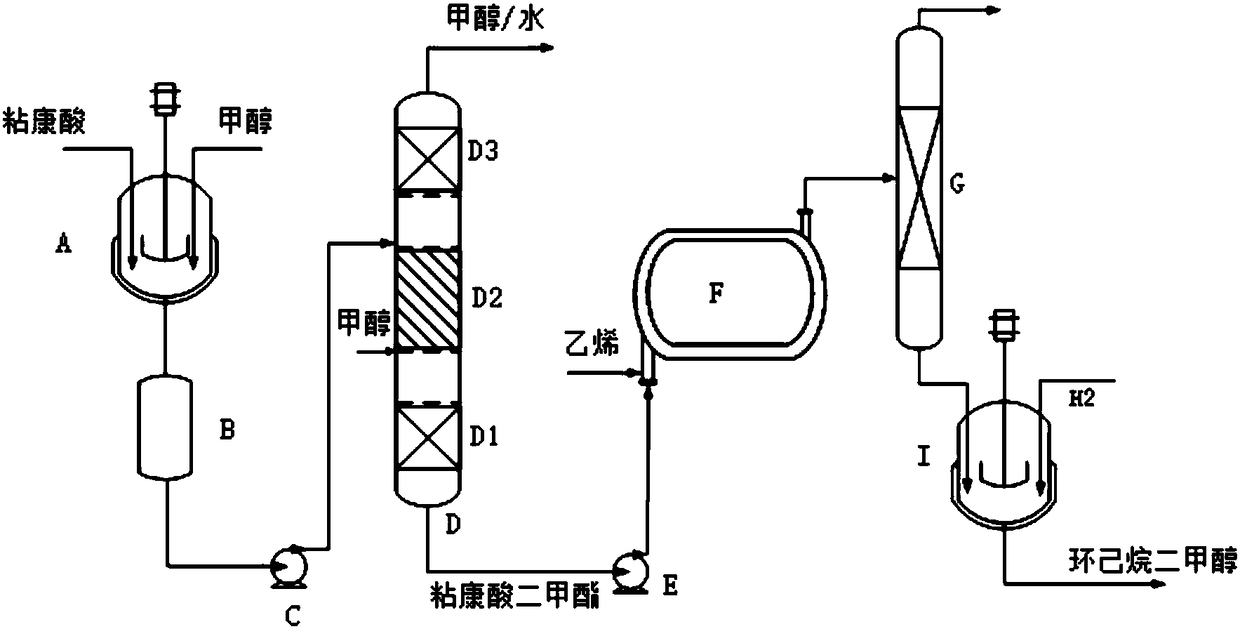

Preparation technology and device of cyclohexanedimethanol

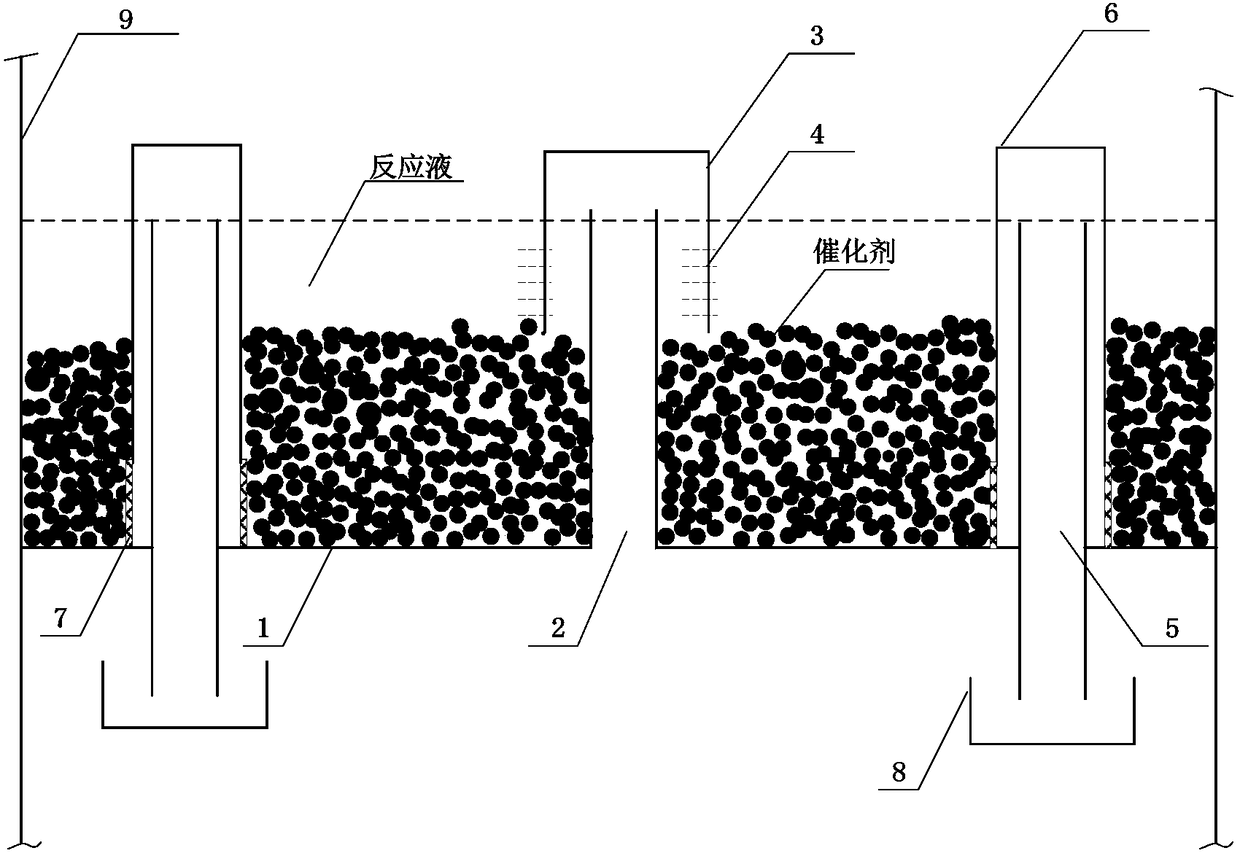

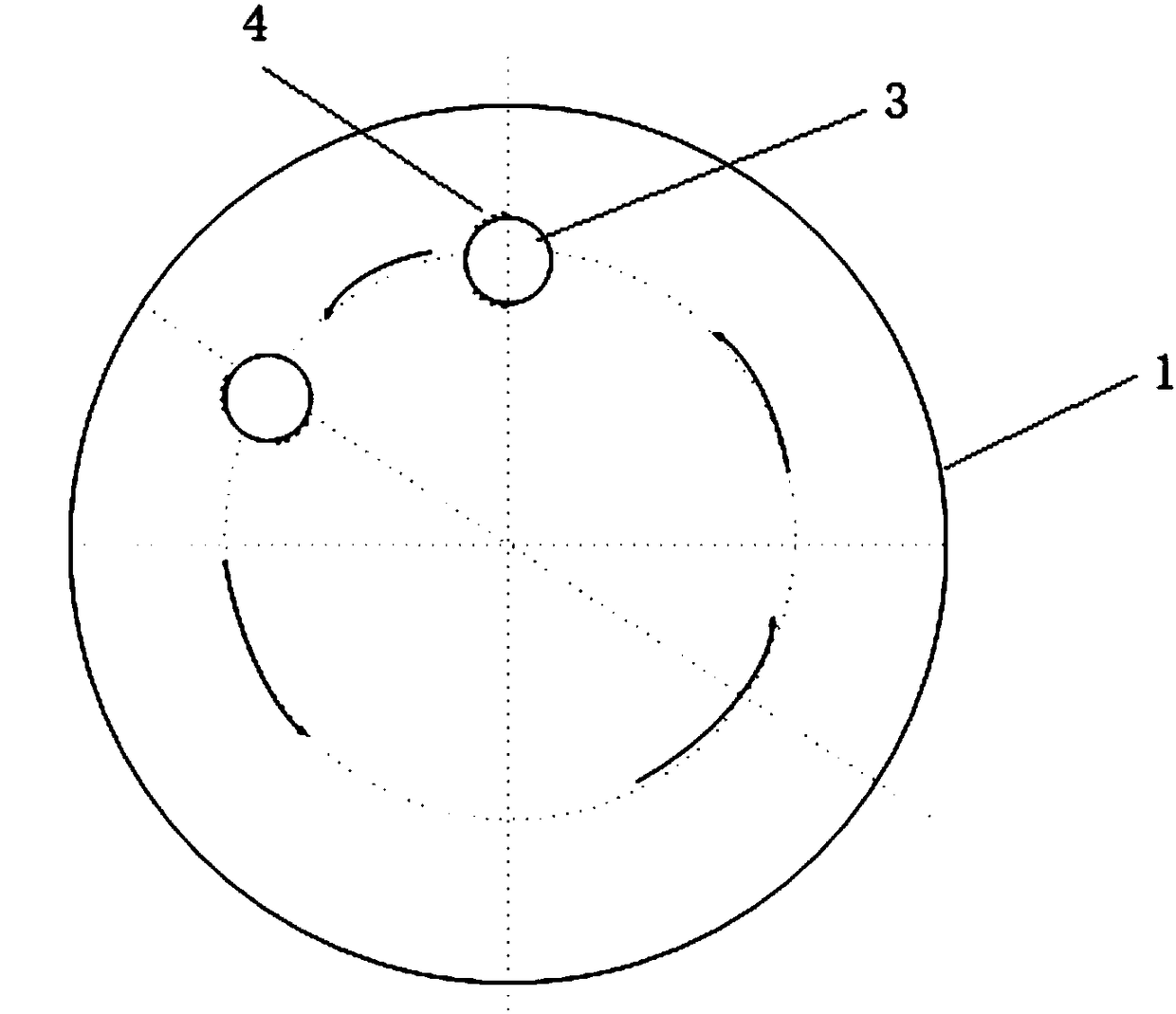

A technology of cyclohexane dimethanol and dialkyl cyclohexene dicarboxylate, which is applied in the field of preparation of cyclohexane dimethanol, which can solve the problem of uneven catalyst distribution, slow liquid phase replacement, and limited liquid holding capacity of sieve trays And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Preparation of Hollow Molecular Sieve Supported Heteropolyacid Catalyst

[0094] Solution configuration: configure tetrapropylammonium hydroxide and NaNO with concentrations of 0.3 and 0.3 mol / L respectively 3 of aqueous solution. Take 1 kg of pure silicon-type molecular sieve S-1 (Dalian University of Technology Qiwangda Chemical Technology Co., Ltd.) with a particle diameter of 120 nm, put it in 5 L of the alkali solution configured above, and keep stirring at 170 ° C for 24 hours; Wash with distilled water, then dry at 100°C under normal pressure for 2 hours, and bake at 500°C for 4 hours in an air atmosphere. Na with a molar ratio of 12:1 2 WO 4 and Na 2 SiO 3 A total of 20g was dissolved in 5L of distilled water, and the above-prepared molecular sieve was placed in the heteropolyacid solution, and the temperature was controlled at 90°C. With stirring, phosphoric acid was continuously added dropwise until the pH value = 1, and the stirring reaction was continue...

Embodiment 2

[0098] Preparation of Hollow Molecular Sieve Supported Heteropolyacid Catalyst

[0099] Solution configuration: configure tetrapropylammonium hydroxide and NaNO with concentrations of 0.3 and 0.3 mol / L respectively 3 of aqueous solution. Take 1 kg of pure silicon-type molecular sieve S-1 (Dalian University of Technology Qiwangda Chemical Technology Co., Ltd.) with a particle diameter of 300 nm, place it in 5 L of the alkali solution configured above, and keep stirring at 170 ° C for 24 hours; Wash with distilled water, then dry at 100°C under normal pressure for 2 hours, and bake at 500°C for 4 hours in an air atmosphere. Na with a molar ratio of 12:1 2 WO 4 and Na 2 SiO 3 A total of 40g was dissolved in 5L of distilled water, and the above-prepared molecular sieve was placed in the heteropoly acid solution, and the temperature was controlled at 90°C. With stirring, phosphoric acid was continuously added dropwise until the pH value = 1, and the stirring reaction was conti...

Embodiment 3DA

[0102] Embodiment 3DA synthesis

[0103] A drainage loop reactor with a volume of 2L is used, the inner diameter of the loop is 10mm, and the diameter of the drainage nozzle is 0.5mm. Add 500ml of dimethyl muconate prepared in the above steps and 5ml of methanol into a 2L drainage loop reactor, fill with ethylene to 3.0MPa at room temperature, preheat to 120°C, maintain the temperature of the system and then fill with CO 2 To 8MPa and add ethylene to maintain the system pressure, react for 10h, take a sample and send it to GC analysis, the conversion rate of dimethyl muconate is about 97%, and the yield of the product cyclohexene dicarboxylate is 92.4% based on dimethyl muconate .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com