Bending machine

A bending machine and frame technology, applied in the field of bending machines, can solve the problems of high cost, low production efficiency, time-consuming and laborious, etc., and achieve the effect of low cost, high production efficiency and good bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

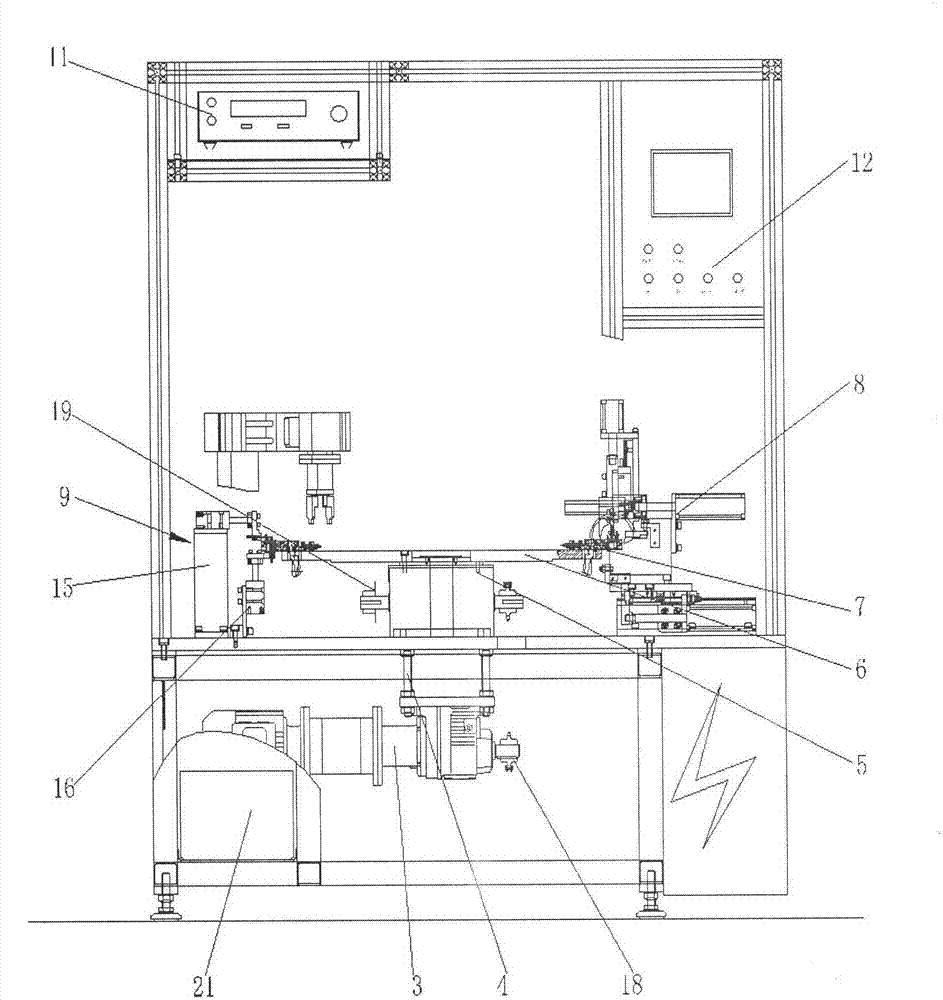

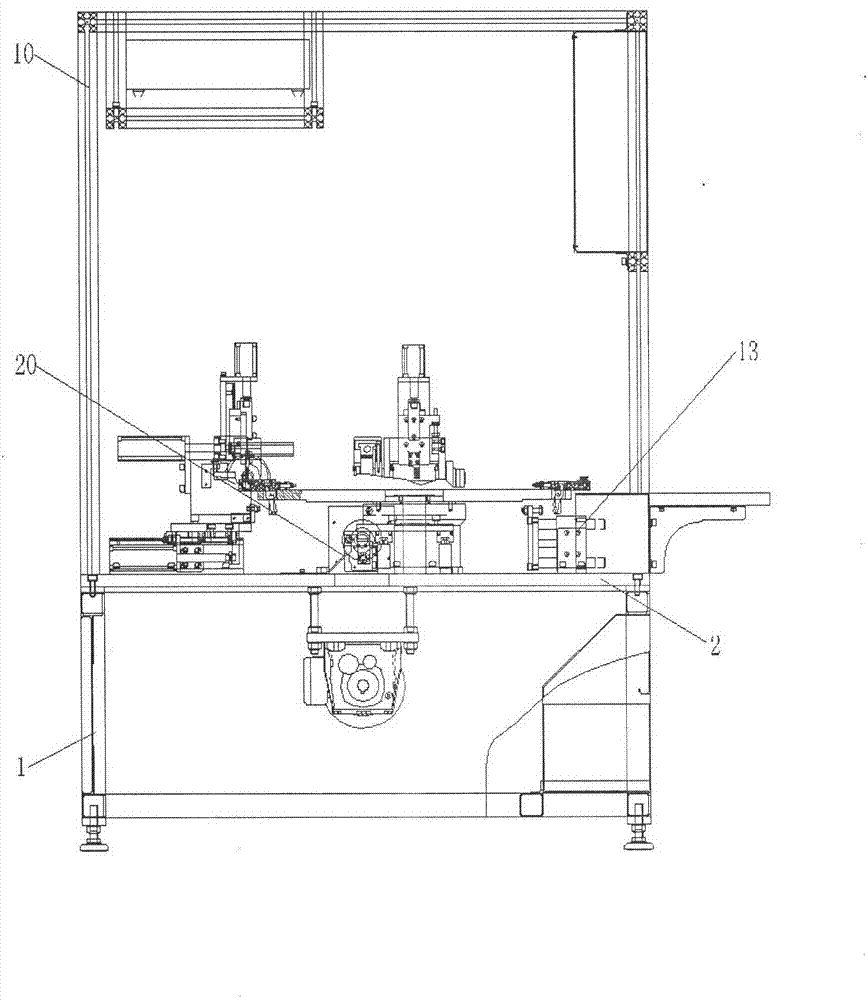

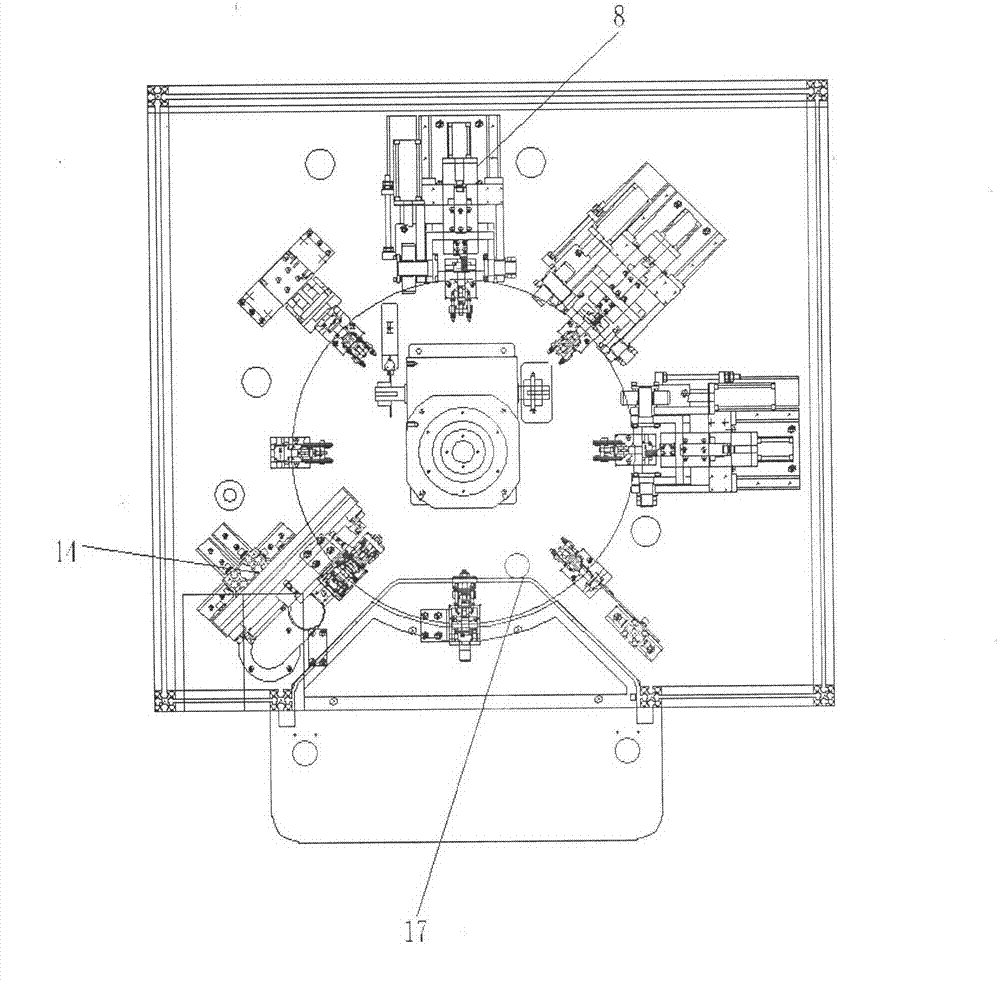

[0027] Such as Figure 1 to Figure 3 Shown: a bending machine, including a frame 1, the upper end of the frame 1 is provided with a platen 2, the middle part of the platen 2 is provided with a motor reducer 3, and the output end of the motor reducer 3 is connected with a chain tension wire The rod 4 and the chain tensioning screw 4 are connected with a splitter 5, the upper end of the splitter 5 is provided with a turntable 6, the upper end of the turntable 6 is evenly distributed with a clamp assembly 7, and the outer periphery of the turntable 6 is provided with a bending assembly 8 and a probe assembly 9, The outer edge of the table 2 is provided with a pressure tester 11 and a control box 12 passing through the upper enclosure structure 10, and a clamp opening cylinder assembly 13 for driving the clamp assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com