Automatic bending device for heat pipe

A bending device and heat pipe technology, applied in the field of machinery, can solve problems such as inconsistent bending effects, affecting production efficiency, and substandard arcs, so as to achieve good bending effects, avoid bending quality differences, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

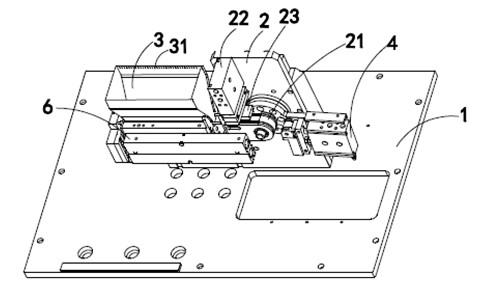

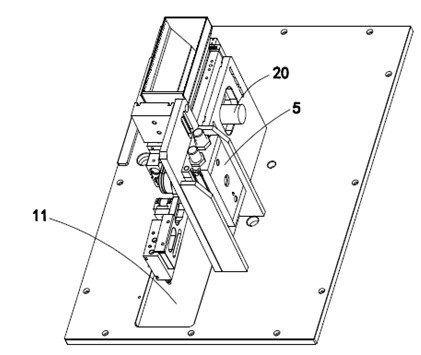

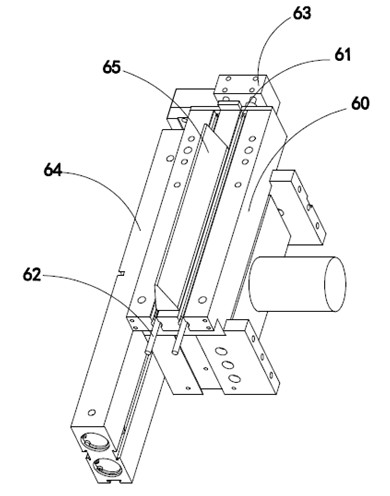

[0017] The invention discloses an automatic bending device for heat pipes, such as figure 1 , figure 2 As shown, a frame 1 is included, a platen 2 is vertically fixed on the frame 1, a vibrator 20 is arranged on one side of the platen 2, and one end of the vibrator 20 passes through the platen 2 and is connected to a The barrel 3 for placing the heat pipe to be bent is provided with a scoring line 31 , and the barrel 3 is an adjustable barrel that can be adjusted according to the specification of the heat pipe and the scoring line.

[0018] A feeding mechanism 6 is arranged under the barrel 3 . Specifically, the feeding mechanism 6 is arranged below the feeding port of the barrel 3, the feeding mechanism 6 is fixed on the frame 1, and the bending device also includes a fixed block 21 and a rotating mechanism 5 that drives the fixed block 21 to rotate. , the rotating mechanism 5 and the vibrating machine 20 are arranged on the same side of the platen 2, the rotating shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com