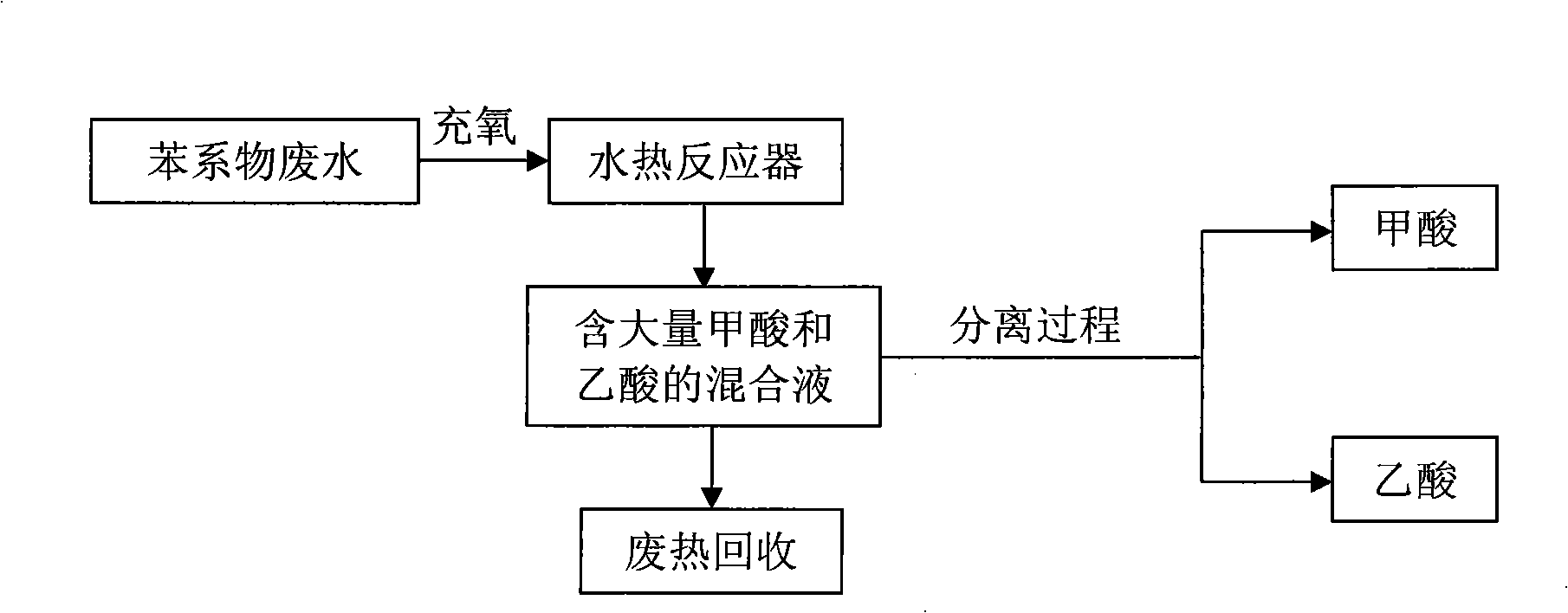

Method for preparing low-grade aliphatic acid from benzene and its homologues waste water

A low-grade fatty acid and benzene series technology, applied in the field of waste recycling, can solve the problems of reaction vessel corrosion, catalyst deactivation, high reaction conditions, etc., and achieve the effects of cost saving, low operating energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, papermaking wastewater.

[0038] Papermaking industrial wastewater is a kind of difficult-to-treat organic wastewater with large water volume, high chroma, high content of suspended solids, high concentration of organic matter and complex components. The main sources of papermaking wastewater are pulping waste liquid, mid-stage water, and paper machine white water. Pulping waste liquid is the most polluted, dark brown, and is called black water. The concentration of pollutants in black water is very high, and it contains a lot of fibers and pigments. The water volume in the middle section is the largest, and the pollutants have relatively high concentrations of lignin, cellulose and volatile organic acids and other components that are difficult to biodegrade, and have deep color, odor, strong pollution, COD Cr 400~700mg / L, BOD 5 200~400mg / L, pH7~14. The main components of paper machine white water are cellulose, hemicellulose, lignin, extractives, etc. ...

Embodiment 2

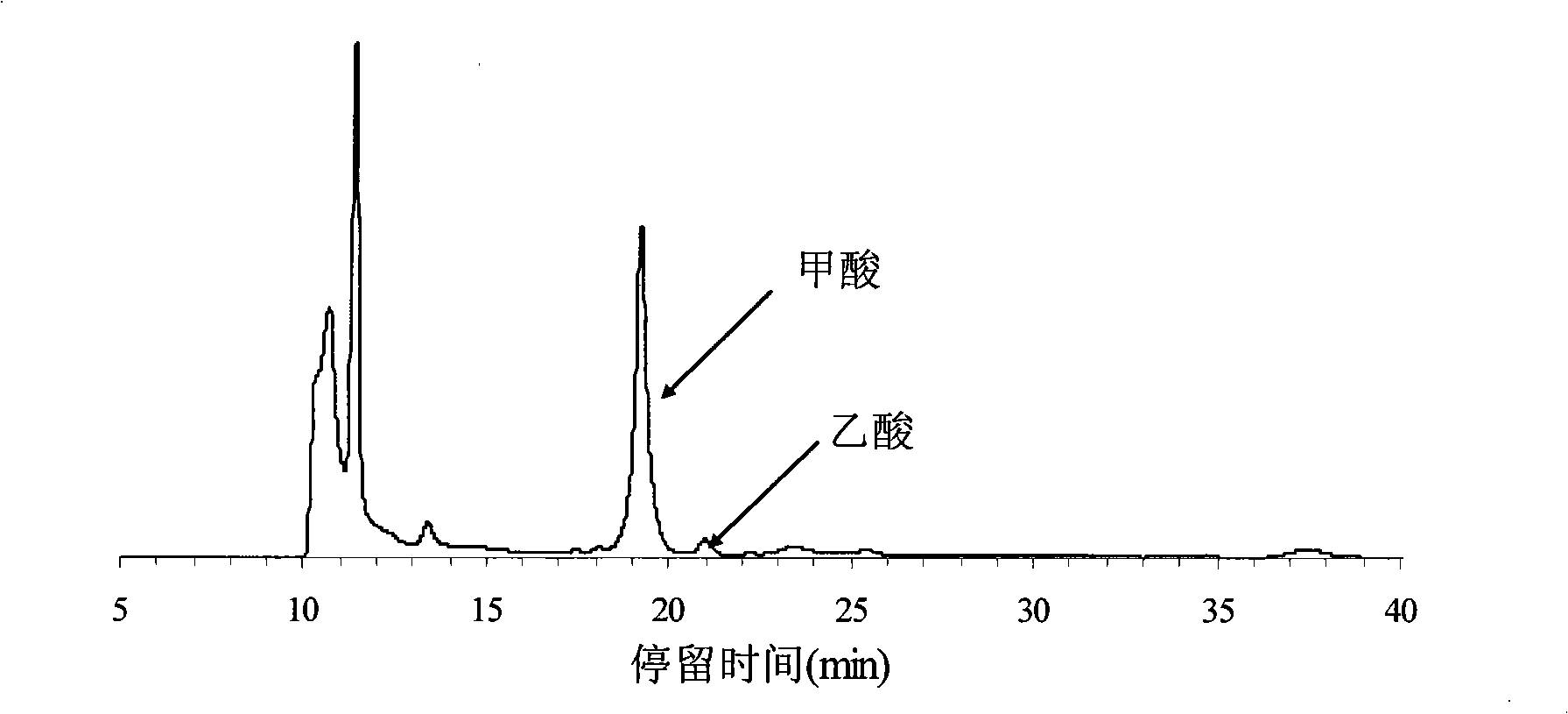

[0041] Embodiment 2, coking waste water.

[0042] Coking wastewater is produced in the process of high-temperature dry distillation of raw coal, gas purification and product refining. Wastewater has complex components and serious pollution, which is a prominent environmental problem in industrial wastewater discharge, and its water quality varies with the composition of raw coal and coking process. In addition to phenols, organic compounds in coking wastewater also include monocyclic and polycyclic aromatic compounds, heterocyclic compounds containing nitrogen, sulfur, and oxygen, including o-methoxyphenol, 1,2-catechol , 2-methoxy-1,4-hydroquinone, etc.

[0043] Put the coking wastewater into the hydrothermal oxidation reactor, at a temperature of 240°C to 450°C, a pressure of 5Mpa to 20Mpa, and a pH of 7 to 14, the amount of oxygen added is such that all the carbon contained in the benzene series in the wastewater is oxidized into CO 2 The required amount of oxygen is 10% ...

Embodiment 3

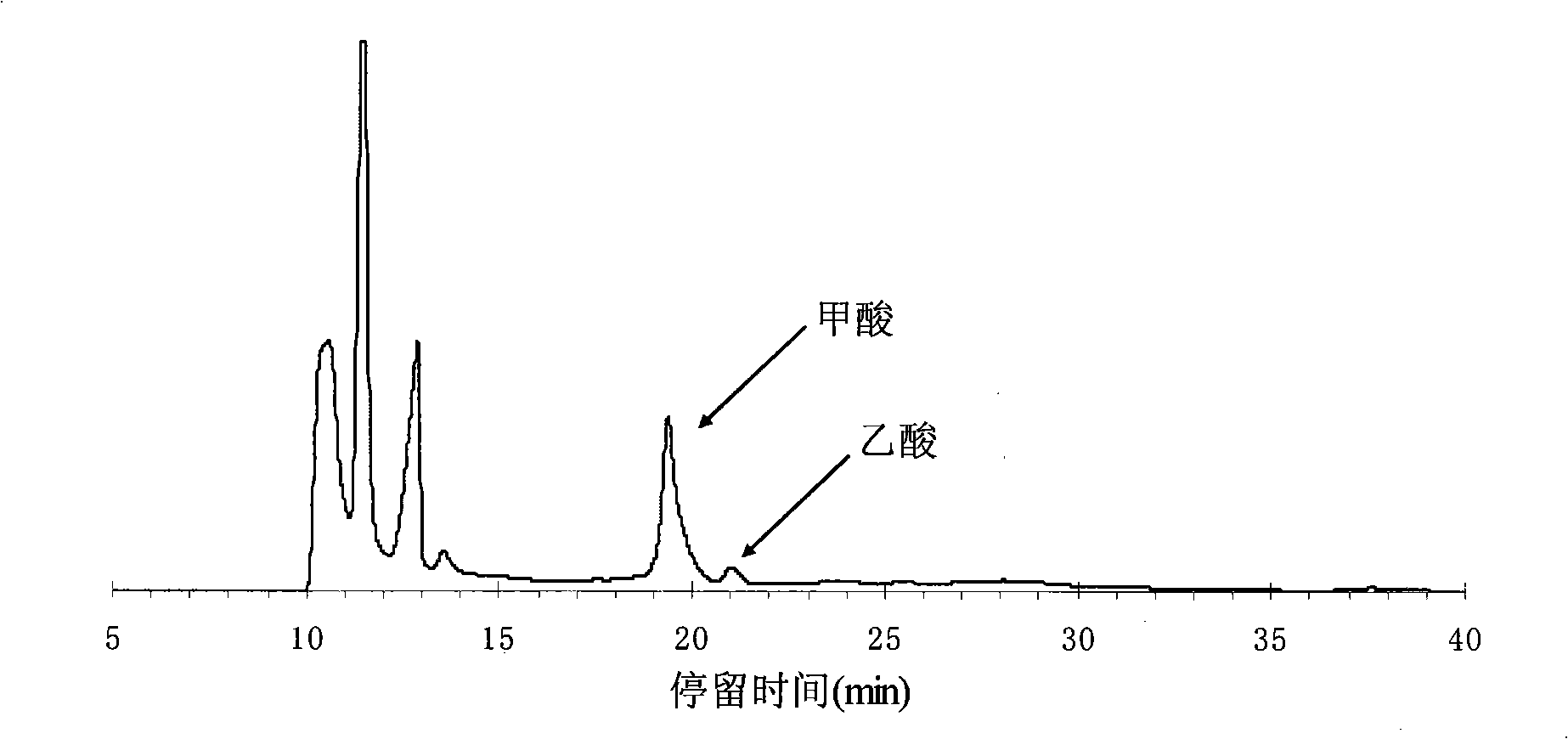

[0045] Embodiment 3. Organic chemical industry wastewater containing benzene series pollutants

[0046] The composition of organic chemical wastewater is complex. Due to the variety of products and different processes, the composition of wastewater is extremely complex. The general characteristics are less suspended solids and more soluble or emulsified organic matter. This is mainly for organic chemical wastewater containing benzene pollutants. Pollutants mainly include benzene pollutants such as phenol and diphenol.

[0047] Add organic chemical wastewater into the hydrothermal oxidation reactor, at a temperature of 250°C to 430°C, a pressure of 8Mpa to 20Mpa, and a pH of 7 to 14. The amount of oxygen added is such that all the carbon contained in the benzene series in the wastewater is oxidized into CO 2 The required amount of oxygen is 10% to 200%, and the reaction time is 30s to tens of minutes. The amount of oxygen added is oxidized to CO by the carbon of benzene series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com