Escherichia coli for producing adipic acid precursor namely cis,cis-muconic acid and application of escherichia coli

A technology of Escherichia coli and muconic acid, applied in the biological field, can solve problems affecting the excessive accumulation of target products, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

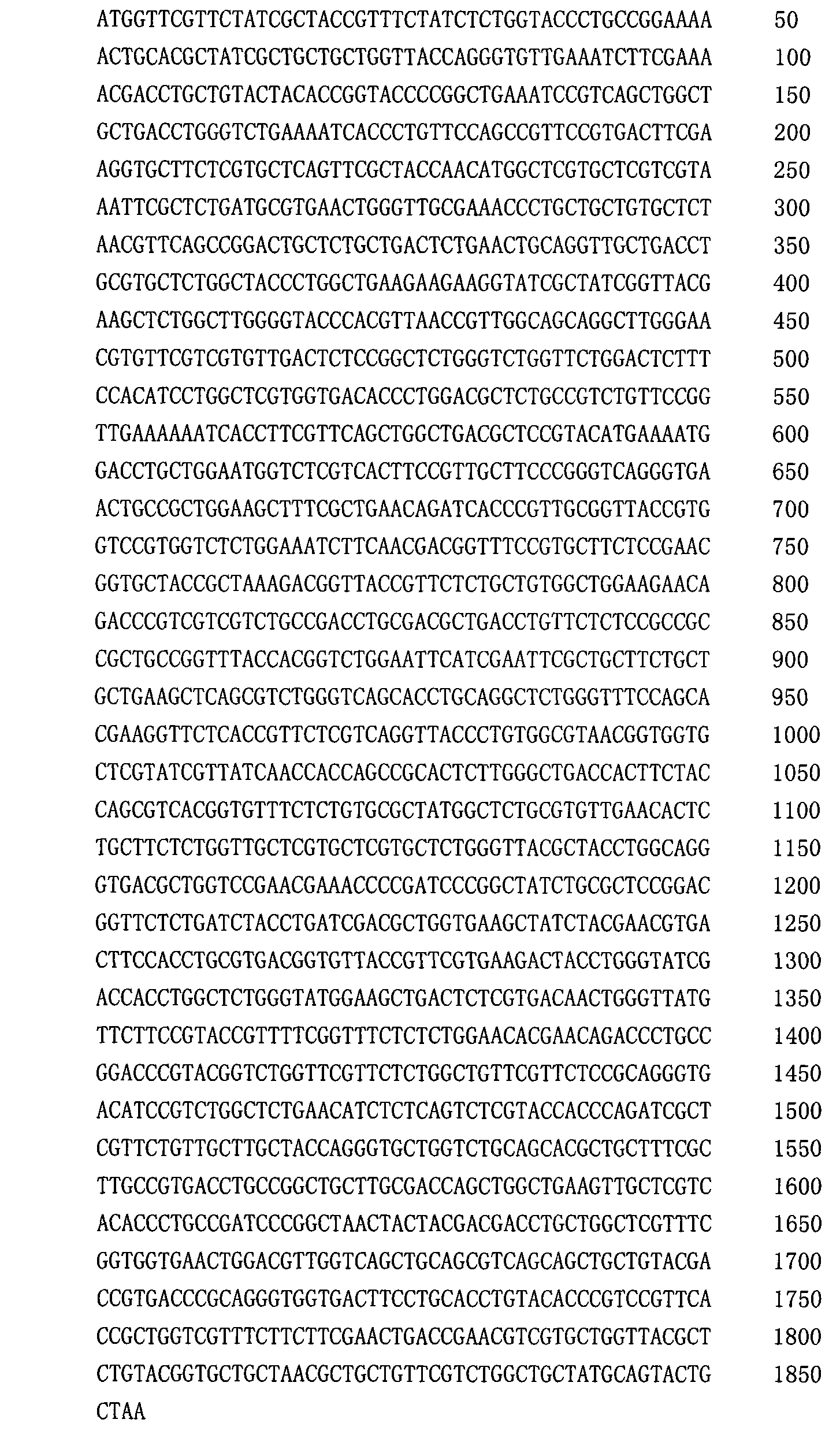

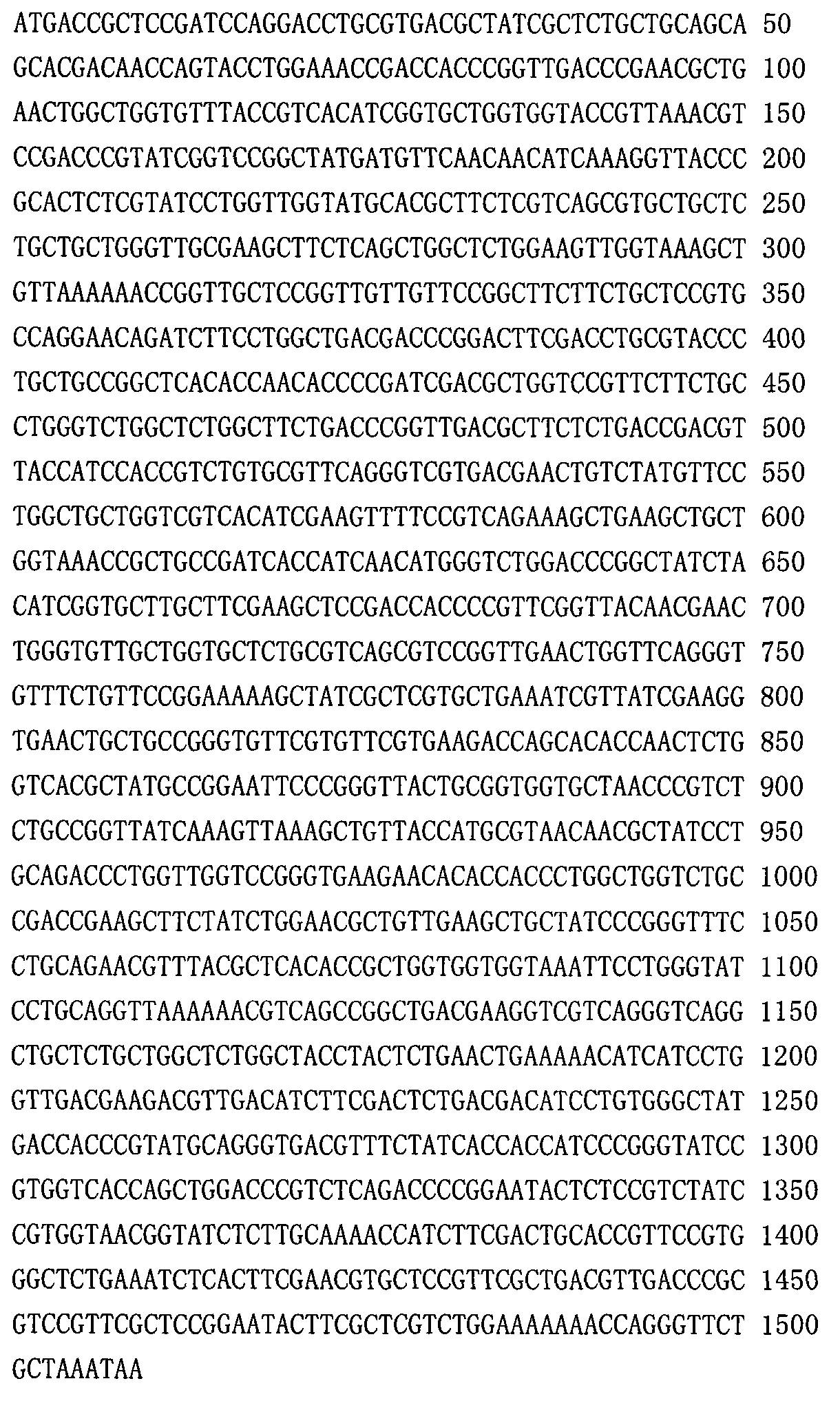

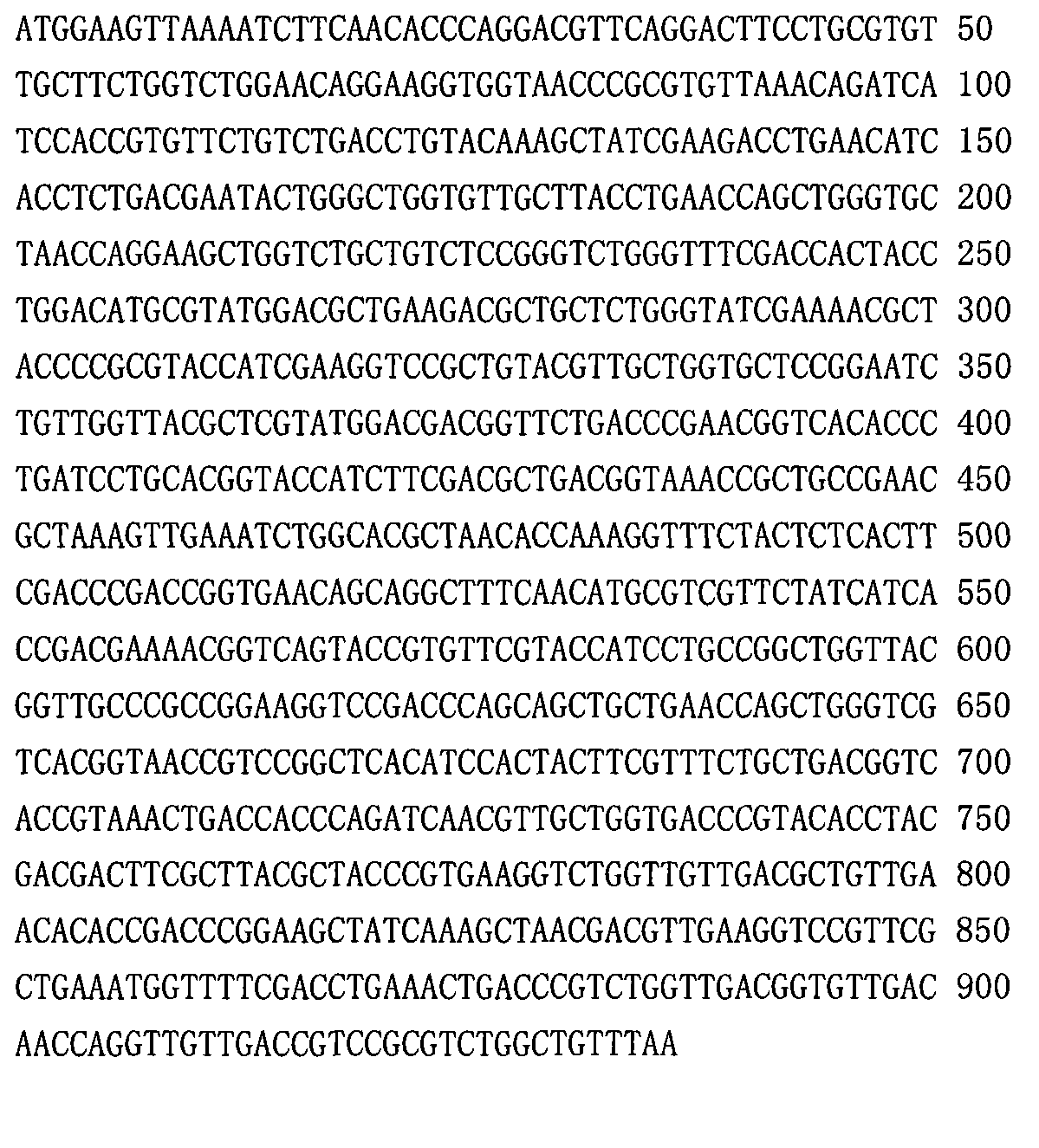

[0017] Example 1 The optimized design and synthesis of 3-dehydroshikimate dehydratase gene, protocatechuate decarboxylase gene and catechol 1,2-dioxygenase gene

[0018] According to the sequences of the 3-dehydroshikimate dehydratase gene aroZ of Klebsiella pneumoniae A170-40, the protocatechuate decarboxylase gene aroY and the catechol 1,2-dioxygenase gene catA of Acinetobacter calcoaceticus, respectively, through codon optimization Novel genes aroZ-jCat, aroY-jCat and catA-jCat (attached Figure 1-3 ), and then use the method of DNA chemical synthesis to obtain these design-optimized genes, which can be used for the creation of heterologous synthetic pathways.

Embodiment 2

[0019] Example 2 Assembly of heterologous expression modules consisting of 3-dehydroshikimate dehydratase, protocatechuate decarboxylase and catechol 1,2-dioxygenase

[0020] 通过合适的限制性内切酶,把人工设计合成的组成型启动子P3(TCTAGAATATGTTATCTCTGGCGGTGTTGACATTTCCGTTTTTTCATGATATAATCGCTCCTGAGCGGATAACAATTTCAAGGAGGACAGCTCCATCAT)、上述设计合成的新基因aroZ-jCat,aroY-jCat和catA-jCat以及人工设计合成的终止子T1(CCGGCTTATCGGTCAGTTTCACCTGATTTACGTAAAAACCCGCTTCGGCGGGTTTTTGCTTTTGGAGGGGCAGAAAGATGAATGACTGTCCACGACGCTATACCCAAAAGAAA ) to form the heterologous expression module CCMA. The restriction enzymes between P3, aroZ-jCat, aroY-jCat, catA-jCat and T1 are NdeI, SacI, NheI, XhoI, respectively. In addition, an RBS binding region (AAGAAGGAGATATAGTA) was added before the initiation codon ATG of the aroY-jCat and catA-jCat genes, respectively. The schematic diagram and sequence of the CCMA module are shown in the attached Figure 4 and 5 .

Embodiment 3

[0021] Example 3 Construction of Escherichia coli (Escherichia coli) TIB-LEc340 CGMCC No 6435

[0022] ClaI and SalI restriction enzyme cutting sites were added to both ends of the DNA sequence of the above-mentioned construction of 3-dehydroshikimate dehydratase, protocatechuate decarboxylase and catechol 1,2-dioxygenase heterologous expression module CCMA point, and then insert the DNA fragment into the corresponding site of the plasmid pACYC184 to obtain the recombinant plasmid pACYC-CCMA (attached Figure 6 ). Then the recombinant plasmid pACYC-CCMA was transferred into shikimate dehydrogenase (AroE) mutant Escherichia coli AB2834 (Escherichia coli AB2834) to obtain the target strain Escherichia coli (Escherichia coli) TIB-LEc340 CGMCC No 6435.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com