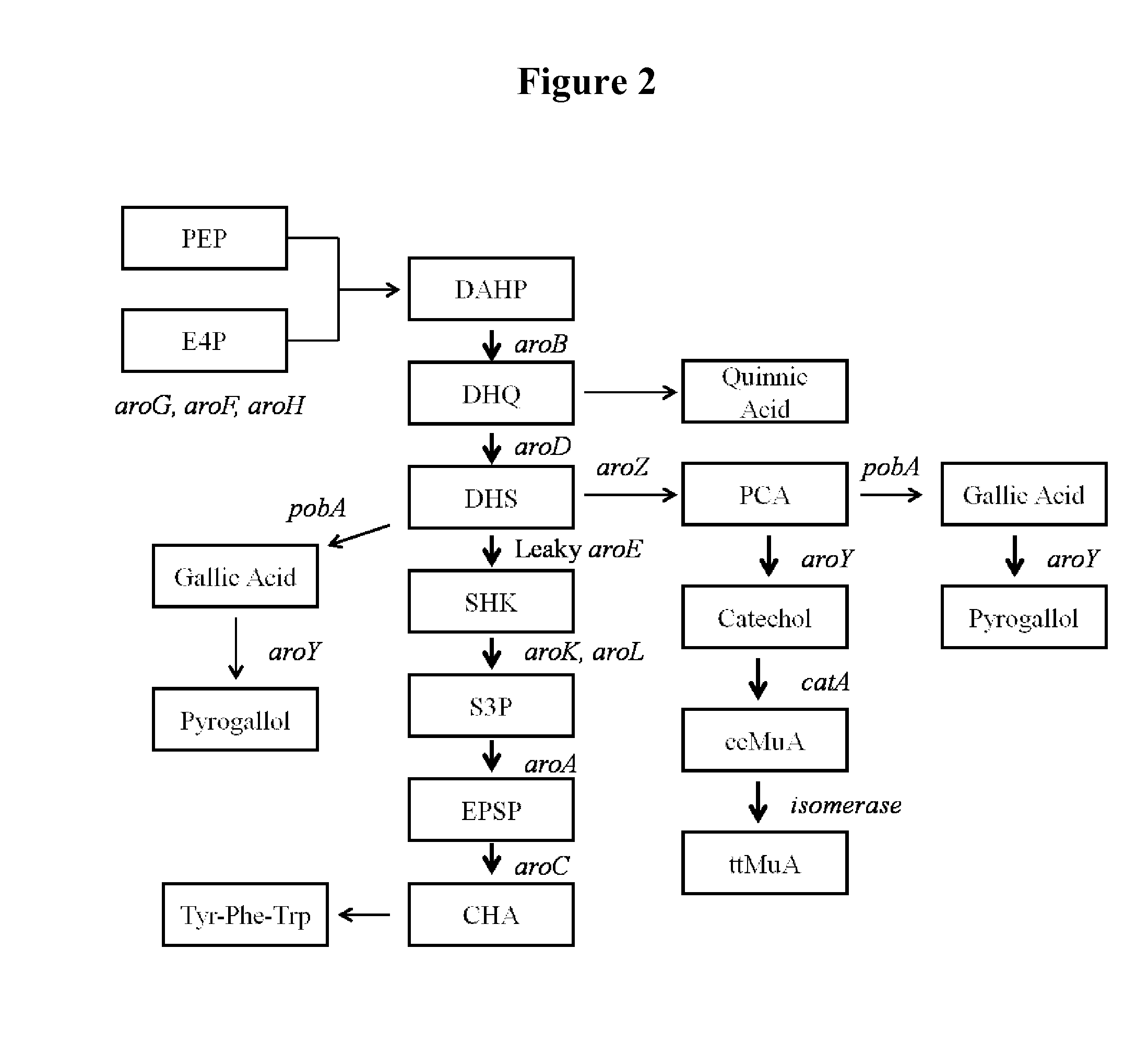

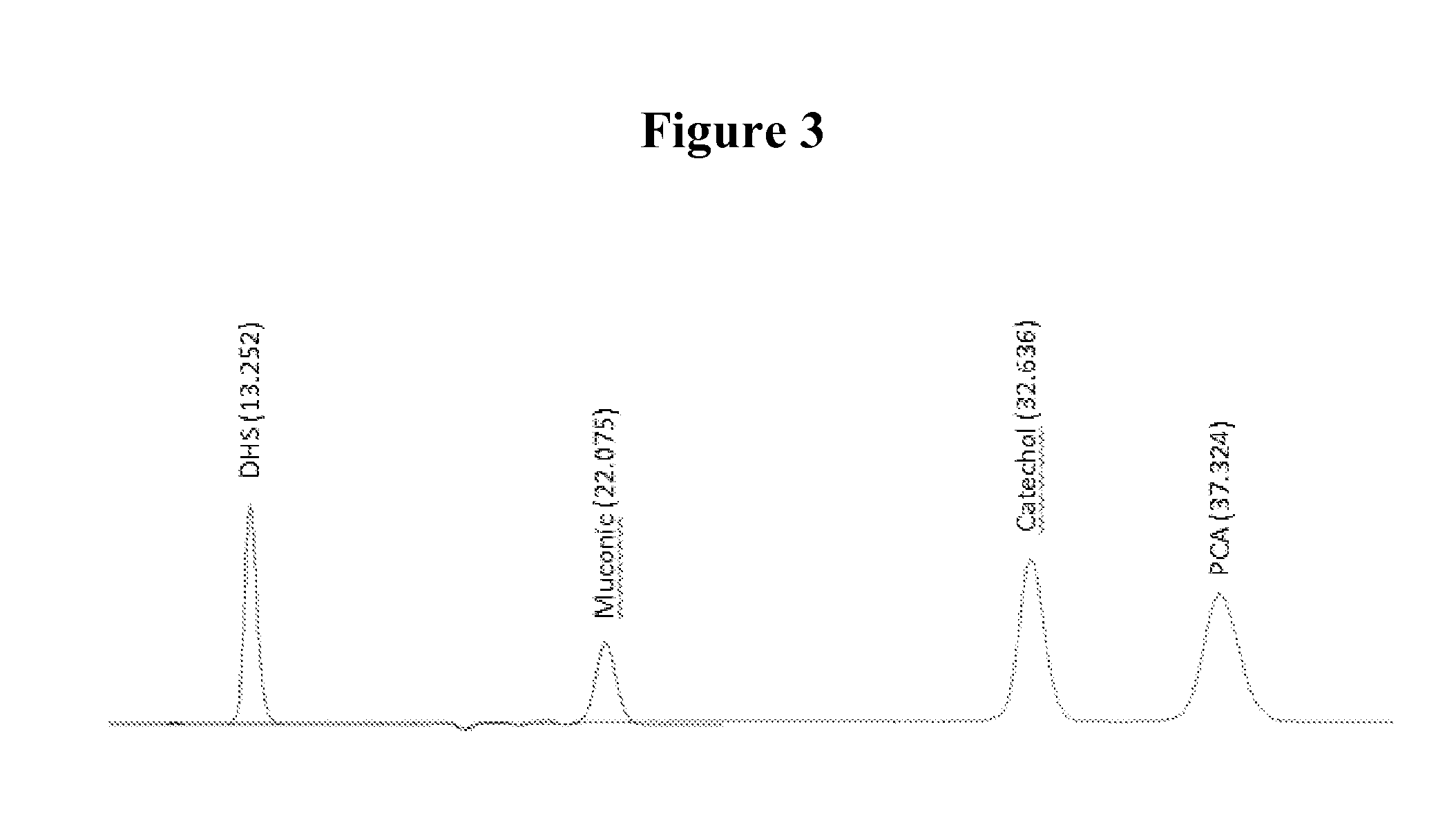

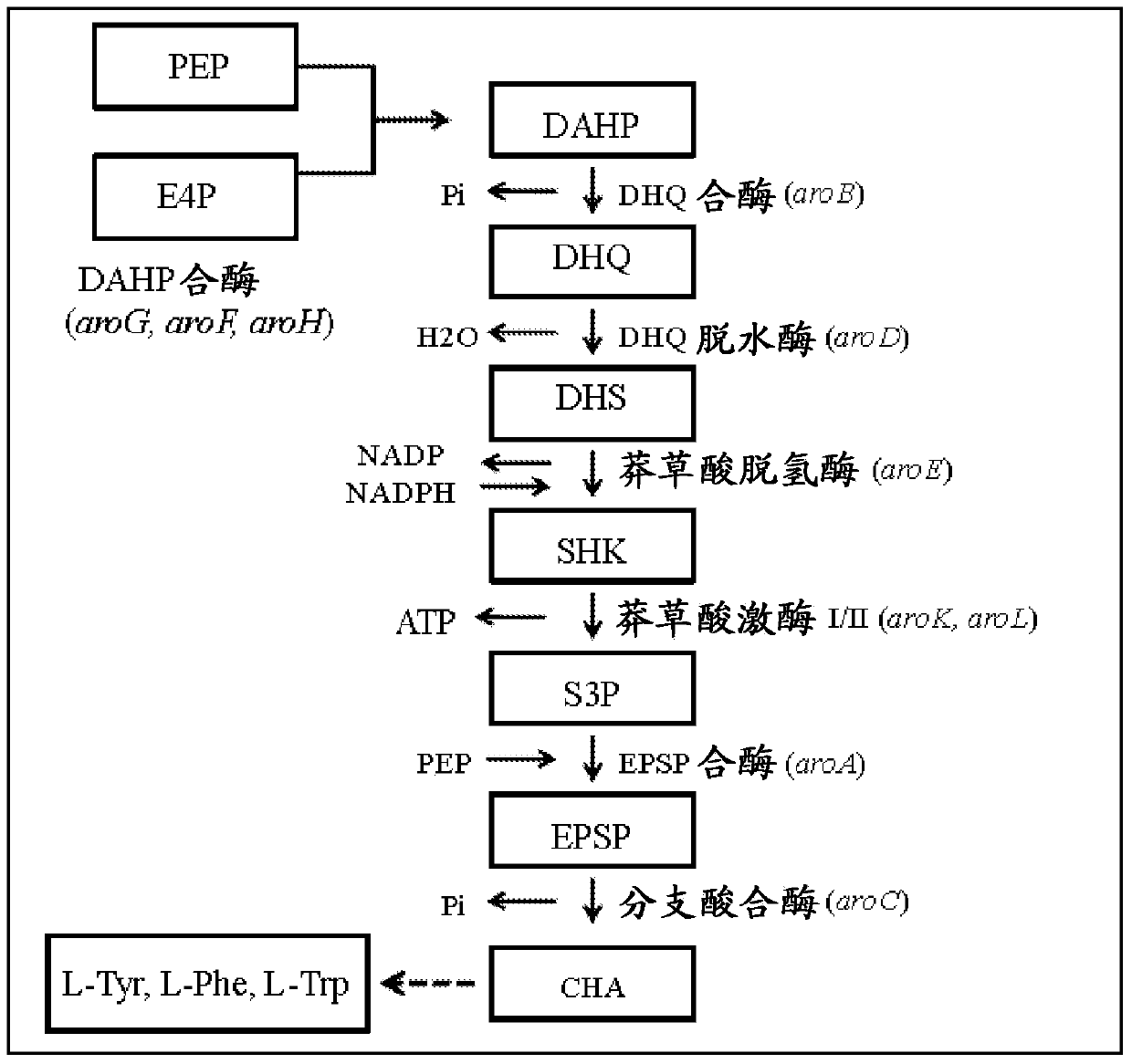

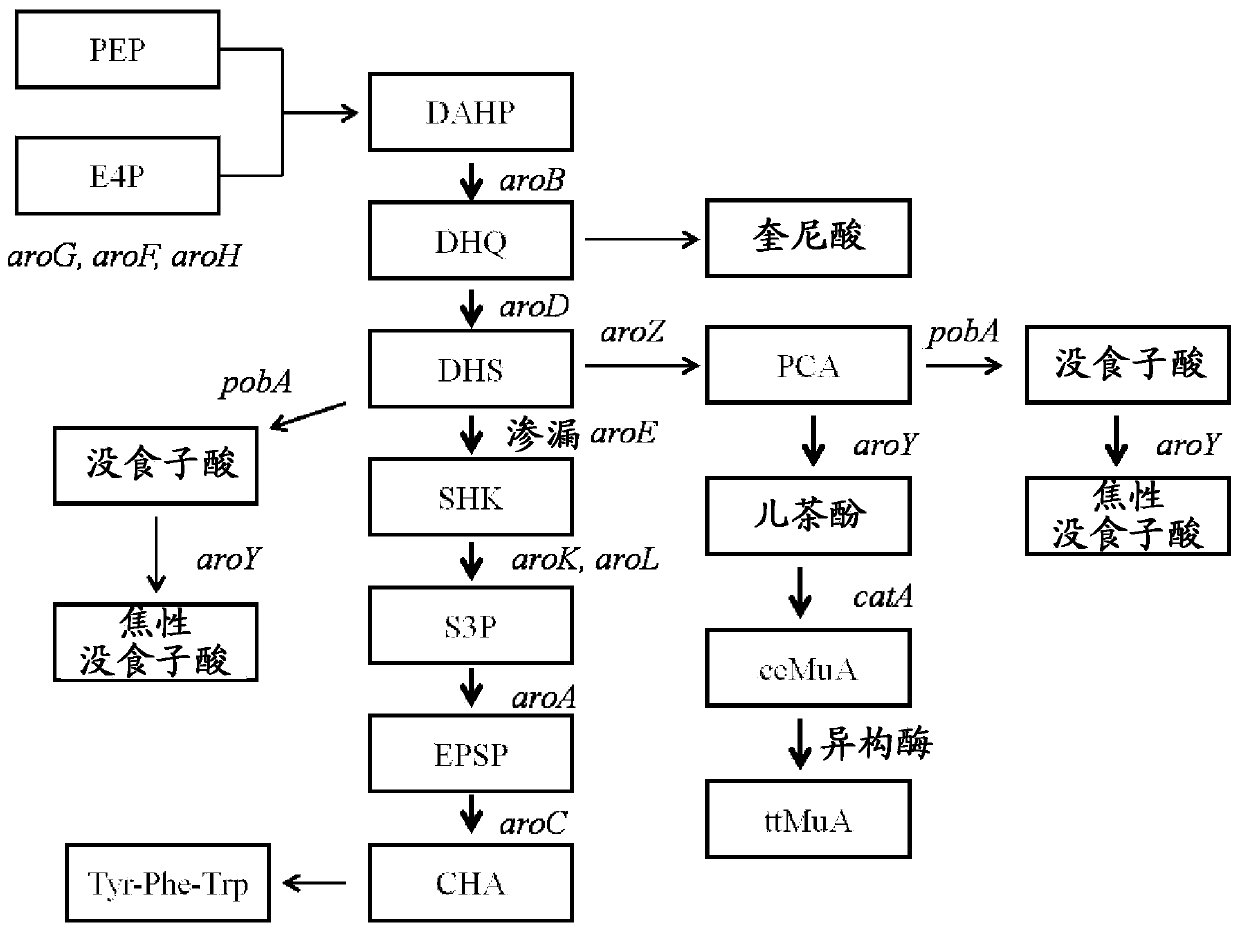

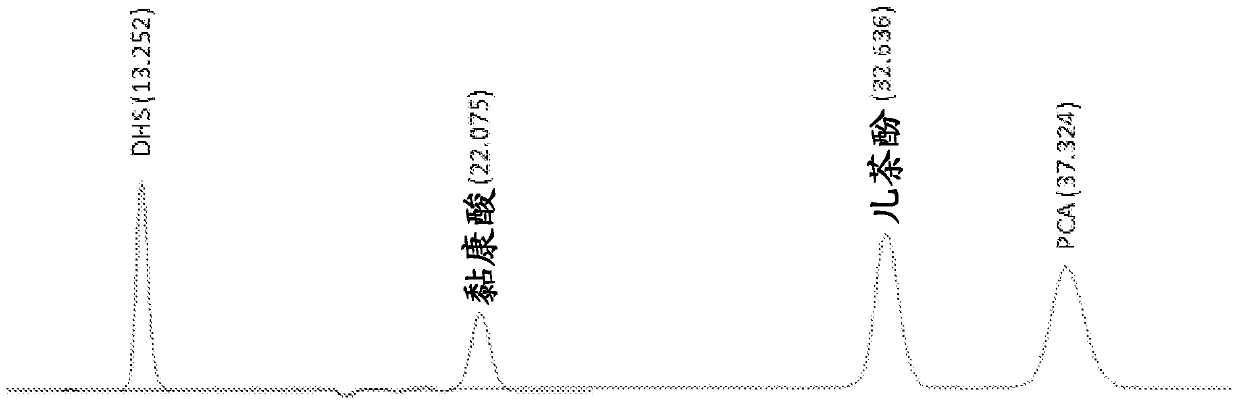

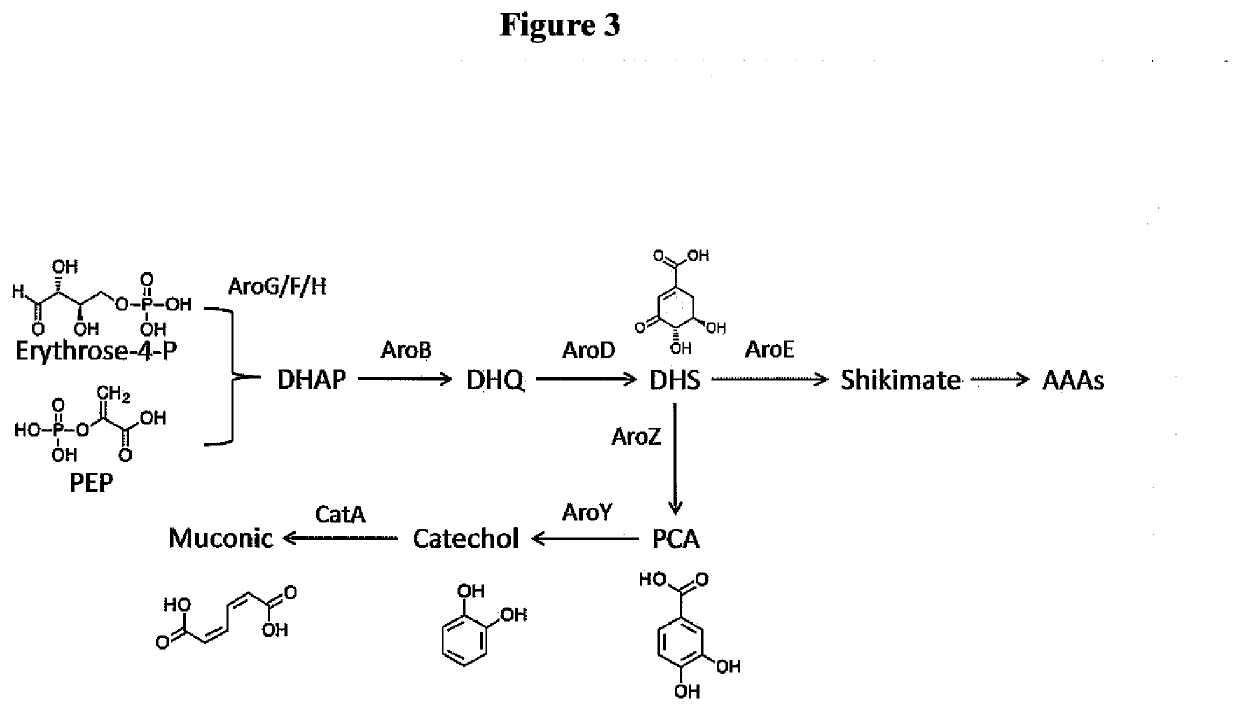

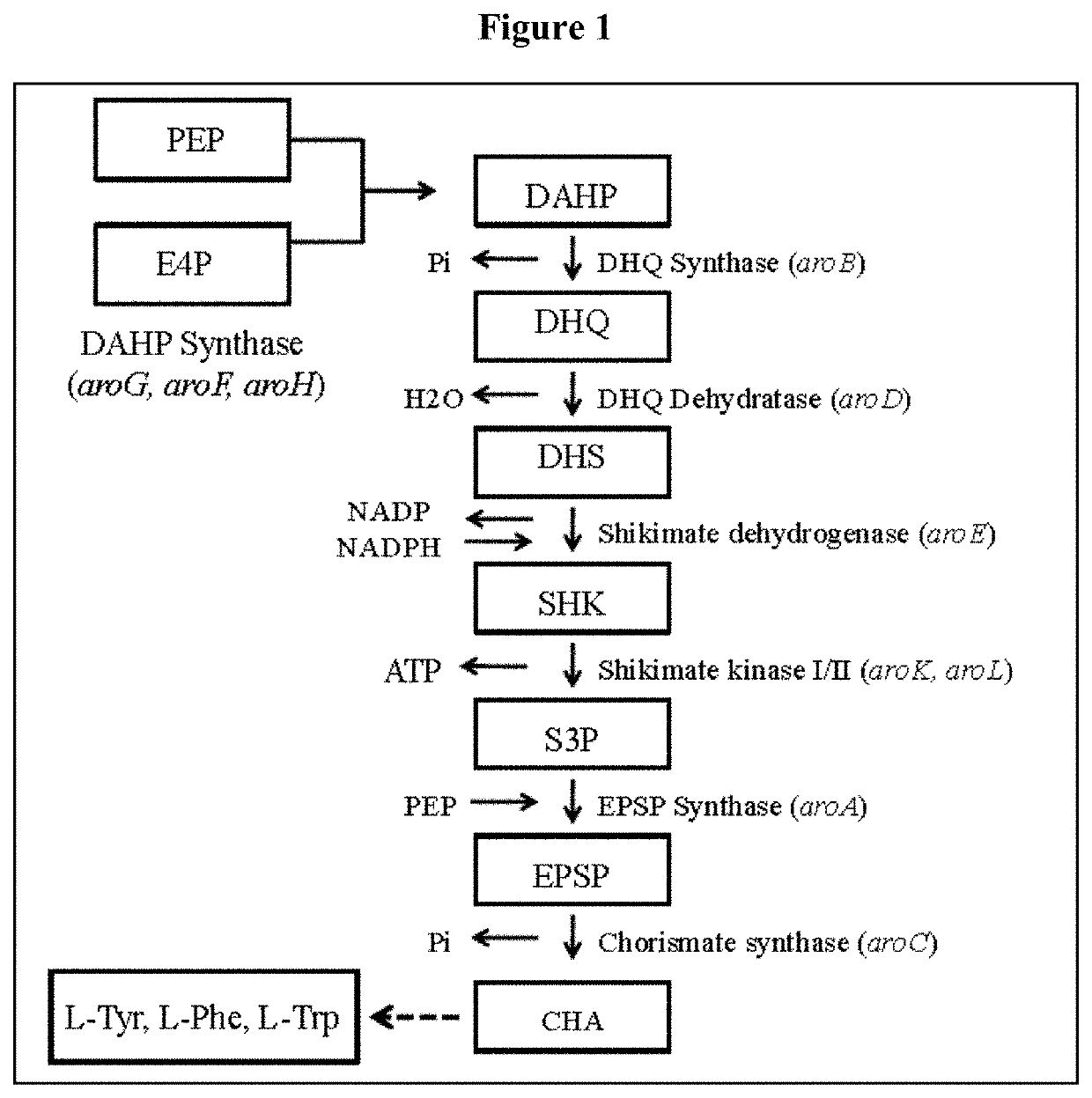

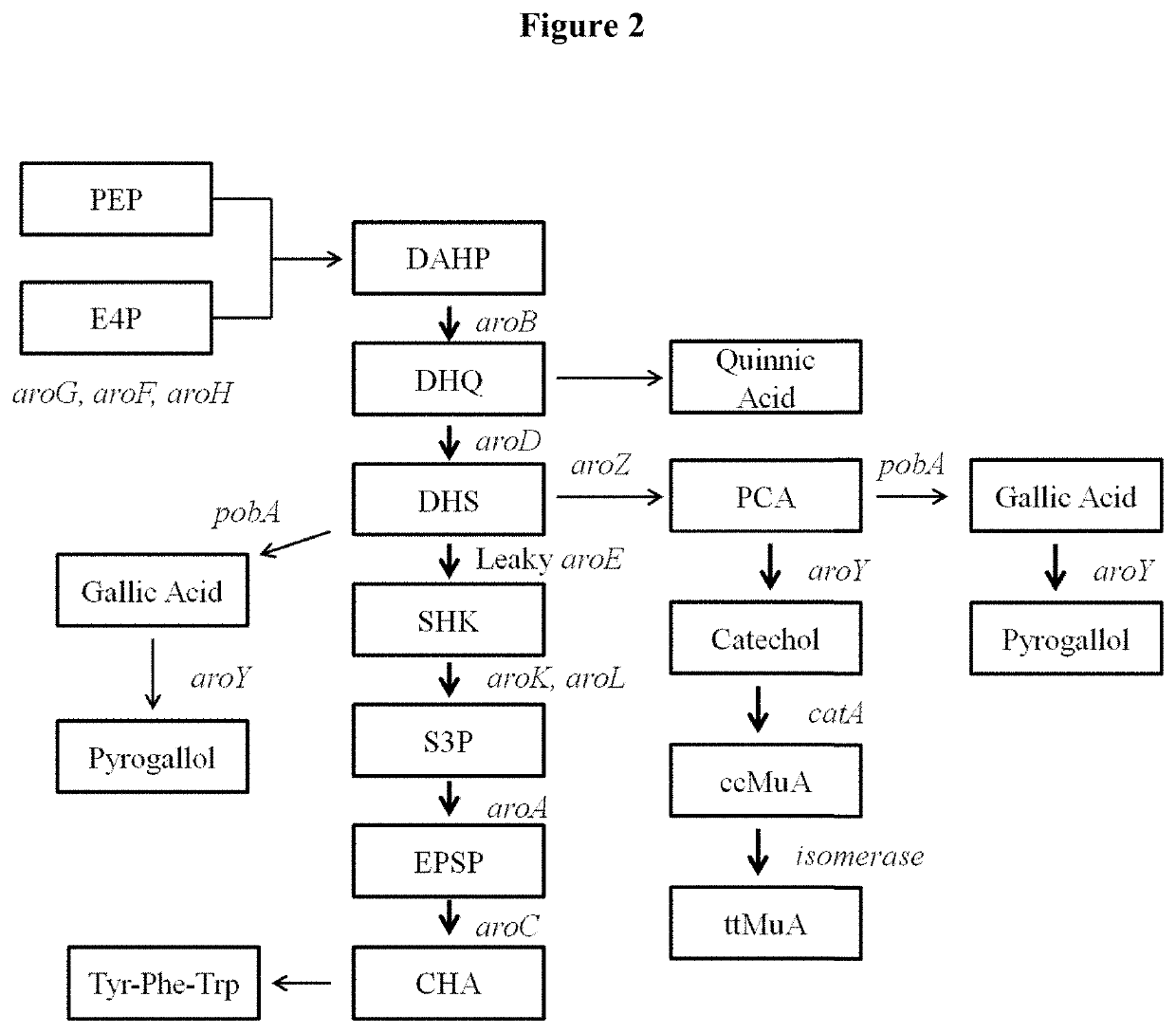

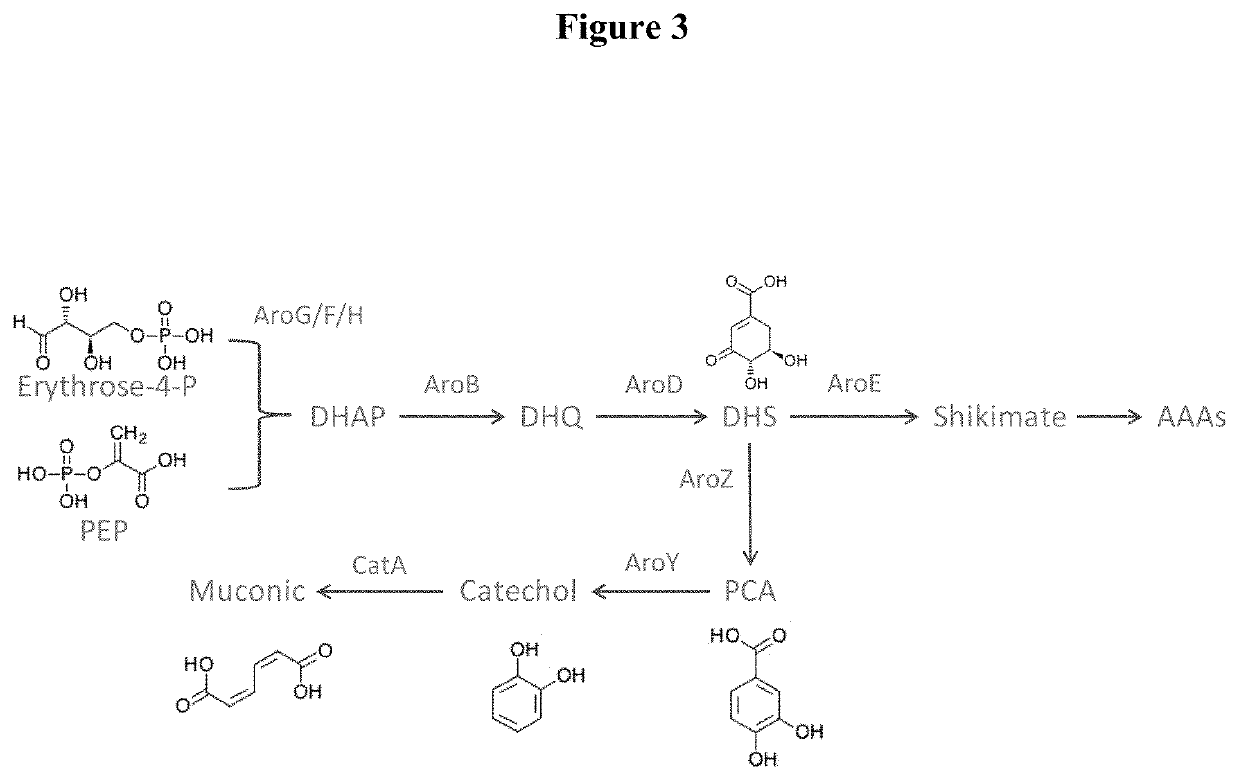

Cis,cis-muconic acid is an important chemical organic acid, has a wide range of application and can be used as a precursor of adipic acid. The cis,cis-muconic acid can be used for producing polymers including nylon 66 and the like after being converted into adipic acid through hydrogenation. The invention provides a recombinant escherichia coli TIB-LEc340 CGMCC No 6435 for producing cis,cis-muconic acid, wherein the recombinant escherichia coli is established by the steps of combining 3-dehydrogenated shikimic acid dehydrase which comes from different microbes and is optimized by codons, protocatechuic acid decarboxylase, catechol 1,2-dioxidase and artificially designed constitutive promoters and terminators into a heterologous expression module, and then introducing the heterologous expression module into shikimic acid dehydrogenase mutated escherichia coli. The escherichia coli TIB-LEc340 CGMCC No 6435 is fermented for 16-120 hours at 30-40 DEG C to obtain fermentation liquor, and the maximum content of cis,cis-muconic acid in the fermentation liquor can reach 52g / L, so that the escherichia coli has a wide application prospect.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

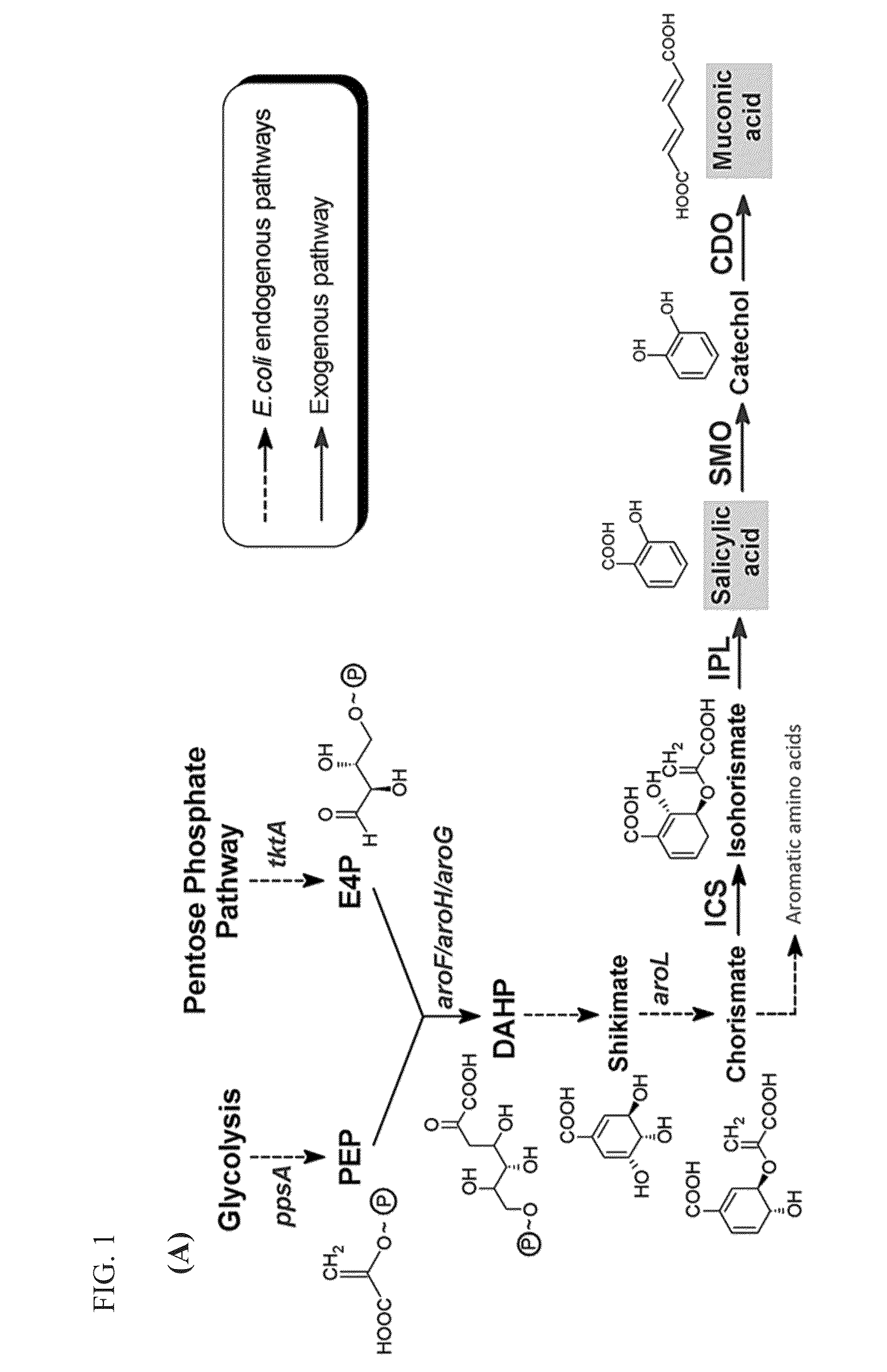

Production of muconic acid from genetically engineered microorganisms

InactiveUS20150044755A1Increase gene expressionImprove throughputBacteriaTransferasesMicroorganismMuconic acid

This present invention is in the field of producing renewable chemical feedstocks using biocatalysts that have been genetically engineered to increase their ability to convert renewable carbon resources into useful compounds. More specifically, the present invention provides a process for producing muconic acid form renewable carbon resources using a genetically modified organism.

Owner:PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

Method for producing hexamethylenediamine

InactiveUS20160326092A1Adipic acid yieldHigh melting pointAmino compound purification/separationOrganic compound preparationMuconic acidHexamethyldiamine

The invention relates to a method for producing hexamethylenediamine, wherein a) a muconic acid starting material is provided, which is selected from among muconic acid, esters of muconic acid, lactones of muconic acid, and mixtures thereof, b) the muconic acid starting material is subjected to a reaction with hydrogen in the presence of at least one hydrogenation catalyst in order to form 1,6-hexanediol, and c) the 1,6-hexanediol obtained in step b) is subjected to amination in the presence of an amination catalyst in order to obtain hexamethylenediamine. The invention further relates to hexamethylenediamine which can be produced by means of said method.

Owner:BASF AG

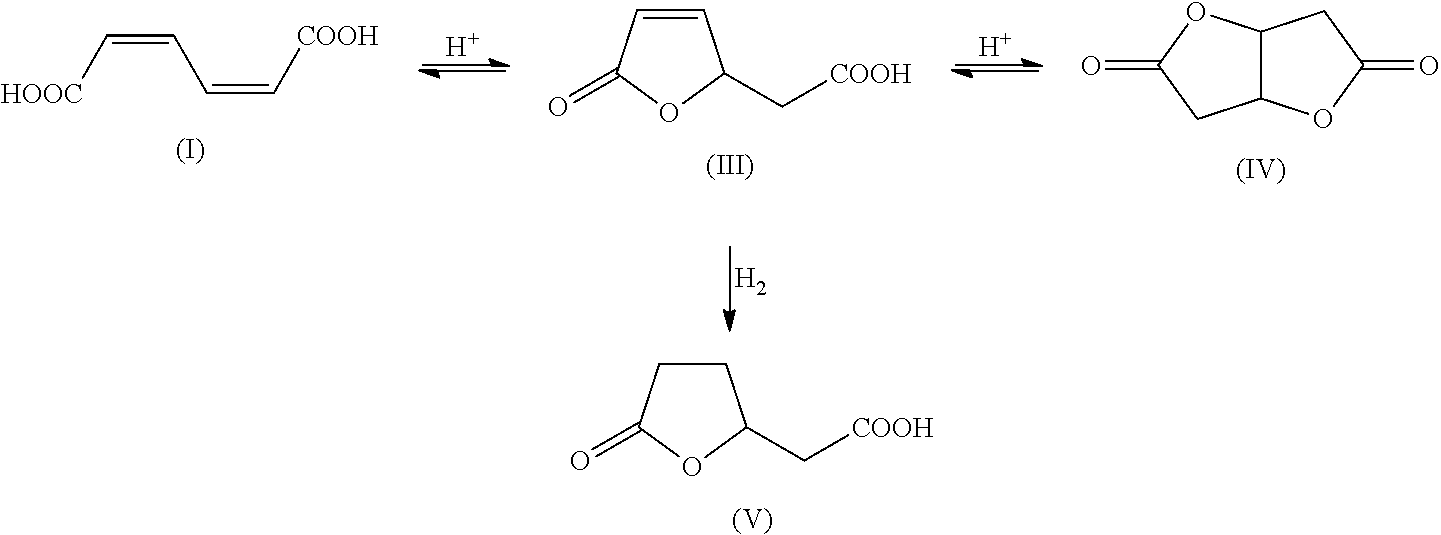

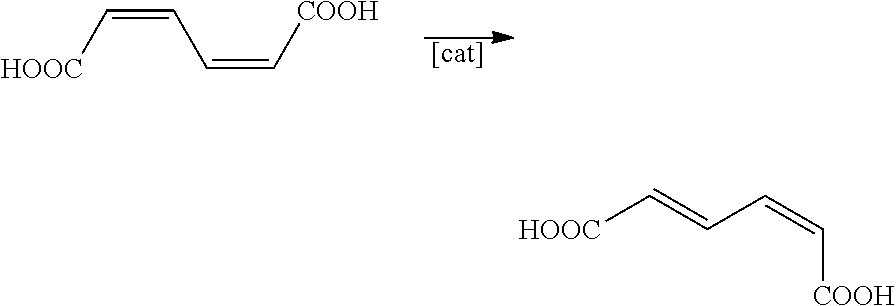

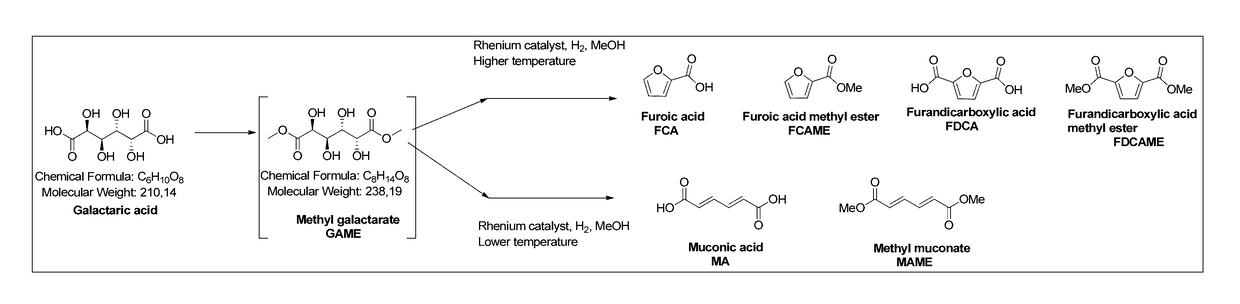

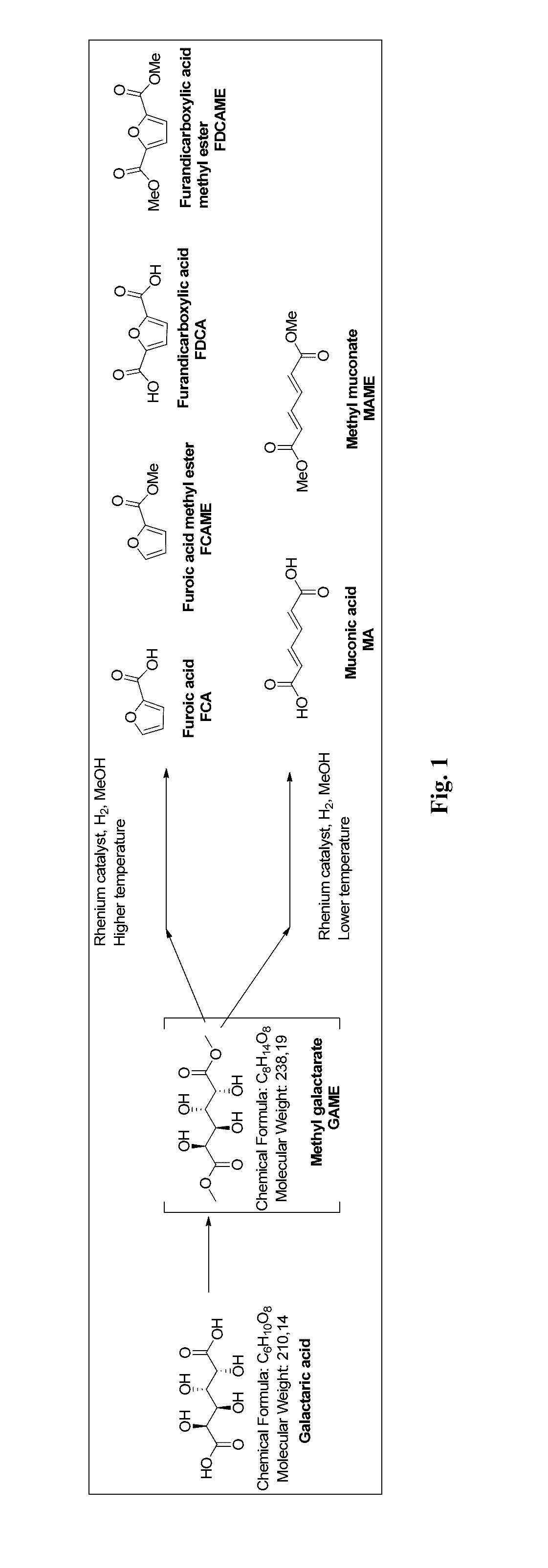

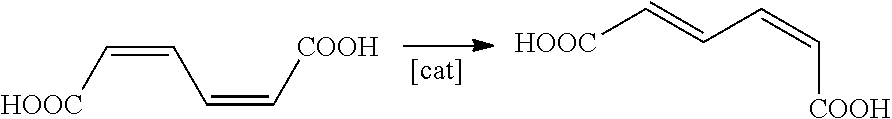

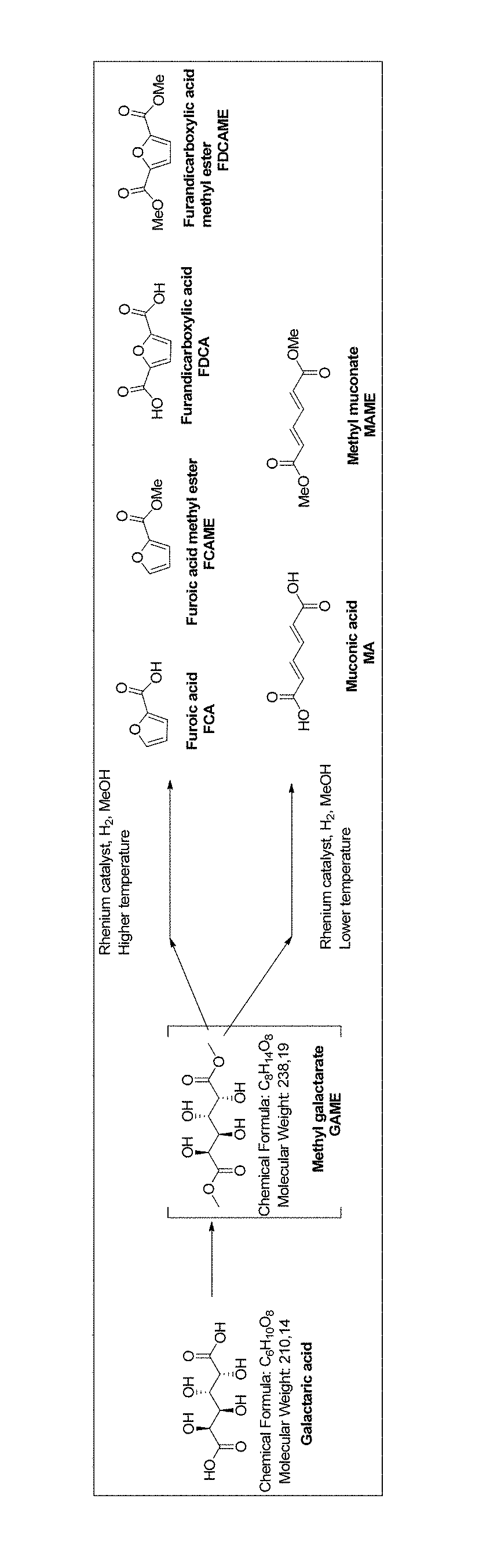

Method for producing muconic acids and furans from aldaric acids

InactiveUS20170137363A1Improve scalabilityEasy to purifyOrganic compound preparationCarboxylic acid esters preparationFuranMuconic acid

The present invention relates to selective catalytic dehydroxylation method of aldaric acids for producing muconic acid and furan chemicals, which can be used directly in fine chemical and polymer applications (FCA / FDCA) and as intermediates in the preparation of industrially significant chemicals, such as terephthalic acid, adipic acid, caprolactone, caprolactam, nylon 6.6, 1,6-hexanediol and multiple pharmaceutical building blocks (MA / MAME).

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Production of muconic acid from genetically engineered microorganisms

This present invention is in the field of producing renewable chemical feedstocks using biocatalysts that have been genetically engineered to increase their ability to convert renewable carbon resources into useful compounds. More specifically, the present invention provides a process for producing muconic acid form renewable carbon resources using a genetically modified organism.

Owner:MYRIANT CORP

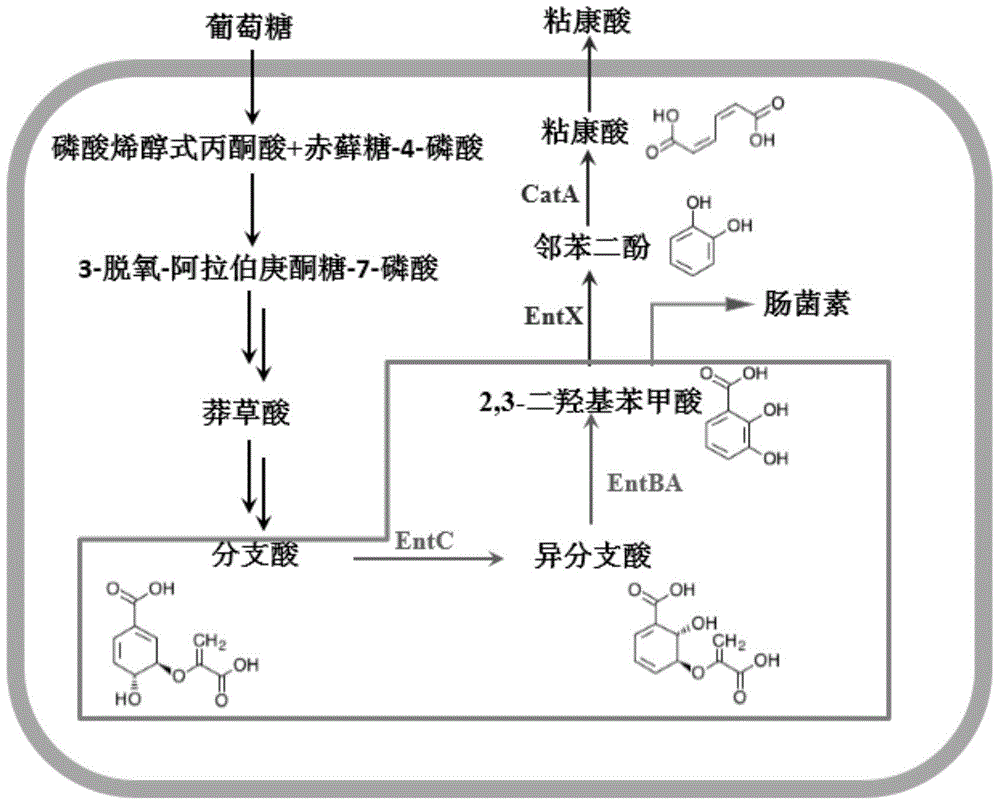

Colibacillus engineering bacterium taking glucose as substrate for synthesizing muconic acid

InactiveCN104099284AReduce the burden onReduce incompatibilityBacteriaMicroorganism based processesEscherichia coliBenzoic acid

The invention discloses a colibacillus engineering bacterium taking glucose as a substrate for synthesizing muconic acid, and belongs to the field of biotechnology. 2,3-dihydroxy benzoic acid (2,3-DHB) is led to colibacillus during the metabolic pathway of muconic acid (MA); the metabolic pathway of colibacillus from glucose to 2,3-DHB is reinforced. The colibacillus engineering bacterium has the advantages that less foreign genes are required; the foreign gene expression load of a host bacterium is reduced; the incompatibility problem of the foreign genes is solved. Moreover, the host bacteria are not auxotroph; the foreign addition of expensive shikimic acid or other aromatic amino acid is avoided; the flask shaking fermentation yield of muconic acid is 1.15 g / L.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Semi-synthetic terephthalic acid via microorganisms that produce muconic acid

The invention provides a non-naturally occurring microbial organism having a muconate pathway having at least one exogenous nucleic acid encoding a muconate pathway enzyme expressed in a sufficient amount to produce muconate. The muconate pathway including an enzyme selected from the group consisting of a beta-ketothiolase, a beta-ketoadipyl-CoA hydrolase, a beta-ketoadipyl-CoA transferase, a beta-ketoadipyl-CoA ligase, a 2-fumarylacetate reductase, a 2-fumarylacetate dehydrogenase, a trans-3-hydroxy-4-hexendioate dehydratase, a 2-fumarylacetate aminotransferase, a 2-fumarylacetate aminating oxidoreductase, a trans-3-amino-4-hexenoate deaminase, a beta-ketoadipate enol-lactone hydrolase, a muconolactone isomerase, a muconate cycloisomerase, a beta-ketoadipyl-CoA dehydrogenase, a 3-hydroxyadipyl-CoA dehydratase, a 2,3-dehydroadipyl-CoA transferase, a 2,3-dehydroadipyl-CoA hydrolase, a 2,3-dehydroadipyl-CoA ligase, a muconate reductase, a 2-maleylacetate reductase, a 2-maleylacetate dehydrogenase, a cis-3-hydroxy-4-hexendioate dehydratase, a 2-maleylacetate aminoatransferase, a 2-maleylacetate aminating oxidoreductase, a cis-3-amino-4-hexendioate deaminase, and a muconate cis / trans isomerase. Other muconate pathway enzymes also are provided. Additionally provided are methods of producing muconate.

Owner:GENOMATICA INC

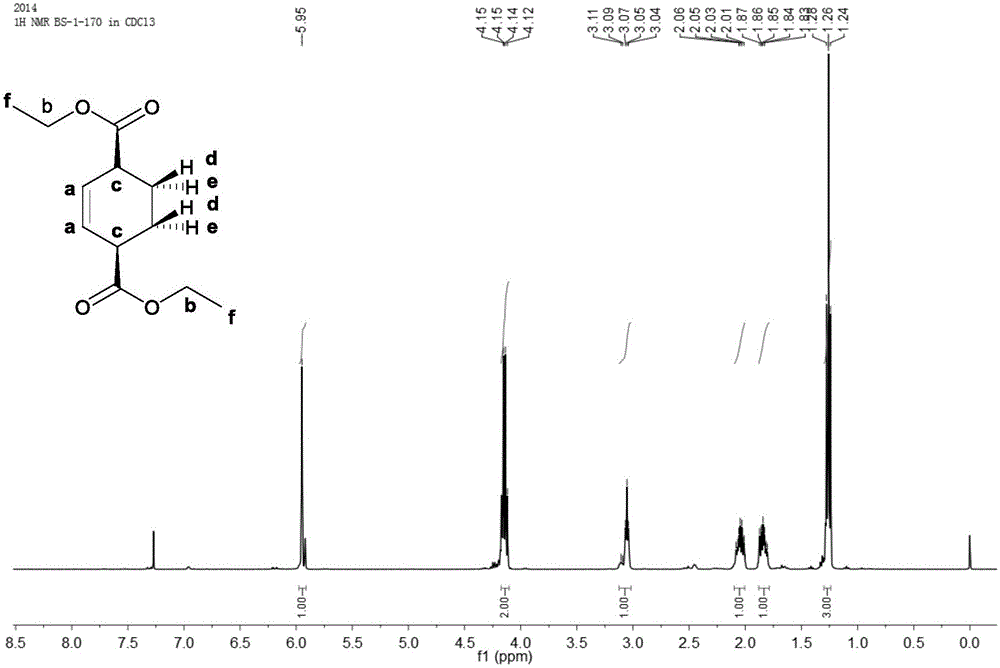

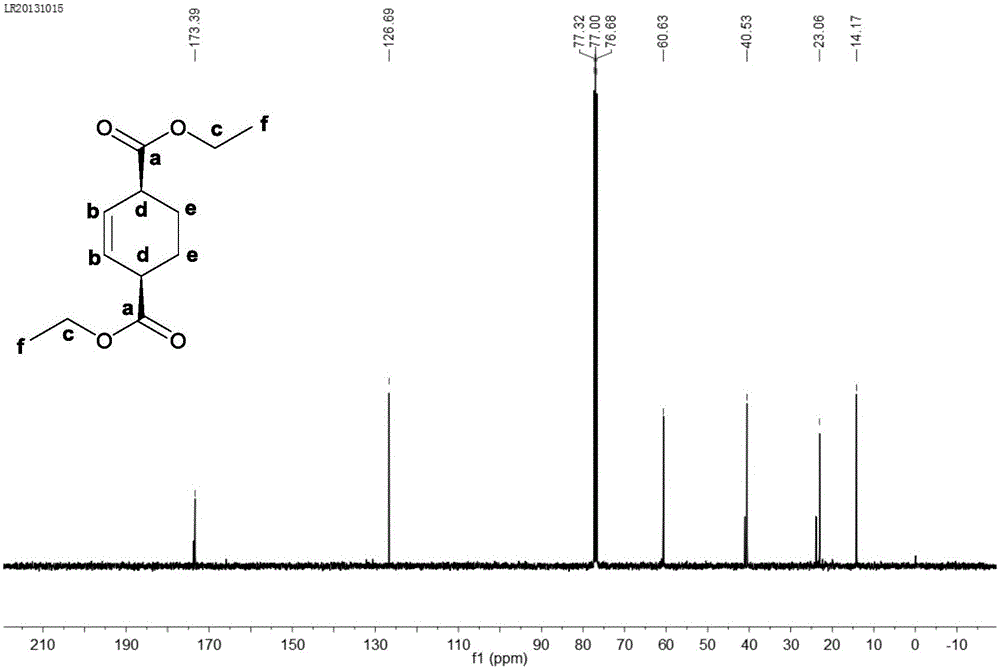

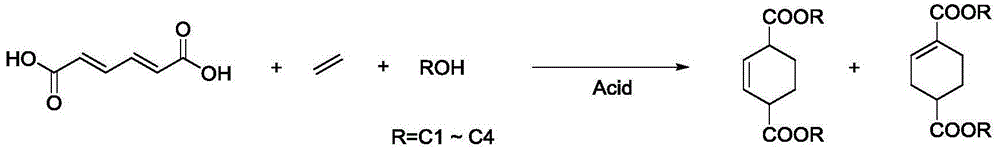

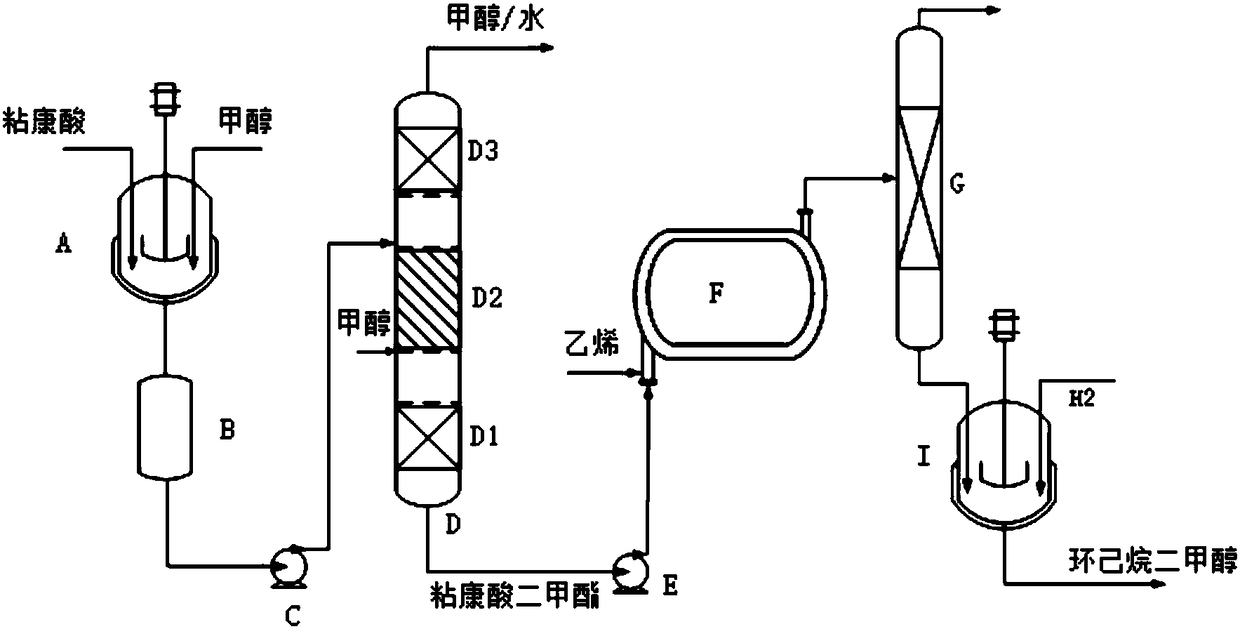

Preparation method of cyclohexene-1, 4-dicarboxylic acid diester

InactiveCN106467466AReduce dependenceOrganic compound preparationCarboxylic acid esters preparationSolid acidCycloaddition

The invention discloses a preparation method of cyclohexene-1, 4-dicarboxylic acid diester. The preparation method comprises that ethene gas under a certain pressure is fed into trans, trans-muconic acid as a raw material, and the raw material and low carbon fatty alcohol undergo a reaction at a certain temperature in the presence of an acid catalyst so that after the esterification and Diels-Alder cycloaddition reactions, cyclohexene-1, 4-dicarboxylic acid diester is high selectively prepared, wherein the acidic catalyst is a protonic acid and / or solid acid catalyst, the low carbon fatty alcohol comprises one or more of C1-C4 monohydric alcohols and dihydric alcohols, the pressure of ethylene is 0.1 to 10MPa, a reaction temperature is 100 to 300 DEG C, and the reaction time is 0.1 to 10 hours. When the trans, trans-muconic acid conversion rate is 99%, total selectivity of the cyclohexene-1, 4-dicarboxylic acid diester is 99% or more.

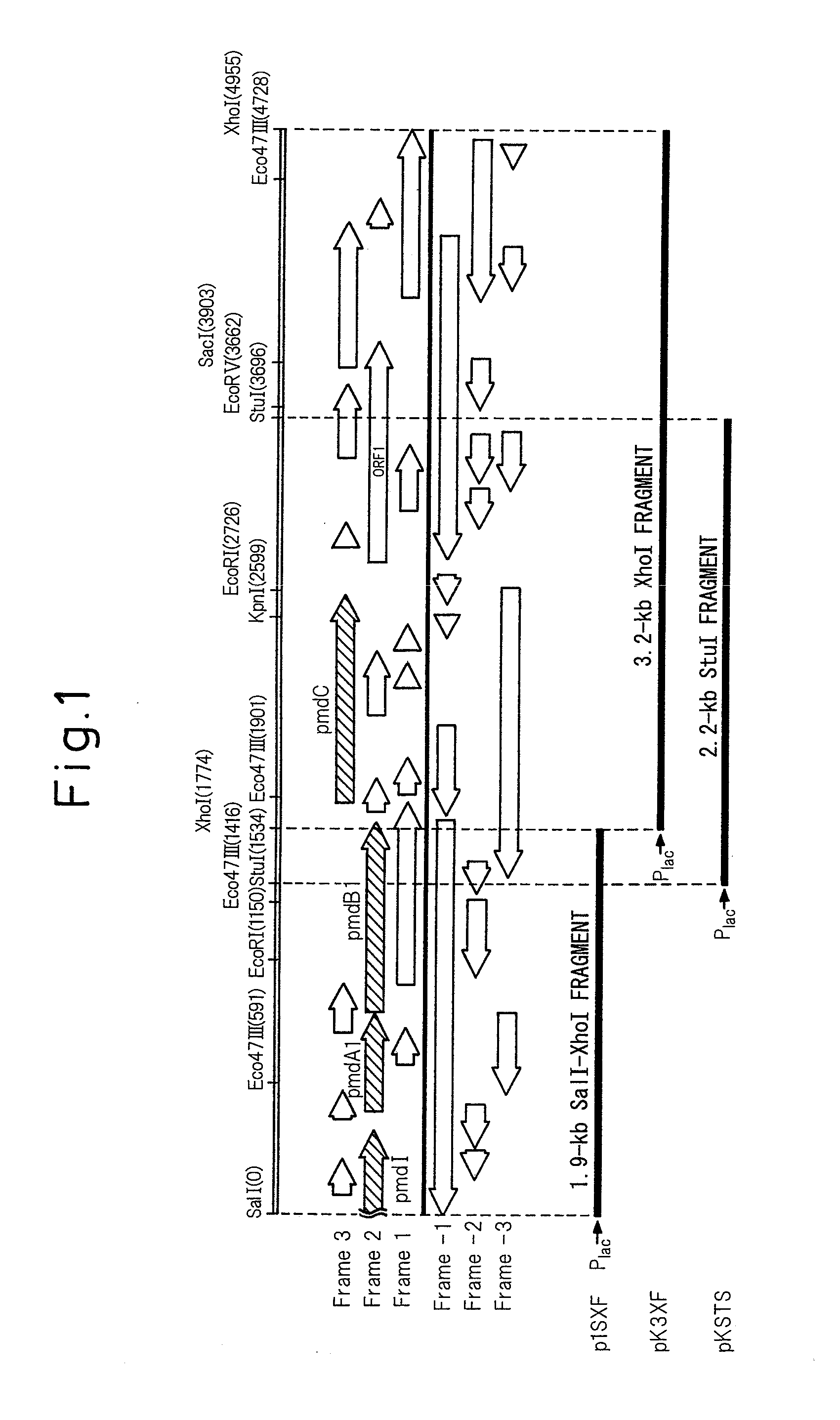

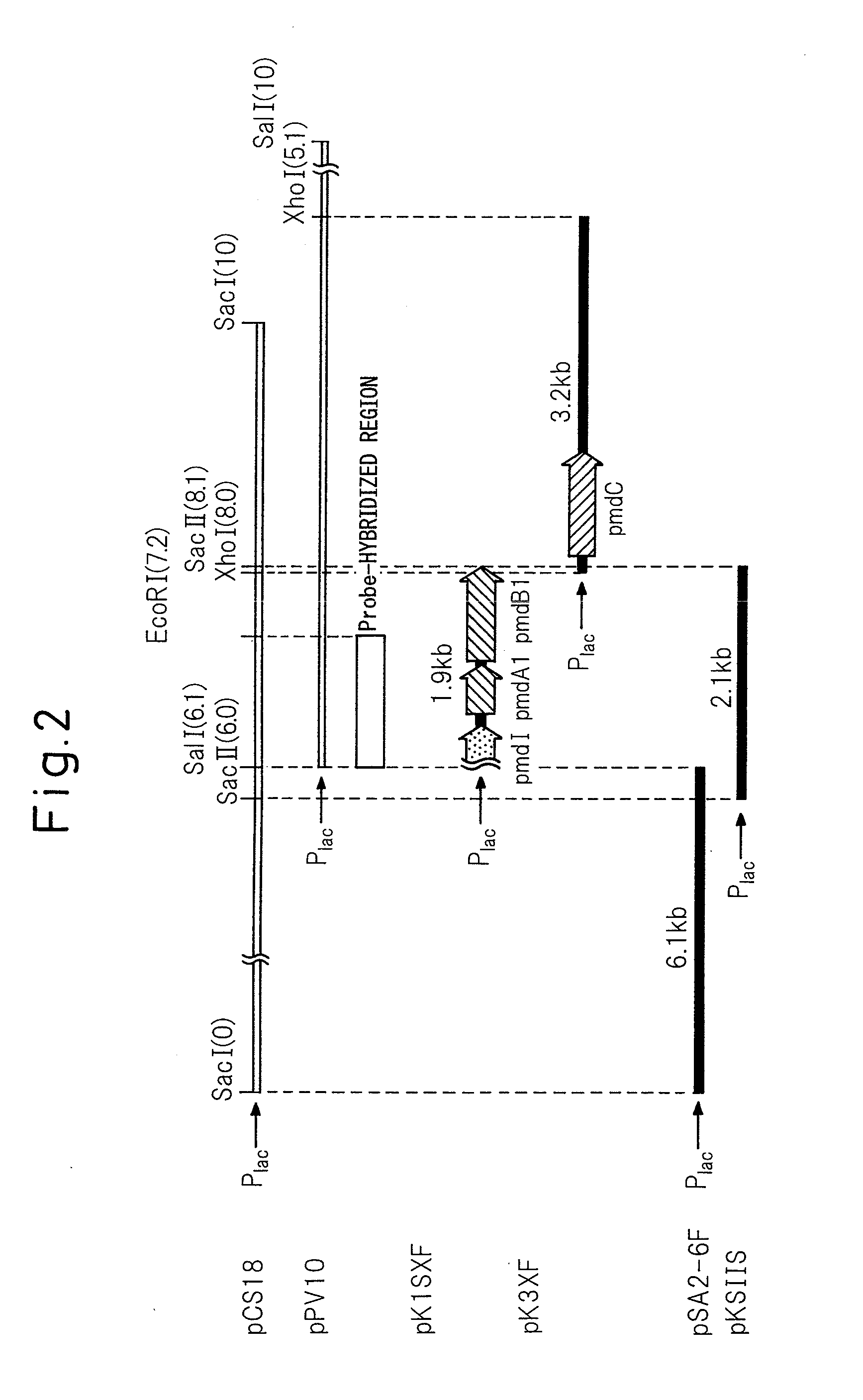

Plasmid, transformants and process for production of 3- carboxymuconolactone

ActiveUS8211683B2High yieldHigh-yield and inexpensive fermentative productionBacteriaOxidoreductasesVanillic acidMuconic acid

Owner:FORESTRY & FOREST PRODS RES INST

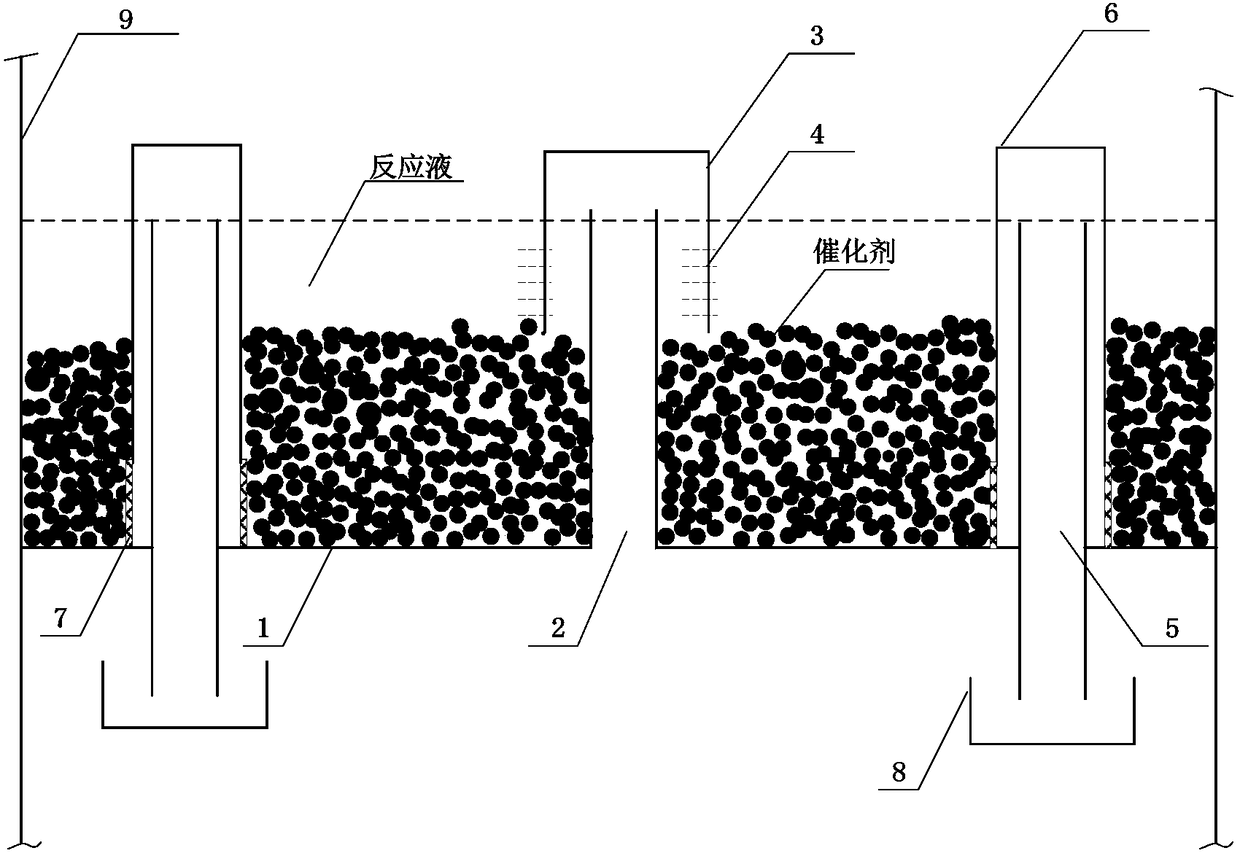

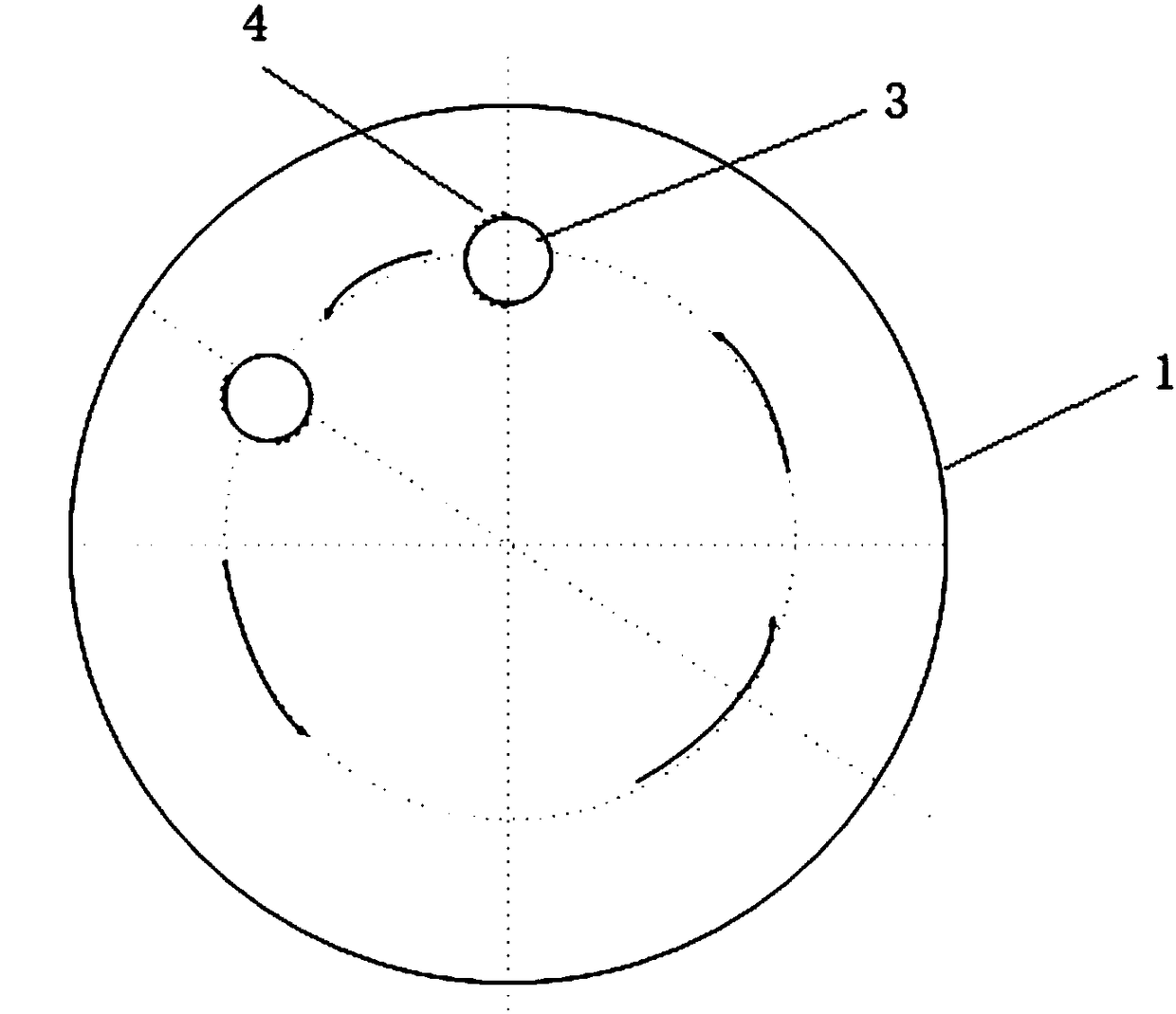

Preparation technology and device of cyclohexanedimethanol

ActiveCN108083978AReduce usageReduce consumptionMolecular sieve catalystsOrganic compound preparationCyclohexanedimethanolMuconic acid

The invention discloses a preparation technology and device of cyclohexanedimethanol. Cyclohexanedimethanol is prepared from biomaterial muconic acid as a raw material through an esterification reaction, a Diels-Alder reaction and a hydrogenation reaction. The complete biomaterial muconic acid is used in the route, use of petrochemical resources is significantly reduced, hydrogen consumption is low, and the reaction yield is high.

Owner:WANHUA CHEM GRP CO LTD

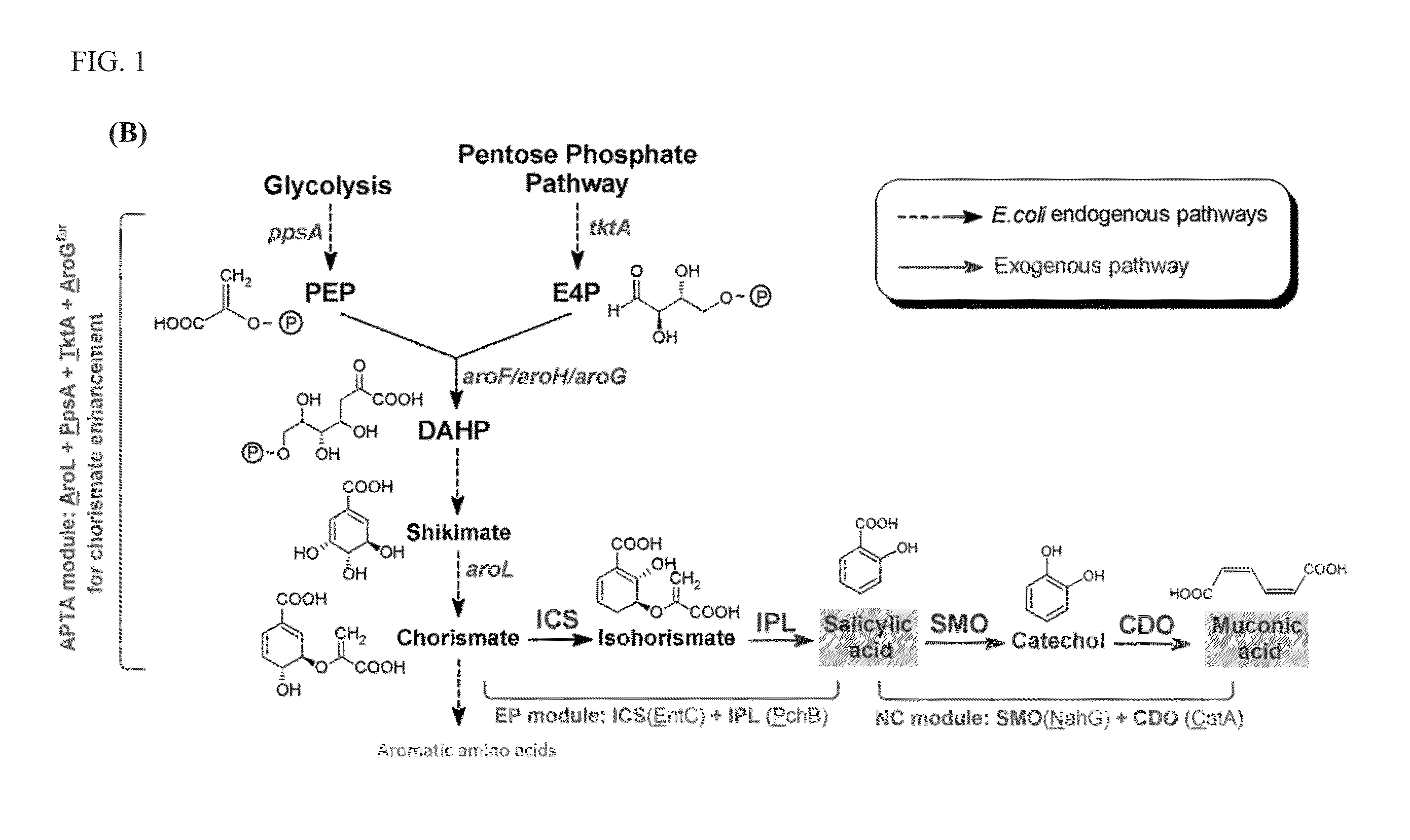

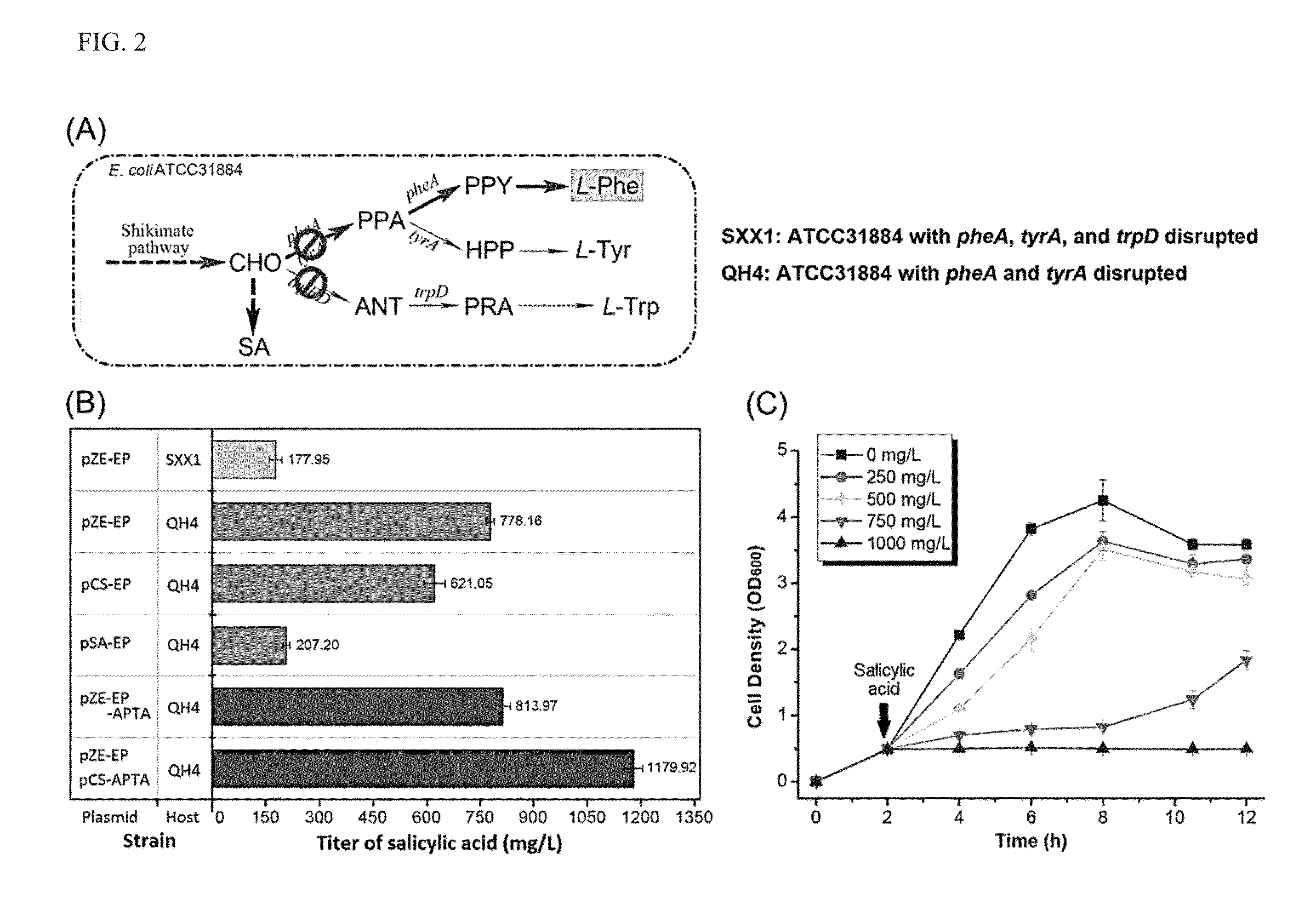

Microbial production of muconic acid and salicylic acid

Owner:UNIV OF GEORGIA RES FOUND INC

Process for preparing caprolactam and polyamides therefrom

Provided herein are processes for preparing caprolactam from a starting material such as one or more of the cis,cis-, cis,trans- and trans,trans-double-bond isomers of muconamide, muconic acid ester, or muconic acid. The starting material, intermediates, and caprolactam prepared therefrom can contain carbon atoms derived from biomass containing detectable 14C content determined according to ASTM D6866 and optionally containing a 14C content up to 0.0000000001% (one part per trillion). Caprolactam so prepared can be used to make various polyamides.

Owner:AMYRIS INC

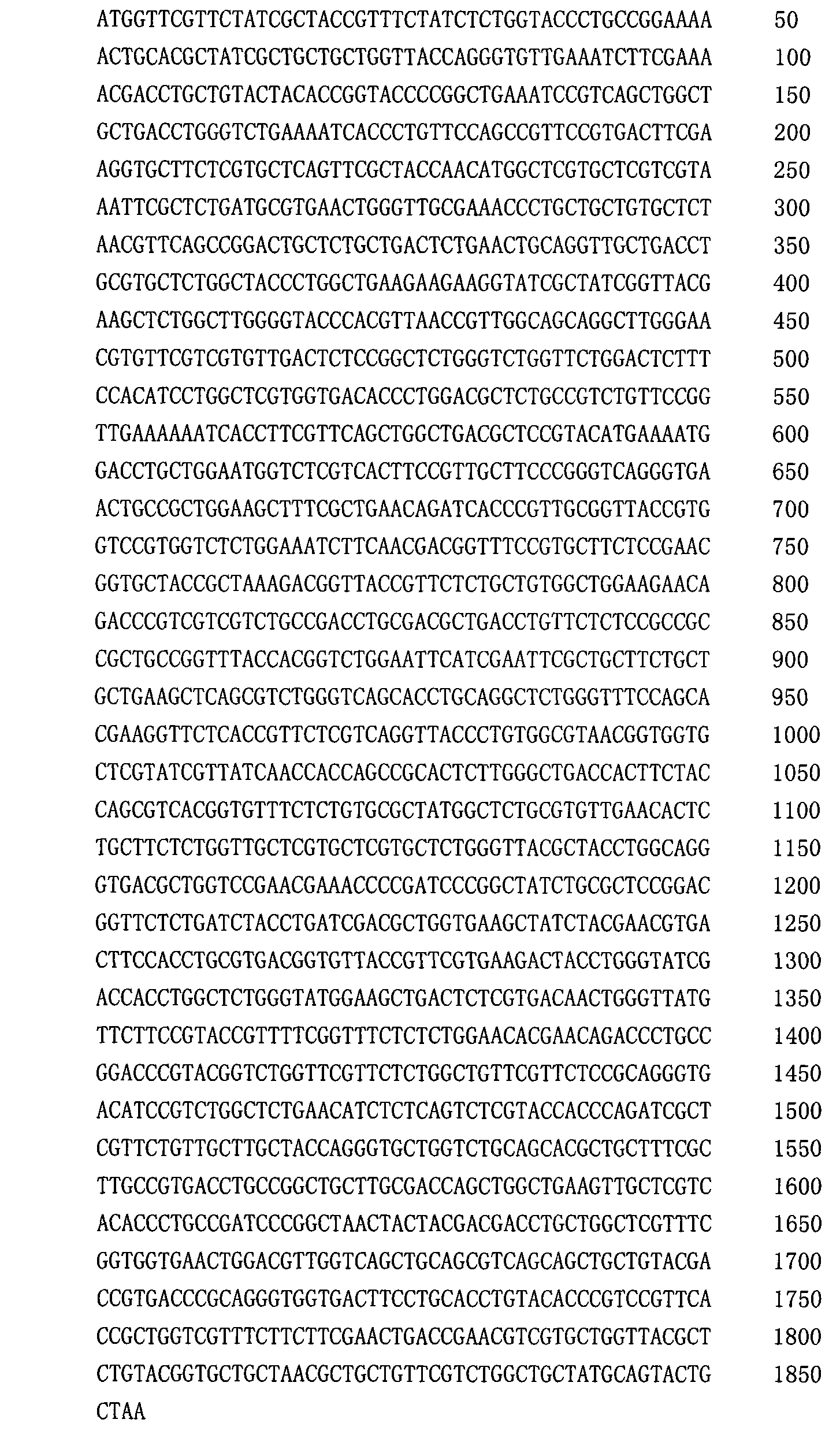

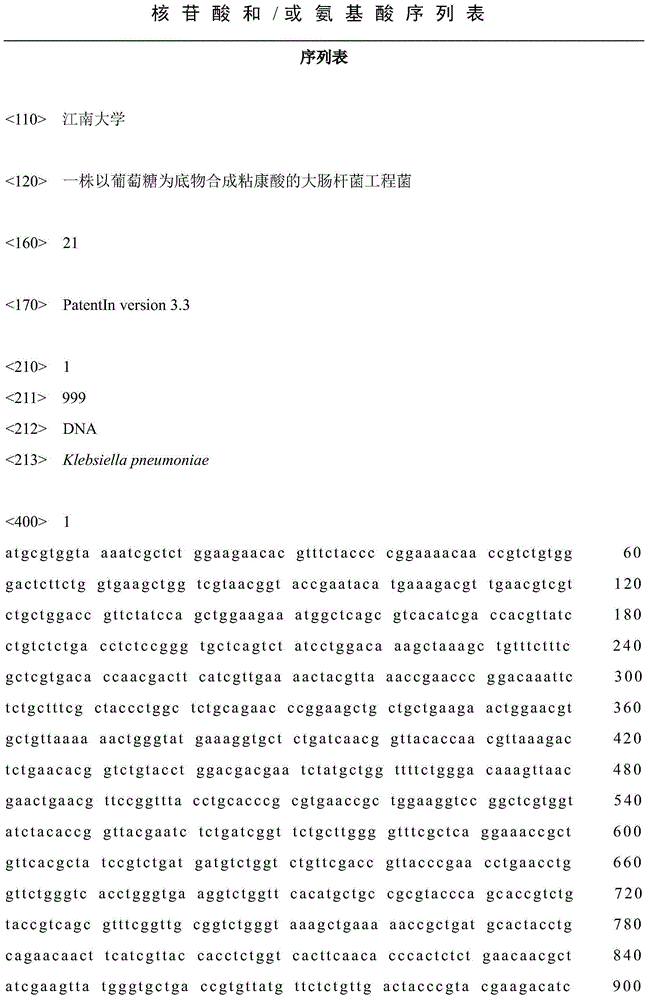

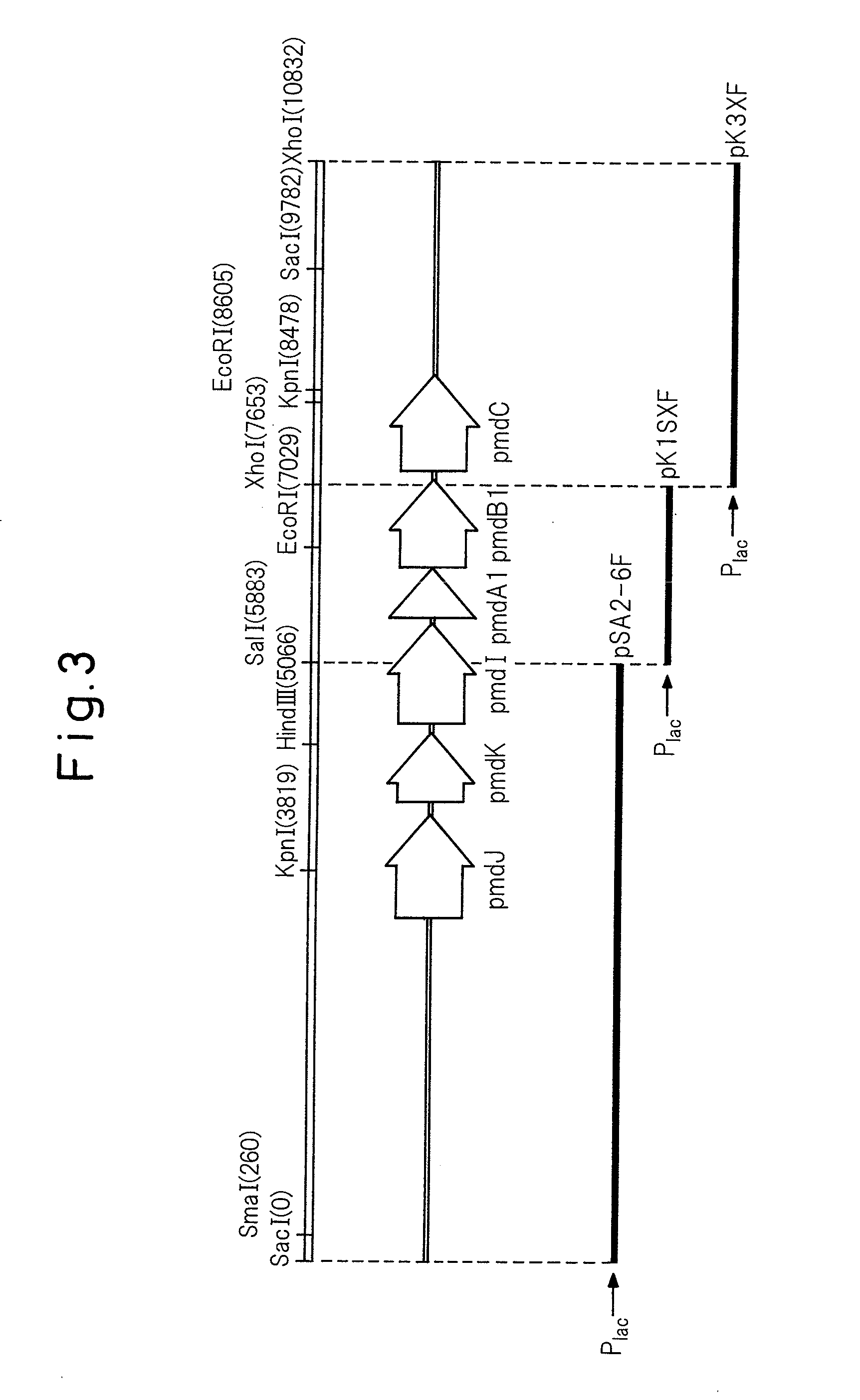

Gene-disrupted strain, recombinant plasmids, transformants and process for production of 3-carboxymuconolactone

Industrial-scale fermentative production of 3-carboxy-cis,cis-muconic acid from terephthalic acid. Also, a protocatechuate 4,5-ring-cleaving enzyme gene-disrupted strain in which the gene coding for (a) the amino acid sequence set forth in SEQ ID NO: 1 or 3, or (b) the amino acid sequence set forth in SEQ ID NO: 1 or 3 which has a deletion, substitution, addition and / or insertion of one or more amino acids and exhibits protocatechuate 4,5-ring cleavage activity, present in the chromosomal DNA of microbial cells, has been disrupted; recombinant plasmids comprising the Tph gene and protocatechuate 3,4-dioxygenase gene; transformants obtained by introducing the recombinant plasmids into the disrupted strain; and a process for production of 3-carboxy-cis,cis-muconic acid and / or 3-carboxymuconolactone characterized by culturing the transformants in the presence of terephthalic acid.

Owner:TOYOTA IND CORP +3

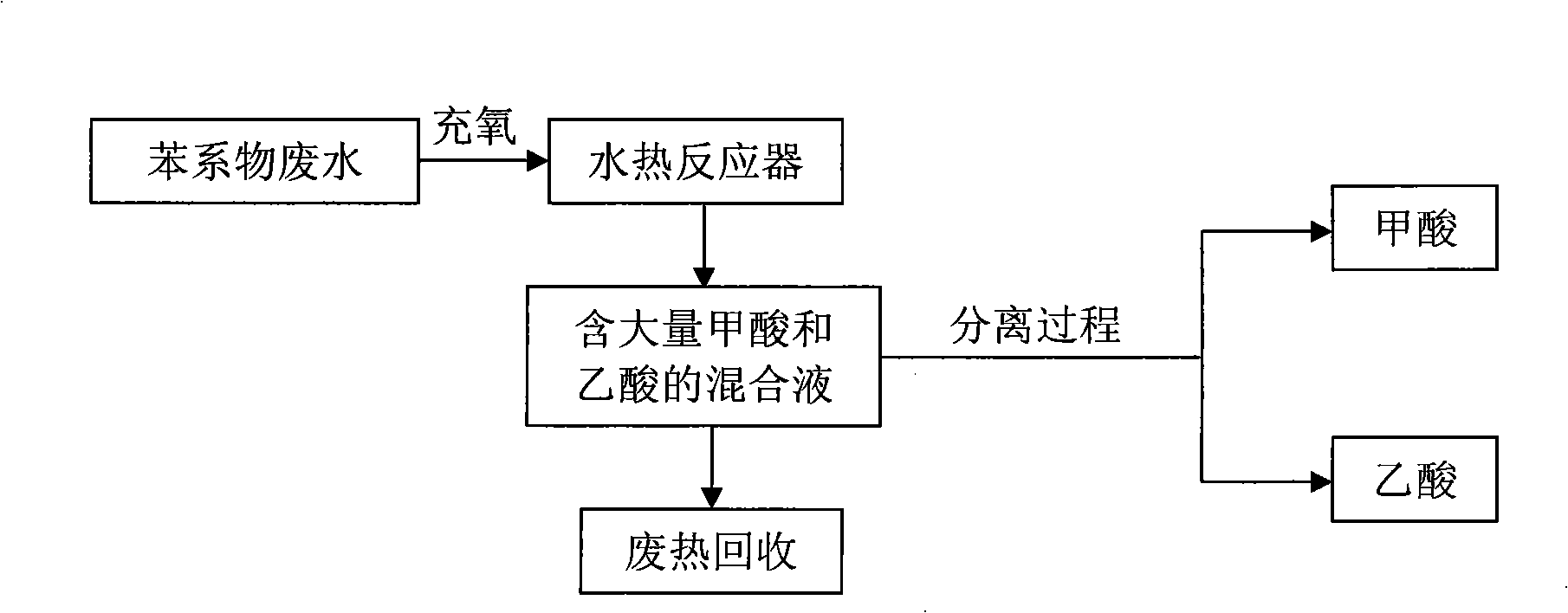

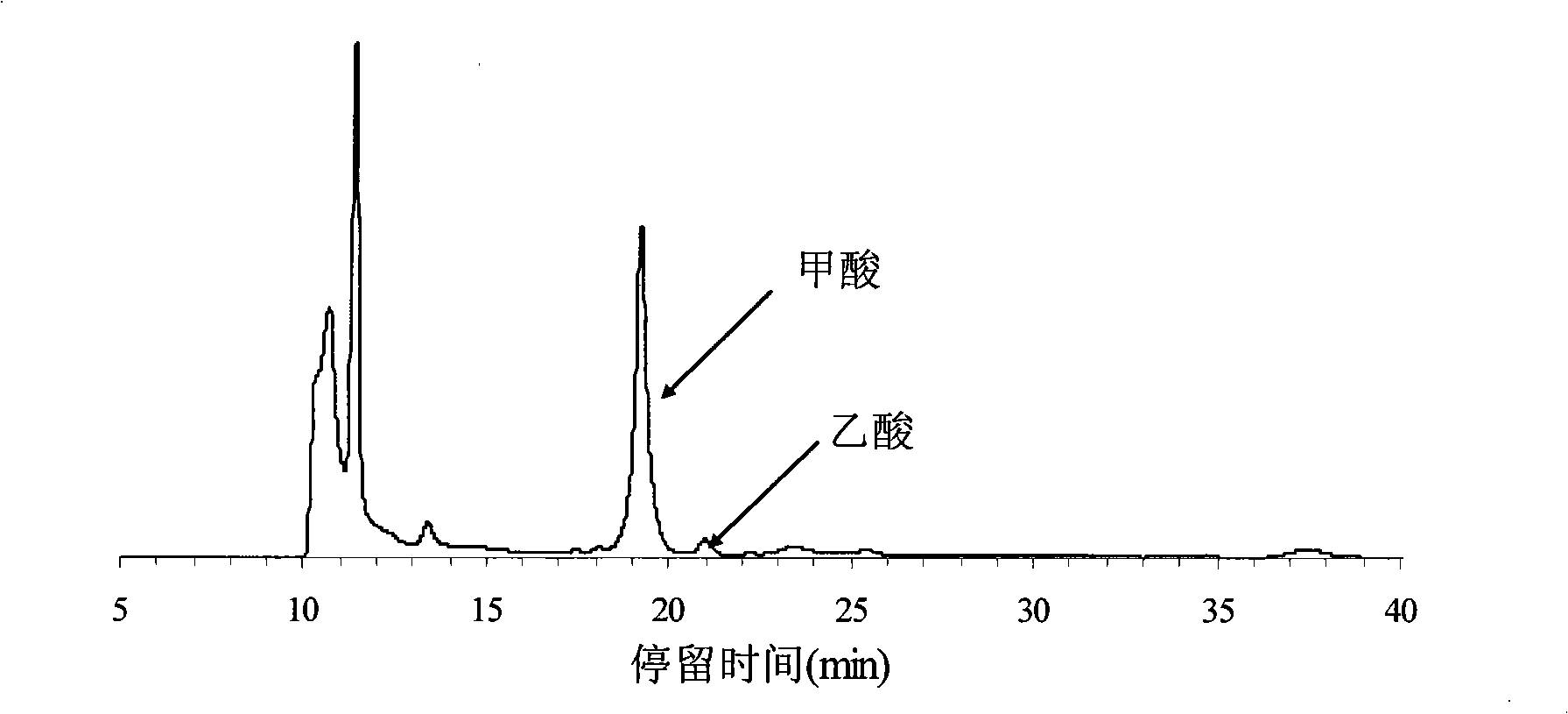

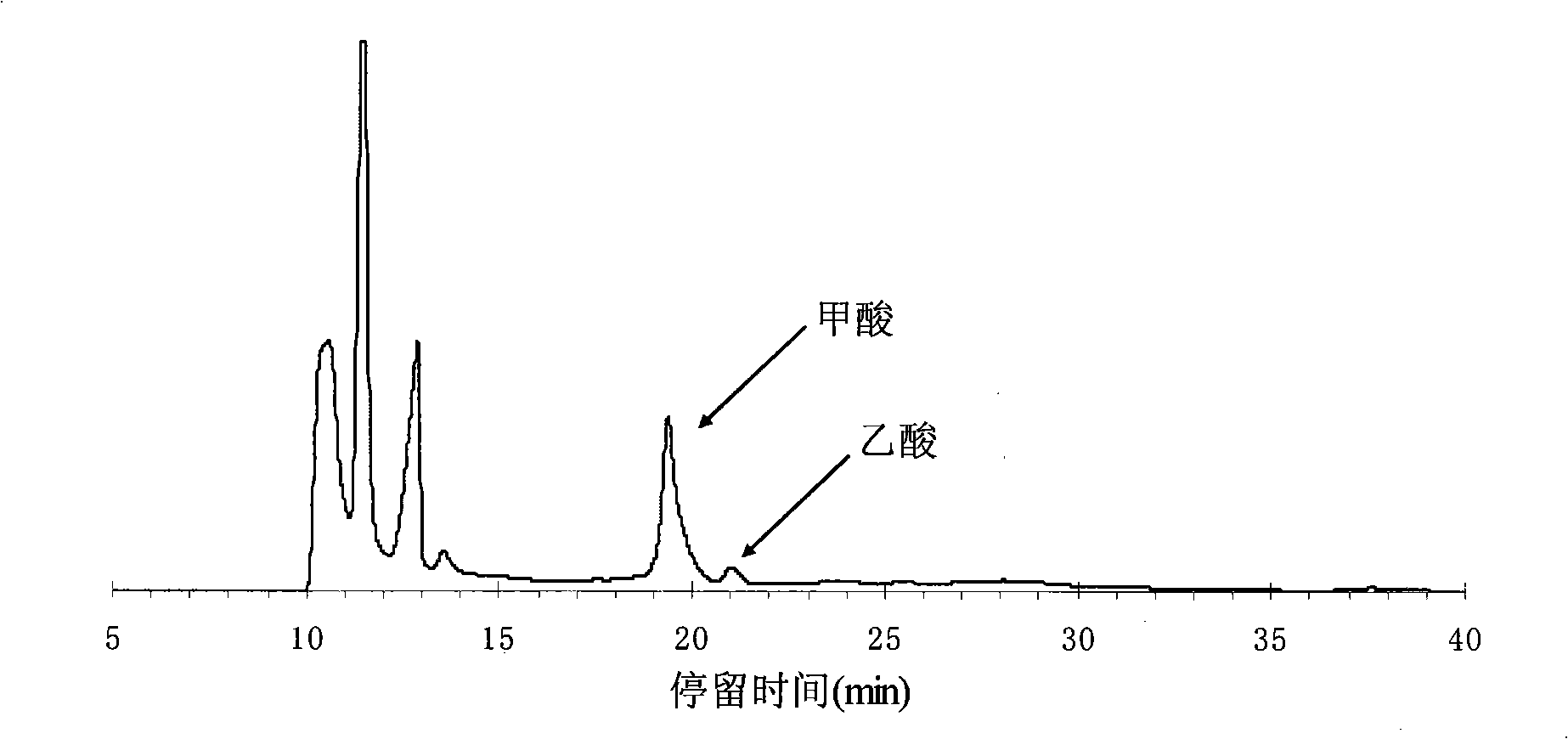

Method for preparing low-grade aliphatic acid from benzene and its homologues waste water

InactiveCN101260031AIncrease concentrationLow costCarboxylic preparation by oxidationDecompositionResource utilization

The invention relates to a method of using benzene series wastewater to prepare low-class fatty acid, in particular to a method of transforming benzene series wastewater into formic acid and acetic acid. The benzene series material of the invention is the organic matter with the molecular structure containing benzene rings. Benzene series wastewater and oxygen (oxygen gas, air or hydrogen peroxide) are first input into a hydrothermal oxidation reactor; then reaction is carried out under the conditions that: the temperature is 200-450 DEG C; the pressure is 5-20 Mpa; the pH value is 7-14; the addition amount of oxygen is 10-200 percent of the needed oxygen content to oxidize all carbon contained in the benzene series material of wastewater into CO2; reaction time is from 30 s to 30 min. The benzene series material is first oxidized to crack benzene rings, generate muconic acid and other unsaturated diacid; a great amount of formic acid and acetic acid is generated further by controlling the hydrothermal oxidation reaction of unsaturated diacid; finally mixed solution containing a great amount of formic acid and acetic acid is separated to prepare formic acid and acetic acid. Differing from the prior method of realizing mineralization through the thermal oxidative decomposition of wastewater, the invention aims to transform wastewater containing benzene series material into formic acid and acetic acid products which can be utilized, so as to realize the resource utilization of wastes.

Owner:TONGJI UNIV

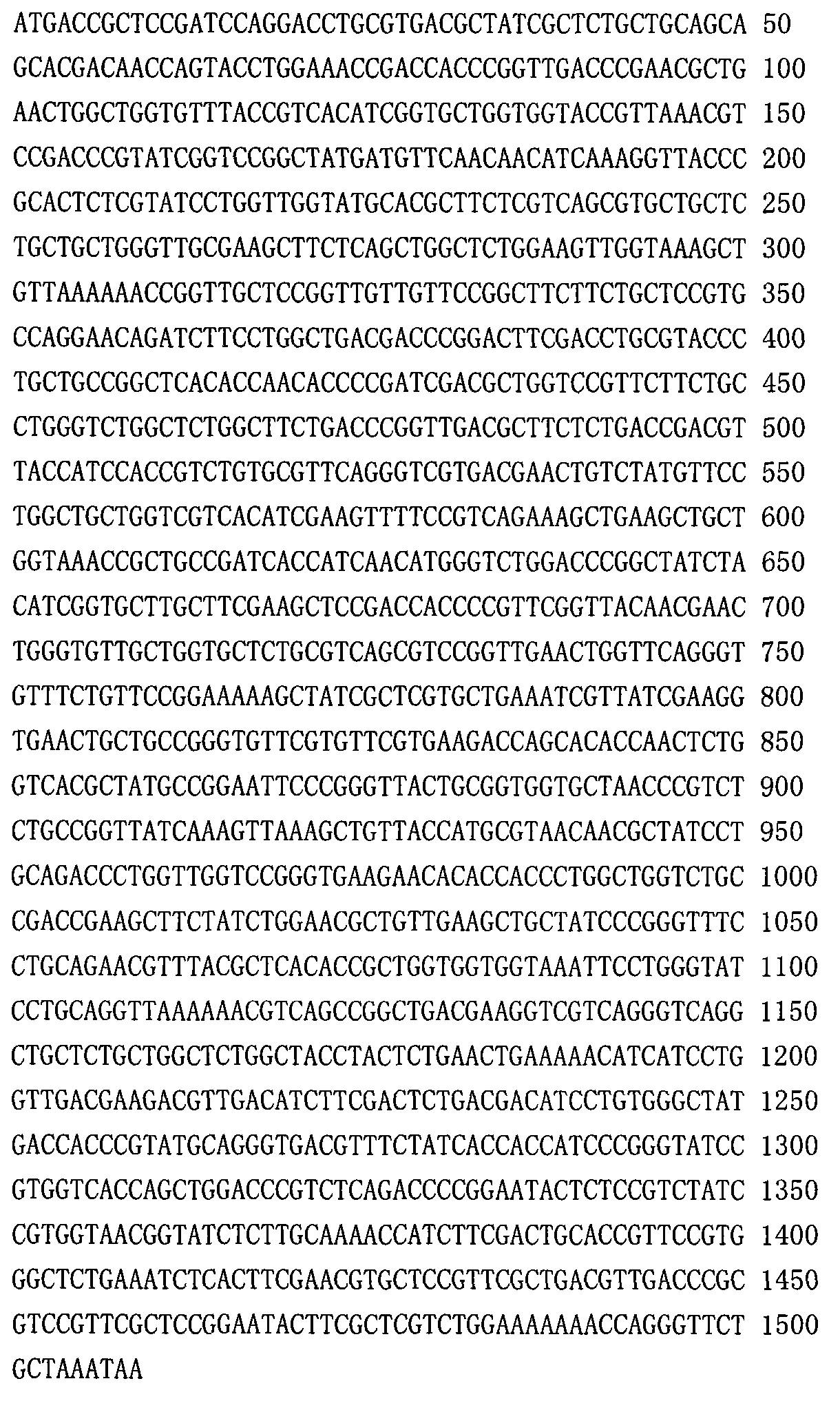

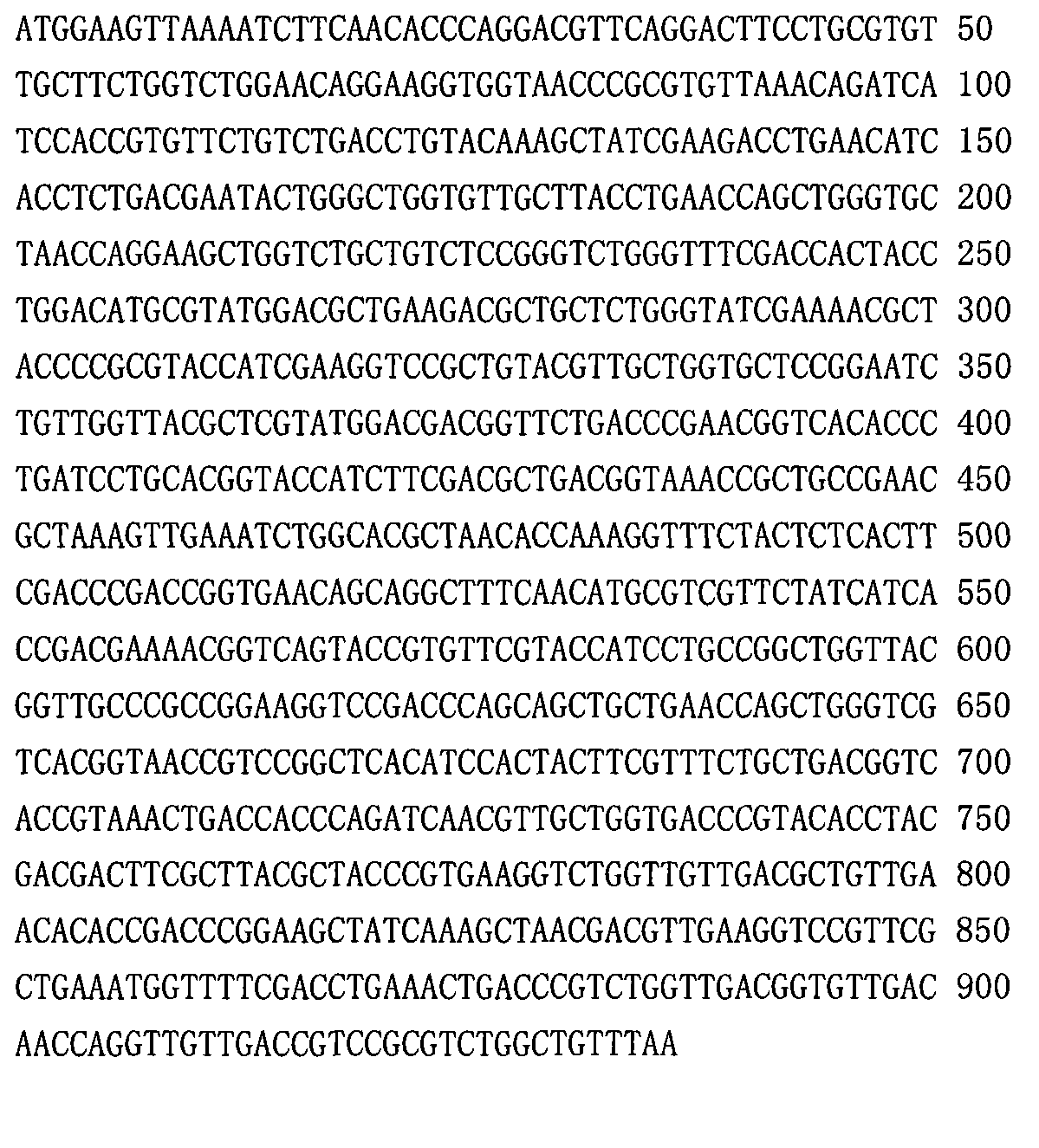

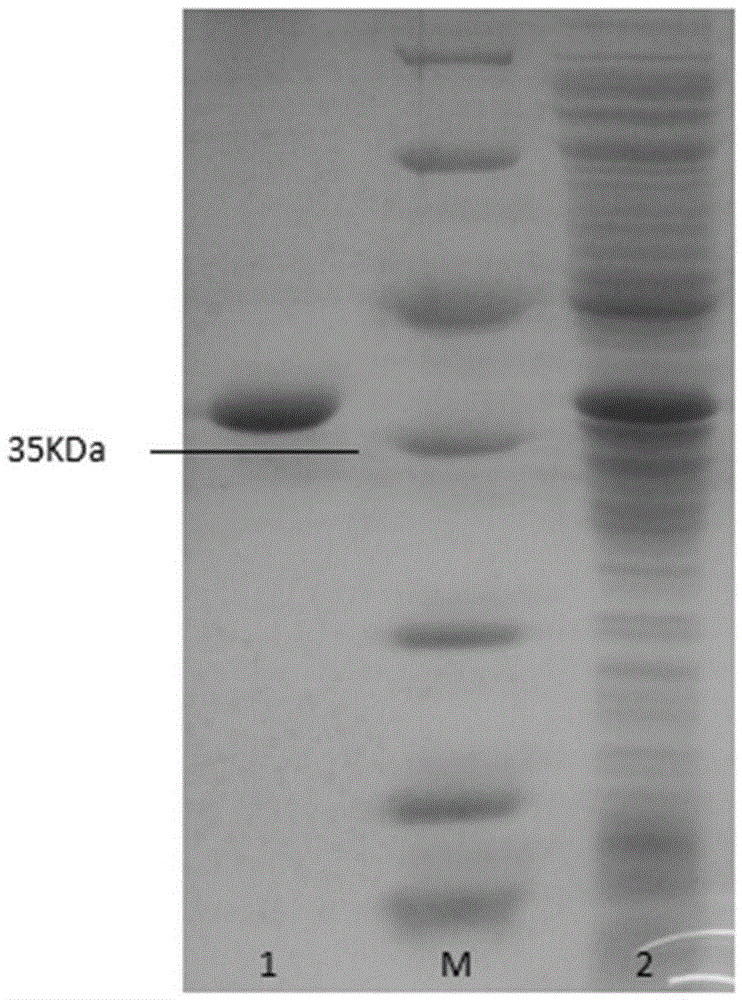

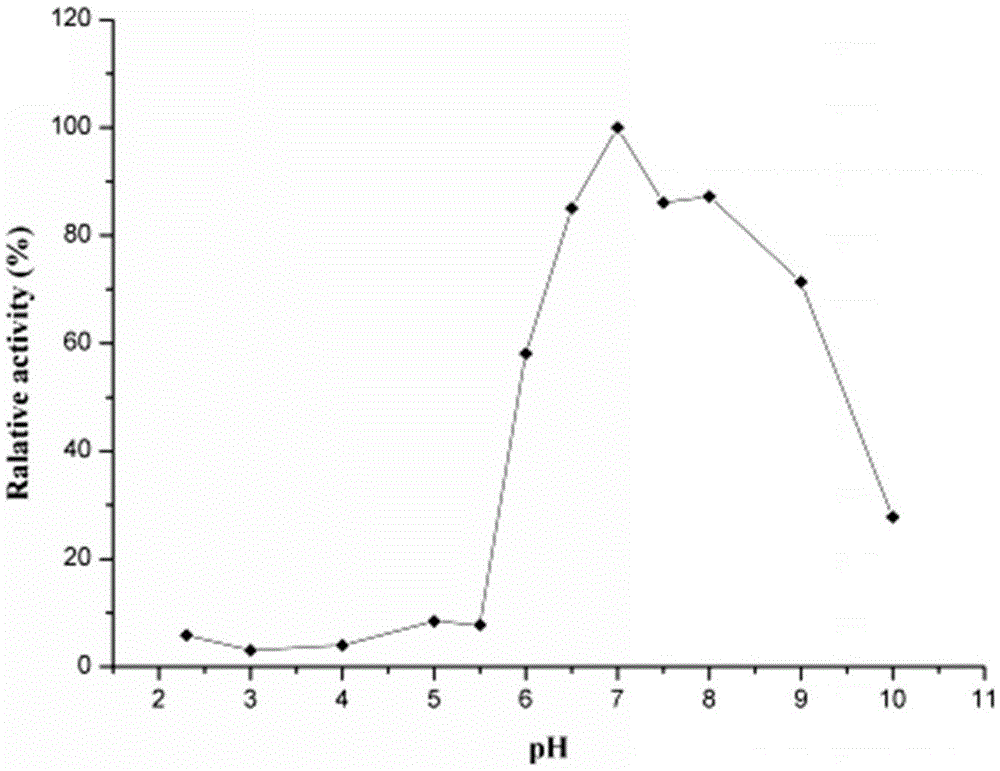

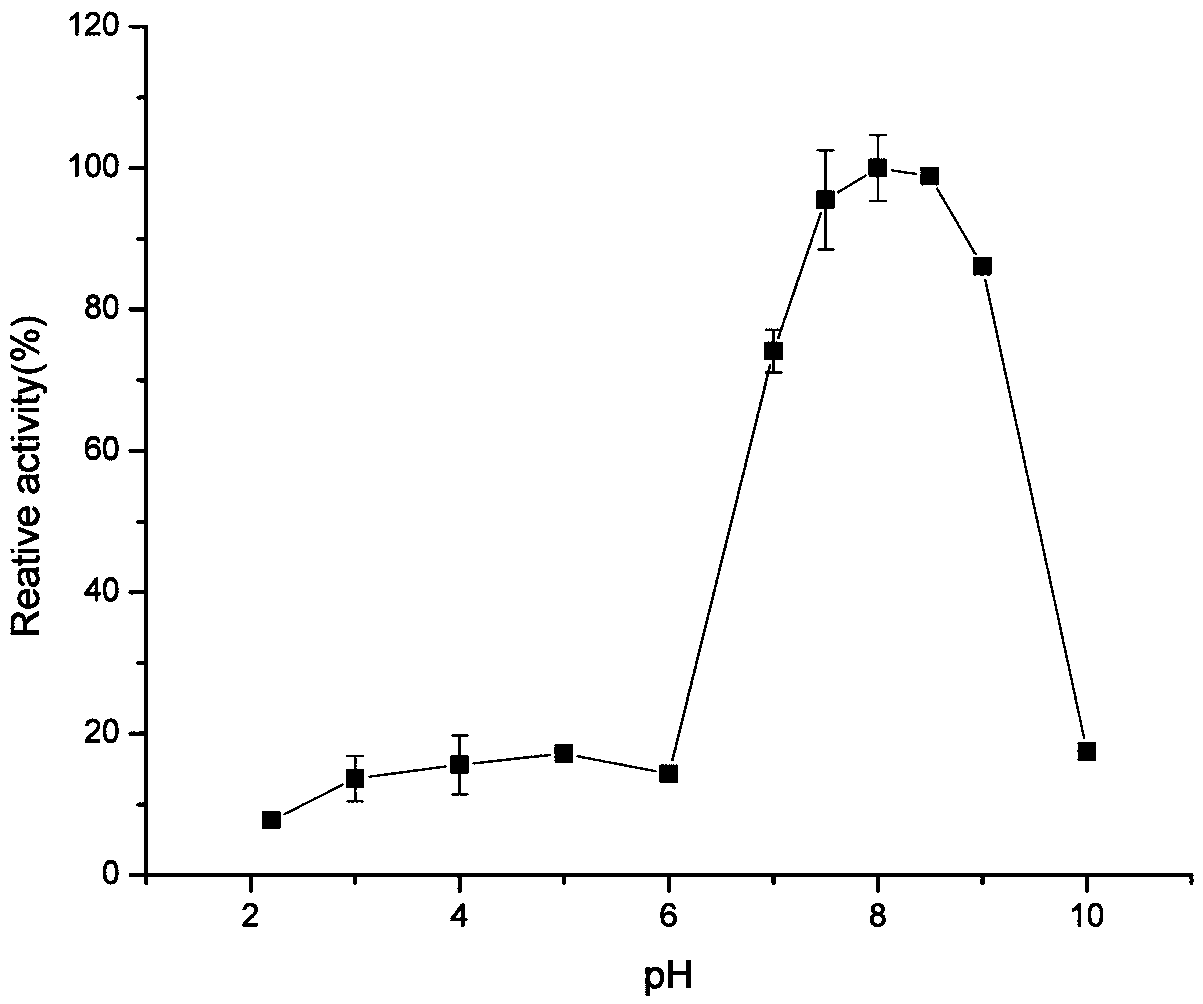

Heat-stable catechol 1,2-dioxygenase derived from animal manure metagenome and coding gene thereof, and preparation method of heat-stable catechol 1,2-dioxygenase

ActiveCN105567651AInhibit enzyme activityEnhanced inhibitory effectOxidoreductasesFermentationPolycyclic aromatic hydrocarbonMuconic acid

The invention discloses a heat-stable catechol 1,2-dioxygenase derived from animal manure metagenome. The amino acid sequence is disclosed as SEQ ID NO.2, the catechol 1,2-dioxygenase has 283 amino acids, and the theoretical molecular weight is 31.91kDa. The nucleotide sequence of the coding gene is disclosed as SEQ ID NO.1, and the gene size is 852bp. The optimal action pH of the heat-stable catechol 1,2-dioxygenase is 7.0; after the catechol 1,2-dioxygenase is used for treatment within the pH range of 7.0-10.0 for 1 hour, the residual enzyme activity is 90% or above. The optimal action temperature is 40 DEG C; after the catechol 1,2-dioxygenase resists the temperatures of 25 DEG C and 40 DEG C for 210 hours, the enzyme activity is basically not influenced, and thus, the catechol 1,2-dioxygenase is a typical heat-stable enzyme; and the catechol 1,2-dioxygenase can be used for enzyme-process synthesis of cis-cis-muconic acid and degradation of polycyclic aromatic hydrocarbons.

Owner:YUNNAN NORMAL UNIV

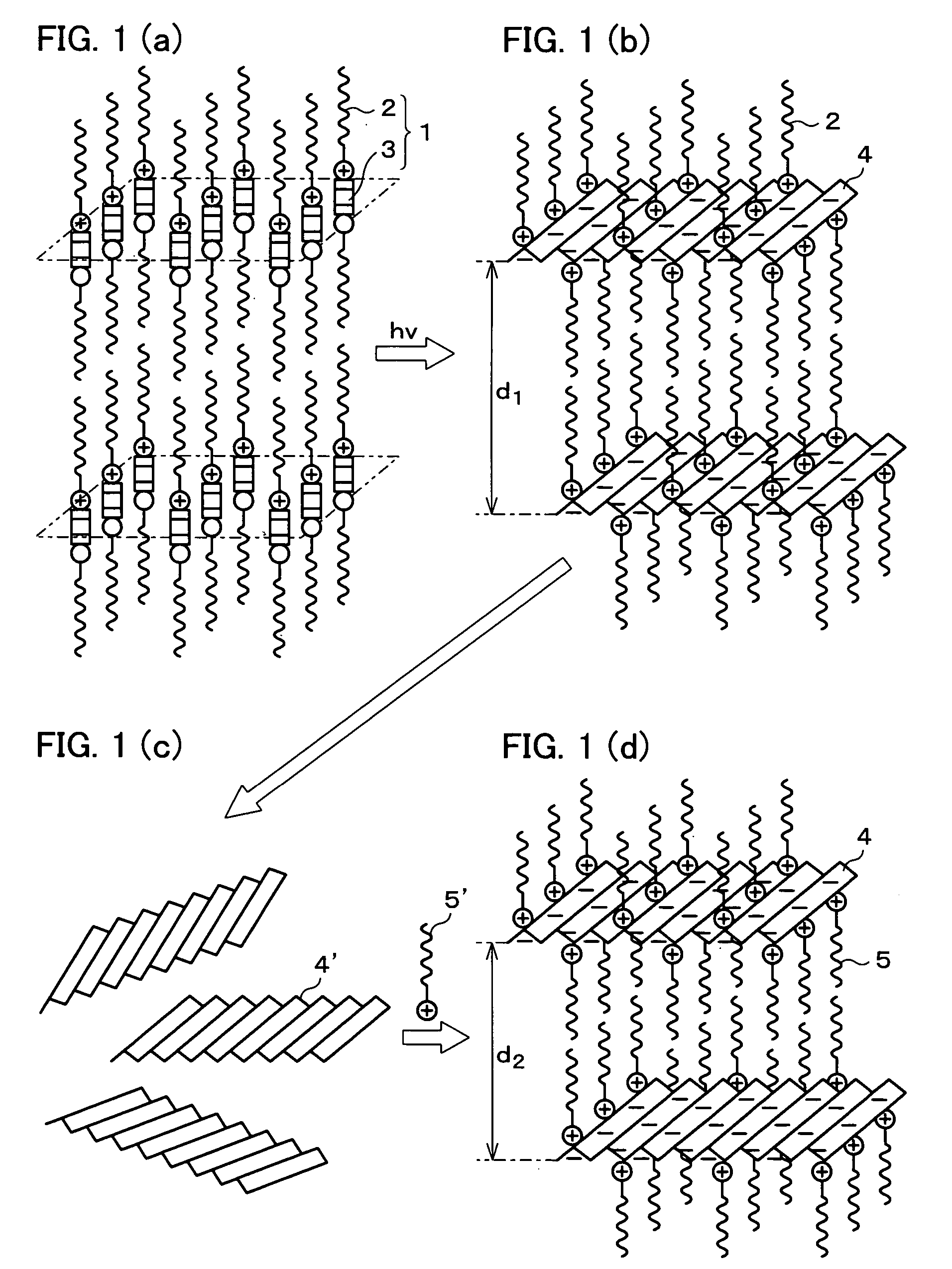

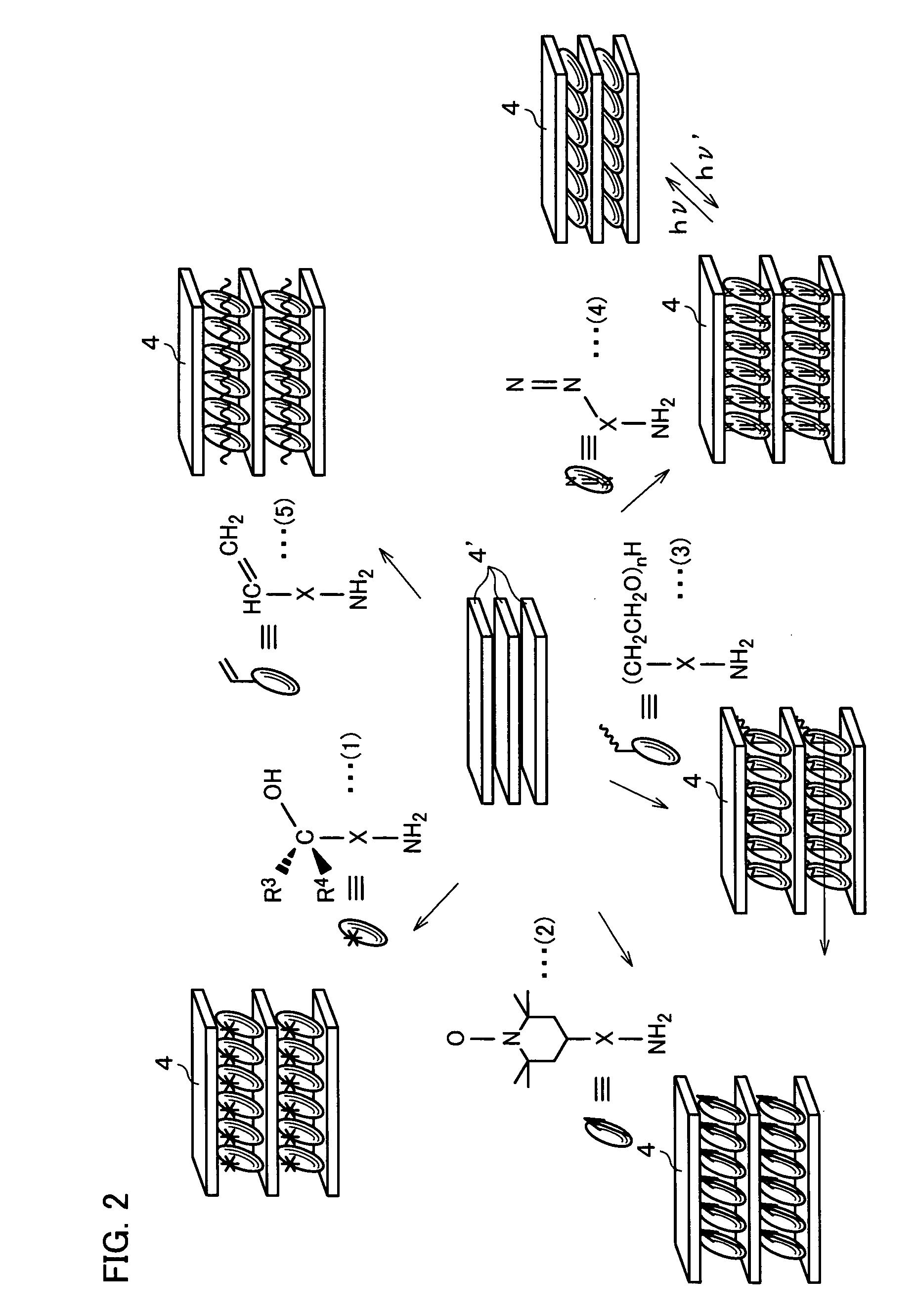

Photoresponsive polymer, built-up type diacetylene polymer, crystals of ammonium carboxylates, and processes for production of them

InactiveUS20050038284A1Increase absorbanceImprove electrical performanceOrganic chemistryLamellar crystalsPolymer science

A crystal of carboxyl acid and at least one compound selected from the group consisting of amine and ammonia are mixed in an absence of a liquid medium. The carboxyl acid is conjugated diene such as (Z,Z)-muconic acid, the conjugated diene including a carboxyl group. The at least one nitrogen-containing compound selected from the group consisting of amine and ammonia is primary amine represented by RCH2NH2, where R is an aryl group, or is a normal alkyl group that contains five or more carbon atoms. Moreover, such amine that is a bivalent group and that is represented by -Ar-N═N-Ar′-, where Ar and Ar′ are independently aromatic hydrocarbon bivalent groups, is intercalated in a layered crystal of a polymer such as polymuconic acid, the layered crystal including a carboxyl group. In this way, a novel photoresponsive polymer is obtaind. Also obtained is a crystal of ammonium carboxylate including at least one kind of carboxyl acid and at least one kind of amine, at least one kind of compound selected from (i) the at least one kind of carboxyl acid and (ii) the at least one kind of amine being a diacetylene derivative. The crystal of ammonium carboxylate is subjected to light or heat, to obtain a built-up type diacetylene polymer.

Owner:JAPAN SCI & TECH CORP

Process for producing nylon-6,6

The present invention relates to a process for producing nylon-6,6 by a) providing a muconic acid starting material selected from muconic acid, esters of muconic acid, lactones of muconic acid and mixtures thereof, b) subjecting the muconic acid starting material provided in step a) at least to some extent to a reaction with hydrogen in the presence of at least one hydrogenation catalyst Hb) to give adipic acid, c1) subjecting the muconic acid starting material provided in step a) to some extent to a reaction with hydrogen in the presence of at least one hydrogenation catalyst Hc1) to give 1,6-hexanediol, or c2) subjecting the adipic acid obtained in step b) to some extent to a reaction with hydrogen in the presence of at least one hydrogenation catalyst Hc2) to give 1,6-hexanediol, d) subjecting the 1,6-hexanediol obtained in step c1) or c2) to amination in the presence of an amination catalyst to obtain hexamethylenediamine, e) subjecting the hexamethylenediamine obtained in step d) and at least a portion of the adipic acid obtained in step b) to polycondensation to obtain nylon-6,6.

Owner:BASF AG

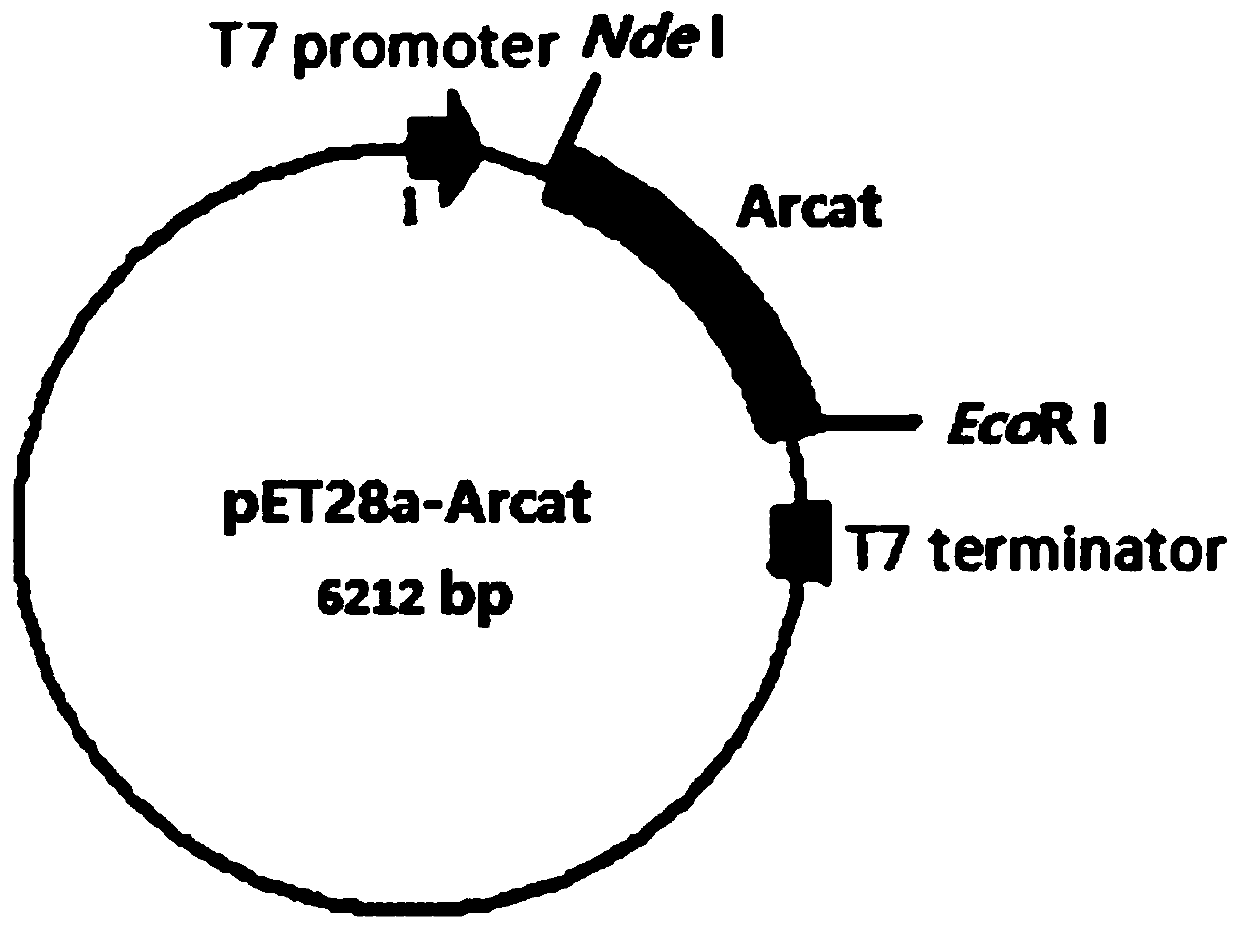

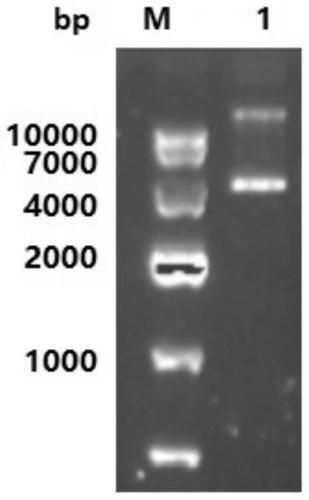

Catechol 1,2-dioxygenase gene and application thereof in synthesis of 4-position substituted cis,cis-muconic acid

ActiveCN111254151AIncrease productionSubstitute Shun improveBacteriaMicroorganism based processesMuconic acidNucleotide

The invention belongs to the field of biotechnology and gene engineering, and particularly discloses a catechol 1,2-dioxygenase gene and an application thereof in synthesis of 4-position substituted cis,cis-muconic acid. The nucleotide sequence of a catechol 1,2-dioxygenase coding gene is shown in SEQ ID NO.1. The expression product catechol 1,2-dioxygenase of the gene can efficiently catalyze 4-position substituted catechol to generate the corresponding 4-position substituted cis,cis-muconic acid. The invention also provides a method for performing whole-cell catalysis to prepare the 4-position substituted cis,cis-mucoconic acid by using a batch feeding strategy; and the method has the advantages of simple process, mild reaction conditions, environmental friendliness, accords with the concept of green economic development, and provides a simple and convenient way for safe and mass production.

Owner:NANJING UNIV OF TECH

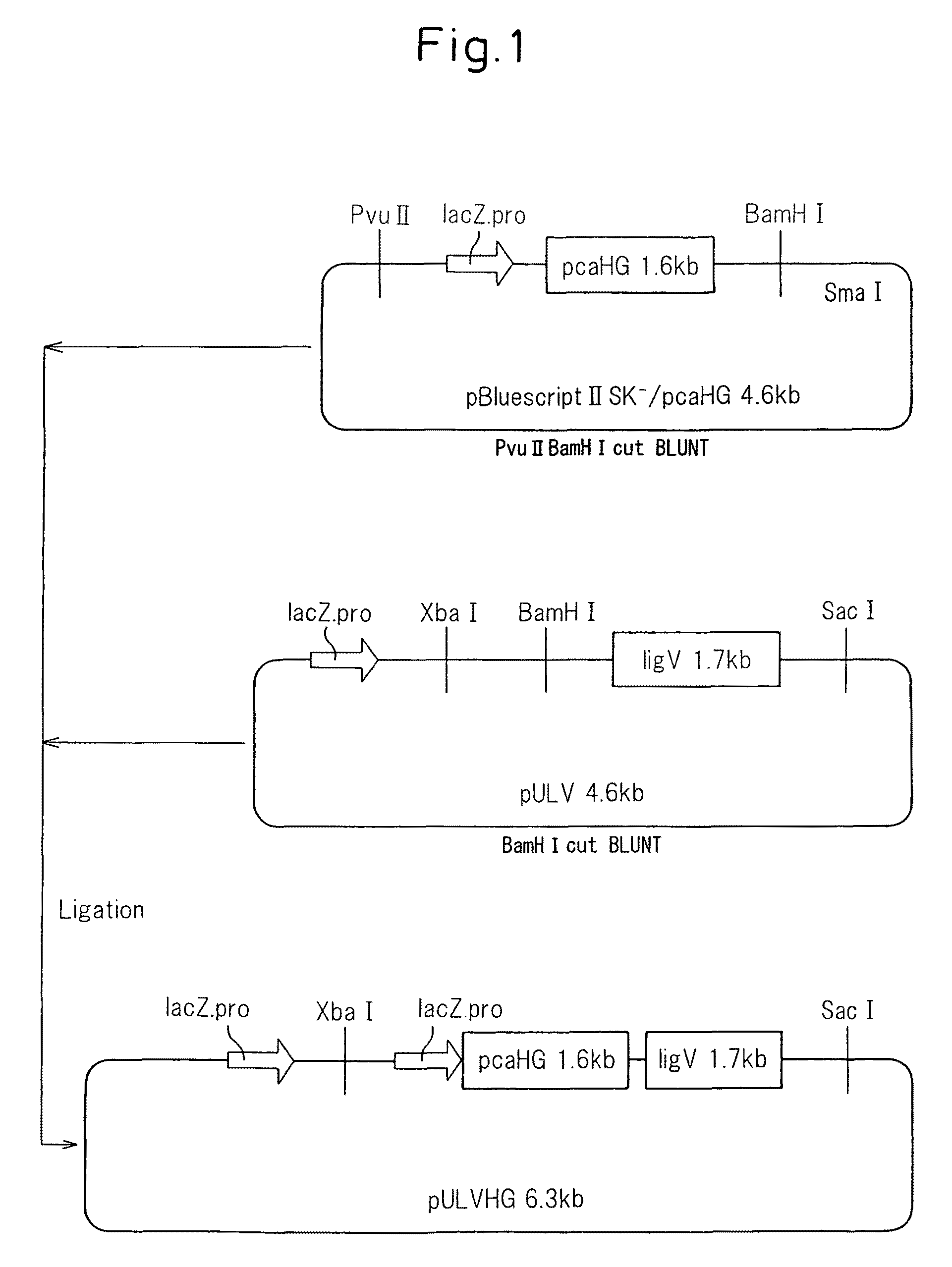

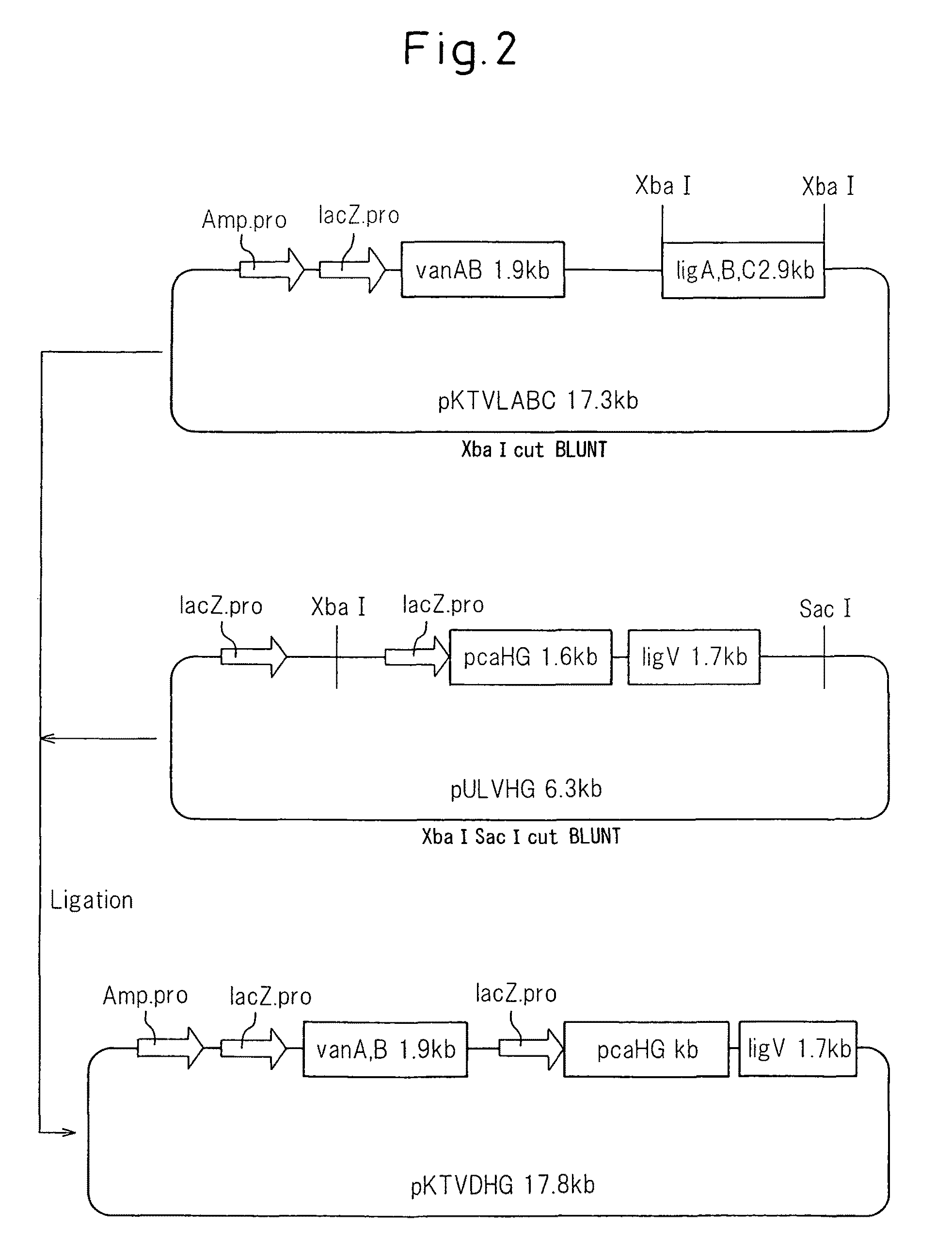

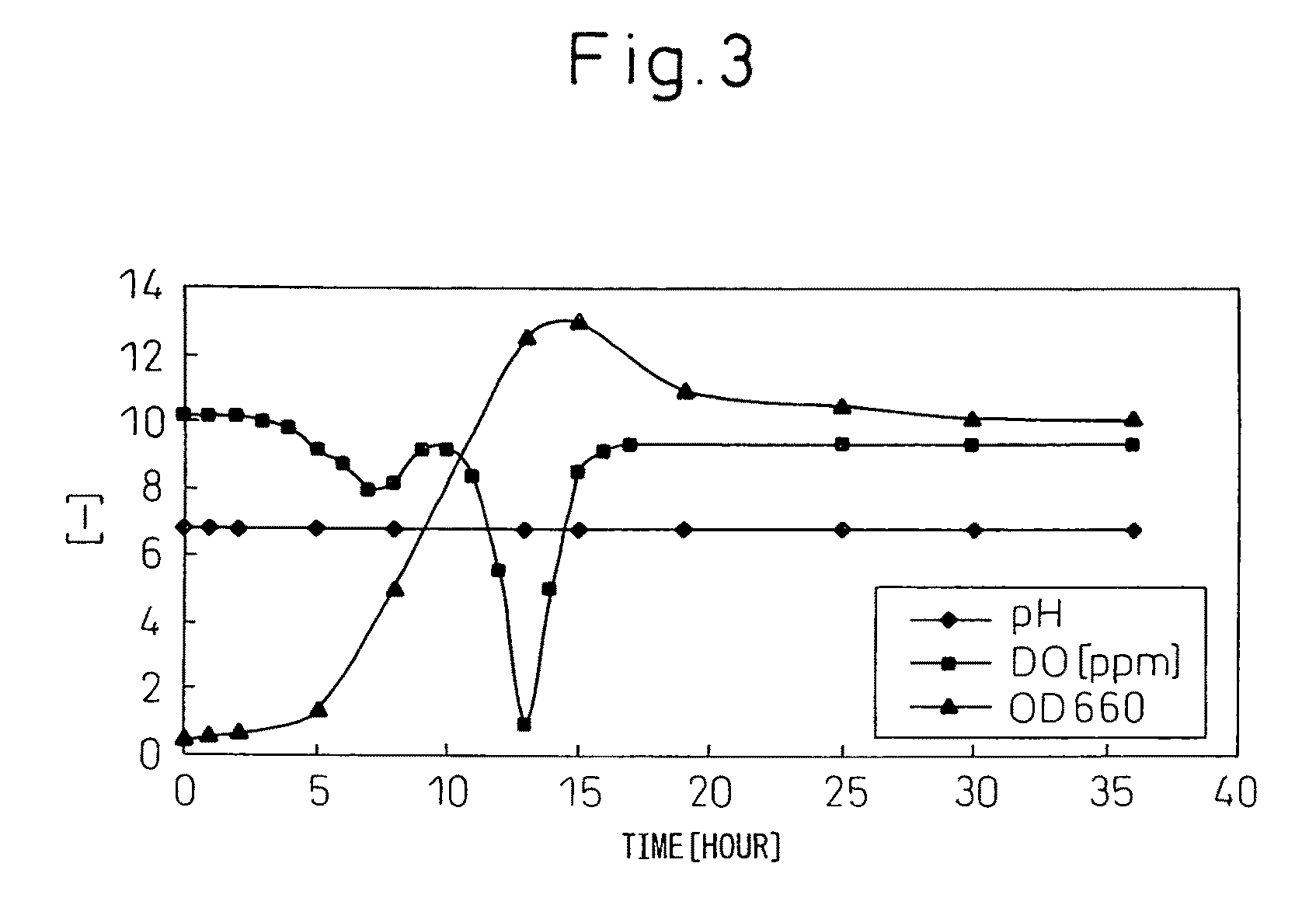

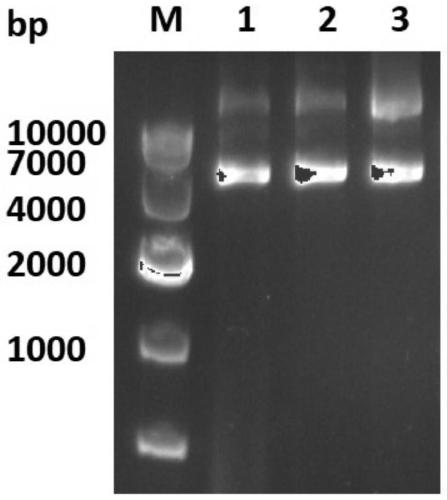

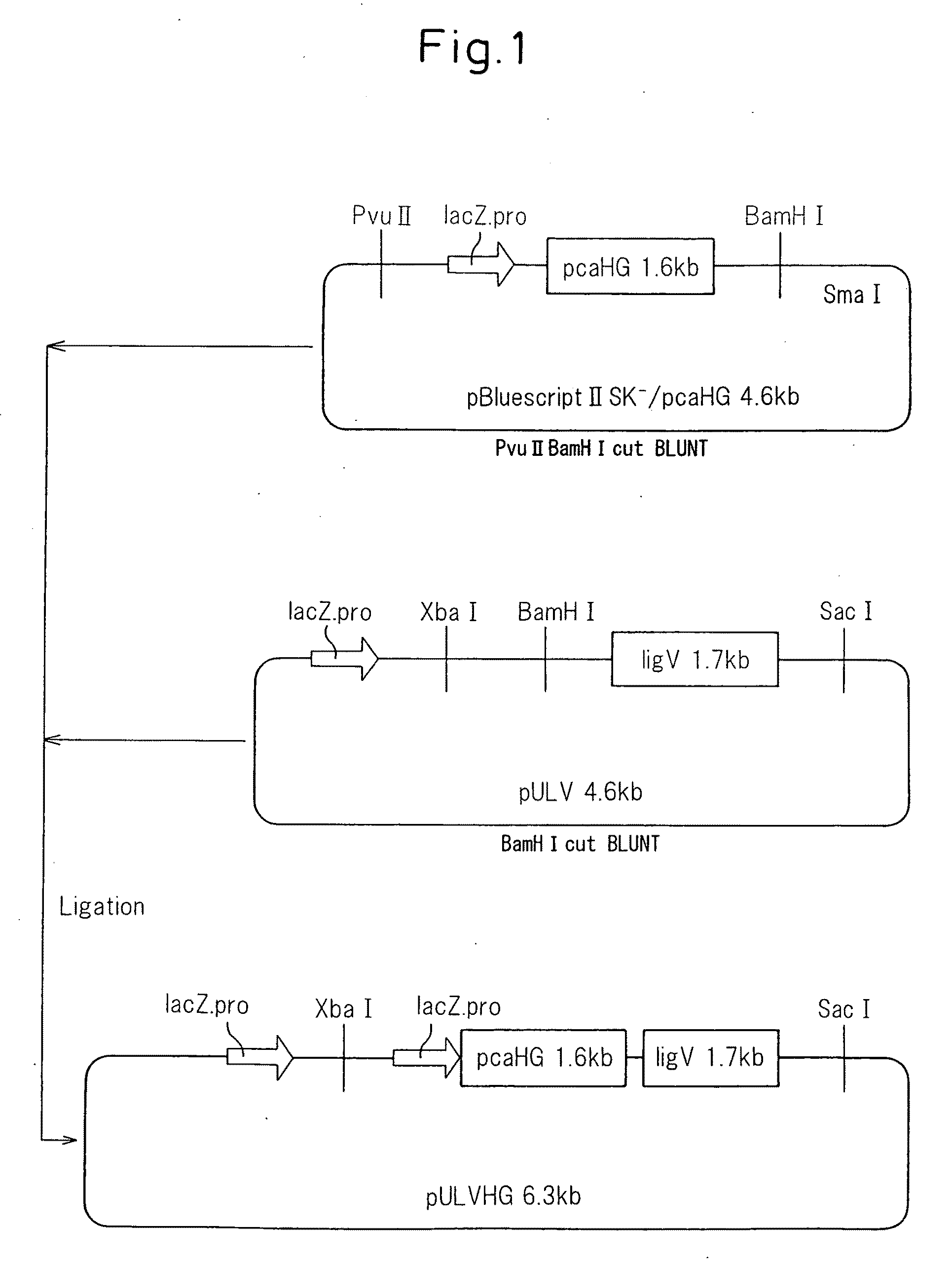

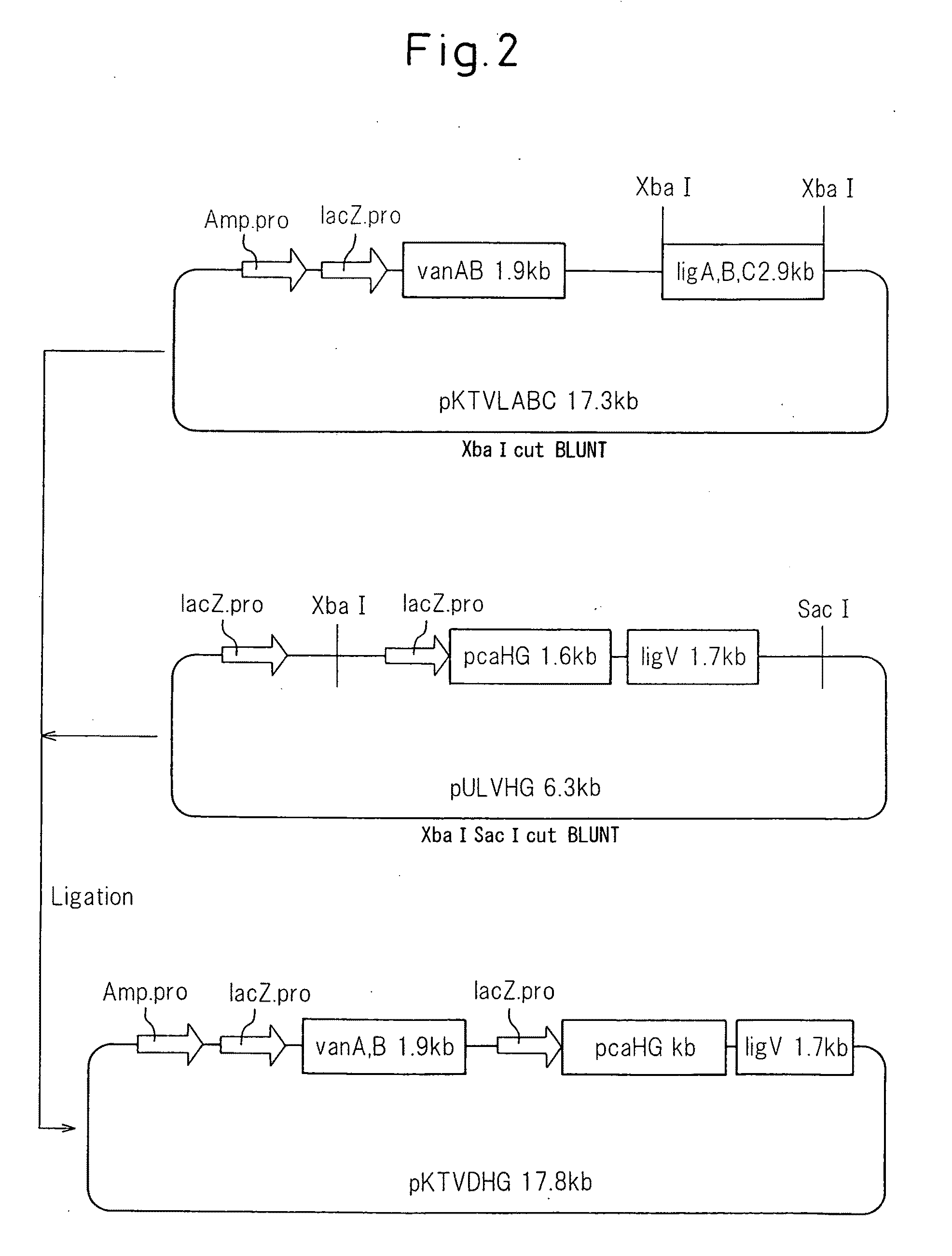

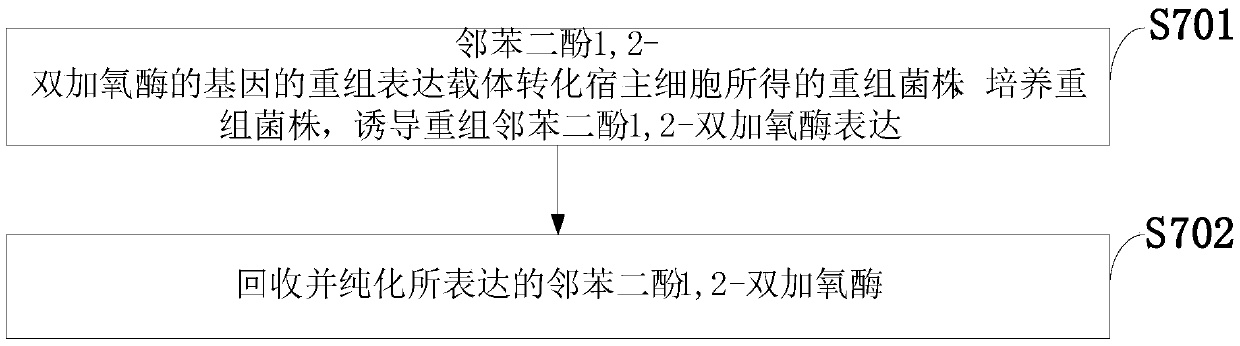

Plasmid, transformants and process for production of 3- carboxymuconolactone

ActiveUS20100075388A1High-yield and inexpensive fermentative productionHigh yieldBacteriaOxidoreductasesMuconic acidVanillic acid

There is provided a process for industrial production of simple 3-carboxy-cis,cis-muconic acid and / or 3-carboxymuconolactone from low molecular mixtures derived from plant components such as vanillin, vanillic acid and protocatechuic acid, via a multistage enzyme reaction.A recombinant plasmid containing a vanillate demethylase gene (vanAB genes), benzaldehyde dehydrogenase gene (ligV gene) and protocatechuate 3,4-dioxygenase gene (pcaHG genes); transformants incorporating the plasmid; and a process for production of 3-carboxy-cis,cis-muconic acid and / or 3-carboxymuconolactone characterized by culturing the transformants in the presence of vanillin, vanillic acid, protocatechuic acid or a mixture of two or more thereof.

Owner:FORESTRY & FOREST PRODS RES INST

Polyamide composition with ultralow viscosity and preparation method thereof

The invention discloses a polyamide composition with ultralow viscosity and a preparation method thereof. The polyamide composition is prepared from following components in percentage by weight: 48 to 55% of 1,6-adipic acid, 40 to 45% of 1,6-hexamethylenediamine, 0.5 to 10% of muconic acid, 0.3 to 10% of maleic anhydride, low molecular weight oligomer accounting for 0.01 to 0.1% of the total weight of the components mentioned above, zinc chloride accounting for 0.01 to 0.05% of the total weight of the components mentioned above, and thermoplastic polyester accounting for 1 to 5% of the total weight of the components mentioned above. During the condensation polymerization process between adipic acid and hexamethylenediamine, muconic acid is introduced into the reaction system, participates in the copolymerization reactions, and generates a synergistic effect with maleic anhydride; in the presence of oligomer with a specific low molecular weight and zinc oxide, the viscosity of polyamide is obviously reduced; the melt index of the polyamide composition is effectively increased, the flowing performance is obviously enhanced, and good mechanical properties are maintained.

Owner:HUAFON GROUP +1

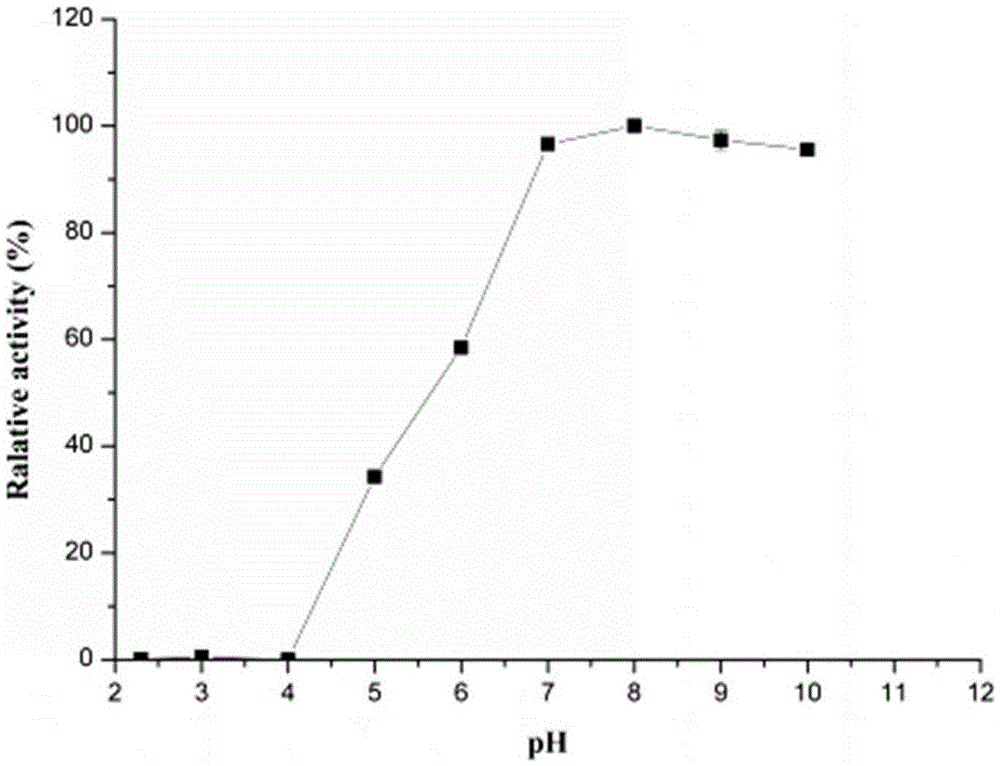

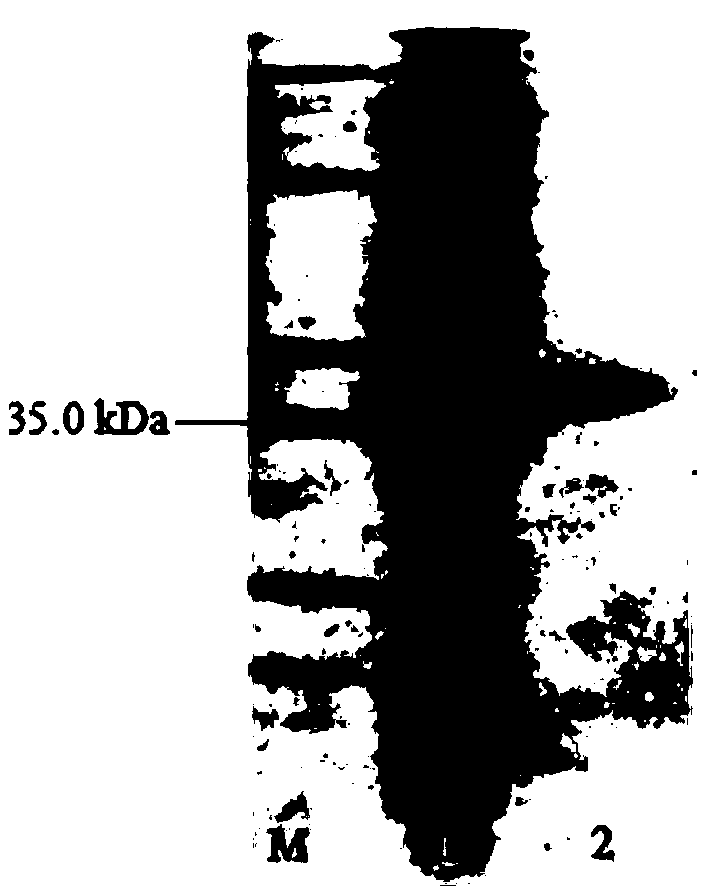

Low-temperature catechol 1,2-dioxygenase from animal waste metagenome, and encoding gene and preparing method thereof

ActiveCN105505893AImprove temperature stabilityGood pHOxidoreductasesGenetic engineeringEnzymatic synthesisMuconic acid

The invention discloses low-temperature catechol 1,2-dioxygenase from animal waste metagenome. The amino acid sequence of low-temperature catechol 1,2-dioxygenase is shown in SEQ ID NO.2, the total number of amino acids is 309, and the theoretical molecular weight is 33.72 kDa; the nucleotide sequence of an encoding gene is shown in SEQ ID NO.1, and the size of the gene is 930 bp. The optimum action pH value of low-temperature catechol 1,2-dioxygenase is 8.0, and after treatment is carried out for 1 h within the pH value range of 7.0-9.0, remaining enzyme activity is 60% or more; the optimum action temperature is 25 DEG C, and the enzyme activity is about 30% and 60% at the temperature of 0 DEG C and 10 DEG C respectively; low-temperature catechol 1,2-dioxygenase tolerates the temperature of 25 DEG C and 37 DEG C for 1 h, the enzyme activity is not affected, low-temperature catechol 1,2-dioxygenase tolerates the temperature of 25 DEG C, 65% or more of enzyme activity can still be kept, and low-temperature catechol 1,2-dioxygenase can be used for enzymatic synthesis of cis,cis-muconic acid and degradation of aromatic compound in low-temperature environment.

Owner:YUNNAN NORMAL UNIV

Method of producing adipic acid or at least a resultant product thereof

The present invention relates to a process for preparing adipic acid or at least one conversion product thereof, in which muconic acid is hydrogenated with hydrogen in the presence of at least one transition metal catalyst C and of an aqueous liquid A in a reaction zone, wherein the muconic acid is at least partly insoluble in the liquid A under the hydrogenation conditions.

Owner:BASF AG

Improved muconic acid production from genetically engineered microorganisms

InactiveUS20200181658A1High activityExcessive activityTransferasesOxidoreductasesBiotechnologyMicroorganism

The subject of this invention is improvements in the yield and titer of biological production of muconic acid by fermentation. Increased activity of one or more enzymes involved in the muconic acid pathway leads to increased production of muconic acid.

Owner:PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

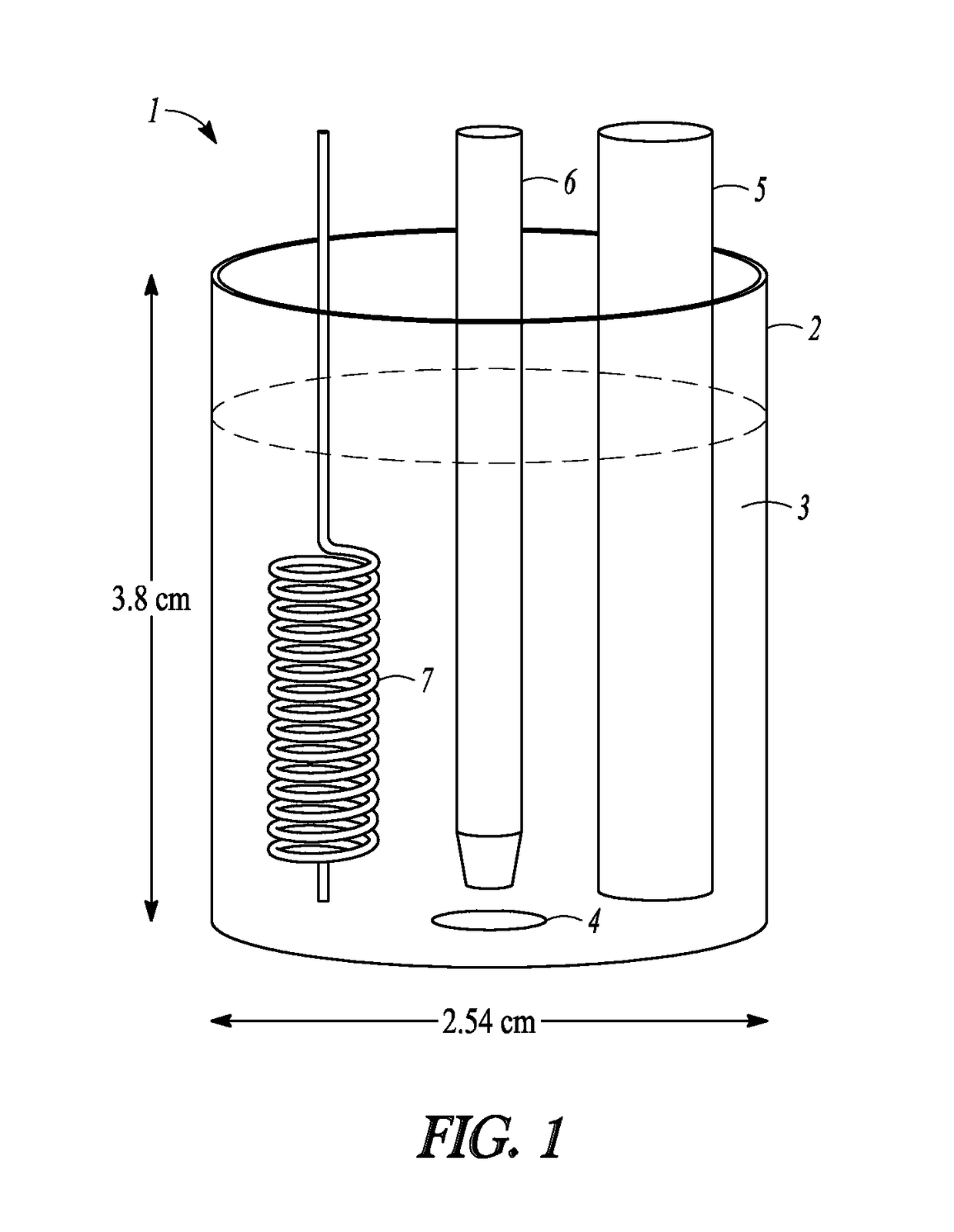

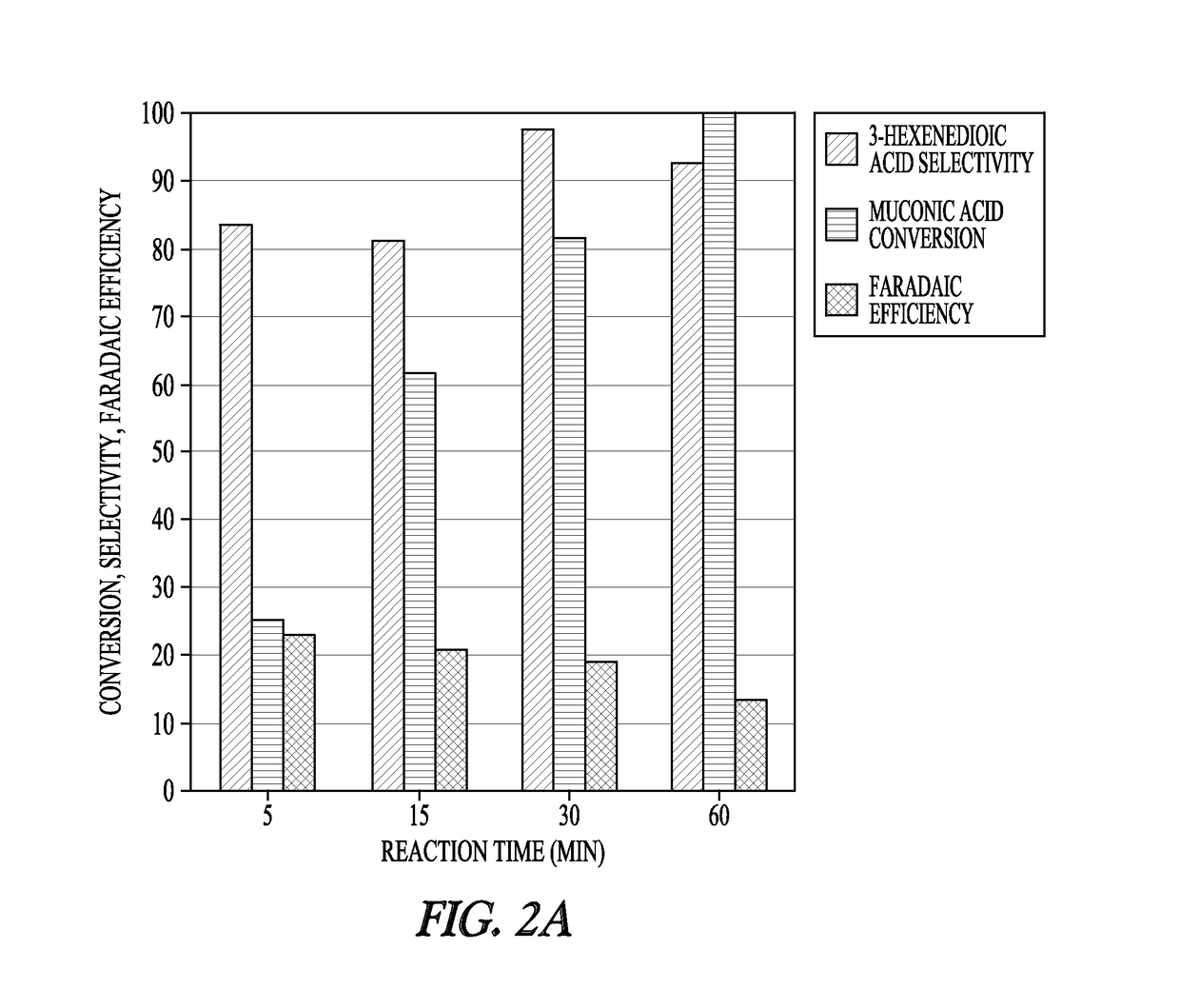

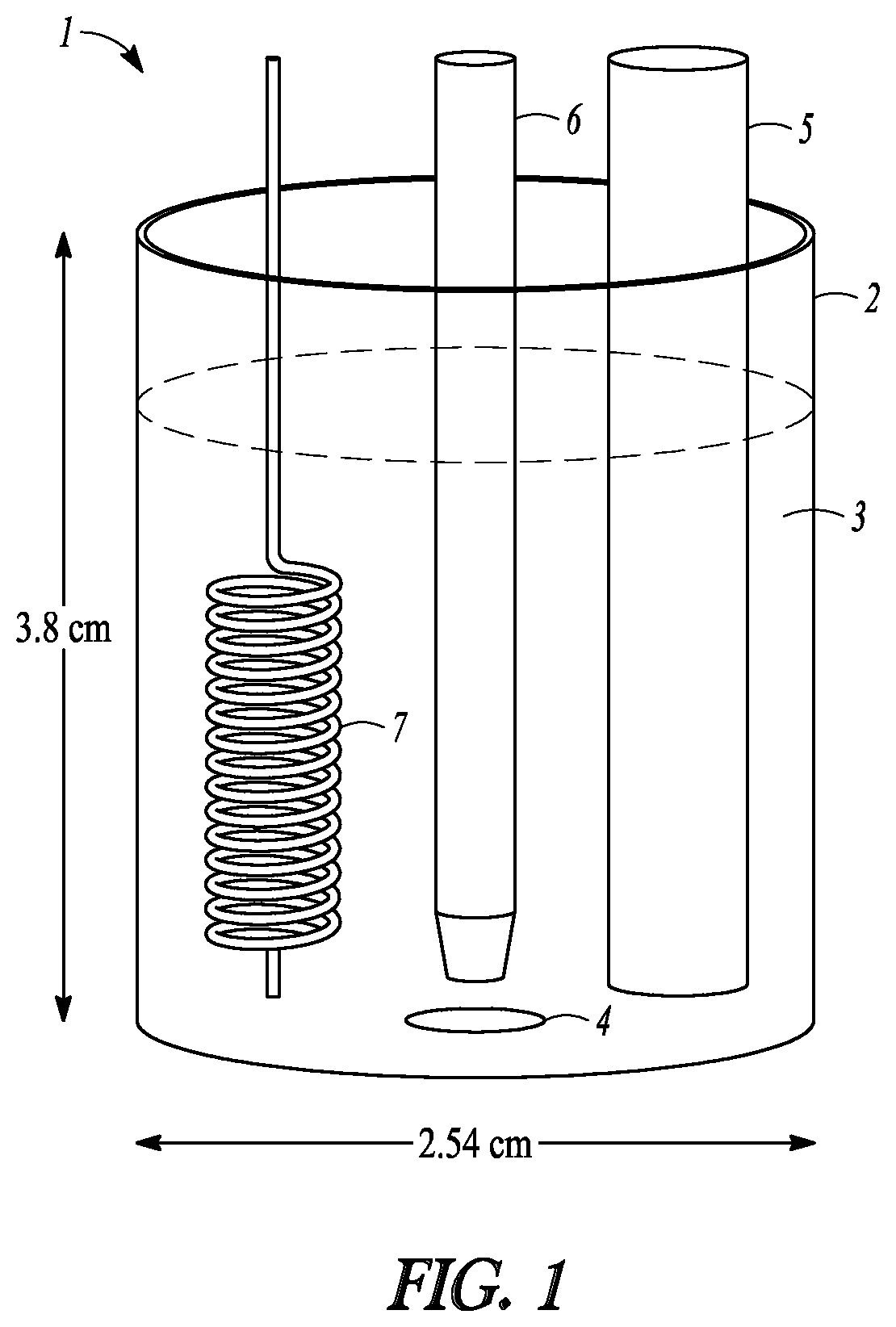

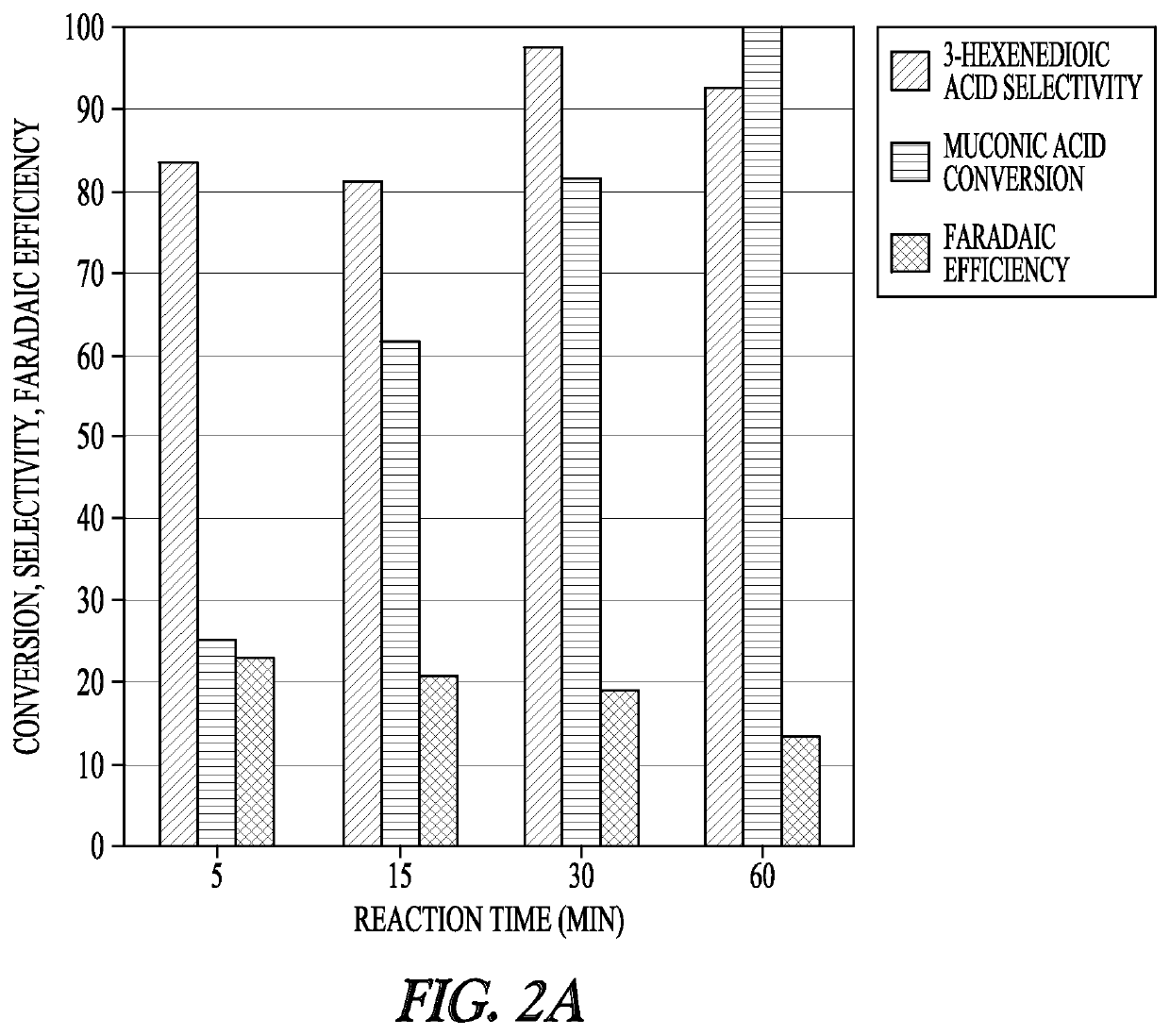

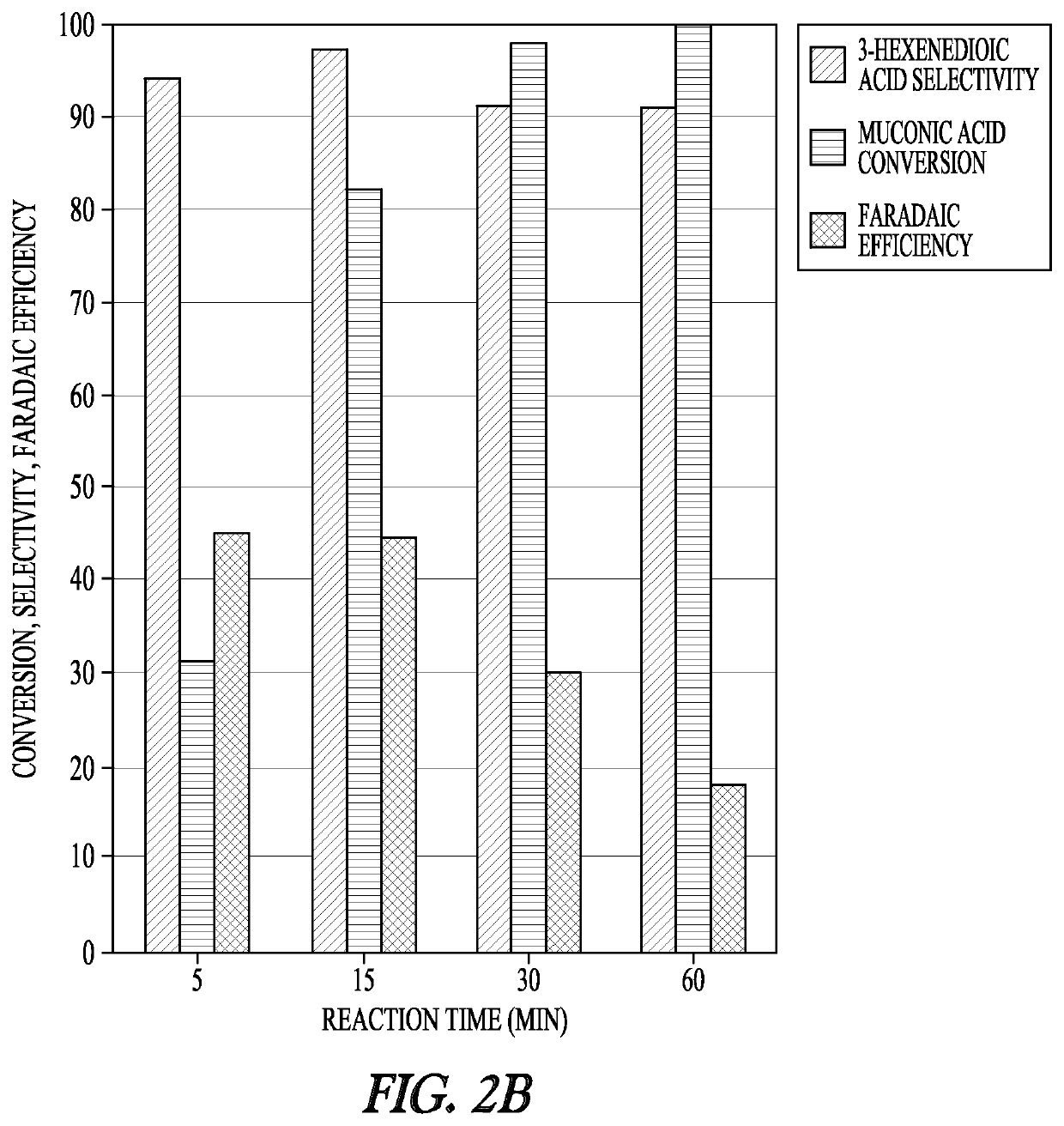

Electrocatalytic hydrogenation of muconic acid

ActiveUS20170342575A1Low catalyst loadingReduce the risk of explosionElectrolysis componentsElectrolytic organic reductionSupporting electrolytePolyester

Various embodiments disclosed relate to electrocatalytic hydrogenation of muconic acid and polymers formed from the reaction products thereof. In various embodiments, the present invention provides an electrocatalytic method to prepare 3-hexene-1,6-dioic acid, 2-hexene-1,6-dioic acid, adipic acid, or a combination thereof, from muconic acid. The method includes passing current through a catalytic cathode in a reactor including an aqueous acidic solution including muconic acid, a supporting electrolyte, and an anode, so as to generate atomic hydrogen on the cathode surface in an amount effective to hydrogenate the muconic acid to yield a product including 3-hexene-1,6-dioic acid, 2-hexene-1,6-dioic acid, adipic acid, or a mixture thereof. Also disclosed is the polymerization of 3-hexene-1,6-dioic acid, 2-hexene-1,6-dioic acid, or a combination thereof with another compound, such as a diamine or a dialcohol, to form a polymer, such as a polyamide or a polyester.

Owner:IOWA STATE UNIV RES FOUND

Muconic acid production from genetically engineered microorganisms

ActiveUS20210277429A1High activityHigh expressionTransferasesOxidoreductasesMicroorganismMuconic acid

The subject of this invention is improvements in the yield and titer of biological production of muconic acid by fermentation. Increased activity of one or more enzymes involved in the muconic acid pathway leads to increased production of muconic acid.

Owner:PTT GLOBAL CHEMICAL PUBLIC COMPANY LIMITED

Electrocatalytic hydrogenation of muconic acid

ActiveUS10633750B2Reduce loadReduce riskElectrolysis componentsElectrolytic organic reductionSupporting electrolytePolyester

Various embodiments disclosed relate to electrocatalytic hydrogenation of muconic acid and polymers formed from the reaction products thereof. In various embodiments, the present invention provides an electrocatalytic method to prepare 3-hexene-1,6-dioic acid, 2-hexene-1,6-dioic acid, adipic acid, or a combination thereof, from muconic acid. The method includes passing current through a catalytic cathode in a reactor including an aqueous acidic solution including muconic acid, a supporting electrolyte, and an anode, so as to generate atomic hydrogen on the cathode surface in an amount effective to hydrogenate the muconic acid to yield a product including 3-hexene-1,6-dioic acid, 2-hexene-1,6-dioic acid, adipic acid, or a mixture thereof. Also disclosed is the polymerization of 3-hexene-1,6-dioic acid, 2-hexene-1,6-dioic acid, or a combination thereof with another compound, such as a diamine or a dialcohol, to form a polymer, such as a polyamide or a polyester.

Owner:IOWA STATE UNIV RES FOUND

Method for producing muconic acids and furans from aldaric acids

InactiveUS9969669B2Easy scalability and purificationReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationFuranGluconic acid

The present invention relates to selective catalytic dehydroxylation method of aldaric acids for producing muconic acid and furan chemicals, which can be used directly in fine chemical and polymer applications (FCA / FDCA) and as intermediates in the preparation of industrially significant chemicals, such as terephthalic acid, adipic acid, caprolactone, caprolactam, nylon 6.6, 1,6-hexanediol and multiple pharmaceutical building blocks (MA / MAME).

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com