Patents

Literature

77results about How to "Realize automatic bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

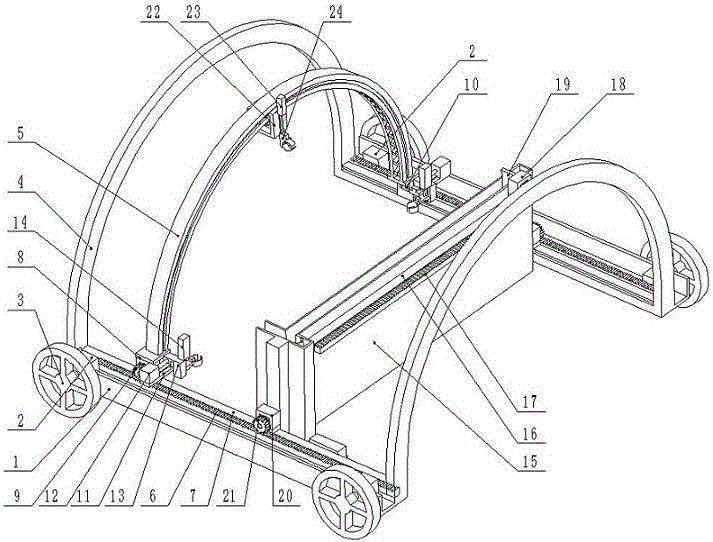

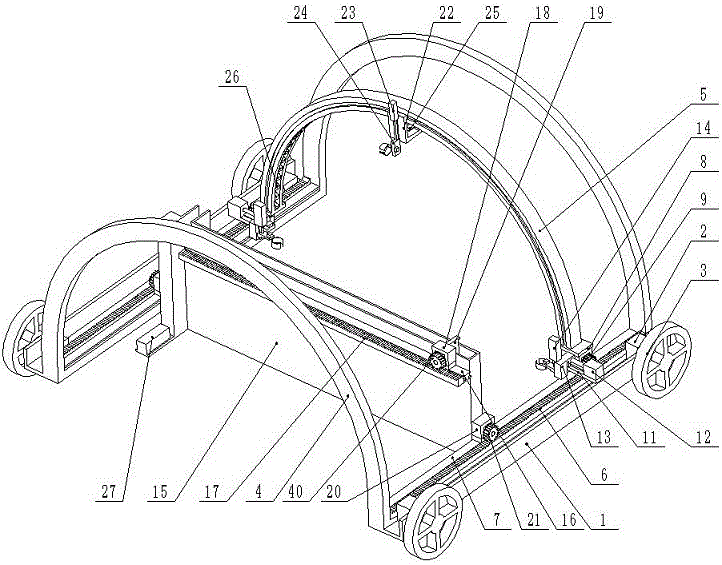

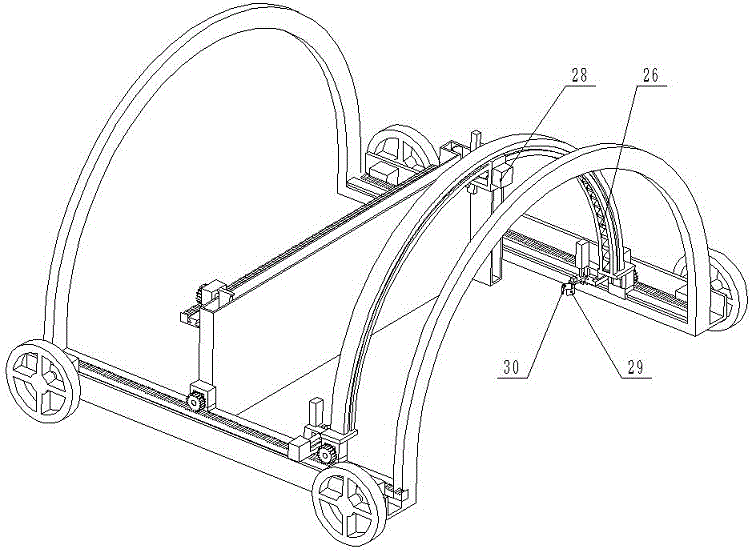

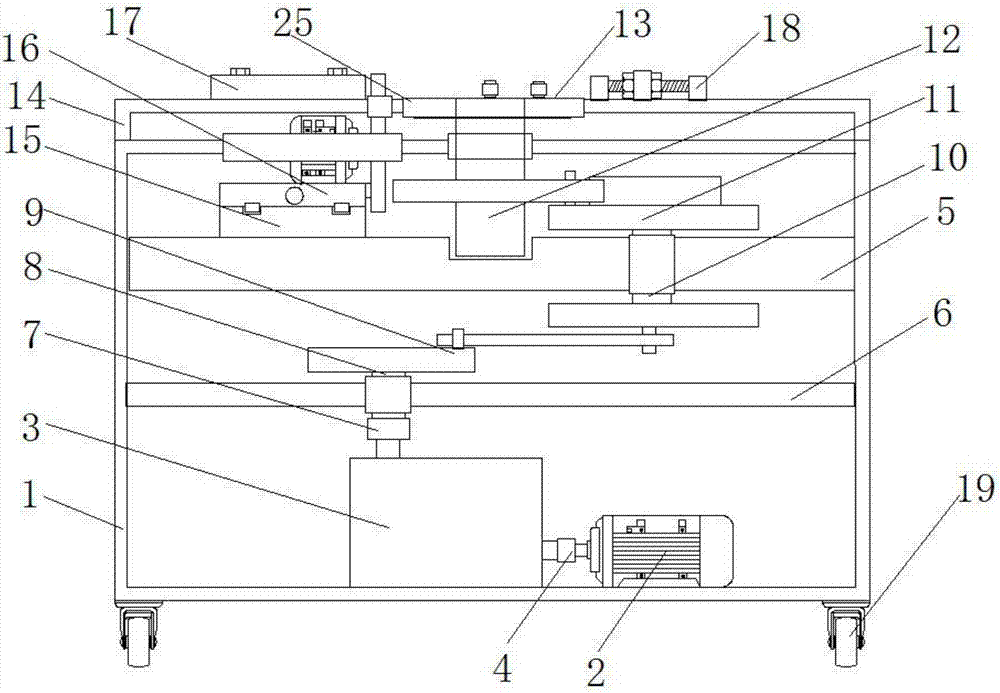

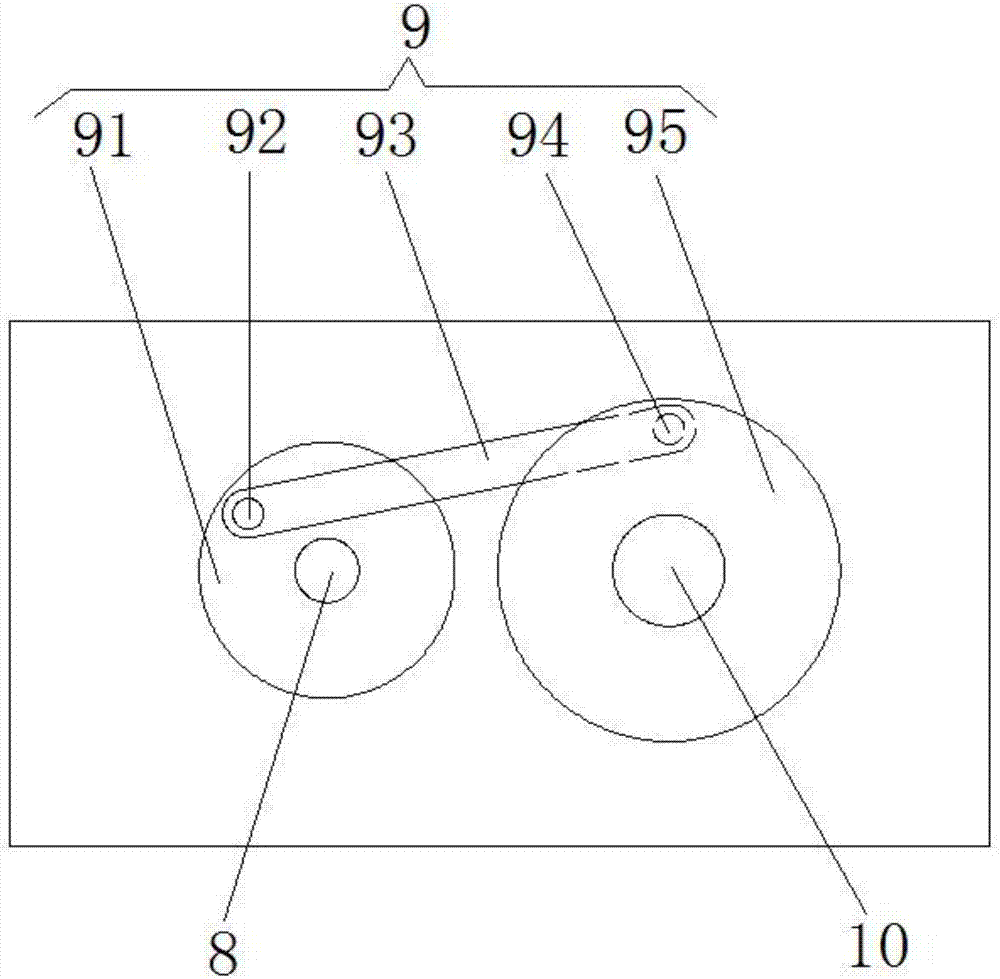

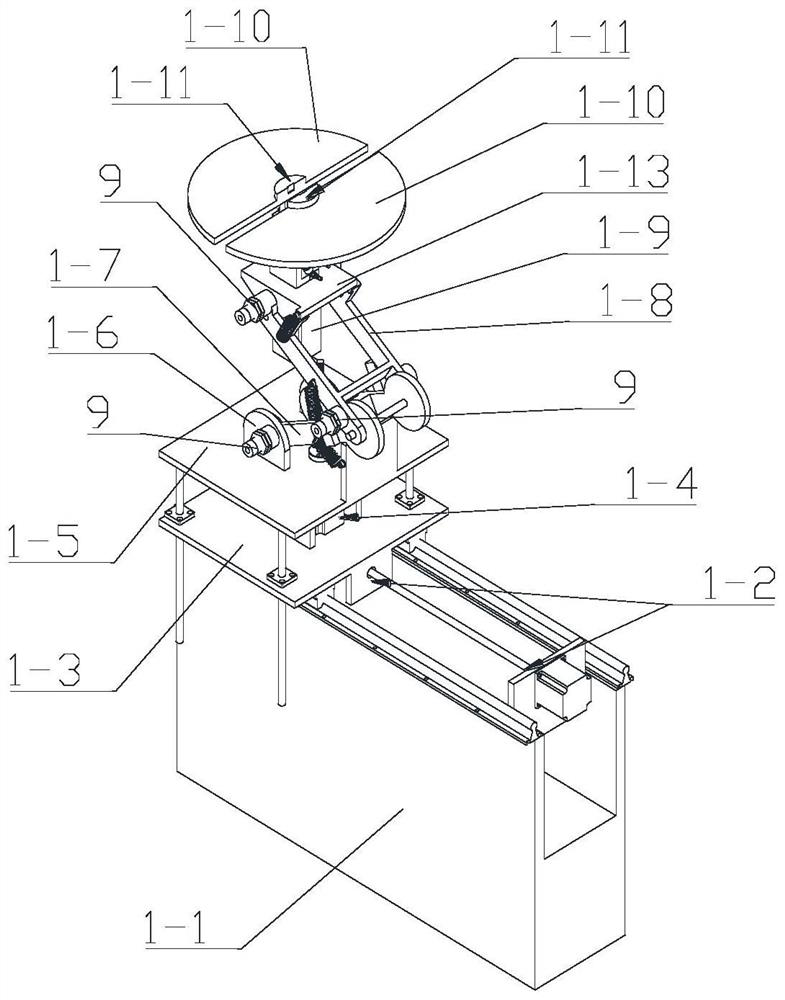

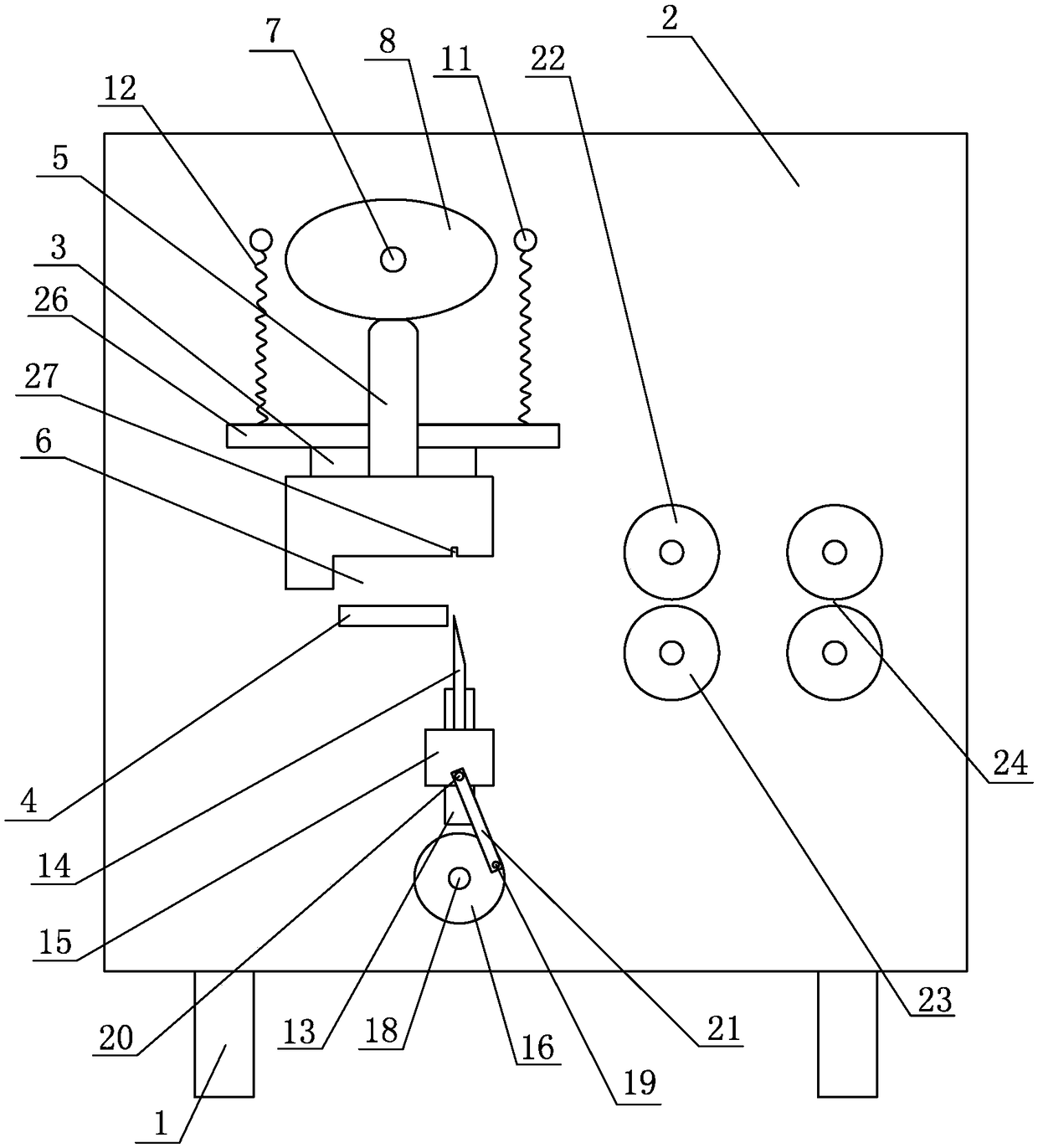

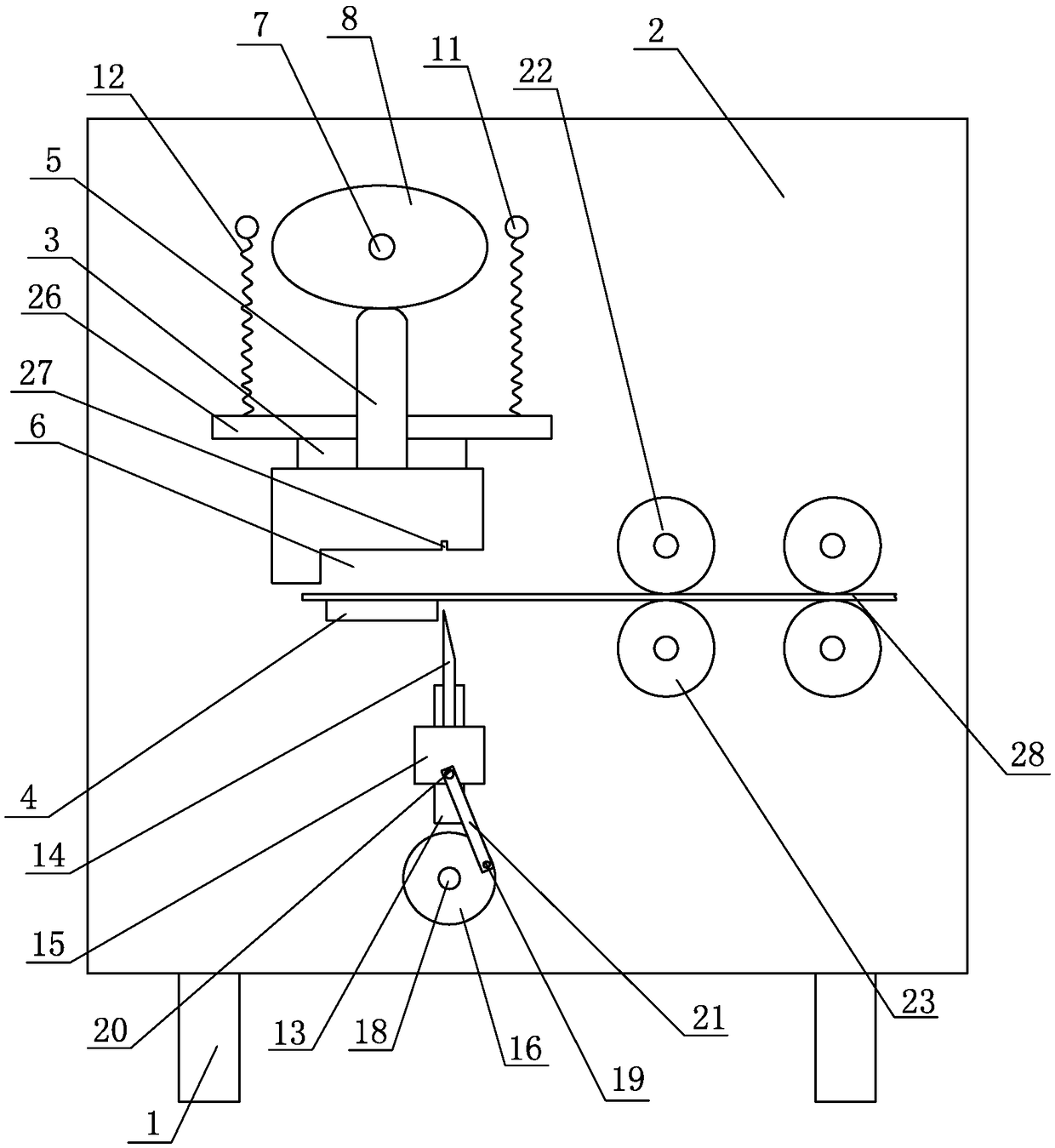

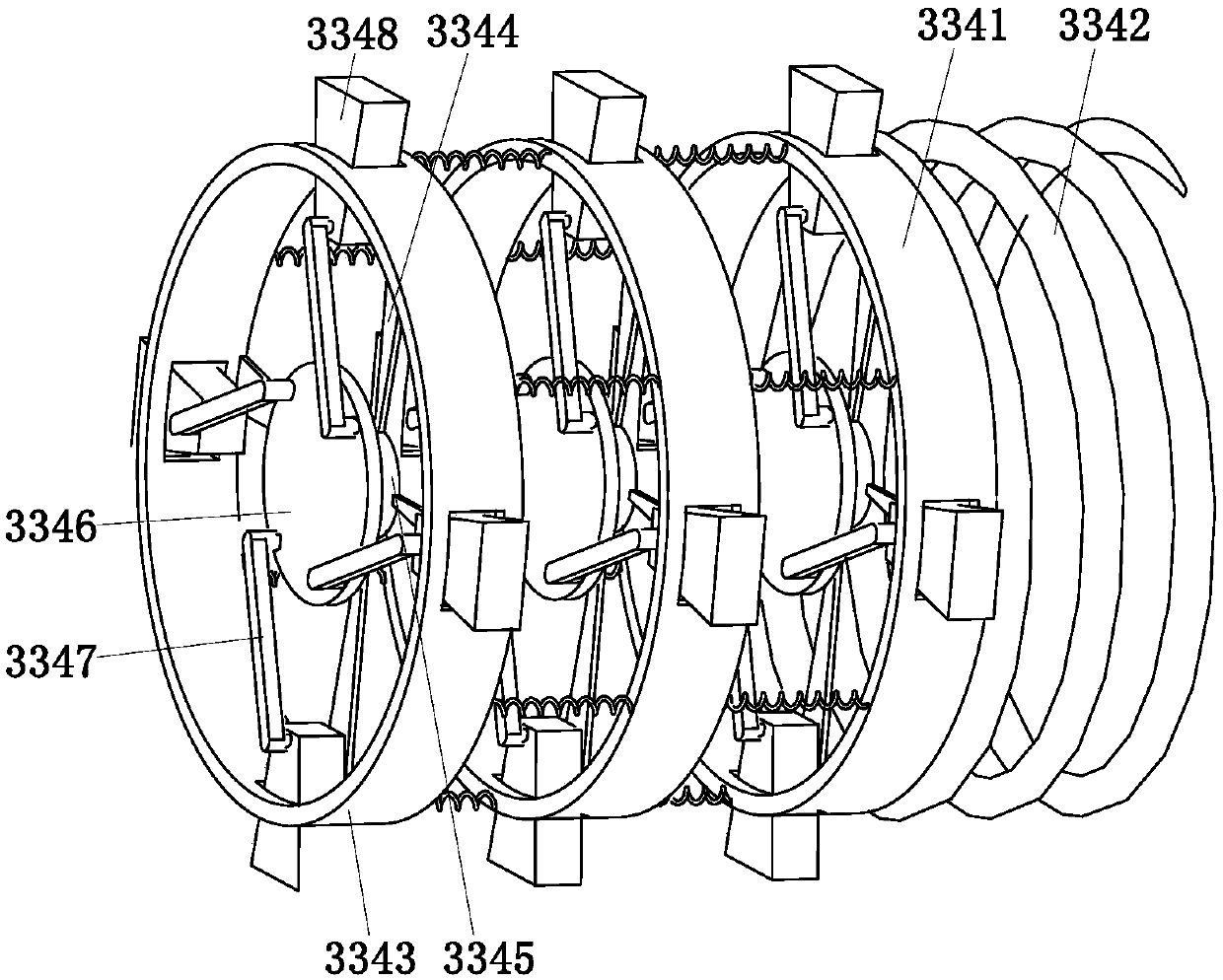

Intelligent vegetable greenhouse framework installing robot

InactiveCN106826751ARealize automatic bendingImprove parallelismManipulatorGreenhouseAgricultural engineering

The invention discloses an intelligent vegetable greenhouse framework installing robot which comprises a chassis, two circular-arc fixing racks, four walking wheels, four walking motors, two moving slide rails, two moving racks, circular-arc bent frames, a material storage box, two bent frame moving slide blocks and the like. Automatic bending of steel pipes for vegetable greenhouses is achieved by arranging the circular-arc bent frames and other structures, and bending shapes are consistent. Mutual matching between the robot with the circular-arc bent frames and other structures is achieved by arranging a steel pipe fixing system, and the action of inserting bent steel pipes into soil is also achieved. The intelligent vegetable greenhouse framework installing robot is reasonable in structure and high in working efficiency, the productive forces are effectively liberated, separation distance settings of vegetable greenhouse frameworks are accurate, the parallelism is good, and the problem of low fitting contact degree between plastic films and frameworks is effectively solved.

Owner:襄阳金美科林农业开发有限公司

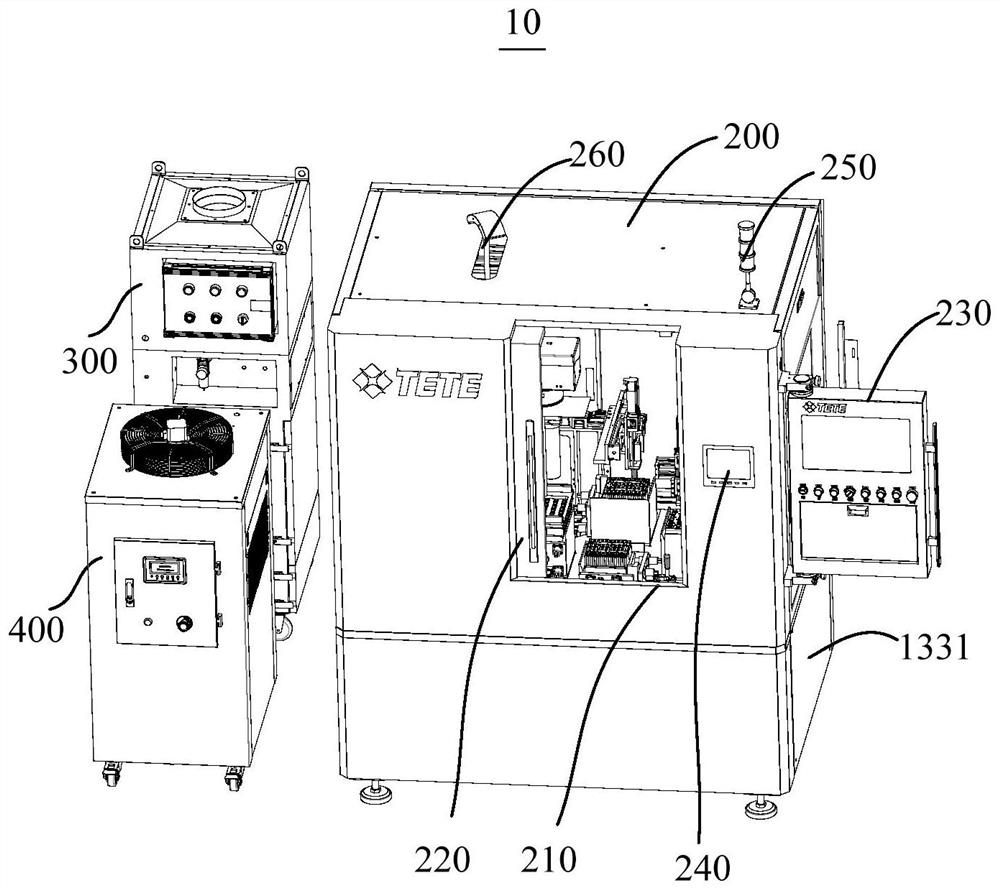

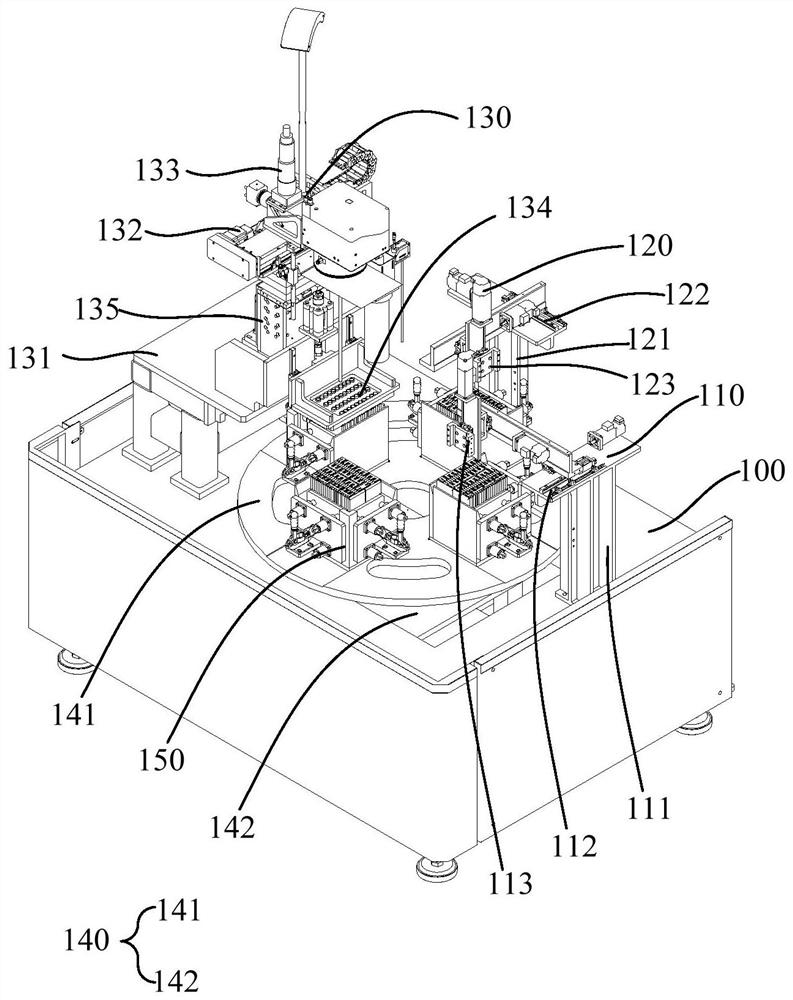

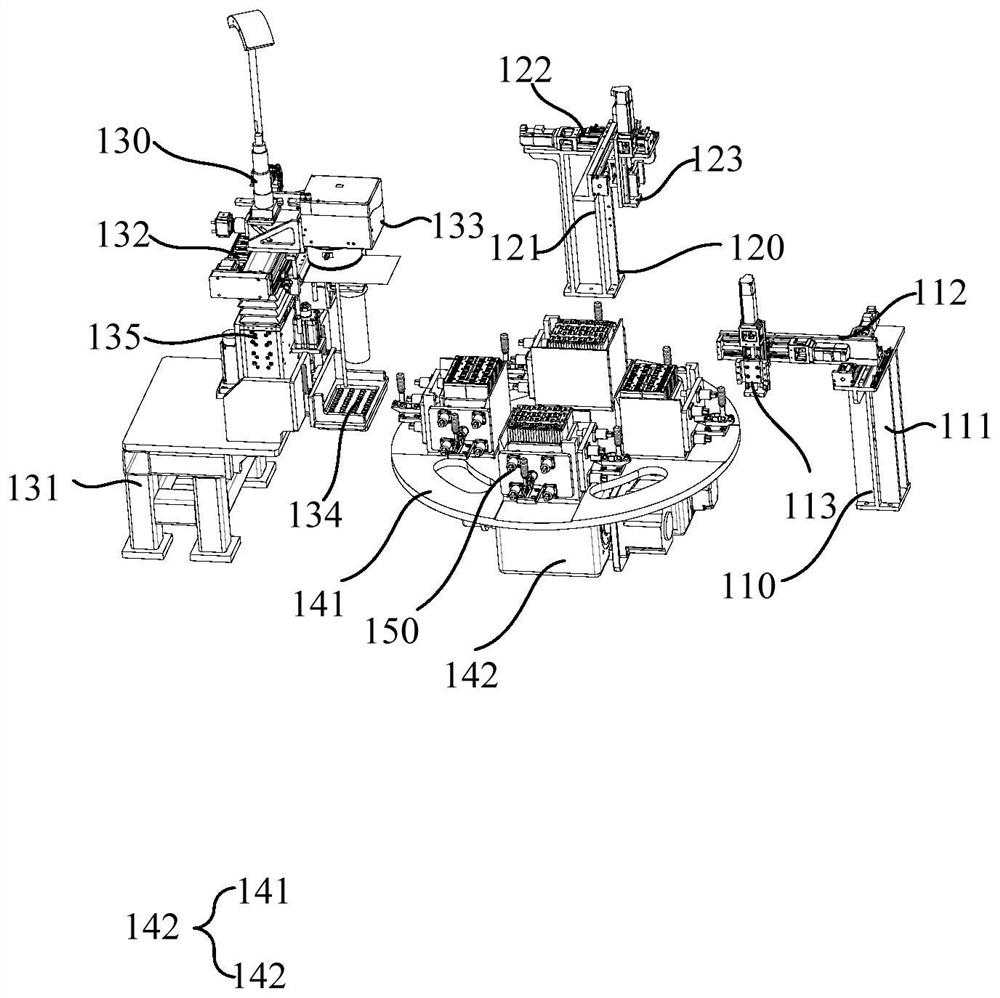

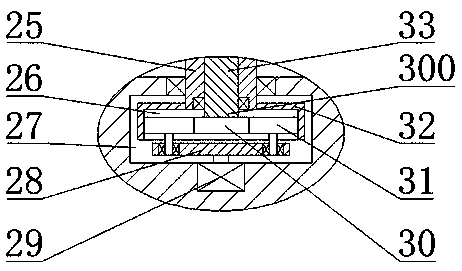

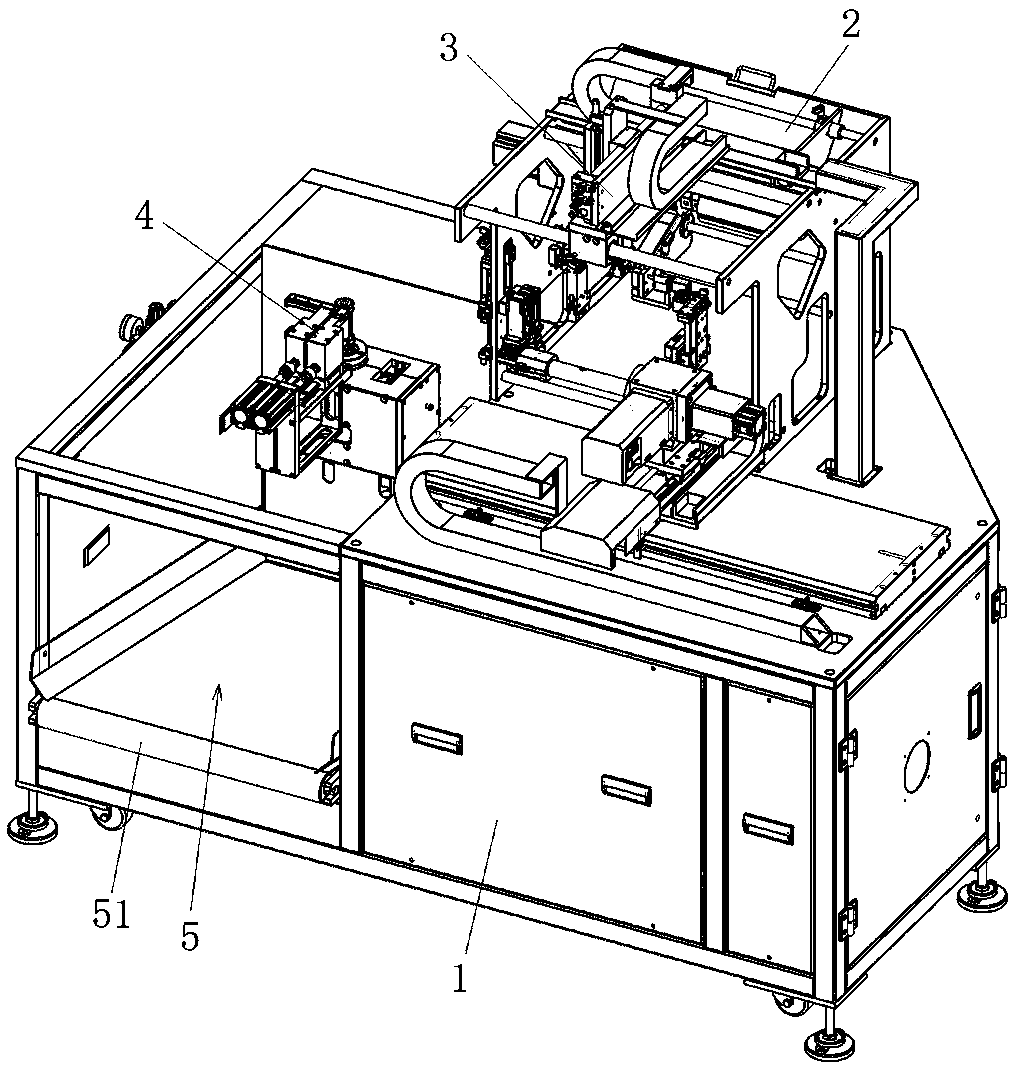

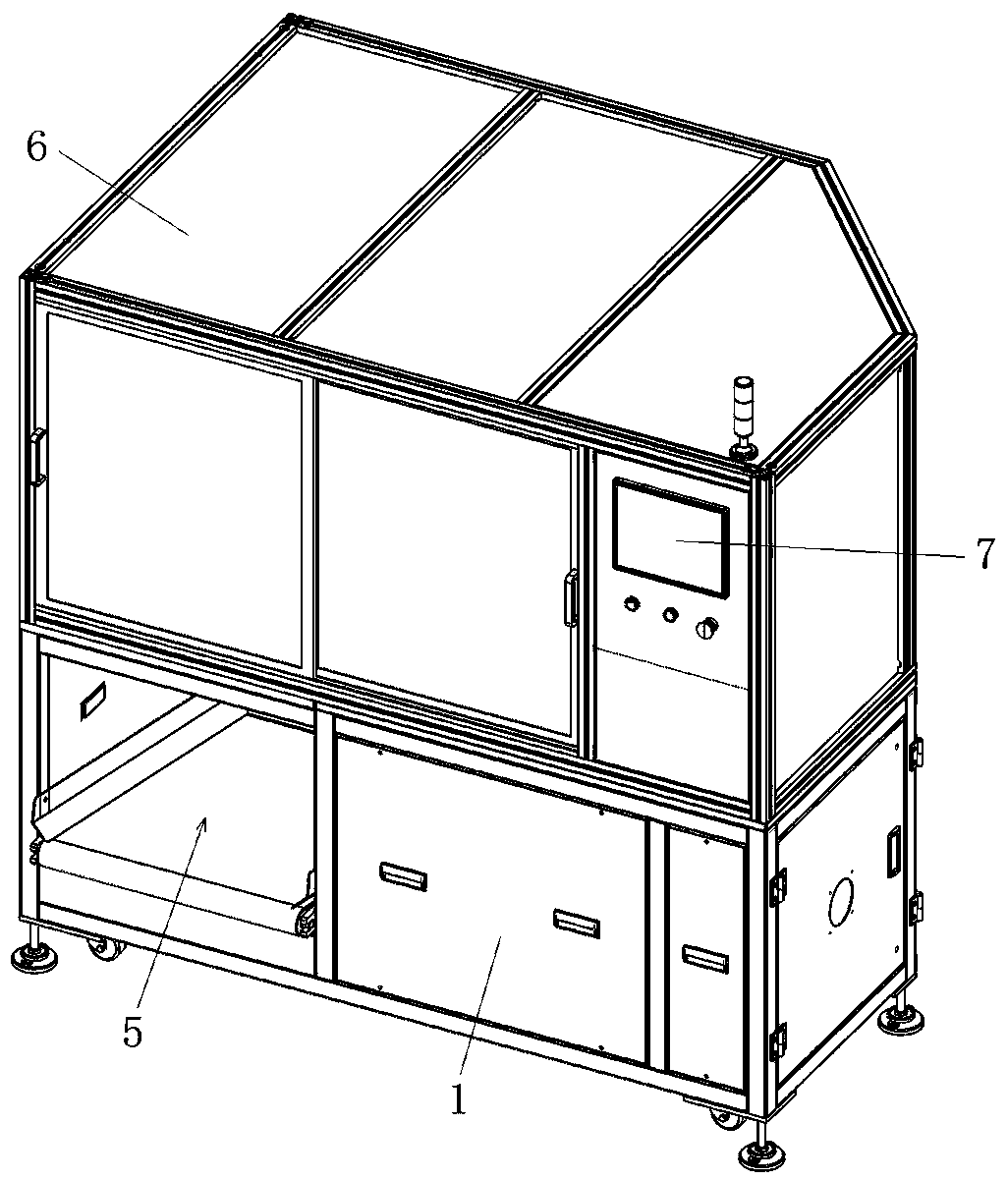

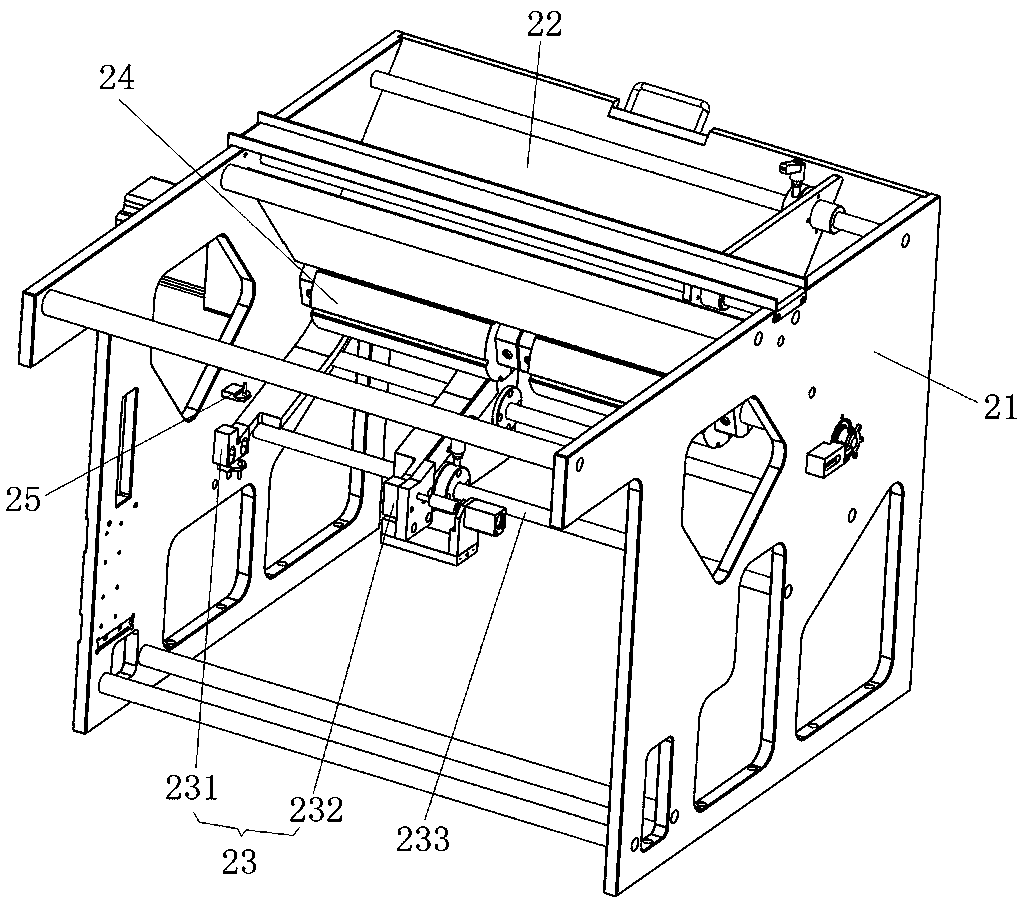

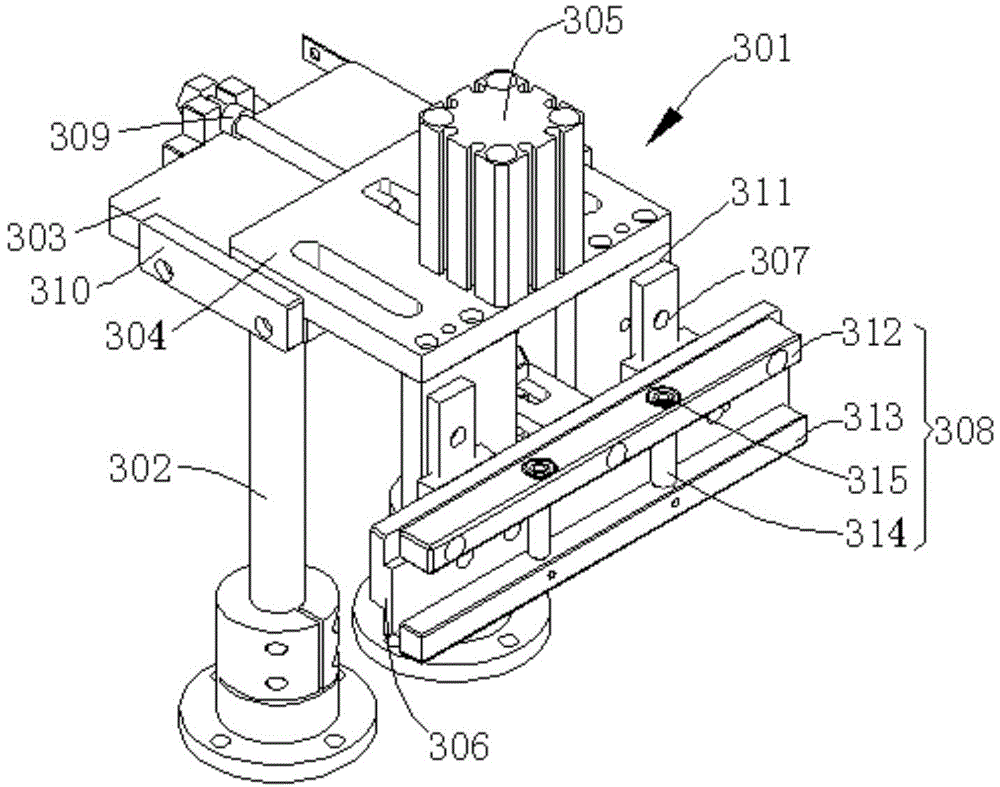

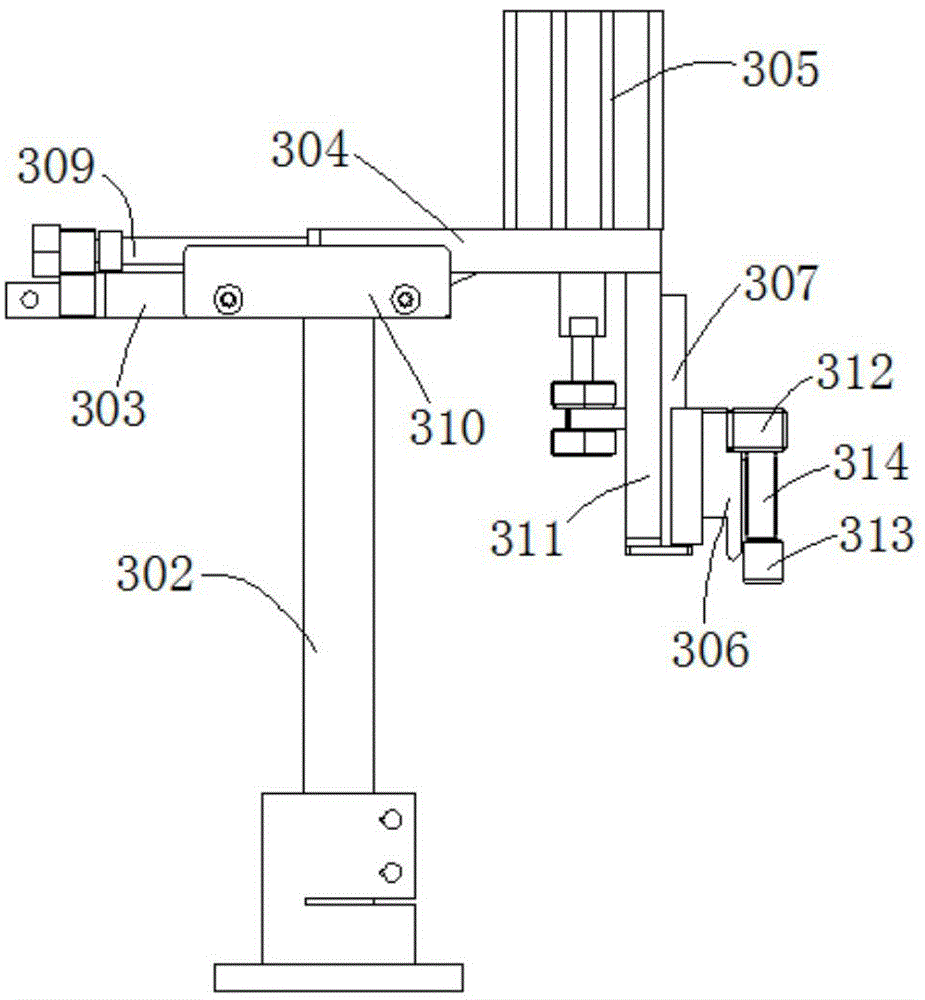

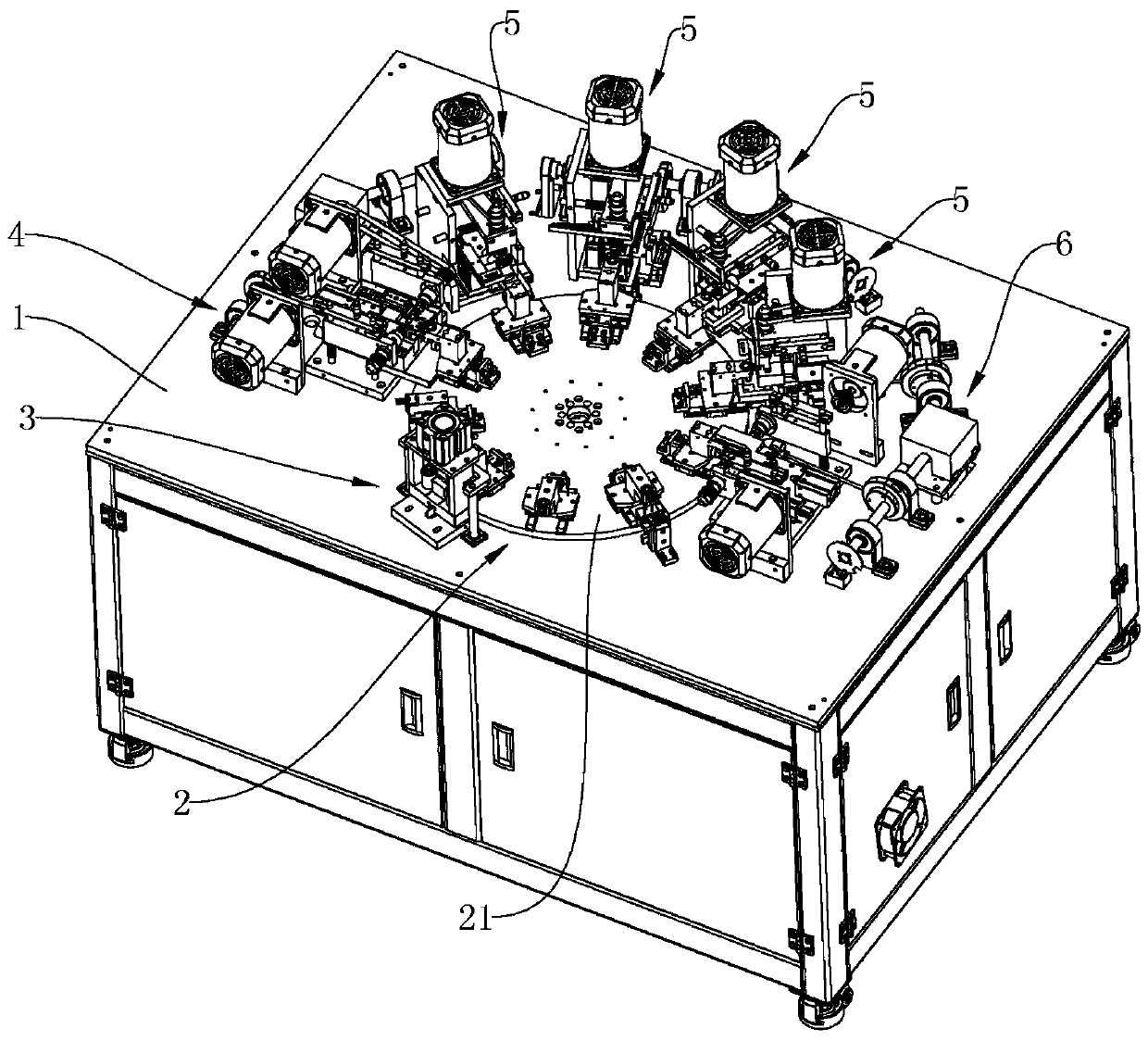

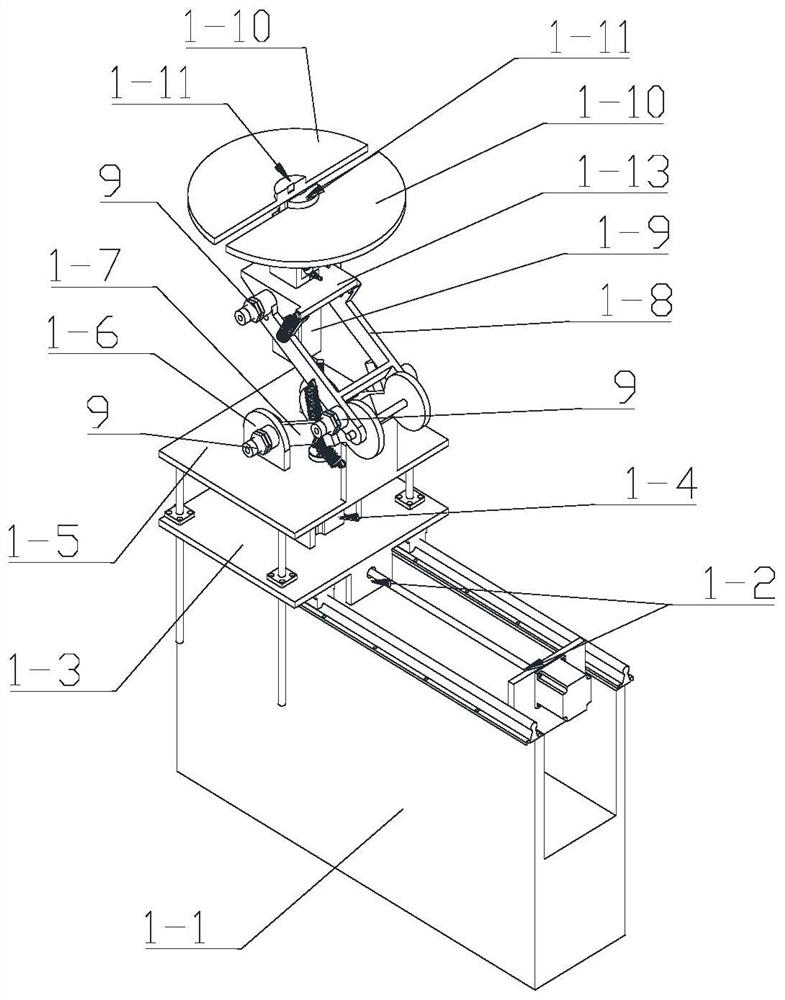

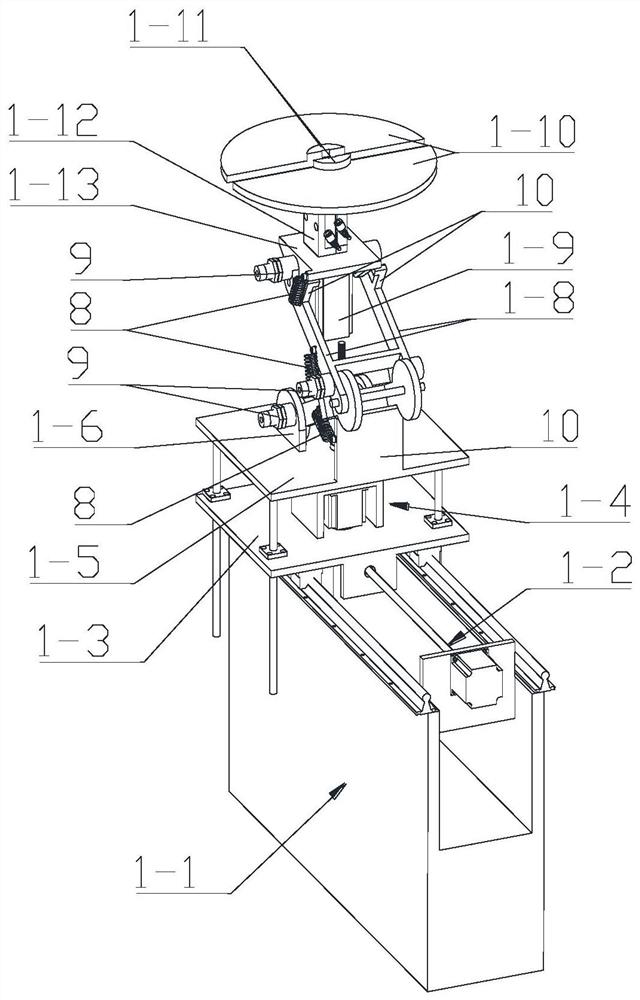

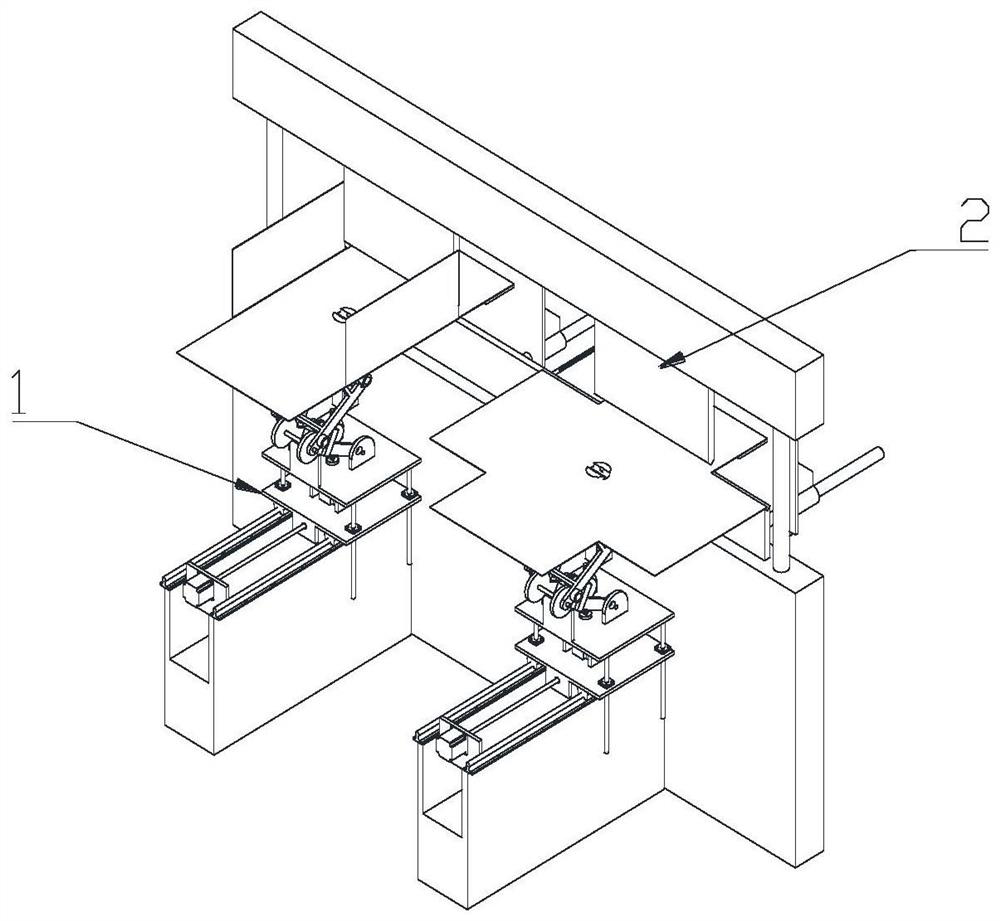

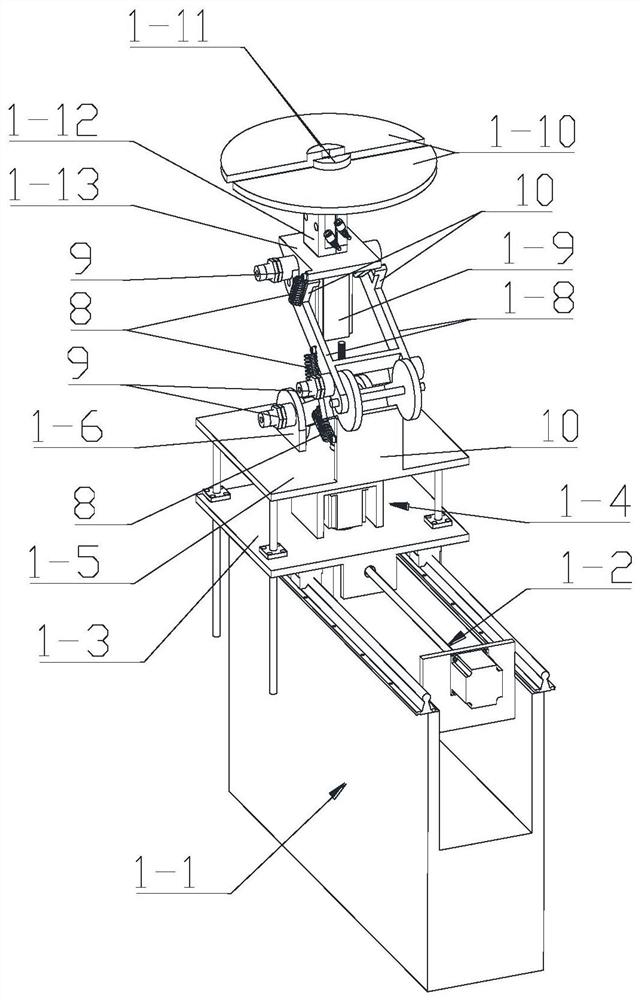

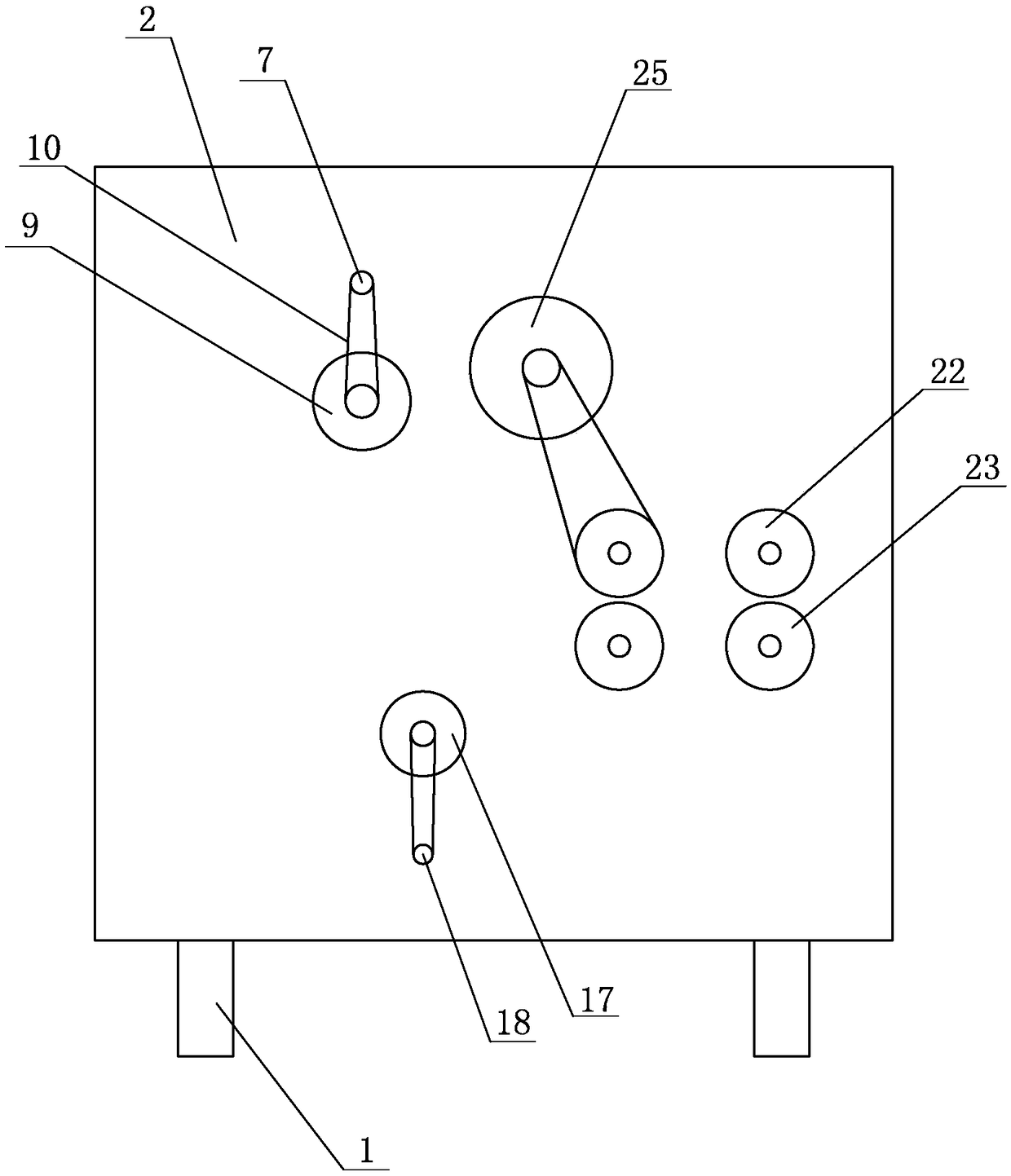

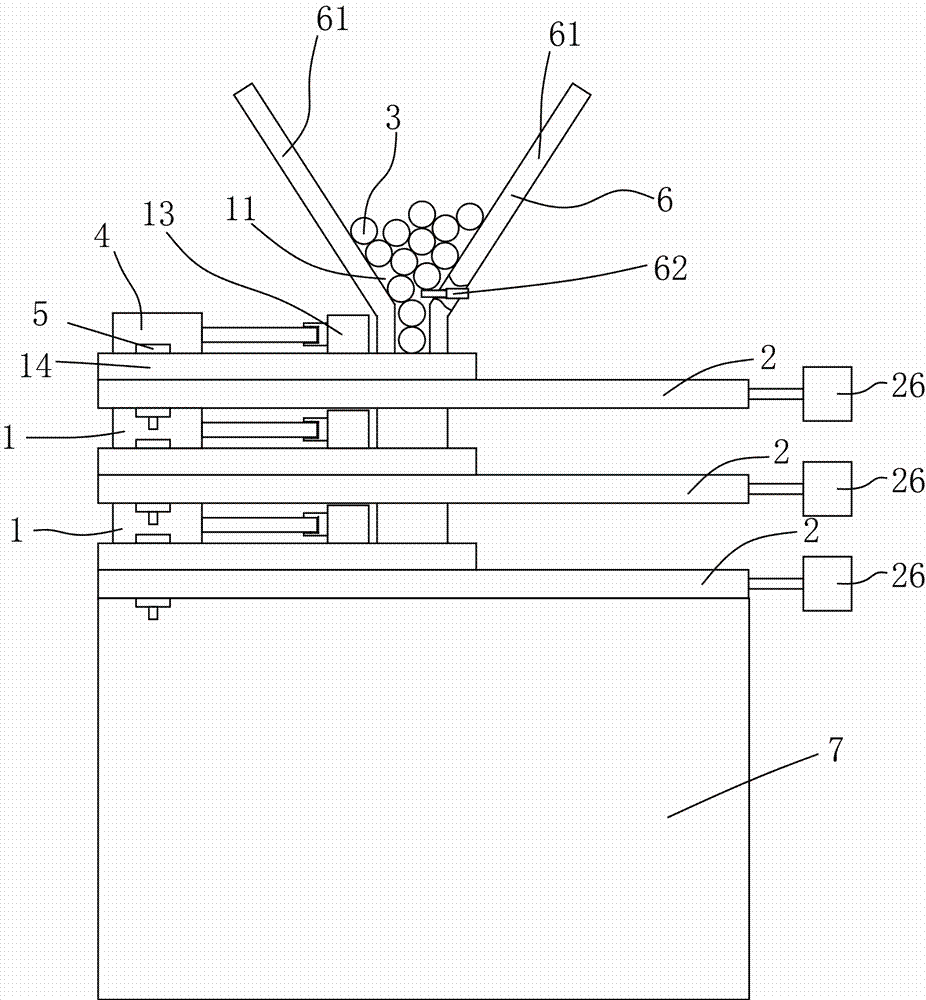

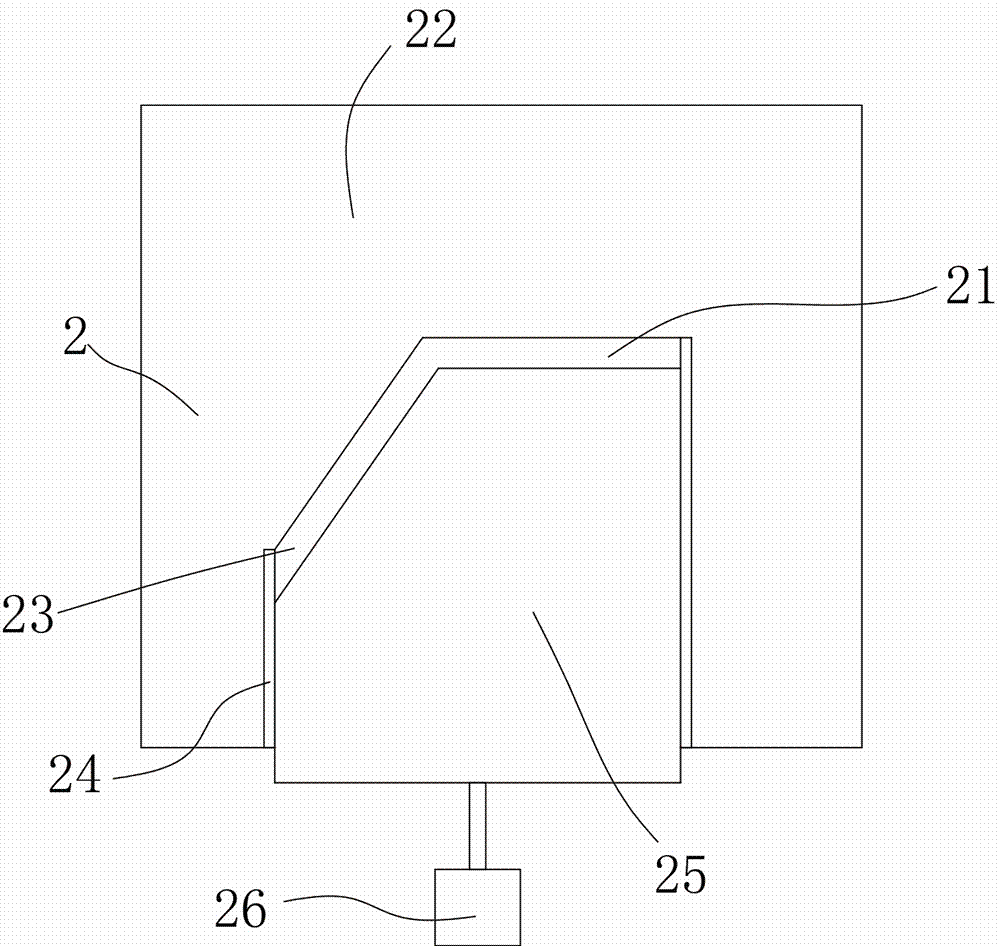

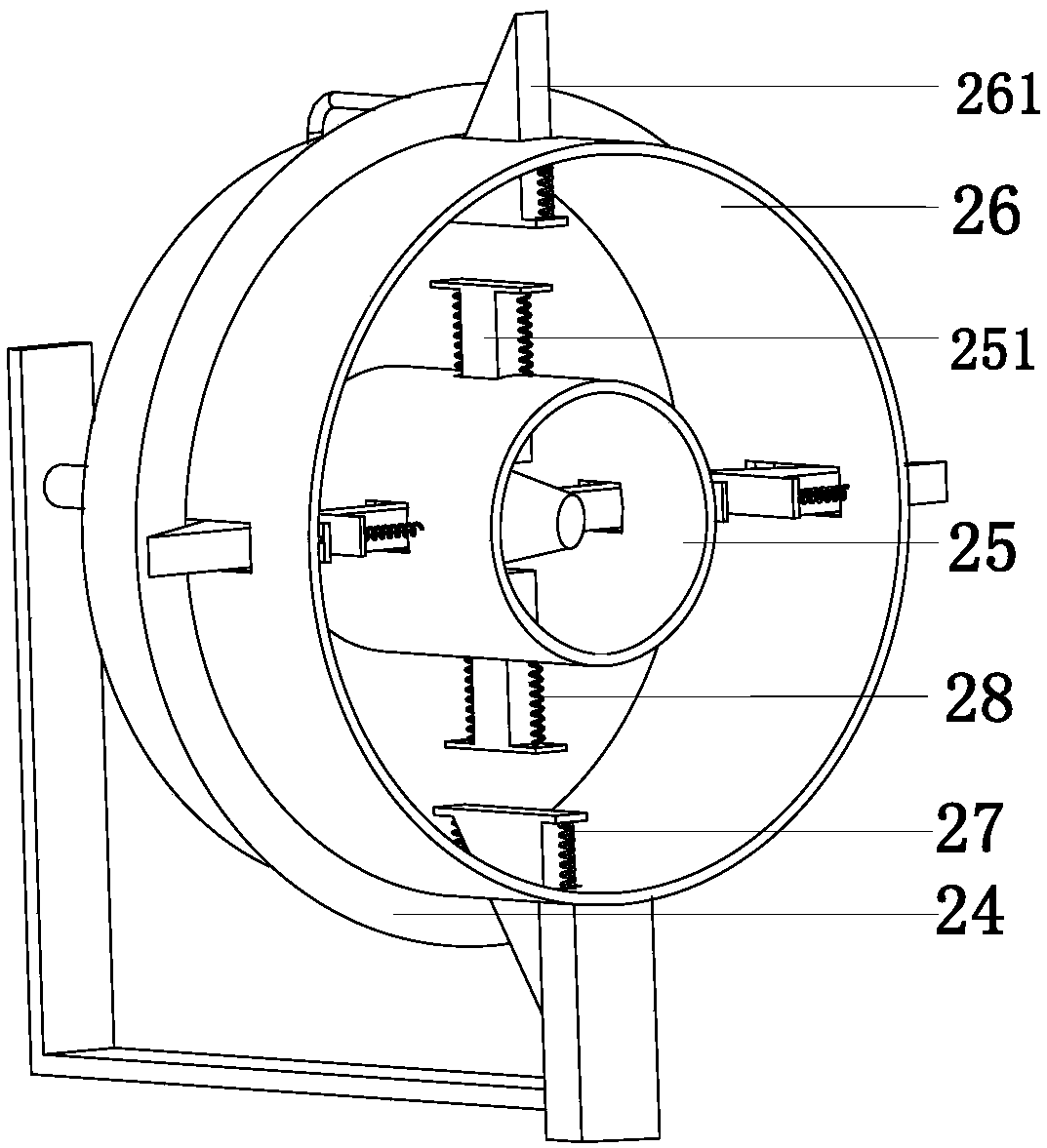

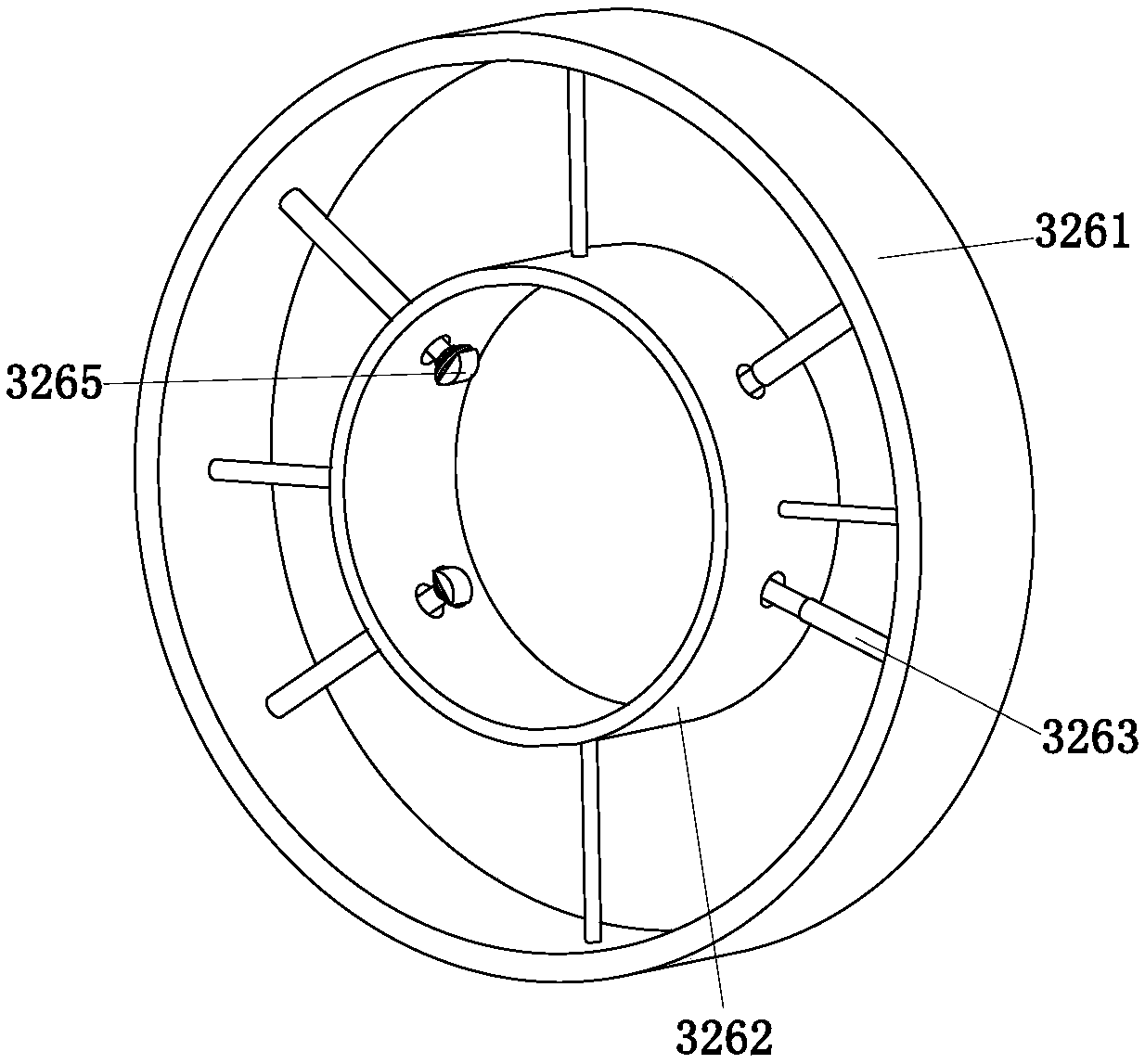

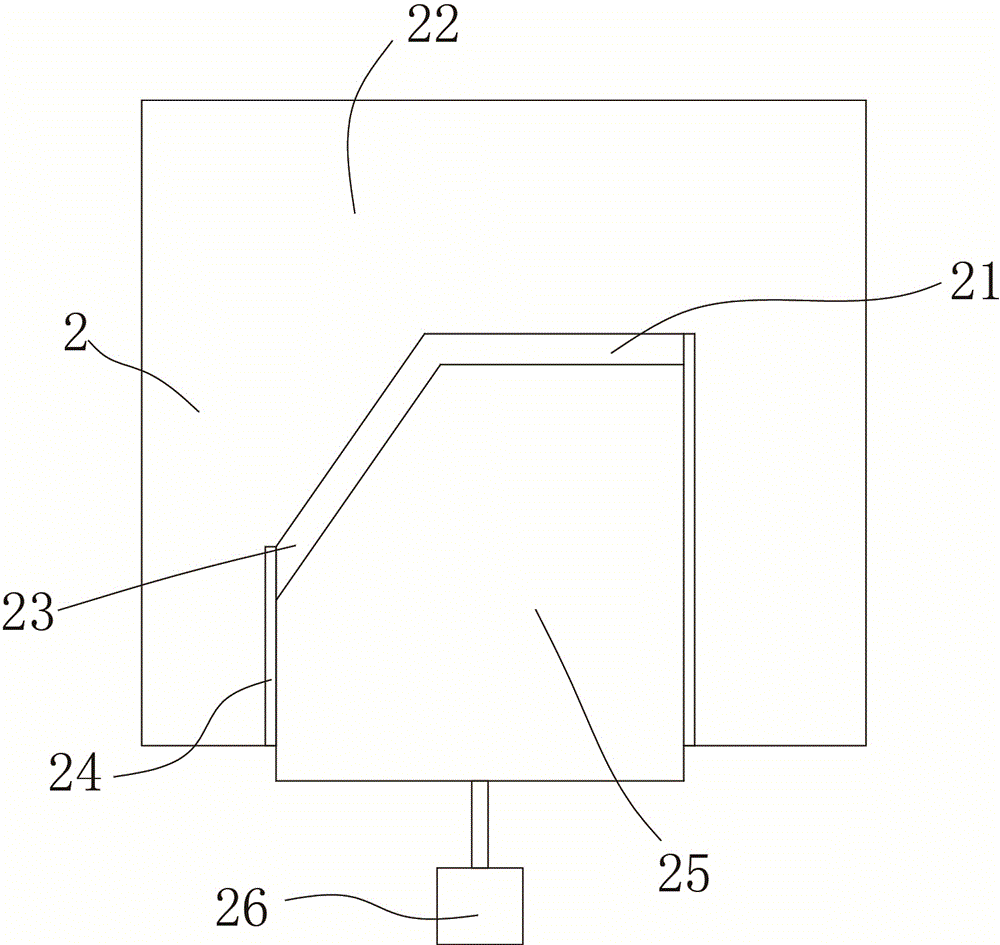

Laser welding device for tab of battery module

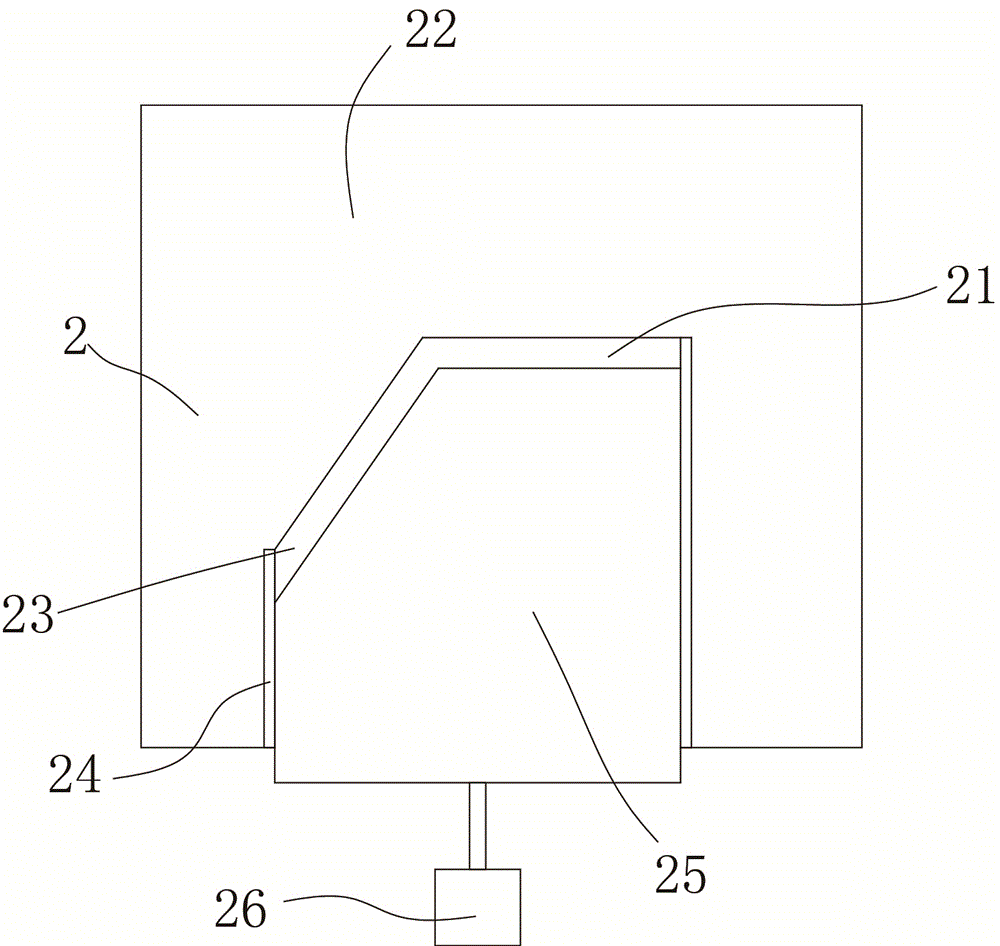

PendingCN113020982AAutomateImprove welding qualitySmall-sized cells cases/jacketsOther manufacturing equipments/toolsPhysicsLaser soldering

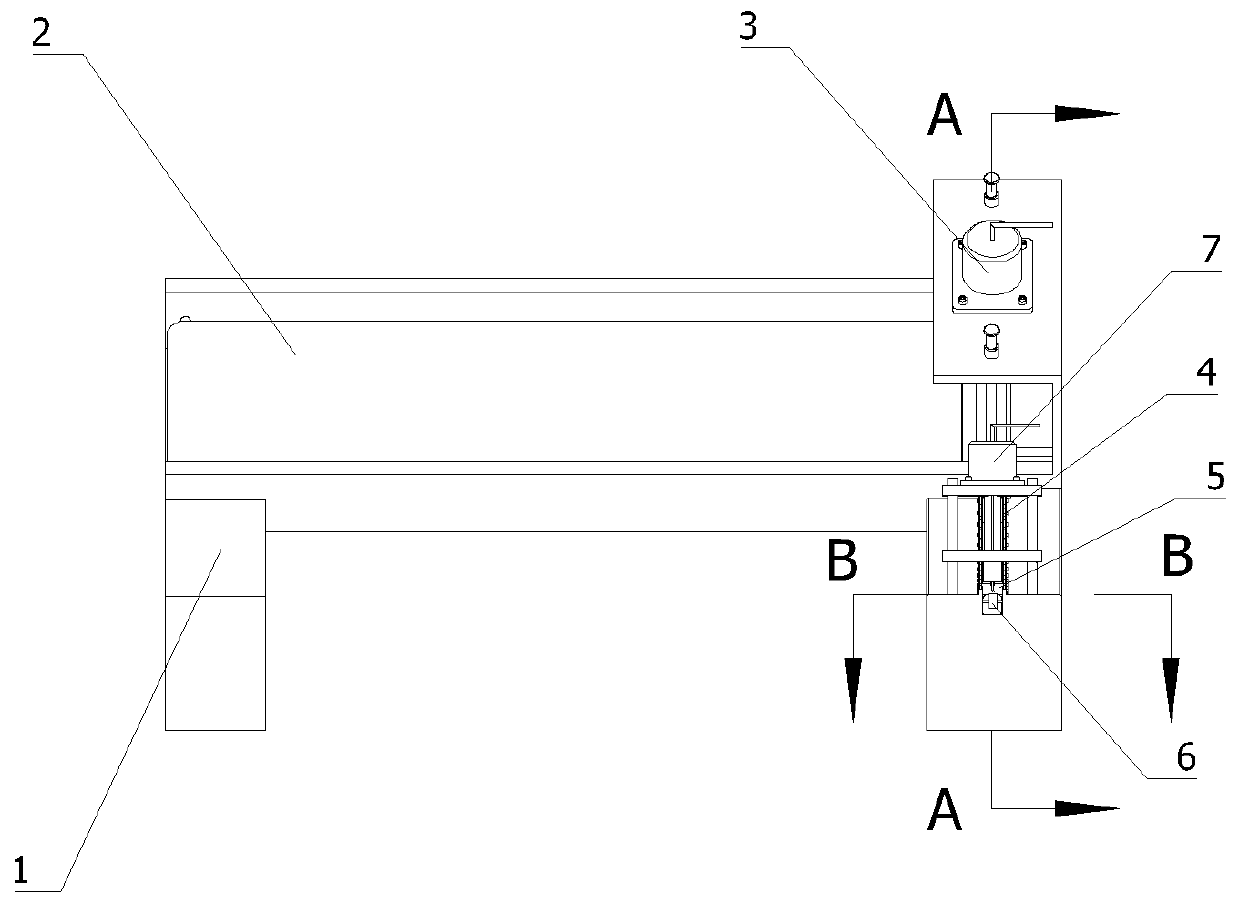

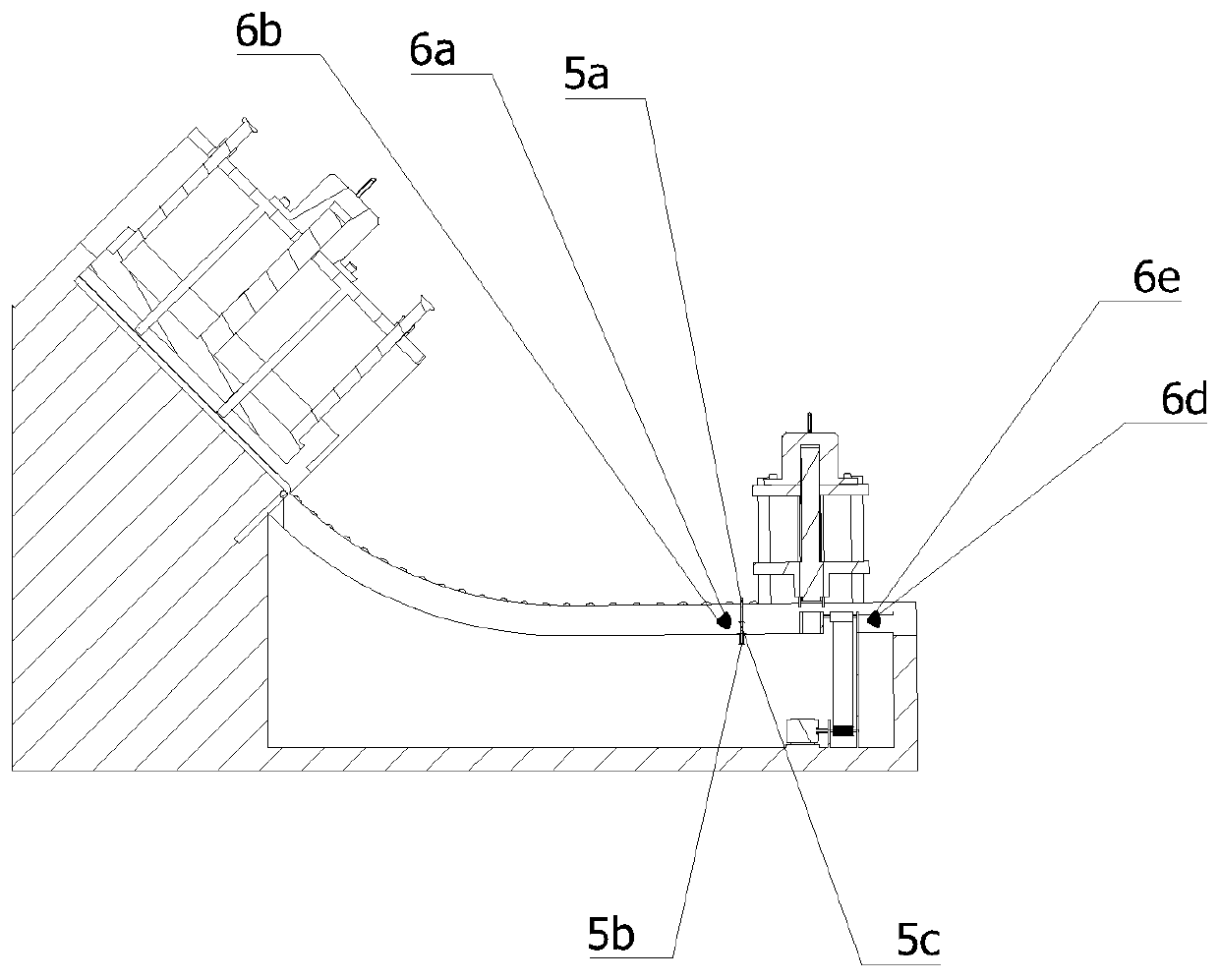

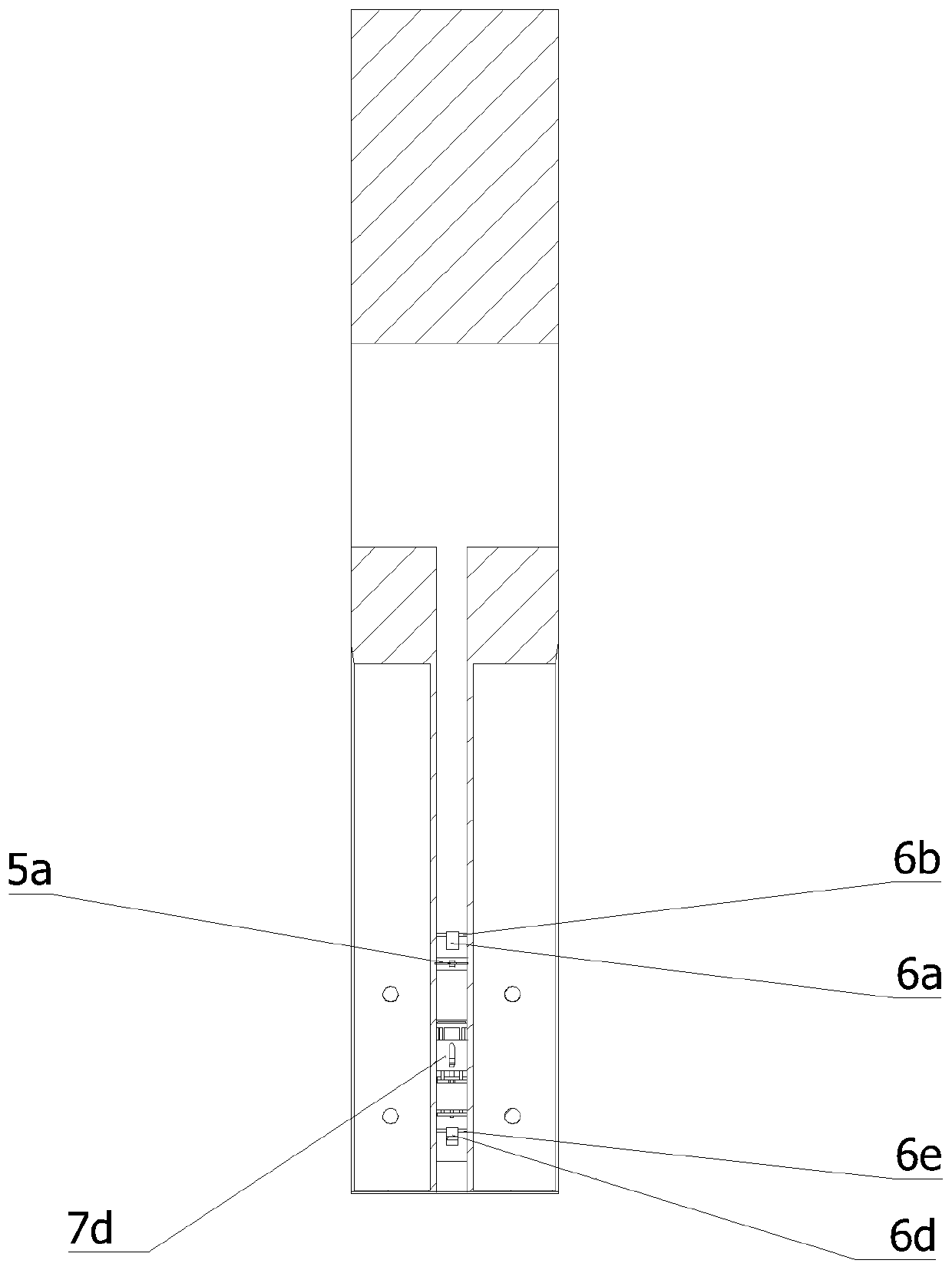

The invention discloses a laser welding device for a tab of a battery module. The device comprises a rack platform, a bending mechanism, a rolling mechanism, a laser welding mechanism and an index plate mechanism, wherein the rack platform is provided with a bending area, a rolling area and a welding area; the bending mechanism is mounted in the bending area and is used for bending the tab of the battery module; the rolling mechanism is mounted in the rolling area and is used for rolling the tab of the battery module; the laser welding mechanism is installed in the welding area and used for conducting laser welding on the tab of the battery module; and the index plate mechanism comprises an index plate and a first driving device, and the first driving device is used for driving the index plate to rotate so as to drive the battery module placed on the index plate to rotate, so that the battery module can pass through the bending area, the rolling area and the welding area. The welding automation of the battery tab can be realized, the quality of tab welding is improved, further, the qualified rate of tab welding is improved, meanwhile, the operation is easy, and application and convenience are achieved.

Owner:SHENZHEN TETELASER TECH CO LTD

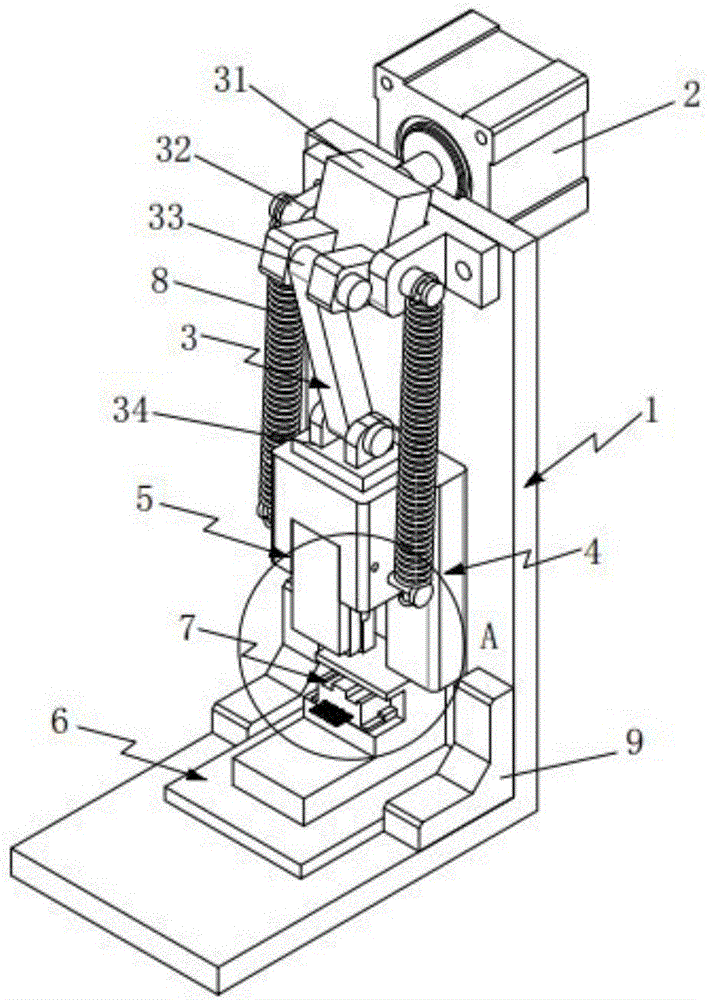

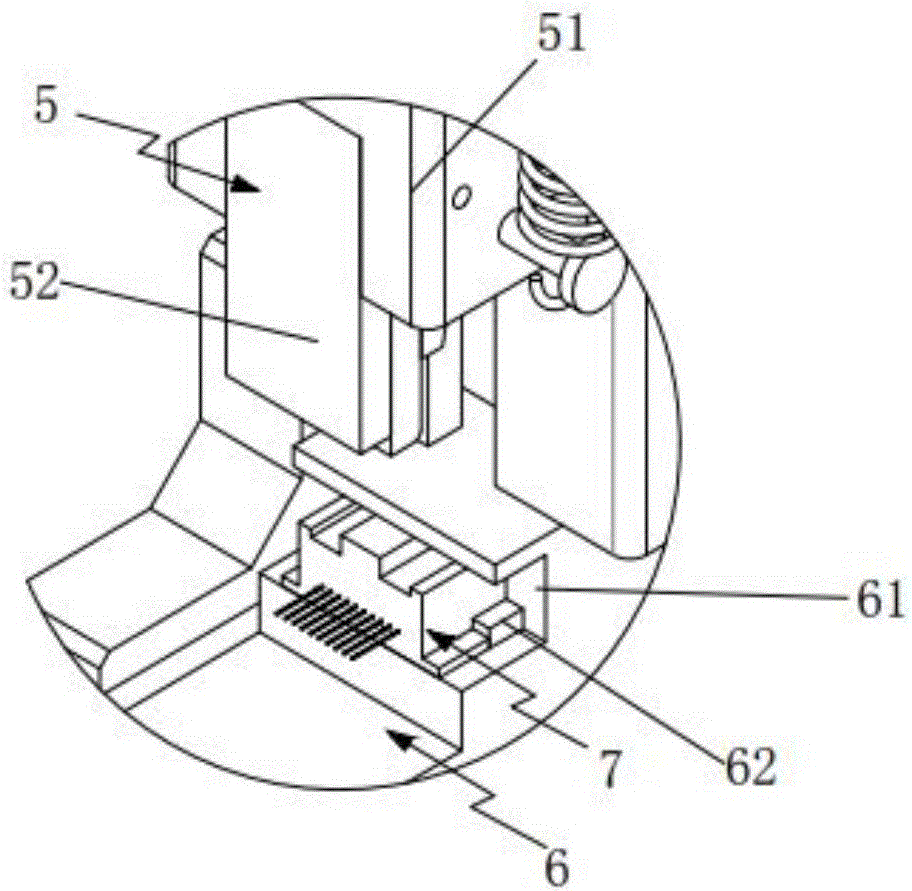

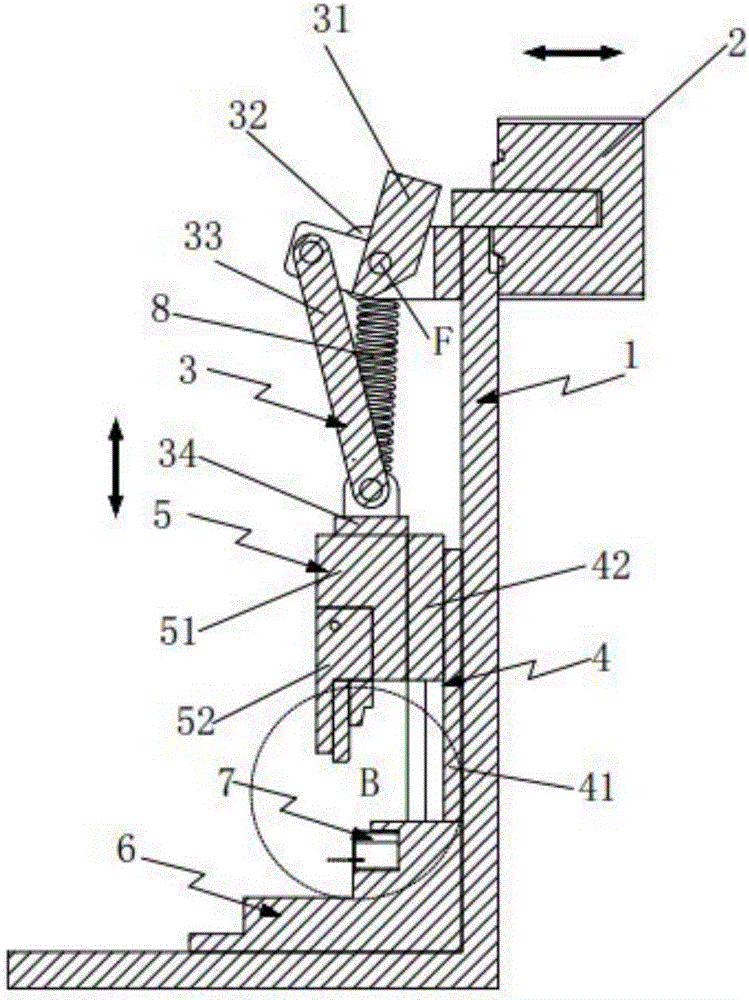

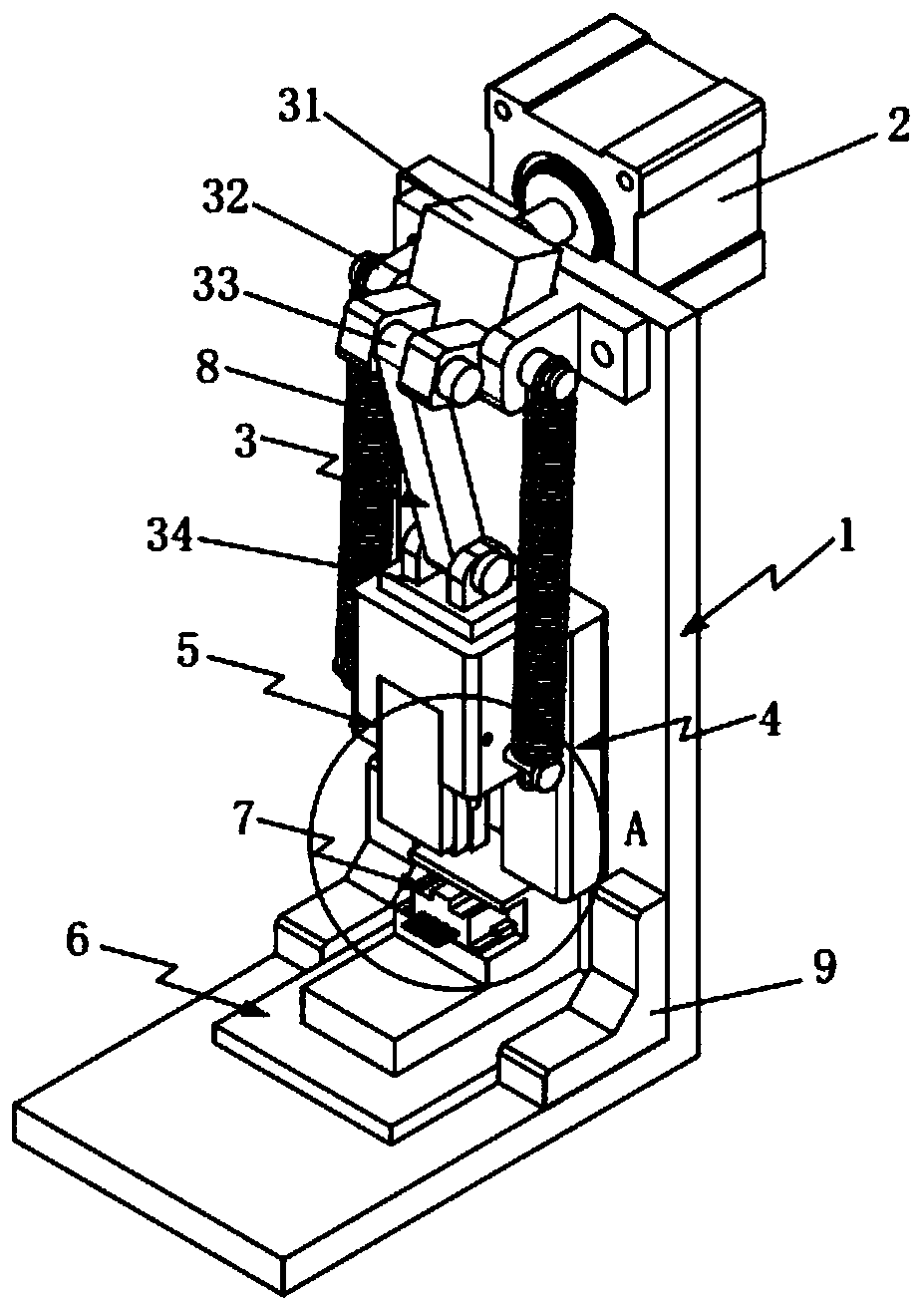

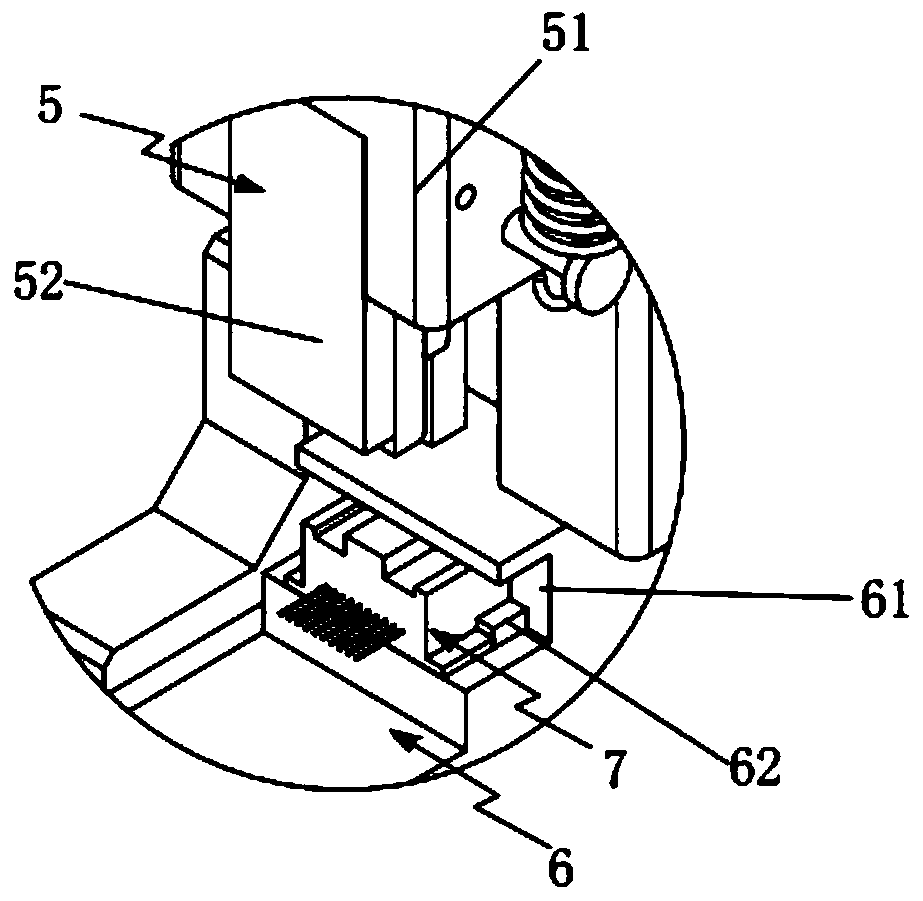

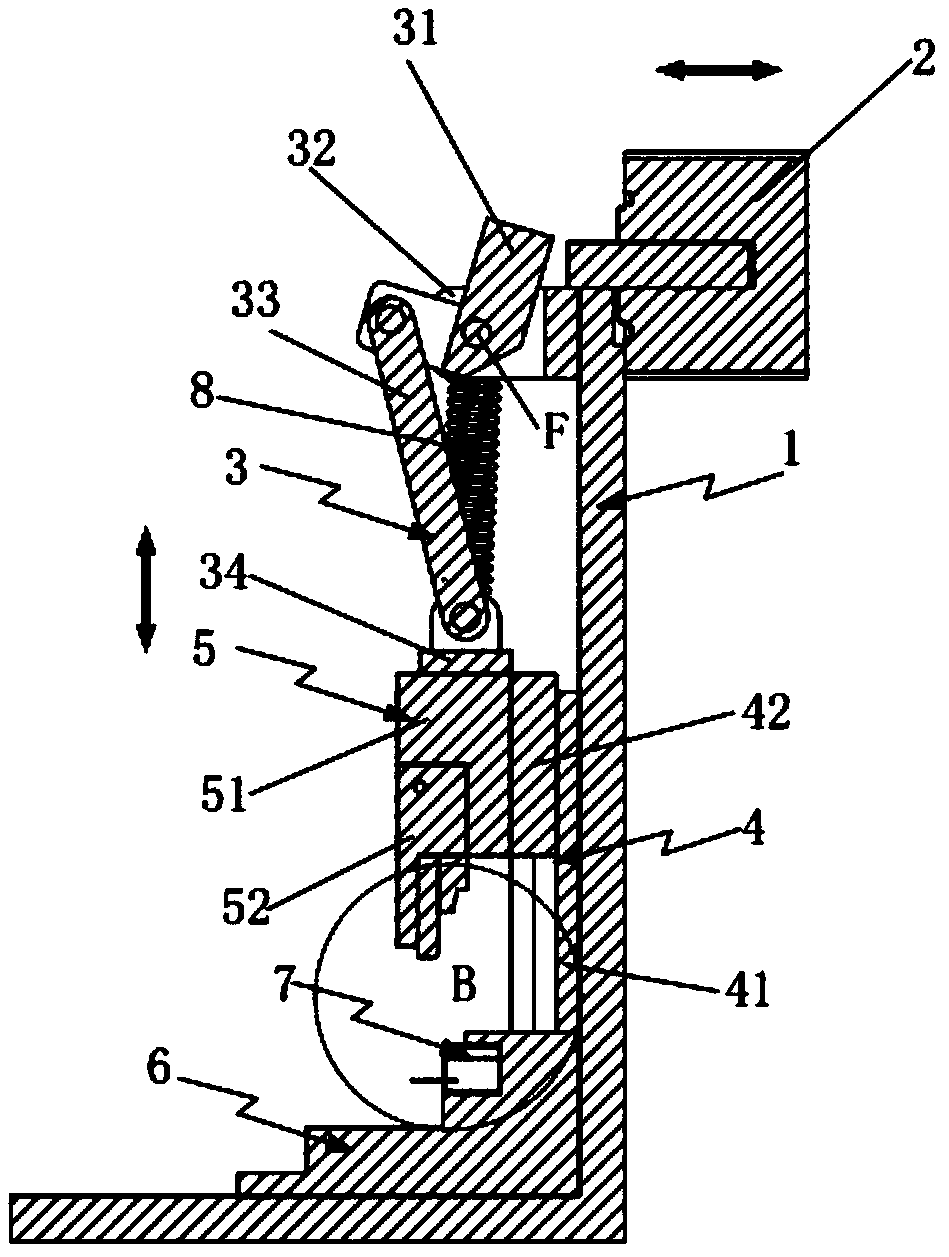

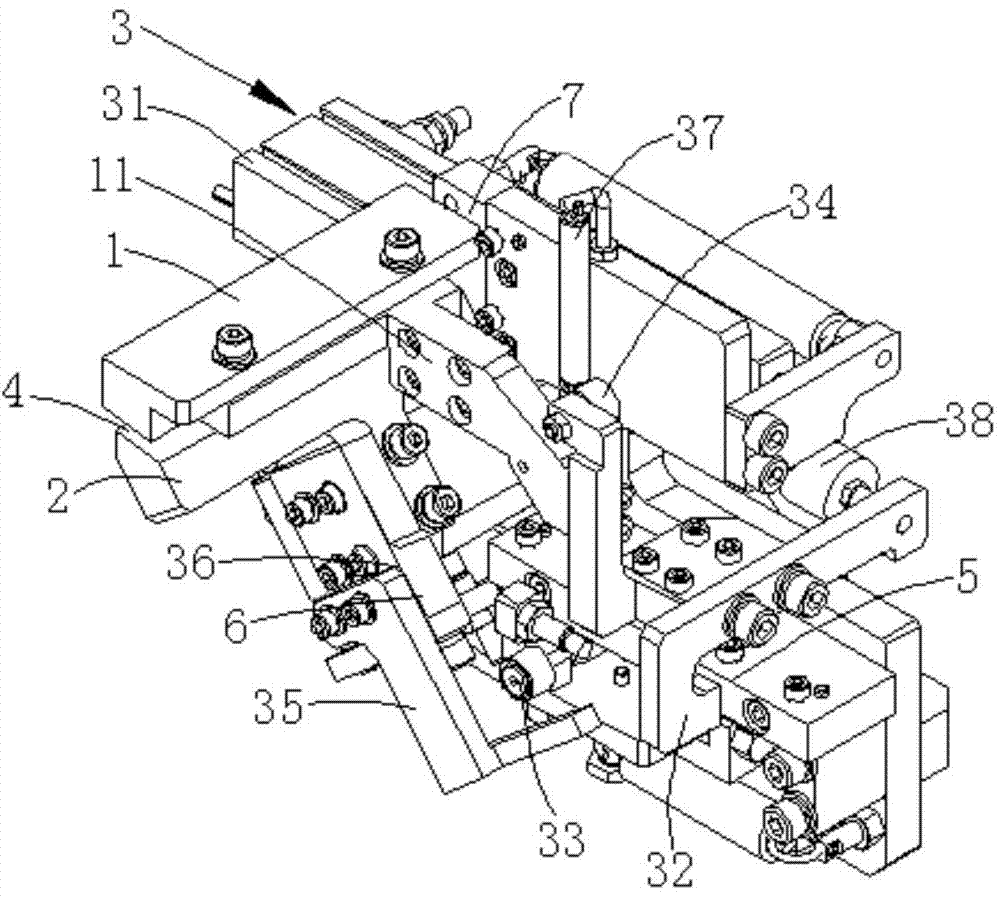

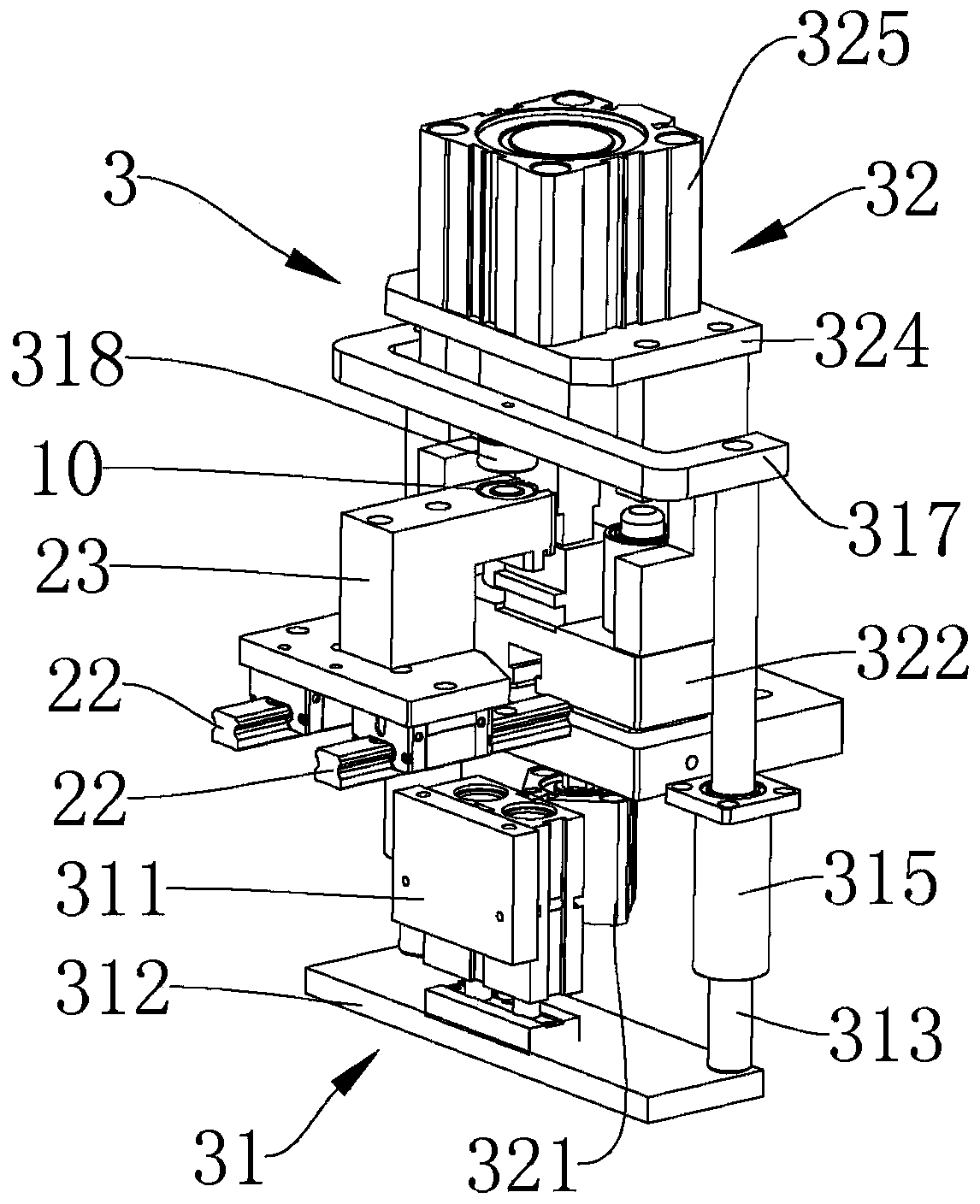

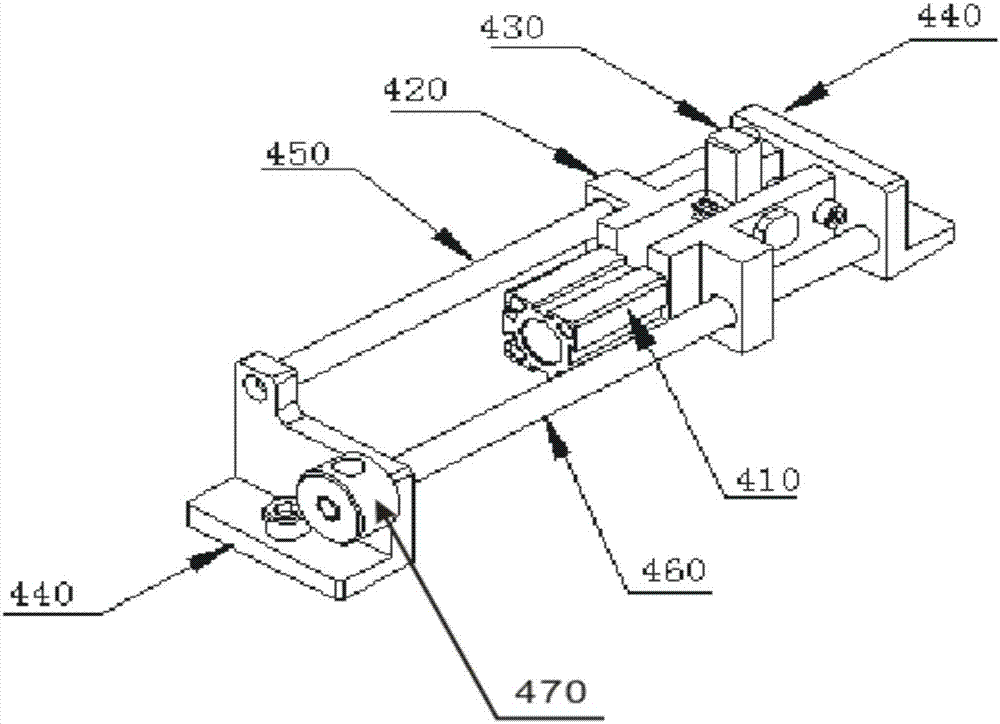

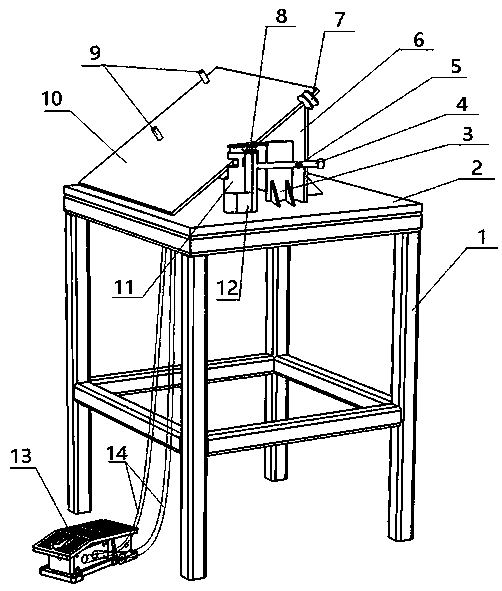

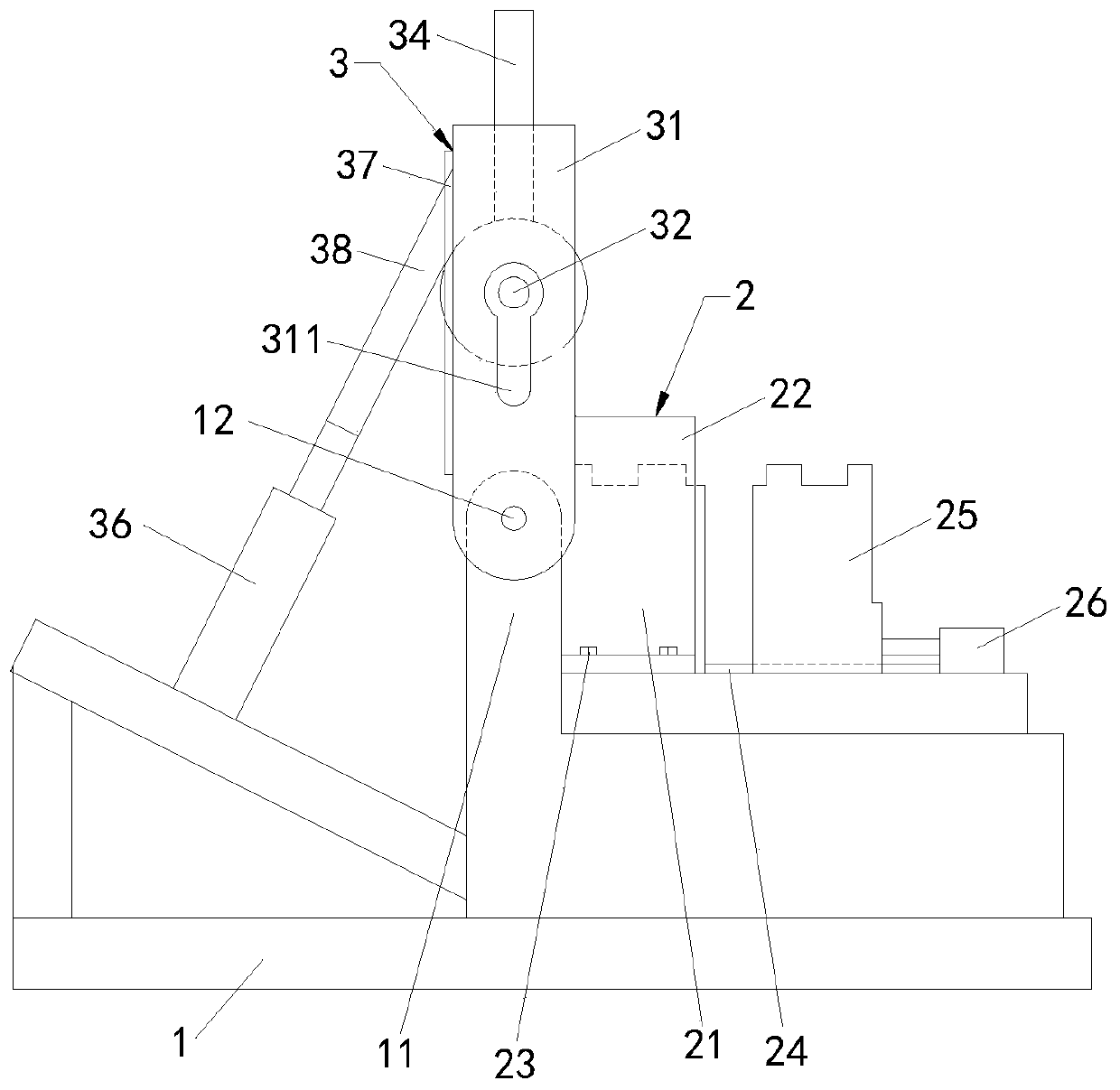

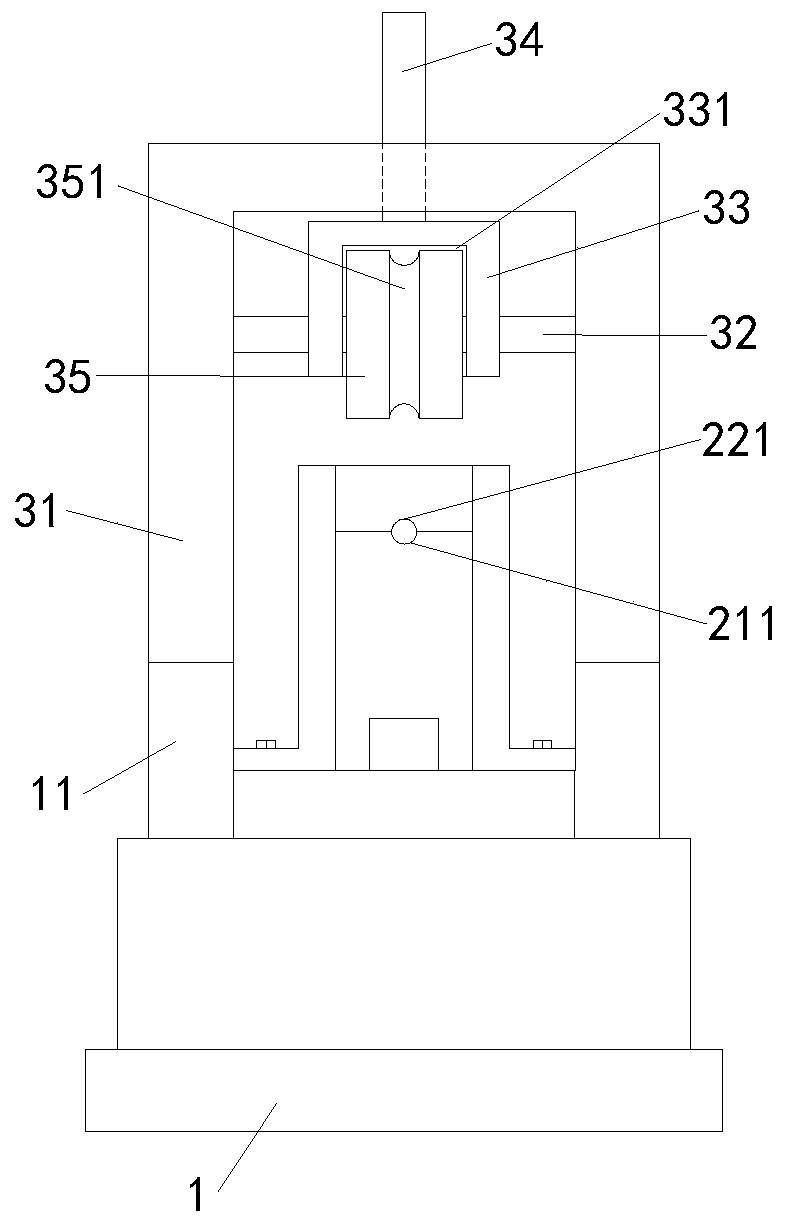

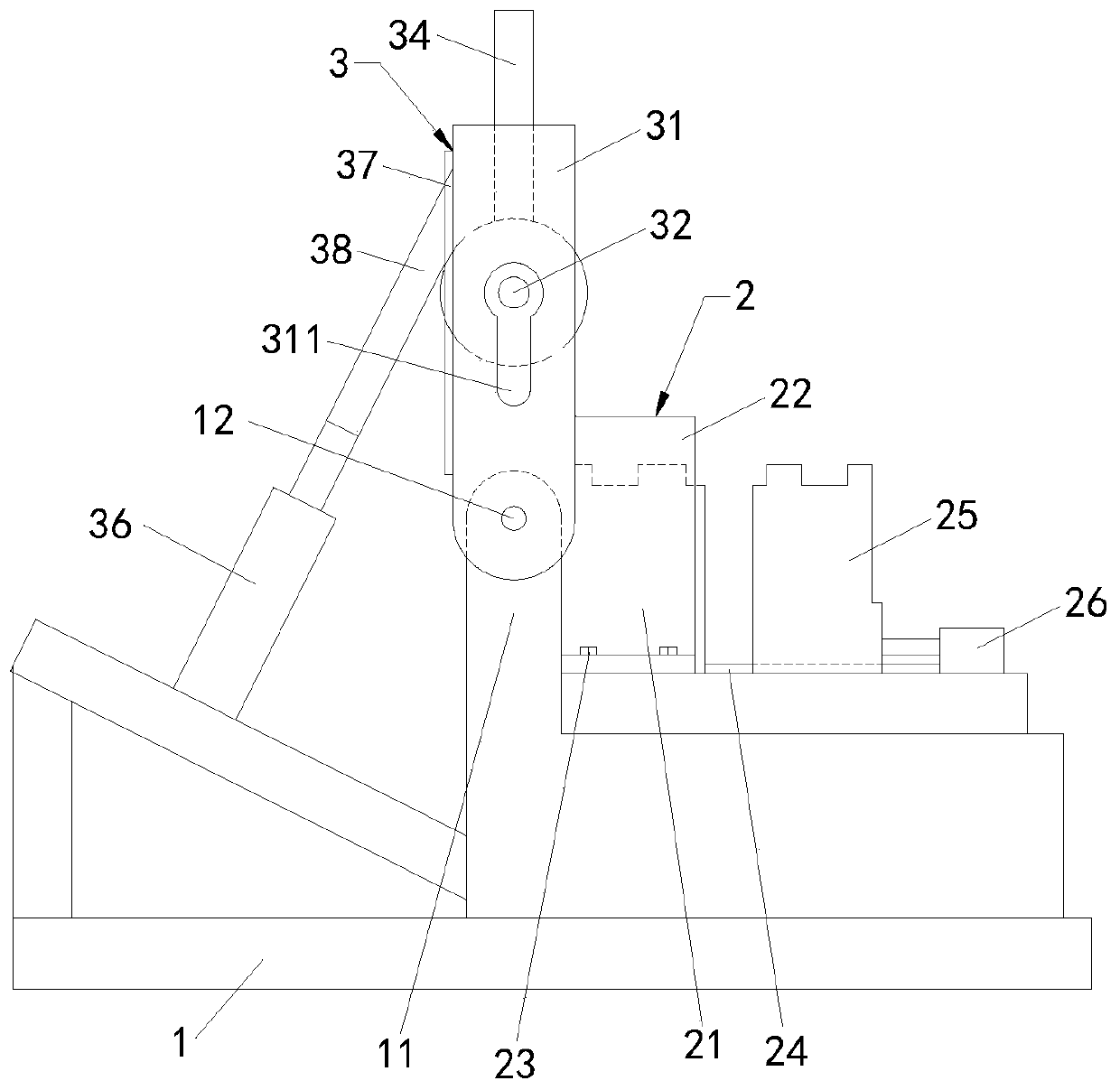

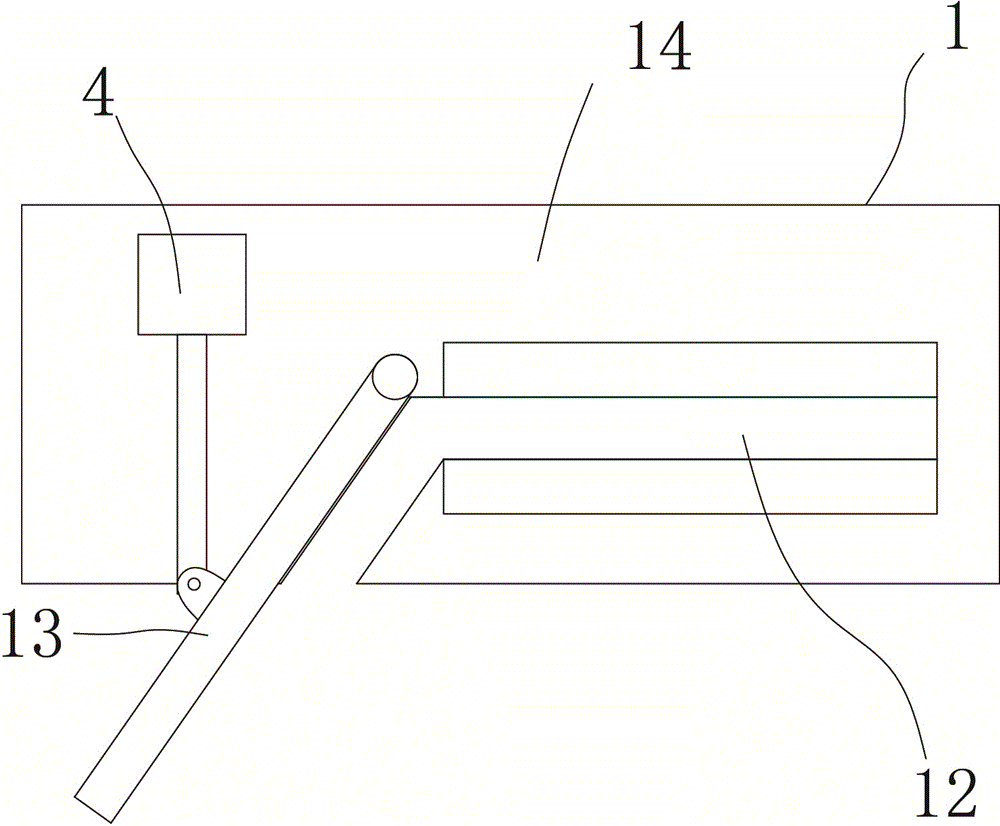

Automatic bending mechanism for connector contact pin

ActiveCN106451021AAvoid rigid forceEliminate the possibility of breakingContact member manufacturingEngineeringMechanical engineering

The invention aims at solving the problems of the prior art, and relates to an automatic bending mechanism for a connector contact pin. Bending work can be effectively carried out on the connector contact pin. The automatic bending mechanism for a connector is characterized by comprising a pushing air cylinder, a connecting rod mechanism and a connector fixing seat, wherein the pushing air cylinder and the connecting rod mechanism are arranged on a rack in the vertical direction; the connector fixing seat is horizontally arranged on the rack and is used for fixedly placing the connector; the connecting rod mechanism is provided with a bending mechanism; the pushing air cylinder pushes the connecting rod mechanism to drive the bending mechanism to carry out a pushing action and pushes the connector to compete the bending work; and the bending mechanism is driven by a recovery spring thereon to reset. According to the automatic bending mechanism for the connector contact pin, automatic production of a connector contact pin device is achieved; full-automatic bending is carried out on a pin header connector contact pin; the waste is reduced; and the work efficiency is effectively improved when the quality of a product is improved.

Owner:今朝联合有限公司

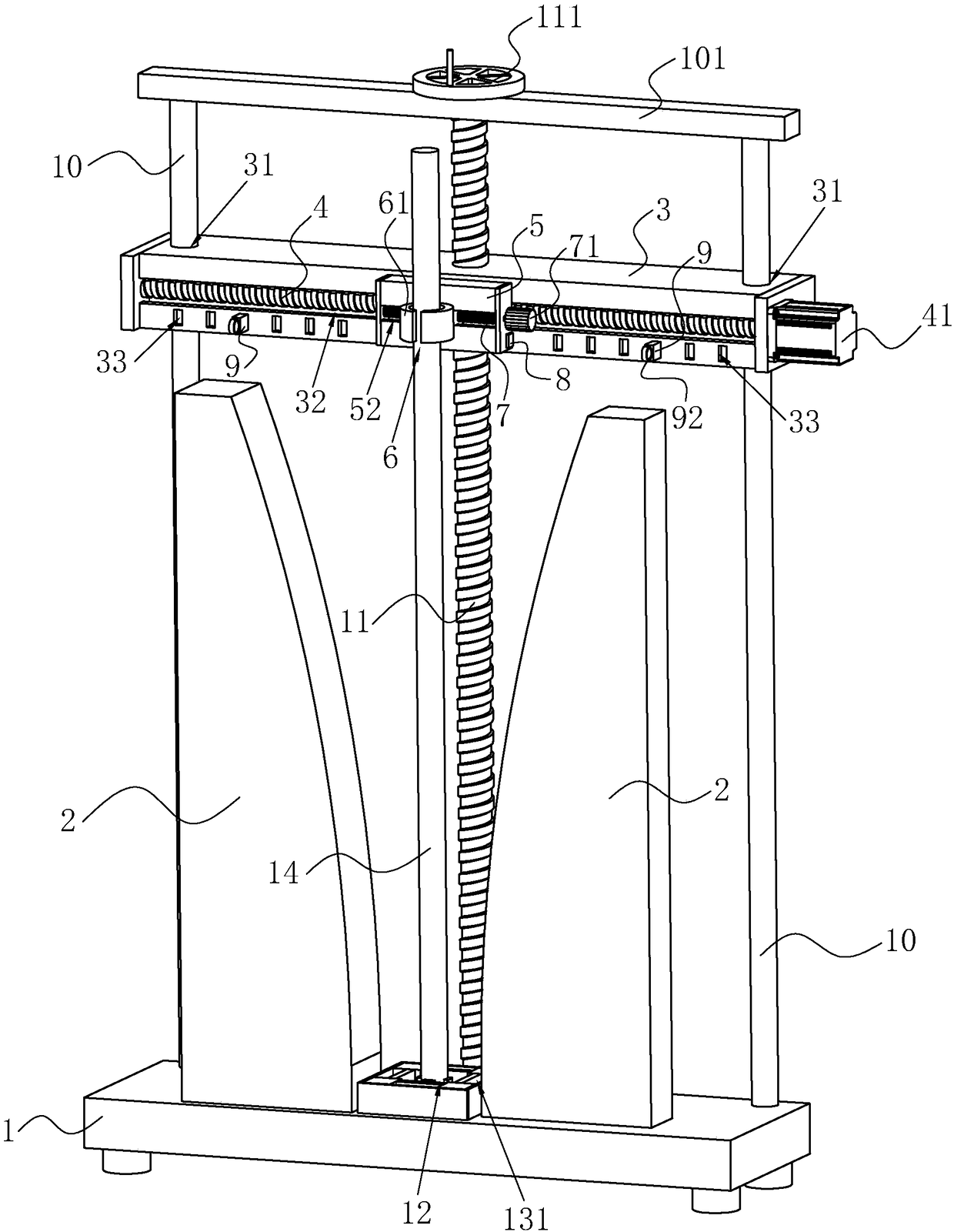

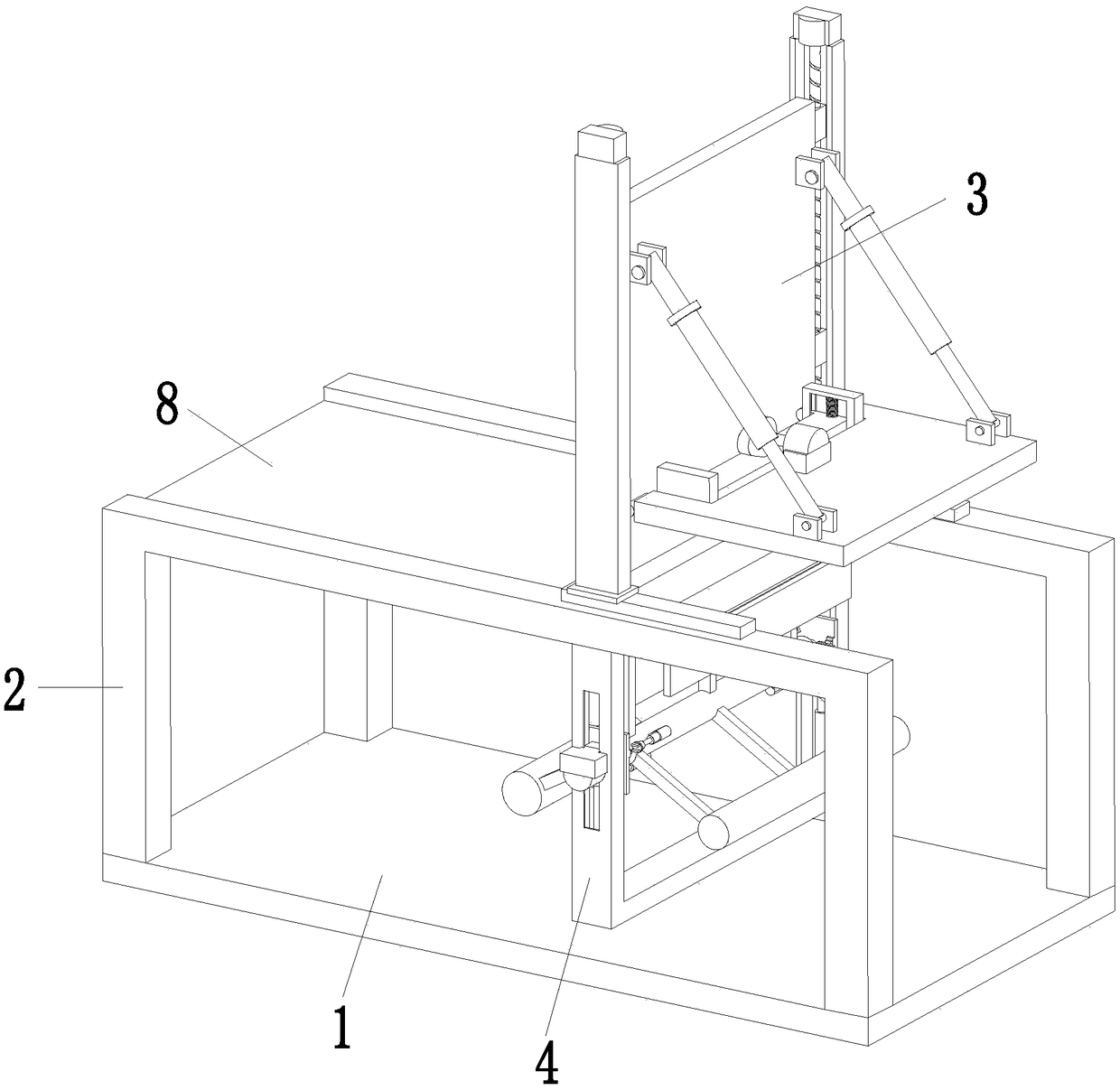

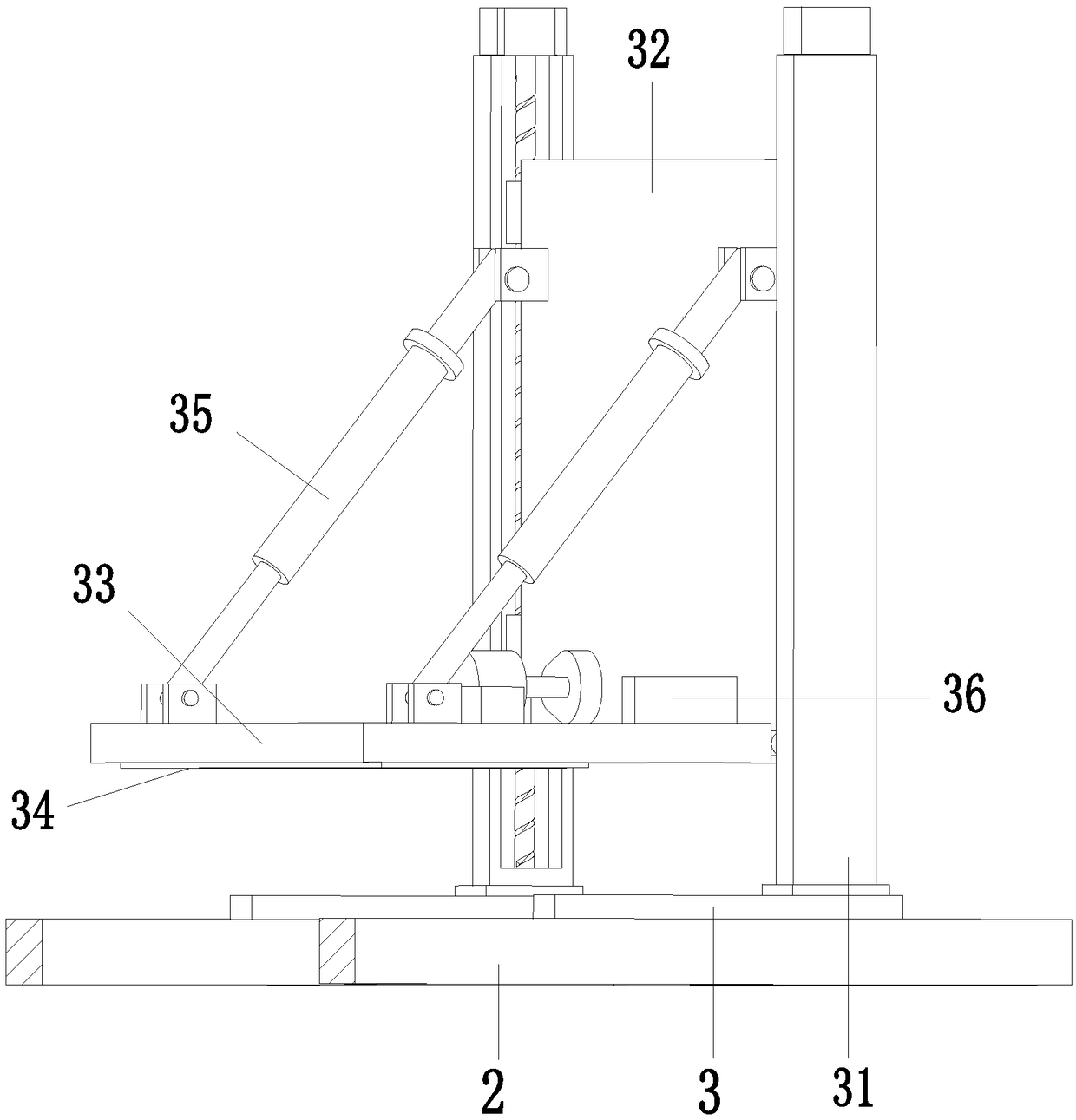

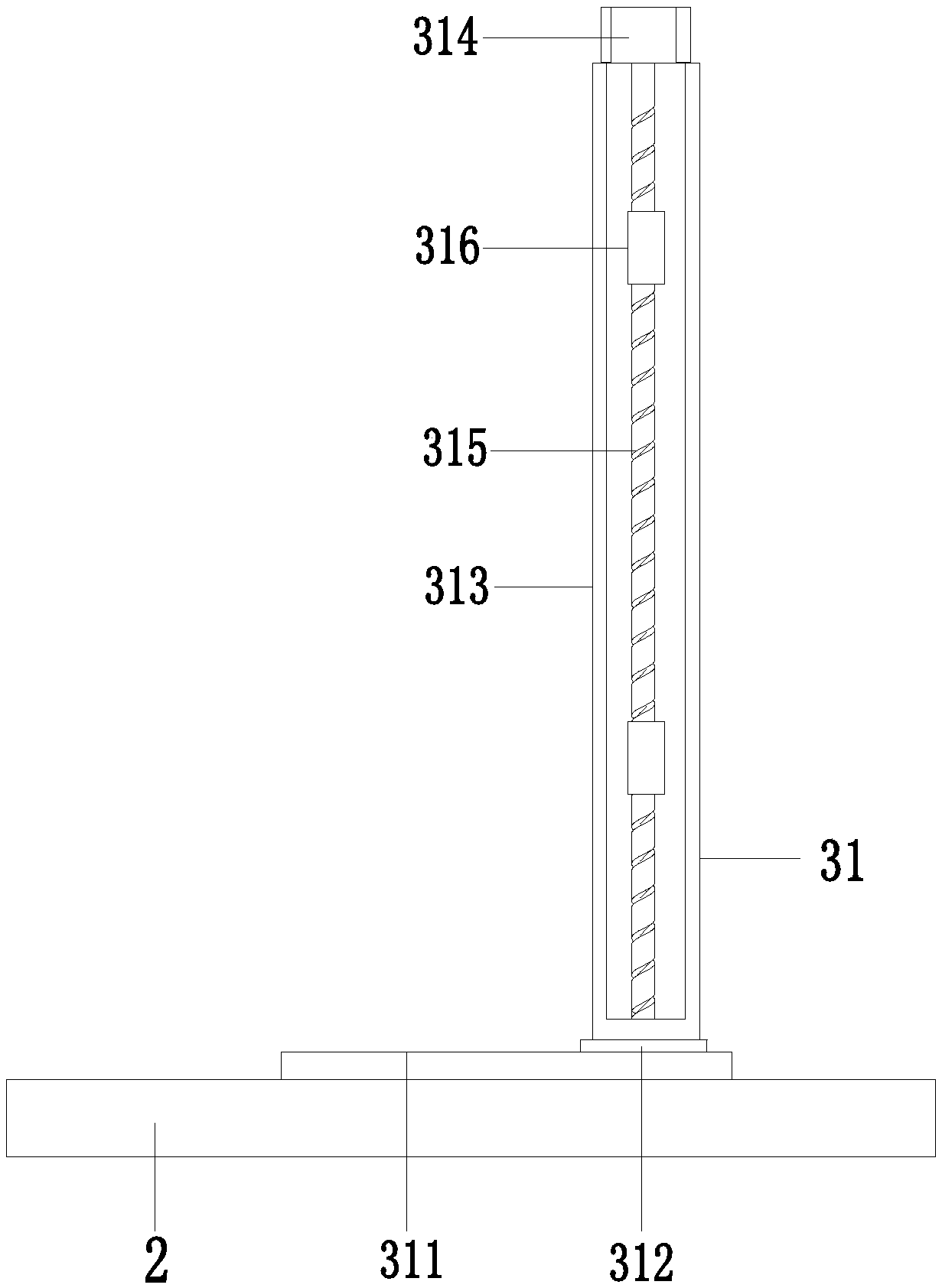

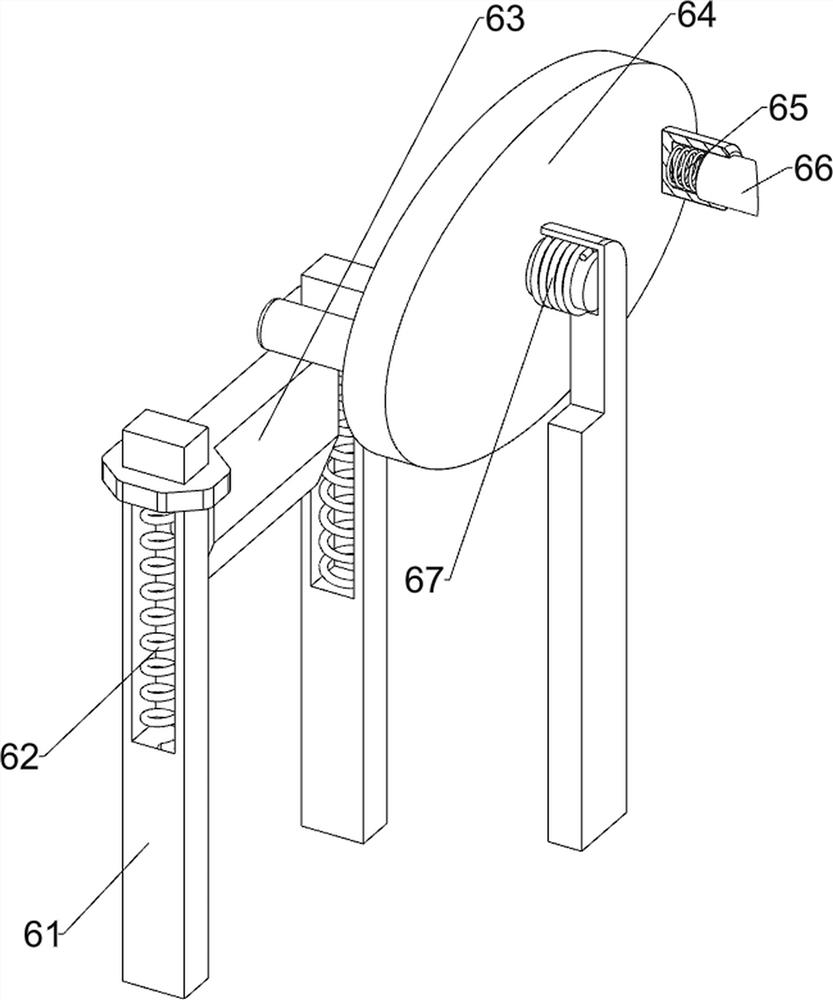

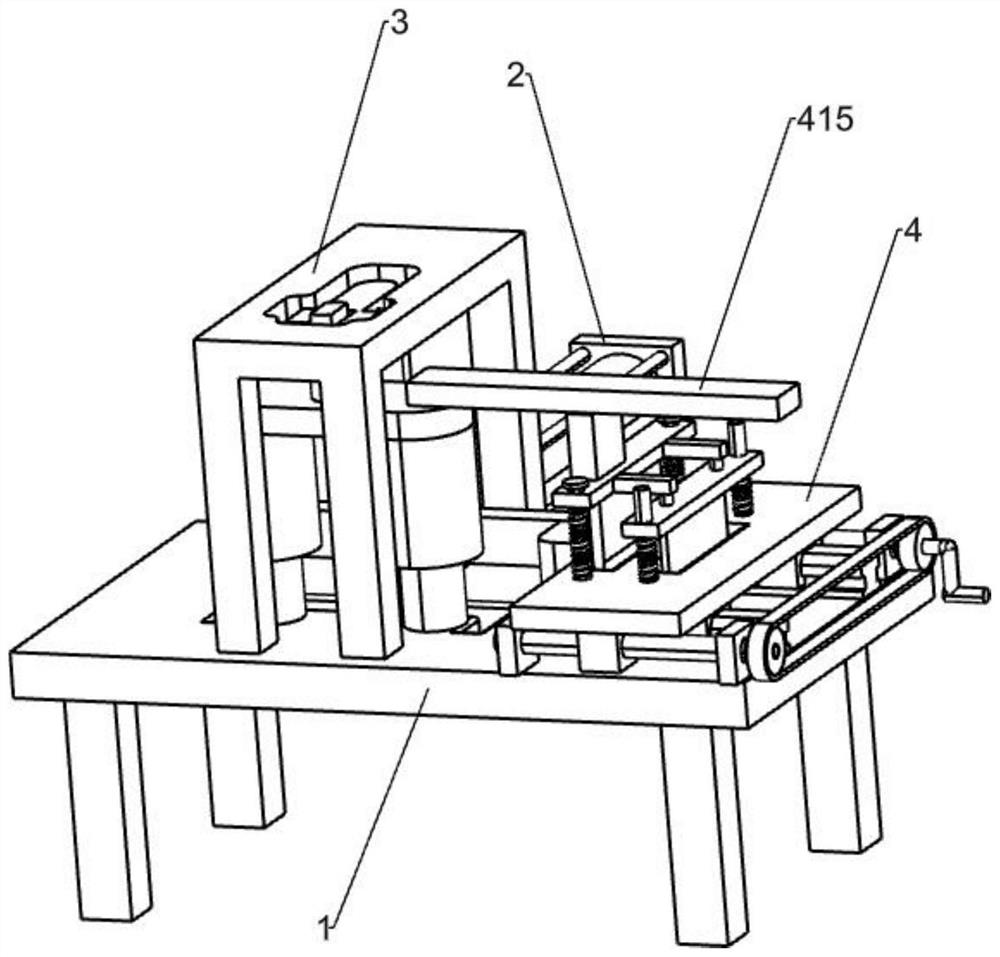

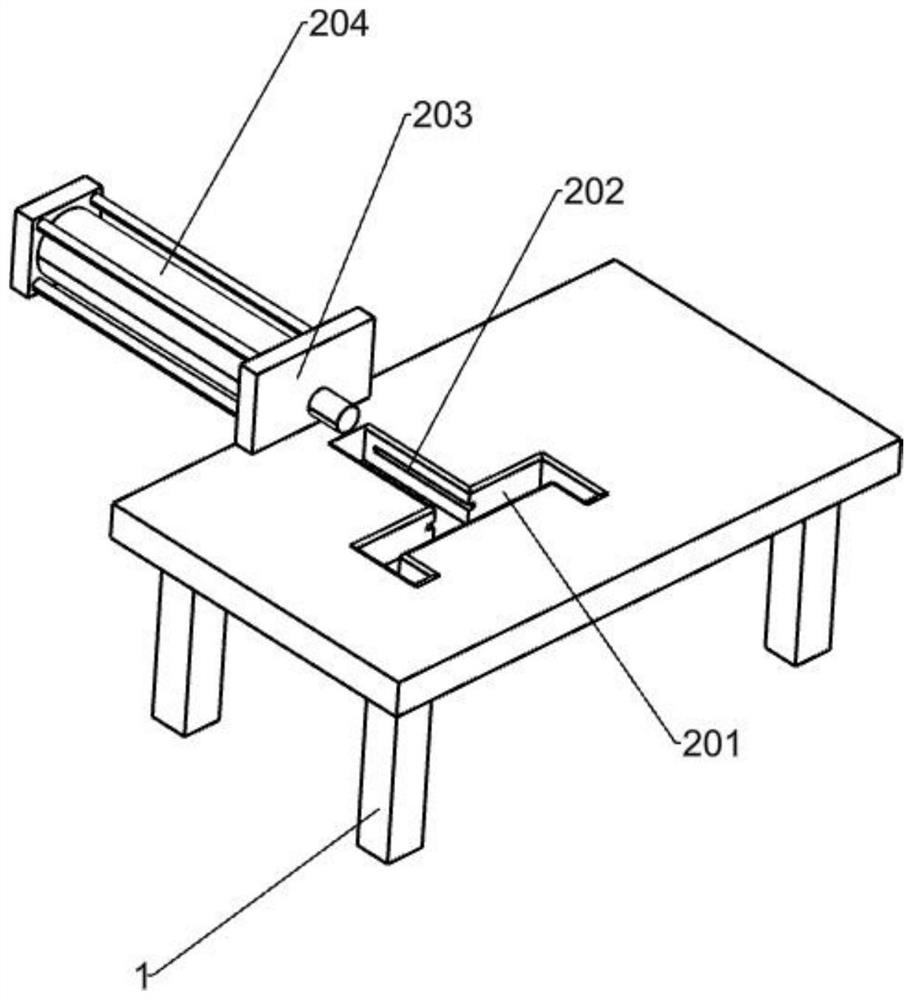

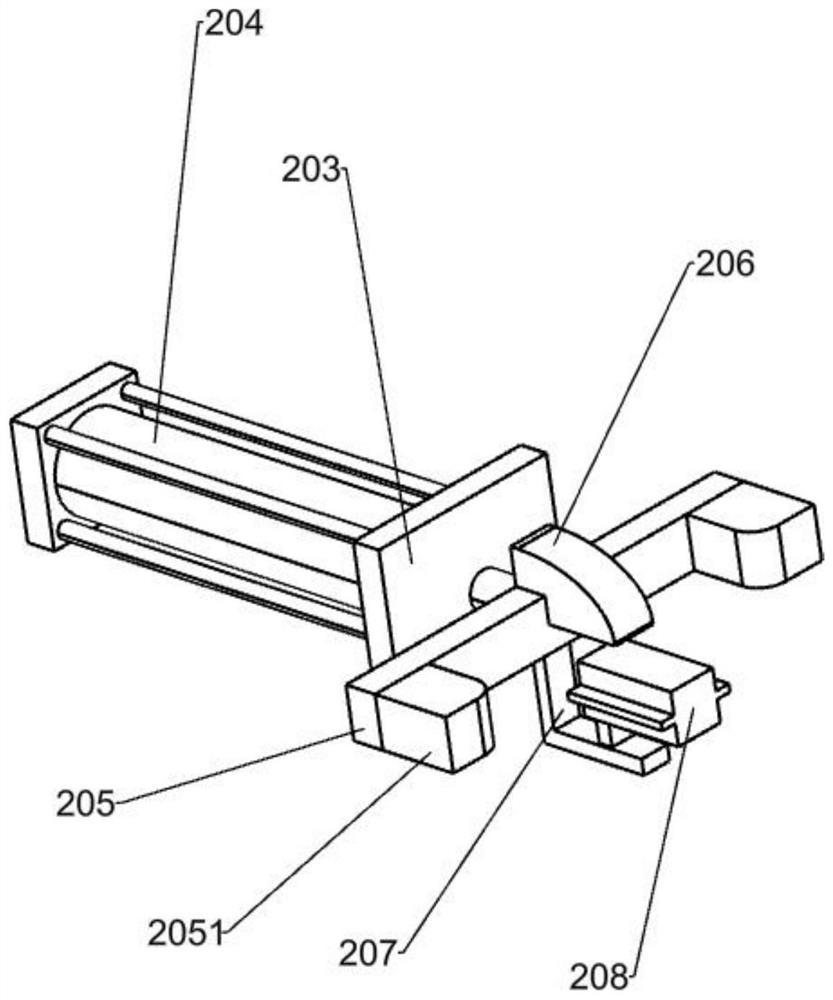

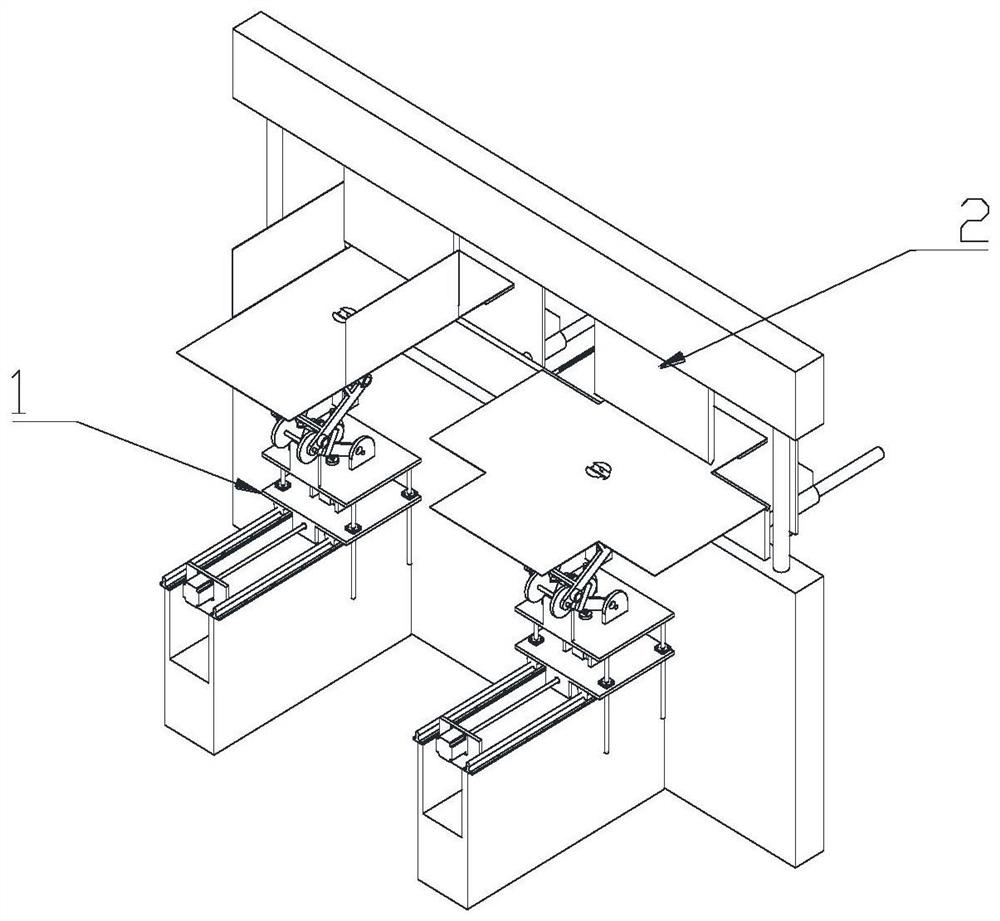

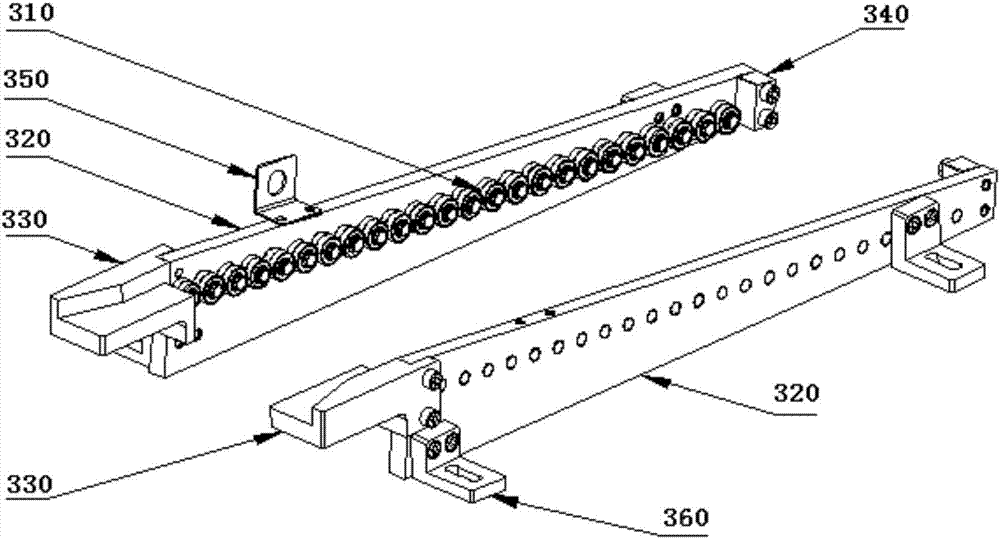

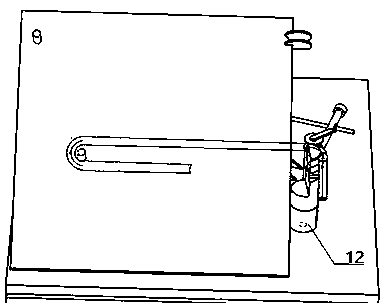

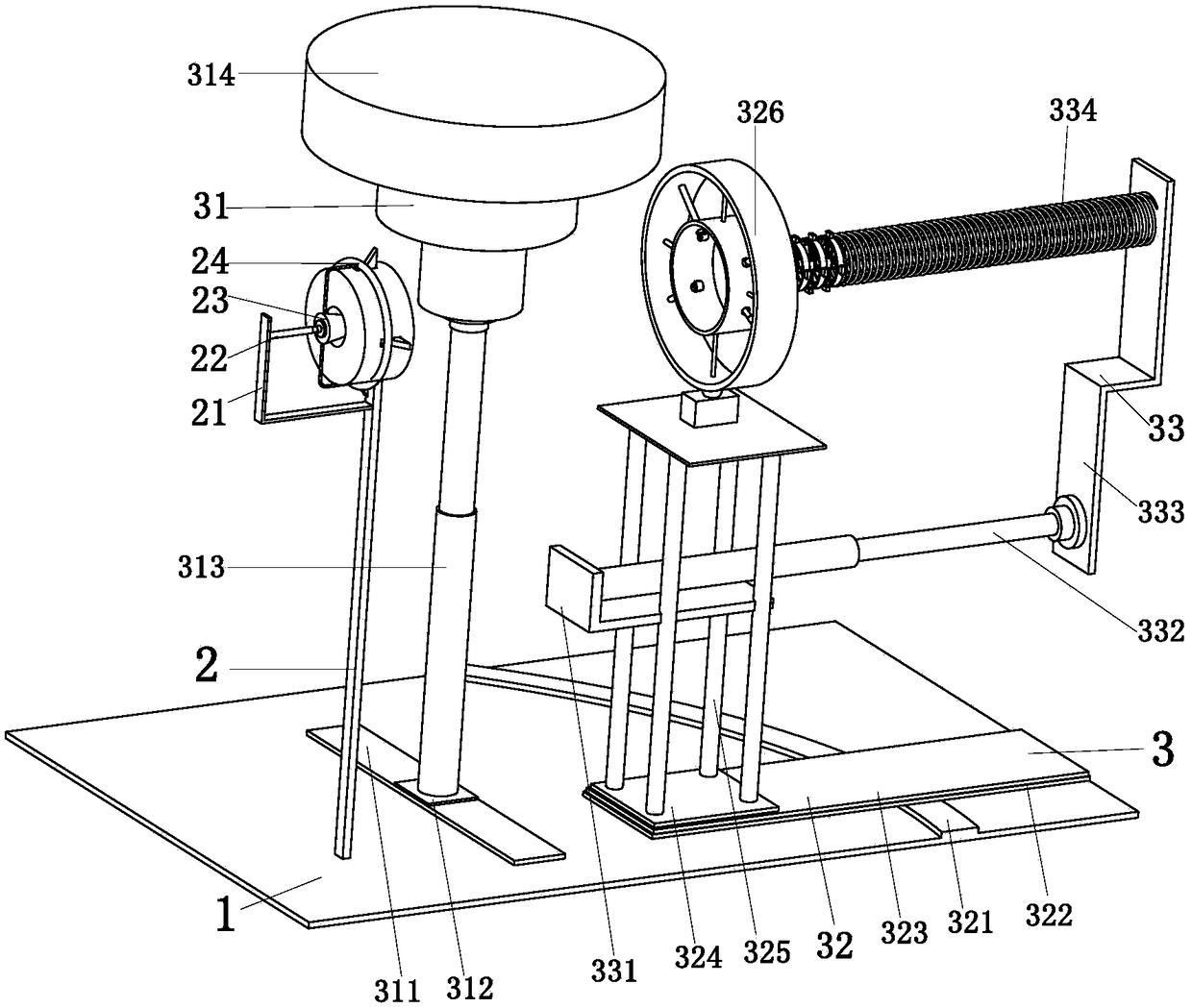

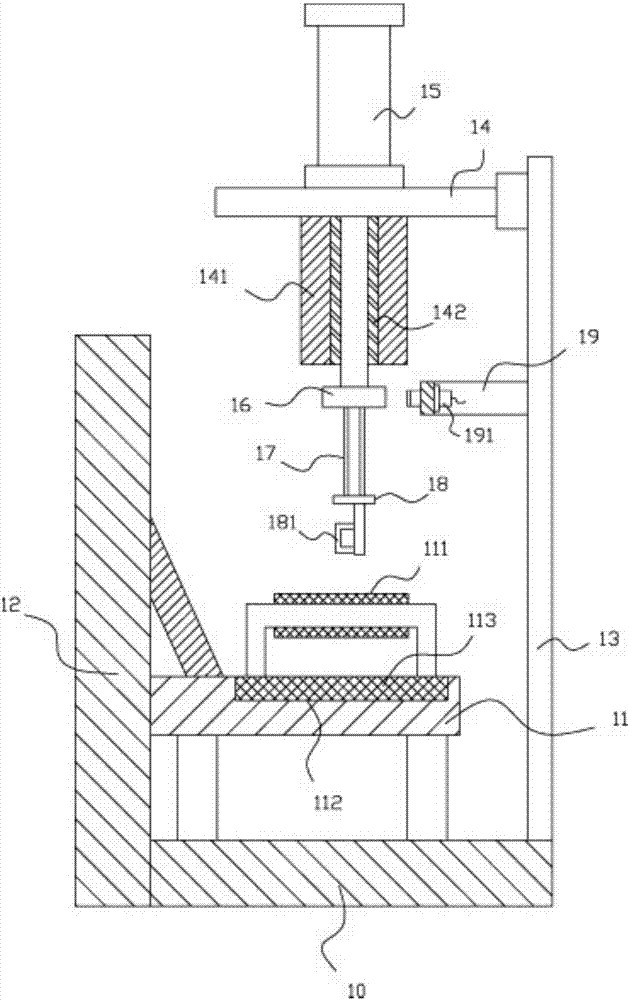

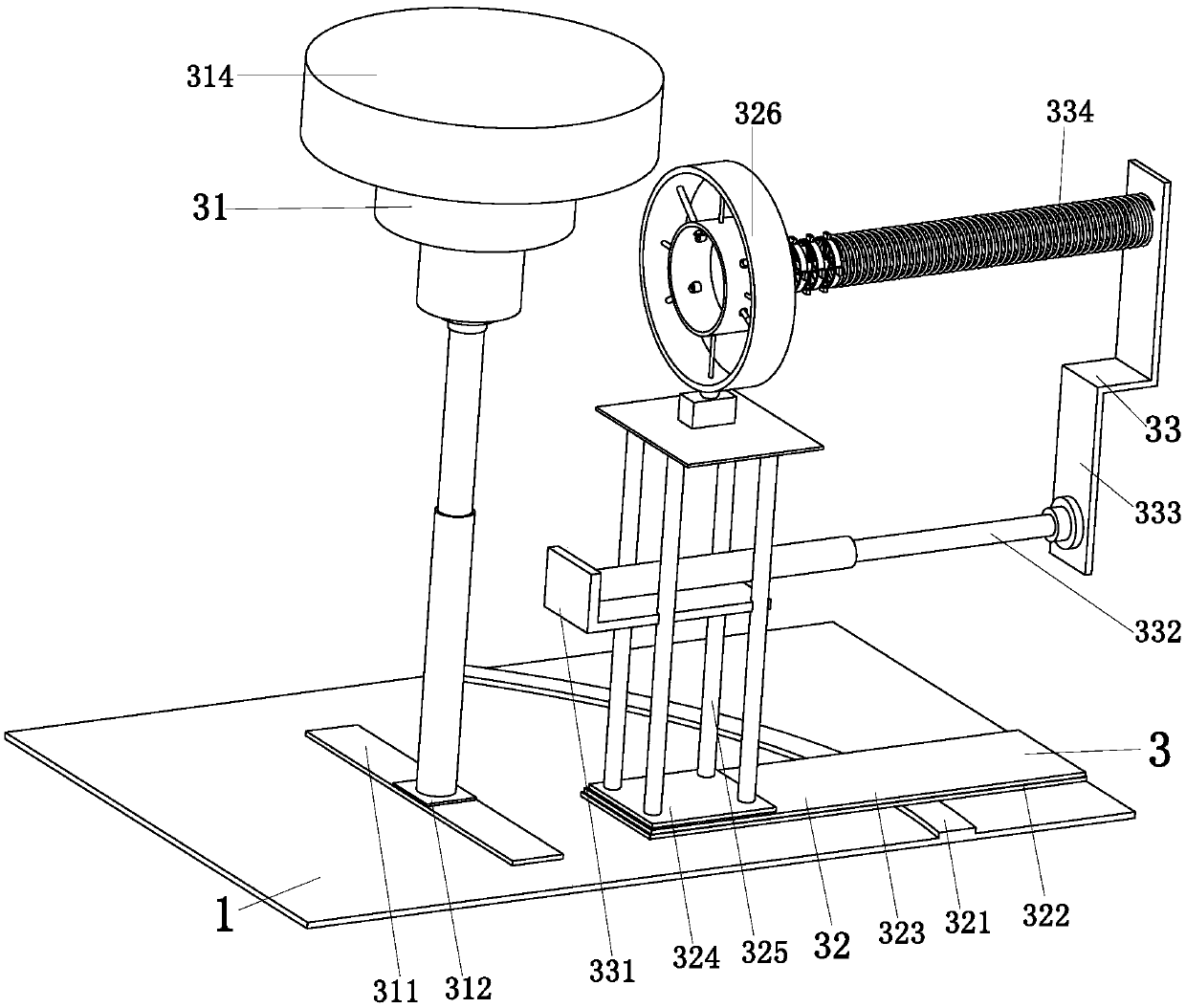

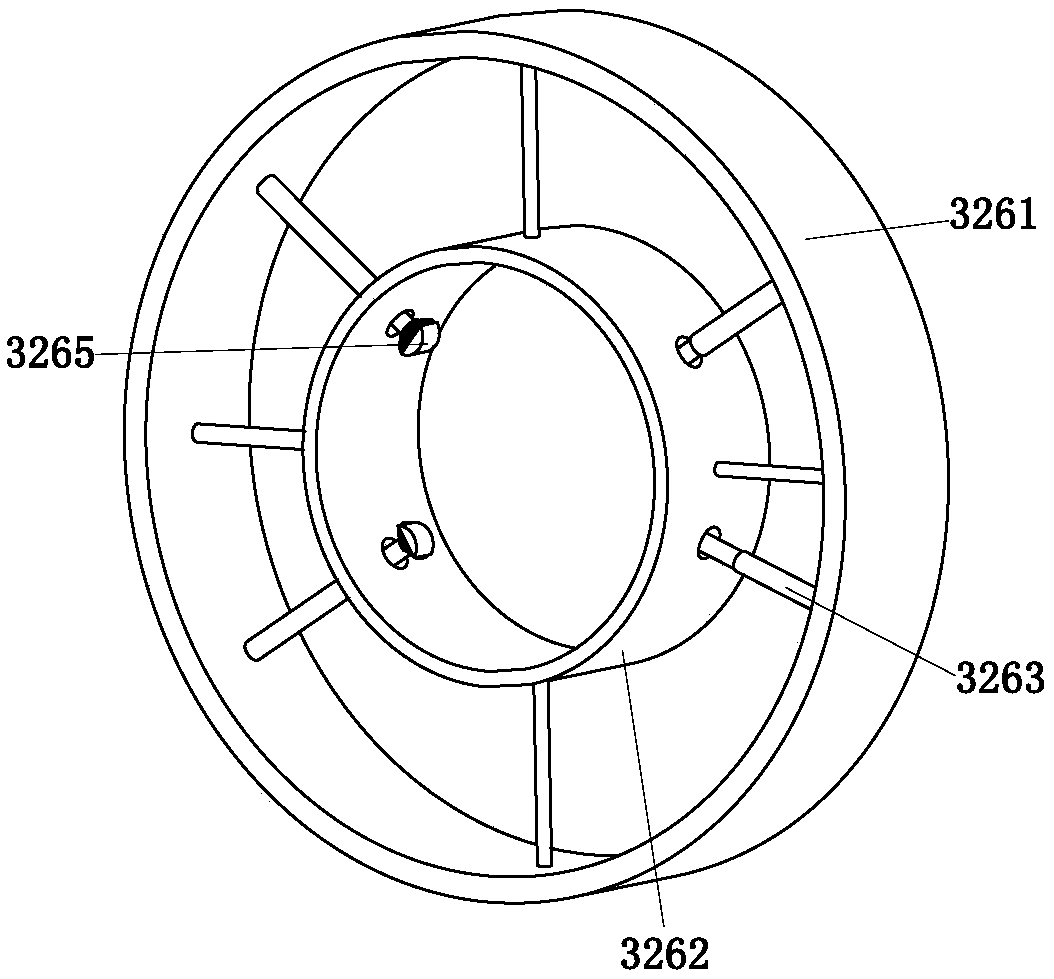

Automatic pipe flexibility tester

ActiveCN109342215ARealize automatic bendingIncrease the scope of applicationMaterial strength using steady bending forcesMechanical engineeringTest equipment

The invention relates to an automatic pipe flexibility tester, which belongs to the technical field of building material test equipment, and aims to solve the problem of the prior art that pipes needto be bent manually when testing with a pipe flexibility tester. The main points of the technical scheme are as follows: the tester comprises a base; two symmetrical curved support plates are providedon the base; a fixing member is provided between the two curved support plates on the base; a mounting platform is provided on one side of a bottom plate; a moving platform which slides along the connecting direction of the two curved support plates is slidably mounted on the mounting platform; the moving platform is provided with a clamping ring which fits the fixing member, and the axis of theclamping ring is vertically arranged; and a drive mechanism which drives the reciprocating slide on the mounting platform is connected with the moving platform. In the use of the tester, the pipe is vertically fixed to the base and positioned between the two curved support plates by the fixing member, and the clamp ring is sleeved outside the pipe. The driving mechanism drives the moving platformto drive the clamping ring to bend in the direction of the two curved support plates on the mounting platform, thereby realizing the bending test of the pipe.

Owner:南通市通佳工程质量检测有限公司

A connector pin automatic bending mechanism

ActiveCN106451021BAvoid rigid forceEliminate the possibility of breakingContact member manufacturingEngineeringMechanical engineering

Owner:今朝联合有限公司

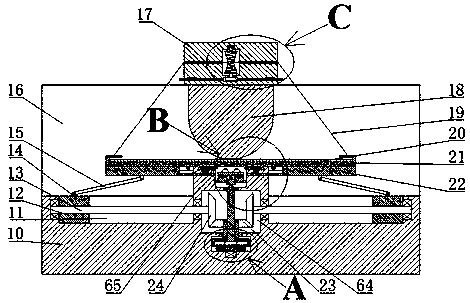

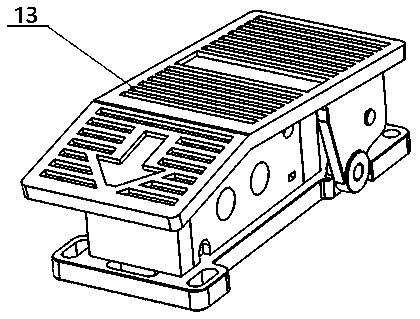

Small special bending machine for 90 degree positioning pin in automobile parts

ActiveCN107470411ARealize automatic bendingReduce labor intensityShearing machinesShearing machine accessoriesFixed frameEngineering

The invention discloses a small special bending machine for a 90 degree positioning pin in automobile parts. The small special bending machine for the 90 degree positioning pin in the automobile parts comprises a box body; the bottom of the inner wall of the box body is fixedly connected with a motor; one end of an output shaft of the motor is fixedly connected with a speed changer; a first supporting plate and a second supporting plate are fixedly connected between the two opposite sides of the inner wall of the box body; an output shaft of the speed changer is fixedly connected with a swinging device; one side of the swinging device is fixedly connected with a rotating device through a second rotating shaft; one side of the rotating device is fixedly connected with a bending device through one end of a third rotating shaft; one side of the top of the first supporting plate is fixedly connected with a fixing base; the top of the fixing base is in sliding connection with a cutting device; and the top of a fixing frame is fixedly connected with a fixing device and a limiting device. The invention relates to the field of automobile part machining. The small special bending machine for the 90 degree positioning pin in the automobile parts solves the problem of traditional manual bending, solves the problem that a bending angle is difficult to control at the same time, improves the production efficiency and the percentage of pass, and lowers the labor intensity.

Owner:南京南方联成汽车零部件有限公司

Curved board bending processing device

The invention relates to the field of wood processing, in particular to a curved board bending processing device. The curved board bending processing device comprises a machine body and bending cavities arranged in the machine body, bending dies are fixedly arranged on the rear end walls of the bending cavities, sliding cavities are symmetrically arranged in the bottom walls of the bending cavities left and right, sliding blocks are arranged in the sliding cavities in a sliding manner, and a boss is arranged between the sliding cavities on left and right. The curved board bending processing device is arranged, automatic bending of boards can be achieved, the bending efficiency of the device is high, and board cooling before bending is avoided; a fixing device is arranged in the device, a wooden board can keep the bending state after the bending is finished, and restoring of the wooden board due to tenacity is prevented. A screw is used for pushing and bending, stability and uniformityare better, board cracking is not prone to happening, the degree of automation is high, the stability is good, and the production, application and popularization are facilitated.

Owner:福州达华家具制造有限公司

Automatic copper pipe bending machine

PendingCN110877066ARealize automatic bendingHigh precisionMetal-working feeding devicesStripping-off devicesMachineMaterial supply

The invention discloses an automatic copper pipe bending machine. The automatic copper pipe bending machine comprises a machine frame, a material supply device, a feeding mechanism and a bending mechanism. The feeding mechanism comprises a second bracket assembly, a material grasping device and a conveying device. The conveying device is arranged on the machine frame. The second bracket assembly and the material grasping device are separately arranged on a supporting frame, the material grasping is arranged above the supporting frame and moves back and forth among a first bracket assembly, thesecond bracket assembly and the conveying device, an aligning device and a material rubbing device are further separately arranged on the second bracket assembly, and the aligning device and the material rubbing device are separately matched with the second bracket assembly; and the bending mechanism is arranged on the machine frame and is arranged on one side of the conveying device, and the bending mechanism is matched with the conveying device. When a copper pipe is bent, the copper pipe is supplied by the material supply device, the copper pipe is conveyed from the material supply deviceto the bending mechanism by the feeding mechanism, and then the copper pipe is bent by the bending mechanism. Automatic bending is achieved, the bending efficiency is improved, and the bending qualityis improved through the aligning device and the material rubbing device.

Owner:广东易库智能仓储设备科技有限公司

Aluminum plastic plate automatic bending equipment and aluminum plastic plate automatic bending process

ActiveCN109175018ARealize automatic bendingEasy to replaceShaping toolsEngineeringUltimate tensile strength

Owner:镇江京和新材料科技有限公司

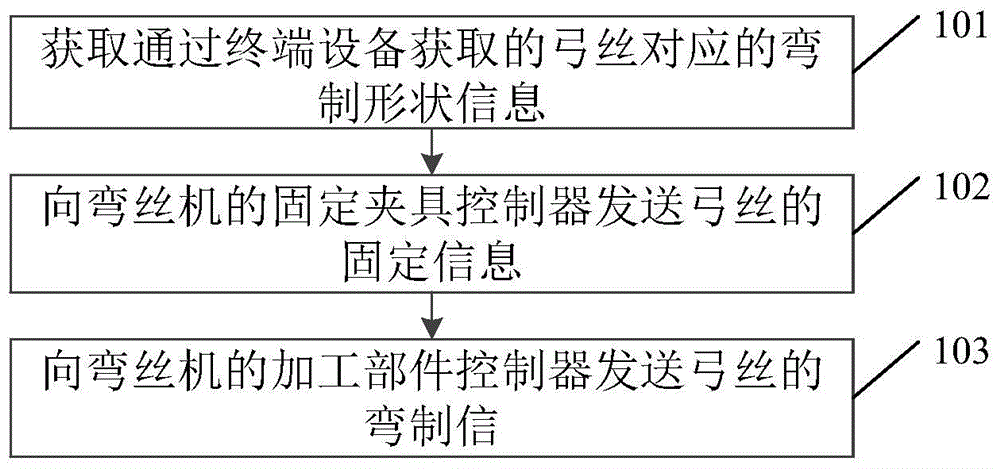

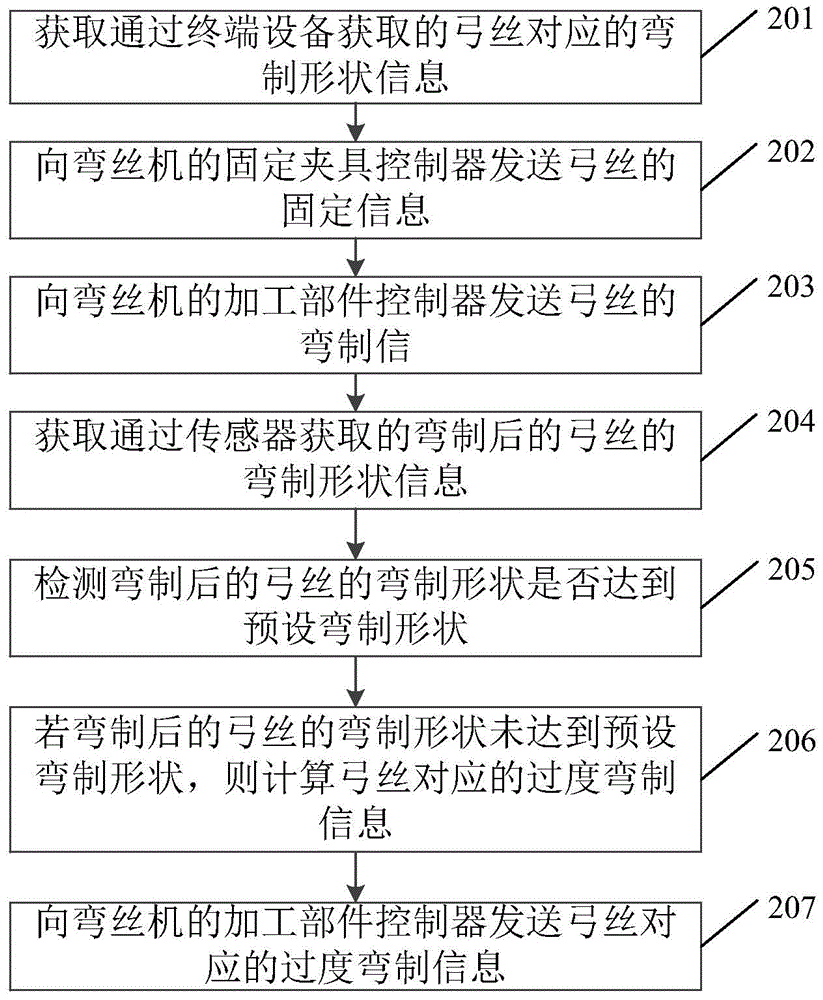

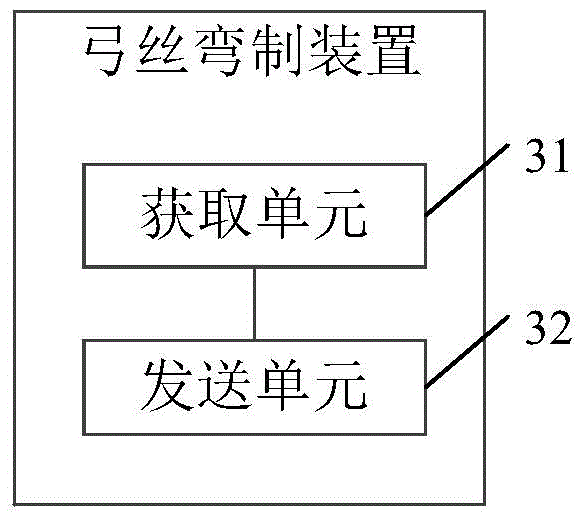

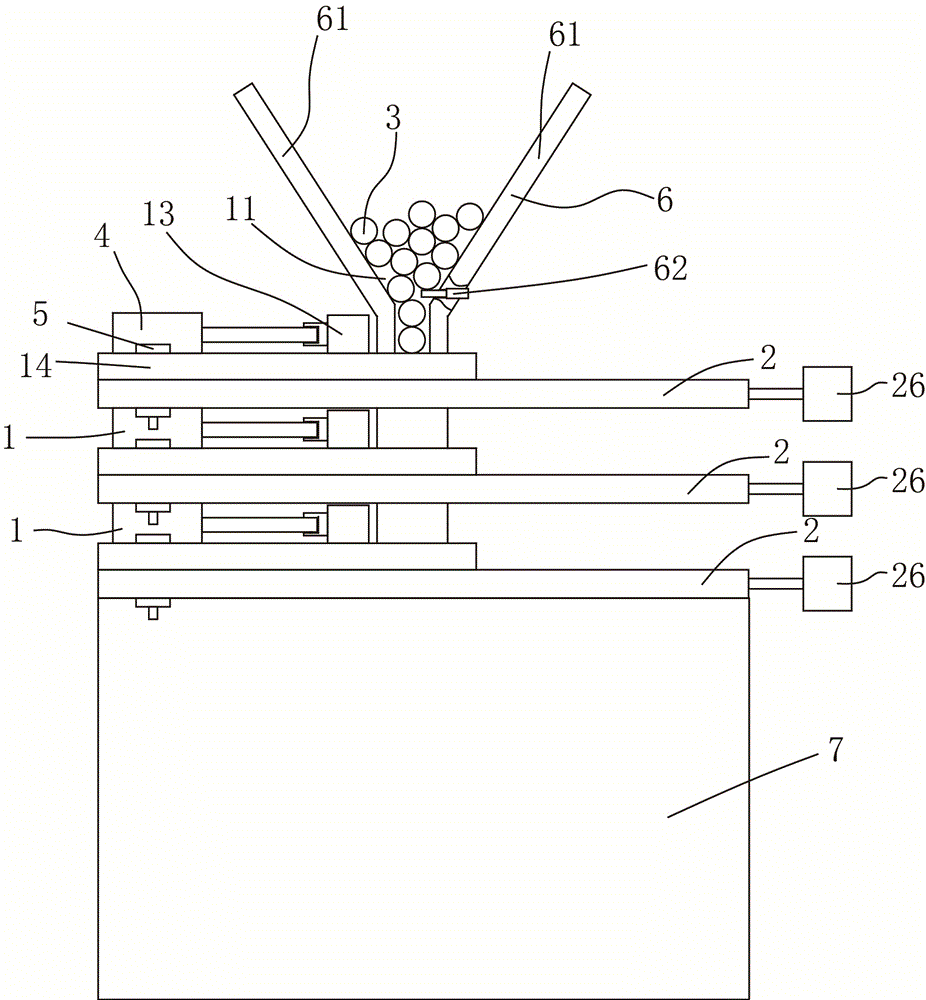

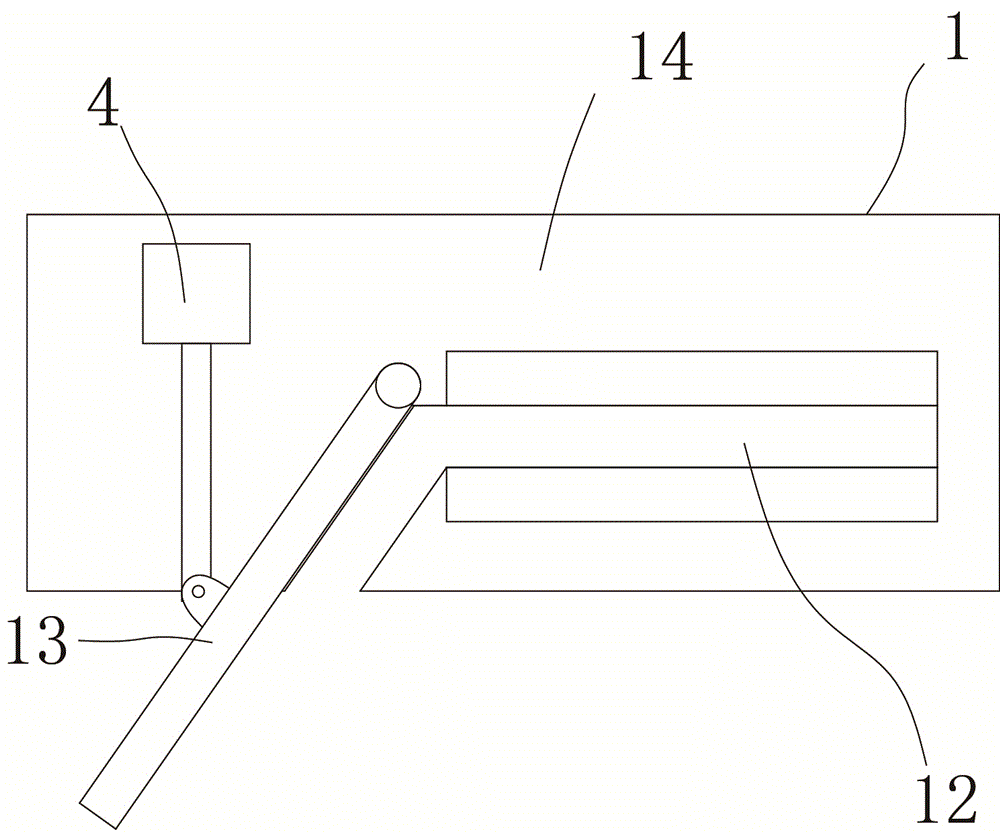

Arch wire bending method and device

The invention discloses an arch wire bending method and device, and relates to the field of medical instruments and apparatuses.The method and device mainly aim at improving the efficiency and precision of arch wire bending.According to the main technical scheme, bending shape information obtained through a terminal device and corresponding to an arch wire is obtained, and the bending shape information includes fixed information and bending information; the fixed information is sent to a fixed clamp controller of a wire bending machine, so the fixed clamp controller controls the fixed clamp of the wire bending machine to clamp and fix the arch wire; the bending information is sent to a machining part controller of the wire bending machine, so the machining part controller controls a machining part of the wire bending machine to bend the arch wire.The arch wire bending method and device are suitable for bending arch wires.

Owner:北京正齐口腔医疗技术有限公司

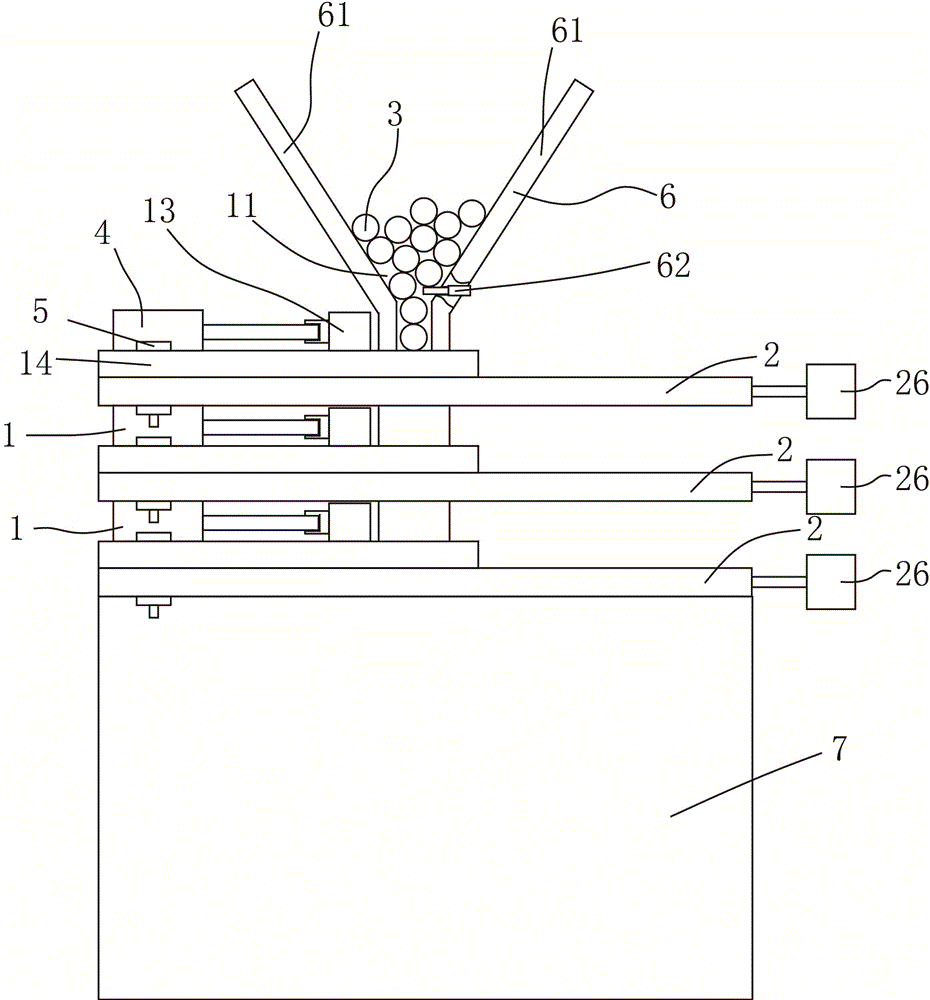

bending machine

The invention discloses a bending machine. The bending machine comprises a plurality of bending mechanisms which are stacked together. A feed port is formed above the uppermost bending mechanism, a partition plate is arranged between every two bending mechanisms, a discharging through hole is formed in each partition plate, and each discharging through hole is matched with a rod formed by bending the bending mechanism above the discharging through hole in shape. Each bending mechanism comprises a fixing groove, a rotating rod and a bottom plate, the rotating rod is rotationally connected with the bottom plate, a driving device is connected to each rotating rod, and all the driving devices are connected with a control device. A storage hopper is connected above the feed port, and an anti-blocking air cylinder is arranged at the lower end of the storage hopper. Through the bending machine, automatic bending can be achieved, working efficiency can be improved, labor cost can be reduced, operating safety is improved, and the feed port of the bending machine can be prevented from getting stuck.

Owner:NINGBO ZHENHAI SHILI ELECTROMECHANICAL

Metal building material bending equipment

ActiveCN113319167ARealize automatic bendingRealize the effect of automatic bendingMetal-working feeding devicesPositioning devicesConstruction engineeringPiston rod

The invention relates to bending equipment, in particular to metal building material bending equipment. The technical problem to be solved is to provide the metal building material bending equipment, which can realize automatic bending and is convenient for automatic cutting. According to the technical scheme, the metal building material bending equipment comprises a supporting frame and a bending mechanism, and the bending mechanism is arranged in the middle of the top of the supporting frame; an air cylinder arranged in the middle of one side of the supporting frame; a bending block arranged on one side of a piston rod of the air cylinder, and the bending block is in sliding fit with the supporting frame; two first rotating wheels symmetrically arranged at the upper part of the supporting frame; a cutting mechanism arranged on one side of the upper portion of the supporting frame; and a feeding mechanism arranged on one side of the supporting frame. The metal building material bending equipment provided by the invention achieves the effects that automatic bending can be achieved, and automatic cutting is facilitated.

Owner:河北腾耀电子设备有限公司

Automatic thin plate bending equipment for industrial production

InactiveCN112044994ARealize automatic bendingEasy to bendMetal-working feeding devicesPositioning devicesWorkbenchIndustrial engineering

The invention relates to bending equipment for industrial production, in particular to automatic thin plate bending equipment for industrial production. According to the technical scheme, the automatic thin plate bending equipment for the industrial production comprises a workbench and a pressing mechanism, and a bending mechanism is installed on the workbench; and the pressing mechanism is arranged on the side, close to the bending mechanism, of the workbench, and the pressing mechanism is matched with the bending mechanism. According to the automatic thin plate bending equipment for the industrial production, thin plates needing to be bent can be fixed and limited through the pressing mechanism, the thin plates can be bent through the bending mechanism, so that automatic bending of the thin plates is achieved; and the redundant thin plates can be cut off through a fine adjustment cutting mechanism, so that the thin plates with different lengths are bent conveniently.

Owner:孟飞星

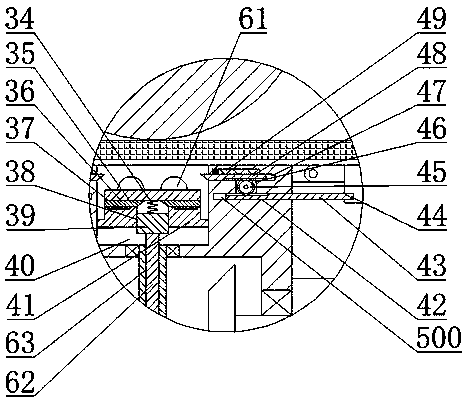

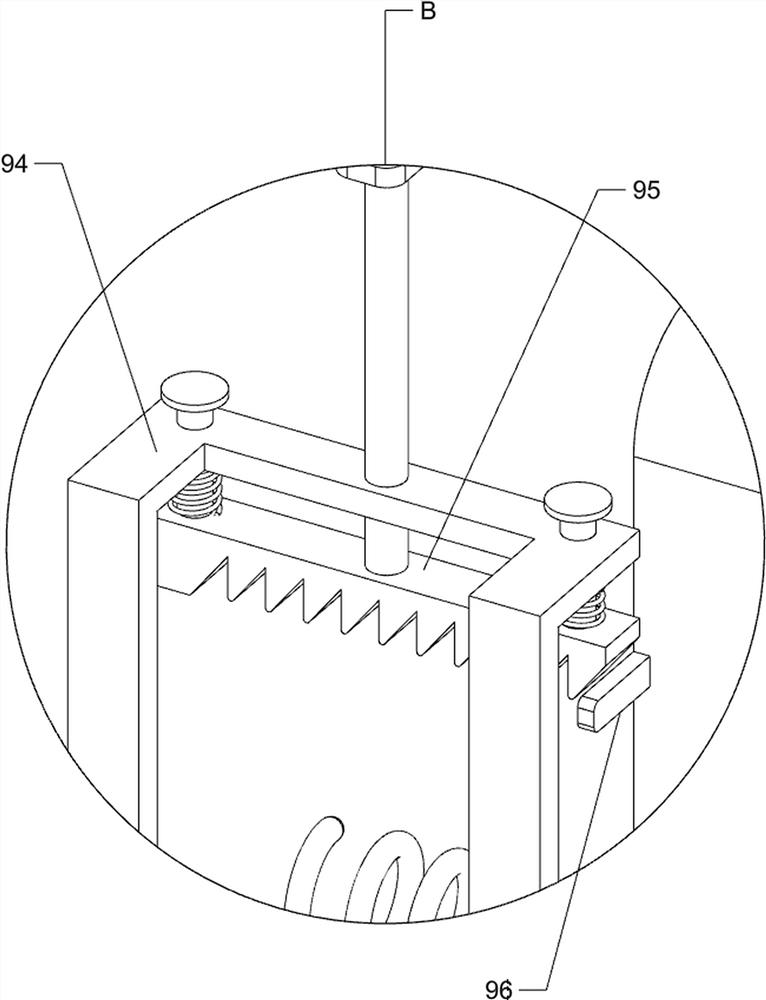

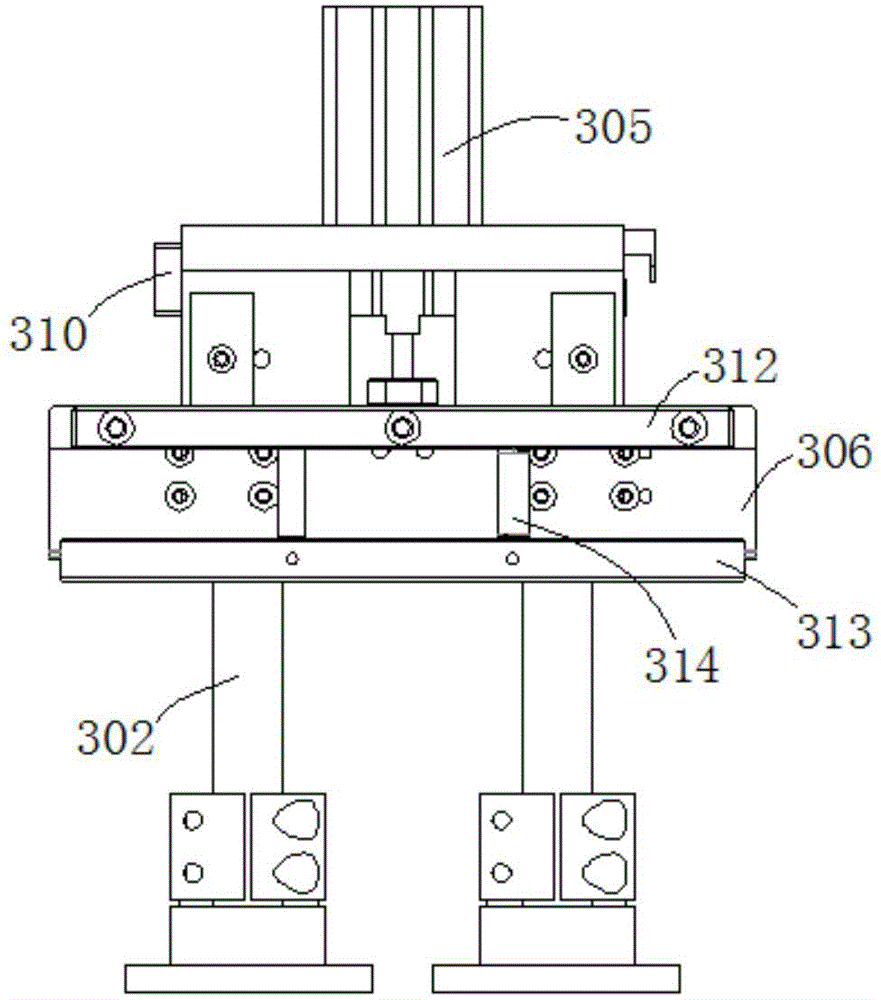

Battery tab bending mechanism

InactiveCN104492873AImprove productivity and precisionReduce manufacturing costCell component detailsEngineeringCam

The invention discloses a battery tab bending mechanism. The mechanism comprises an upper bending head, a lower bending head and a bending head driving mechanism, wherein the upper bending head and the lower bending head vertically face each other; a bending gap is formed between the upper bending head and the lower bending head; the bending head driving mechanism comprises a first cylinder, a moving plate, a first cam bearing, a second cam bearing and a cam bearing slide block; the moving plate is connected with the first cylinder; the first cam bearing and the second cam bearing are both connected with the moving plate; the first cam bearing is connected with the lower bending head through the cam bearing slide block; the second cam bearing is connected with the upper bending head; the motor drives the moving plate to move, and synchronously drives the first cam bearing and the second cam bearing to move; the first cam bearing drives the lower bending head to ascend through the cam bearing slide block; the second cam bearing drives the upper bending head to descend. The mechanism can realize automatic bending of battery tabs, improves the working efficiency and the precision of the tab bending, reduces the production cost, and can achieve the speed requirements of modern great industry production lines.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

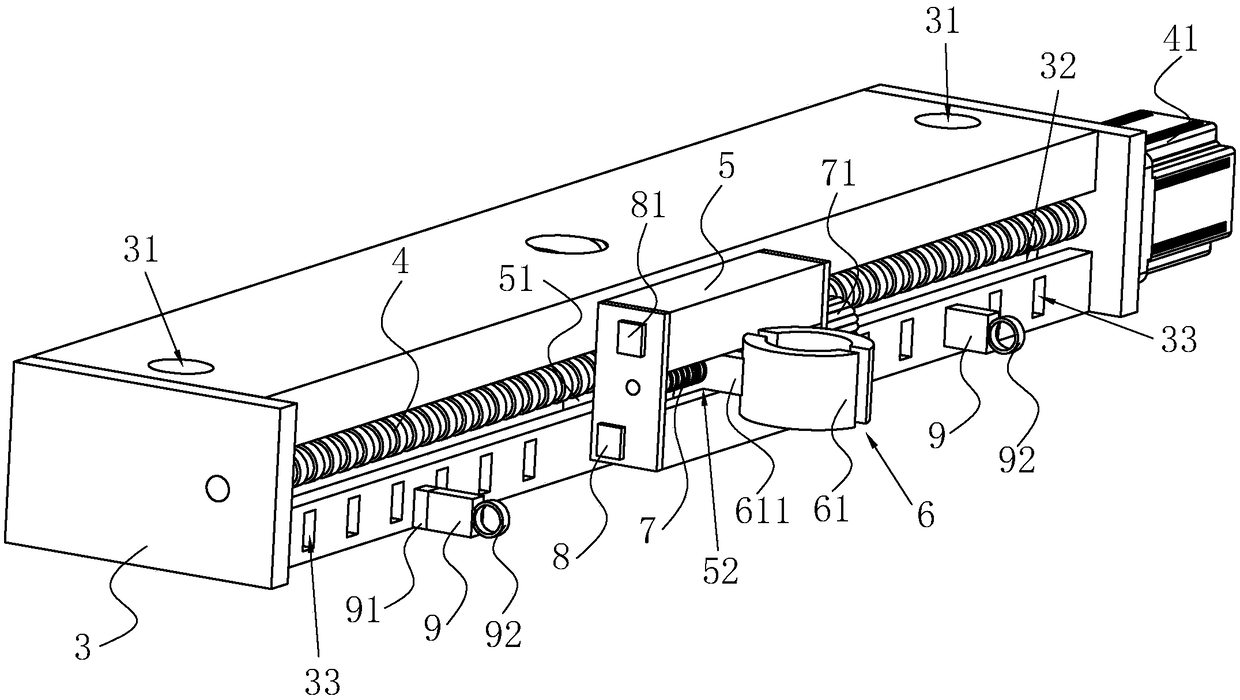

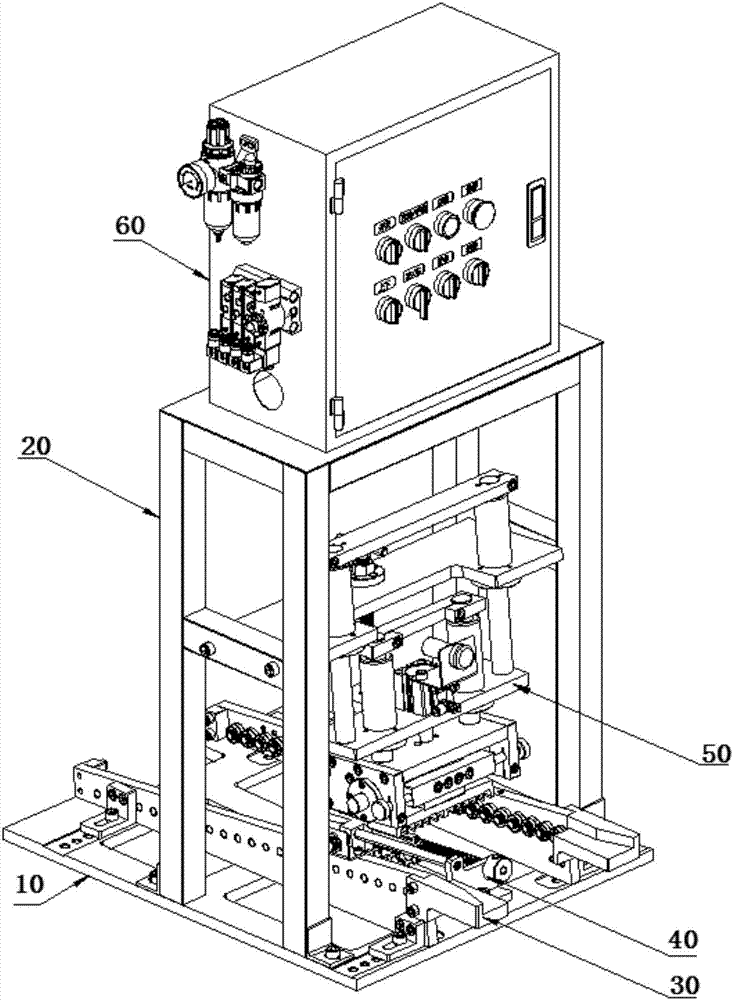

Bending mechanism of battery cutting shaper

InactiveCN104362383ARealize automatic bendingReduce processing timeFinal product manufactureElectrolyte accumulators manufactureEngineeringMechanical engineering

The invention discloses a bending mechanism of a battery cutting shaper. The bending mechanism comprises a first bending mechanism and a second bending mechanism which are oppositely arranged, wherein the first bending mechanism and the second bending mechanism comprise fixed support plates, adjusting plates, driving parts and bending cutters, wherein the adjusting plates are positioned on the fixed support plates; the driving parts are fixed on the adjusting plates, and the lower ends of the driving parts are connected with the bending cutters in a floating way; and the bending cutters move up and down under the driving of the driving parts to automatically bend the side edge of a battery. The bending mechanism disclosed by the invention can be used for achieving the automatic bending of the side edge of the battery in a battery cutting shaping procedure without adopting manual operation, thereby shortening the integral procedure time and improving the working efficiency and the product bending quality.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

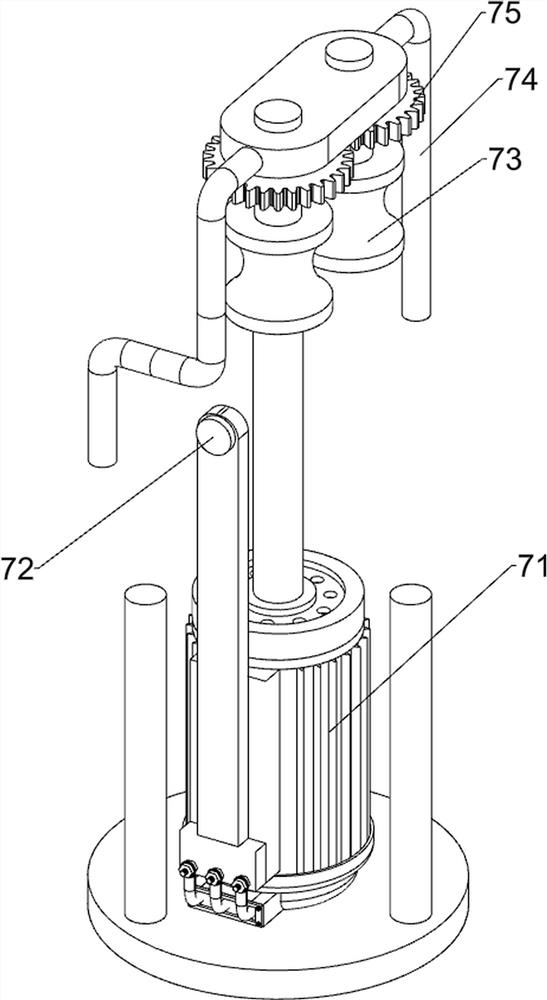

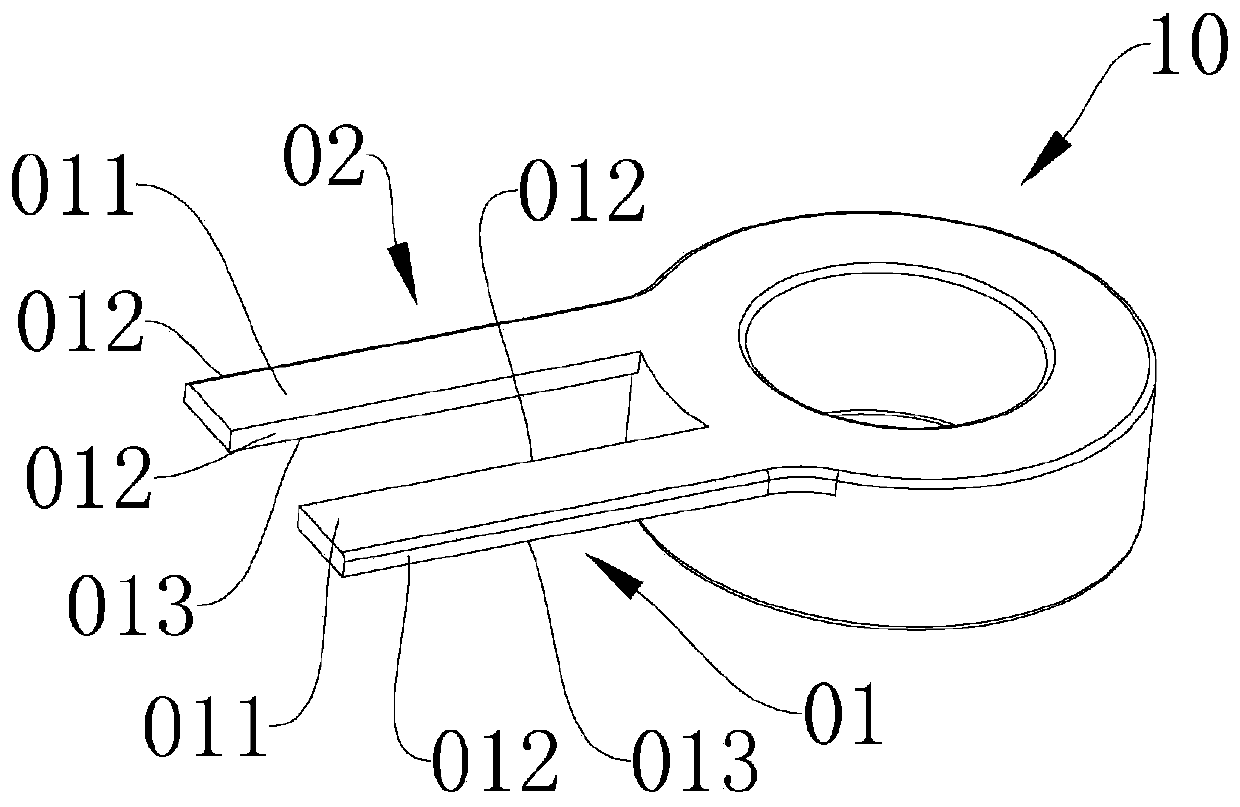

Full-automatic electromagnetic coil terminal paint removing machine

InactiveCN110911154ARealize automatic bendingRealize functionCoils manufactureStructural engineeringMechanical engineering

The invention discloses a full-automatic electromagnetic coil terminal paint removing machine. The full-automatic electromagnetic coil terminal paint removing machine includes a machine frame, a turntable device which is arranged on the rack and is used for transferring the electromagnetic coil, bending devices which are sequentially arranged along the moving direction of the turntable device andare used for bending terminals of the electromagnetic coil, a front surface paint removing device which is used for removing paint on the front surface of the electromagnetic coil terminal, four sidesurface paint removing devices which are used for removing paint on the side surfaces of the electromagnetic coil terminal, and the back surface paint removing device is used for removing paint on theback surface of the electromagnetic coil terminal. The rotary disc device comprises a rotary disc with the axis rotationally connected to the rack. According to the electromagnetic coil terminal paint removing machine, the bending device, the front surface paint removing device, the four side surface paint removing devices and the back surface paint removing device are adopted, so that the functions of automatically bending and depainting terminals of electromagnetic coils are realized, the depainting efficiency is high, and the depainting quality is stable and reliable.

Owner:东莞沛波电子有限公司

Water tank bending method and device for stainless steel cabinet production

ActiveCN112974579AImprove work efficiencyReduce work costsMetal-working feeding devicesPositioning devicesClip deviceSelf adaptive

The invention discloses a water tank bending method and device for stainless steel cabinet production. The device comprises a clamping device and a bending device, wherein the clamping device comprises a machine table, a clamping manipulator and a moving driving mechanism, wherein the moving driving mechanism is used for driving the clamping manipulator to enter a working station of the bending device, the clamping manipulator comprises a workbench, a clamping mechanism, a rotation driving mechanism used for driving the clamping mechanism to rotate, a lifting mechanism used for driving the clamping mechanism to vertically move and a supporting mechanism used for supporting the clamping mechanism to swing in a self-adaptive mode in the bending process, the bending device comprises a machine frame, a bending cutter and a bending driving mechanism used for driving the bending cutter to move vertically, a cutter holder is arranged on the machine frame and located below the bending cutter, and a cutter groove matched with a cutting edge of the bending cutter is formed in the cutter holder. According to the water tank bending device, a stainless steel water tank can be automatically machined, and the automation degree and the working efficiency are higher.

Owner:GUANGZHOU BAINENG KITCHEN CABINET CO LTD

A sink bending method and device for the production of stainless steel cabinets

ActiveCN112974579BRealize automatic bendingImprove work efficiencyMetal-working feeding devicesPositioning devicesRobot handStructural engineering

Owner:GUANGZHOU BAINENG KITCHEN CABINET CO LTD

Automatic pole lug bending device

ActiveCN107876597ASolve the problem of poor process consistencyRealize automatic bendingMetal-working feeding devicesCell component detailsMechanical engineeringLead–acid battery

Owner:JIANGSU LEOCH BATTERY

Water tank manufacturing method and equipment used for stainless steel cabinet production

ActiveCN113020359ARealize automatic bendingImprove work efficiencyMetal-working feeding devicesPositioning devicesSS - Stainless steelEquipment use

The invention discloses a water tank manufacturing method and equipment used for stainless steel cabinet production. The equipment comprises a stainless steel plate storage device, a clamping device, a bending device, a water tank storage device and a carrying device. The clamping device comprises a machine table, a workbench, a clamping mechanical arm and a moving driving mechanism used for driving the clamping mechanical arm to enter the working station of the bending device. The clamping mechanical arm comprises a clamping mechanism, a rotating driving mechanism and a supporting mechanism. The bending device comprises a support, a bending cutter and a bending driving mechanism, a cutter holder is arranged at the position, below the bending cutter, of the support, and the cutter holder is provided with a cutter groove cooperating with a cutting edge of the bending cutter. The carrying device comprises a rack, multiple sets of carrying modules arranged on the rack and a carrying driving mechanism. According to the water tank manufacturing equipment, a stainless steel water tank can be automatically machined, and the automation degree and the working efficiency are higher.

Owner:GUANGZHOU BAINENG KITCHEN CABINET CO LTD

Steel plate bending and cutting device

PendingCN109332996ARealize automatic rise recoveryRealize automatic bendingNibbling shearing machinesEngineeringMechanical engineering

The invention discloses a steel plate bending and cutting device. The device is characterized by comprising a rack, a vertical plate, a bending mechanism, a cutting mechanism and a conveying mechanism; the bending mechanism comprises a vertical sliding rail, a positioning block and a bending block; the bending block is glidingly arranged on the vertical sliding rail; a groove is formed in the bottom of the bending block and is matched with the positioning block; a rotating shaft is arranged above the vertical sliding rail; an elliptic wheel is arranged on the rotating shaft; a limiting bolt isarranged in the position, located on each of two sides of the rotating shaft, of the vertical plate; a spring is arranged on each limiting bolt; the top of each spring is connected with the corresponding limiting bolt; the bottoms of the two springs are connected with the two sides of the bending block; the peripheral surface of the elliptic wheel makes contact with the top of the bending block;and the cutting mechanism is arranged under the right side of the positioning block. By the aid of the steel plate bending and cutting device, the bending and cutting efficiency of products is improved, and the machining safety is improved.

Owner:苏州裕庆金属制品有限公司

Full automatic bending machine

The invention discloses a full automatic bending machine. The full automatic bending machine comprises a plurality of bending mechanisms which are overlapped, wherein a feeding port is arranged above the bending mechanisms at the topmost end, a partition plate is arranged between every two adjacent bending mechanisms, a discharging through hole is formed in each partition plate, and the shape of each discharging through hole is matched with the shapes of rods bent by the bending mechanism above the corresponding discharging through hole. Each bending mechanism comprises a fixing groove, a rotating rod and a bottom plate, wherein each rotating rod is rotationally connected with the corresponding bottom plate, each rotating rod is connected with a driving device, and the driving devices are connected with a control device. Each partition plate comprises a partition plate body which is provided with a notch, sliding rails are arranged on two sides of each notch, a sliding plate matched with the corresponding sliding rails is arranged in each notch, each sliding plate is connected with a first air cylinder controlling sliding of the corresponding sliding plate, each first air cylinder is connected with the control device, a storage hopper is connected with the feeding port, and an anti-blocking air cylinder is arranged at the lower end of the storage hopper. The full automatic bending machine can achieve automatic bending, improve working efficiency and reduce labor cost, and the feeding port of the full automatic bending machine can be prevented from being blocked.

Owner:NINGBO ZHENHAI SHILI ELECTROMECHANICAL

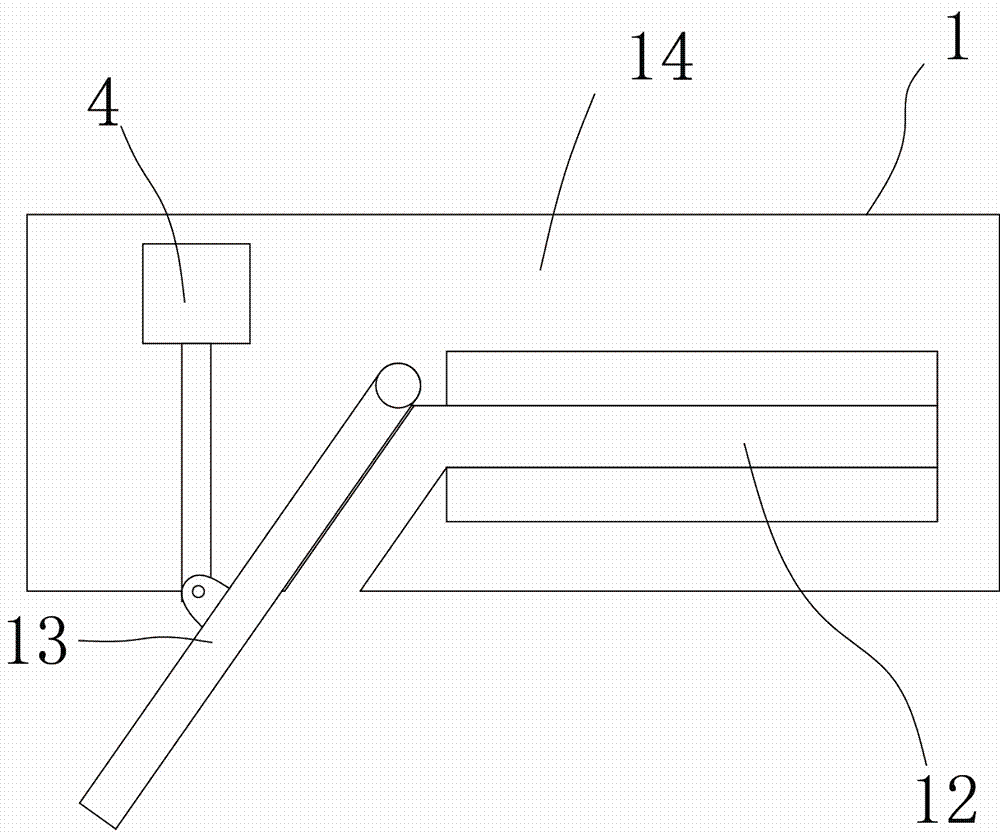

Bending machine

InactiveCN109482771ASimple structureReduce manufacturing costHeat exchange apparatusAir pumpPulp and paper industry

The invention relates to a bending machine and belongs to the technical field of bending equipment. The bending machine comprises a rack, an upper panel, an air cylinder supporting plate, a handle, anair cylinder, a vertical plate, a bending wheel, a pin, positioning pins, a bottom plate, a leaning wheel, a rotating block, a step switch, air pipes and a deformation wheel. The rack is welded to the upper panel. The air cylinder supporting plate and the vertical plate are welded to the upper panel. A certain angle is formed between the bottom plate and the upper panel, and the bottom plate andthe upper panel are welded to the vertical plate. The bending wheel and the positioning pins are welded to the bottom plate. The leaning wheel is connected with the upper panel through a screw. The deformation wheel is connected with the rotating block through the pin. The air cylinder is connected with the handle through a nut so as to transmit powder. The handle is welded to the rotating block.The step switch is connected with the air cylinder and an externally-connected air pump through the air pipes. An air cylinder piston rod is controlled to move through pressing of the step switch. Thebending machine is simple in structure and low in manufacturing cost, pneumatic back bending is used for replacing traditional manual back bending, physical force is saved, and the work efficiency isimproved.

Owner:KUNMING UNIV OF SCI & TECH

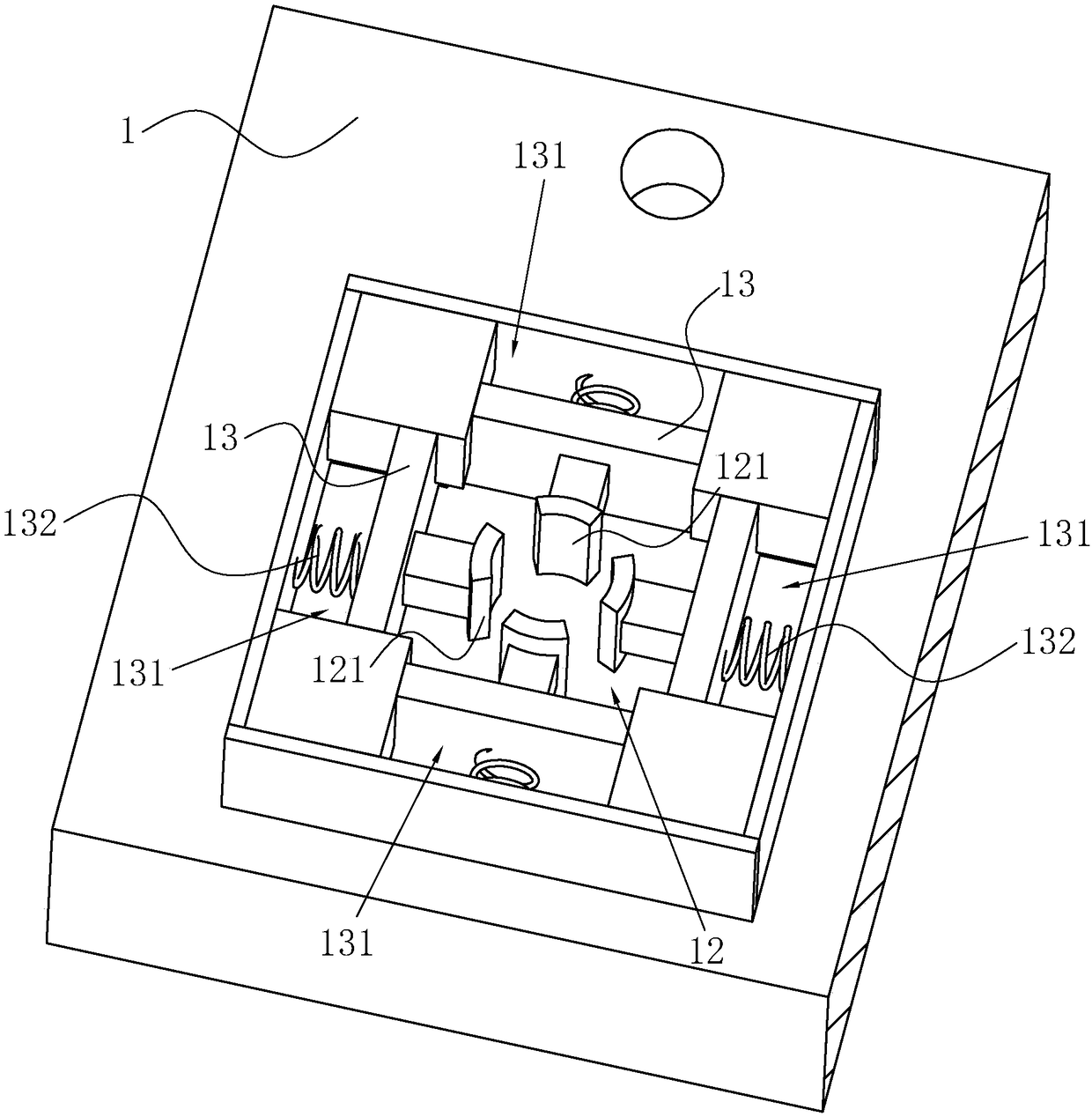

Steel pipe bending machine

The invention relates to a steel pipe bending machine. The steel pipe bending machine comprises a bottom plate, a fixing device and a bending device, wherein the bottom plate is provided with the fixing device and the bending device, and the fixing device is located in front of the bending device. The fixing device comprises a fixing frame, a fixing cylinder, a fixing wedge-shaped column, a fixingcompression ring, a fixing inner sleeve and a fixing outer sleeve. The bending device comprises a bending platform, a bending moving mechanism and a filling mechanism. The bending platform and the bending moving mechanism are mounted on the bottom plate. The problems that the bending effect of existing manual bending of a steel pipe by means of tools is not ideal, when the pipe is thicker, the steel pipe is difficult to bend by artificial power and the bending position is prone to being flat inwards; an existing bending radian of the steel pipe is relatively fixed generally, the bending radian of the steel pipe needs to be changed by manually changing a machine, the operation time is prolonged by manually changing the machine, and the work efficiency is reduced are solved.

Owner:江苏永上钢管有限公司

Bending machine

PendingCN110038937ARealize automatic bendingImprove product qualityMetal-working feeding devicesPositioning devicesPipe fittingEngineering

The invention provides a bending machine which comprises a base, a positioning mechanism on the base and a bending mechanism on one side of the positioning mechanism, wherein the bending mechanism comprises a rotary bracket, a bending shaft mounted on the rotary bracket, a fixed block fixedly connected with the bending shaft, a guiding shaft arranged at the top of the fixed block and in sliding fit with the rotary bracket, a bending block connected with the bending shaft, and a bending air cylinder for driving the rotary bracket to rotate. The positioning mechanism positions a product, and theproduct can be a pipe fitting or a sensor and the like with a smaller size; the bending mechanism bends one end of the product; in specific, after elevating the fixed block, the product is put into,the fixed block is pushed to descend, the bending air cylinder drives the rotary bracket to rotate, the rotary bracket drives the fixed block and the bending block to rotate by certain angle, and thebending block bends the product by certain angle, so that automatic bending of the product is realized, the bending curvature is fixed, the product quality is stable, manpower is saved and volume production is facilitated.

Owner:SUZHOU UNIV OF SCI & TECH

Upper limb rehabilitation exercise mechanism for medical rehabilitation

InactiveCN107126347AGood effectImprove efficiencyChiropractic devicesTelescopic cylinderPhysical exercise

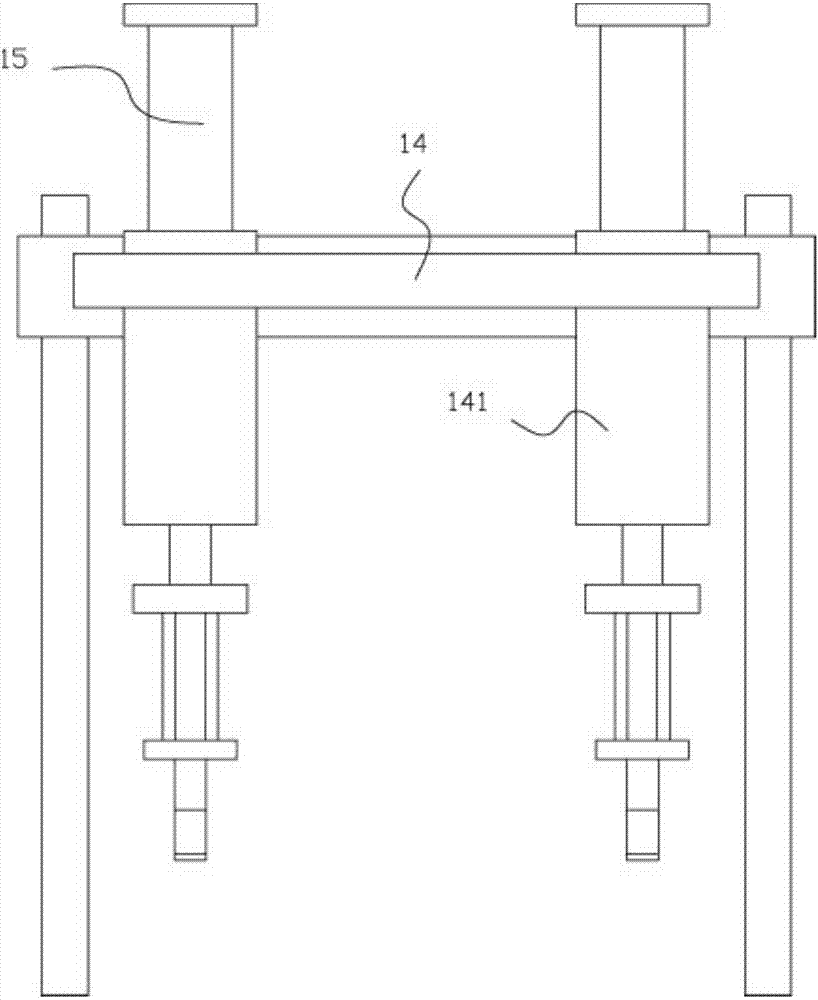

The invention discloses an upper limb recovery exercise mechanism for medical rehabilitation, comprising a base plate and a seat, the seat is fixed in the middle of the top surface of the base plate, a vertical plate is provided on the left side of the base plate, and the backrest of the seat is fixed on the vertical plate On the two sides of the bottom plate in front of the seat, vertical columns are fixed, the upper connecting plate is fixed on the upper part of the two vertical columns, and the telescopic cylinder is fixed on the top surface of both sides of the upper connecting plate, and the end of the push rod of the telescopic cylinder A connecting block is fixed through the upper connecting plate, a plurality of elastic belts are fixed on the bottom of the connecting block, a pulling plate is fixed on the bottom of the elastic belt, and a gripping portion is fixed on the bottom surface of the pulling plate. After holding the grip part by hand, it can be pushed by the push rod of the telescopic cylinder to realize automatic stretching and lowering, and automatic bending of the arm, so as to perform rehabilitation exercises on the arm. It has good effect and high efficiency without the assistance of others.

Owner:FOSHAN KEYI AUTOMATION TECH CO LTD

Electrical mounting rail bending machine

InactiveCN110756652ARealize automatic bendingRealize openingMetal-working feeding devicesMetal working apparatusElectrical connectionStructural engineering

The invention relates to the field of electrical mounting rails, in particular to an electrical mounting rail bending machine. The electrical mounting rail bending machine comprises a rack, a linear transmission mechanism, a first stamping device, a slide rail mechanism, a material blocking mechanism, a step type feeding mechanism, a second stamping device, a sensor and a controller, wherein the linear transmission mechanism and the first stamping device are fixedly mounted on the rack in an inclined mode; the slide rail mechanism is arranged below the first stamping device; the material blocking mechanism is arranged on the slide rail mechanism; the sensor clings to the side, close to the first stamping device, of the material blocking mechanism; the step type feeding mechanism is mountedon the slide rail mechanism; the second stamping device is arranged above the slide rail mechanism; and the linear transmission mechanism, the first stamping device, the material blocking mechanism,the step type feeding mechanism, the second stamping device and the sensor are electrically connected to the controller. The electrical mounting rail bending machine realizes automatic bending and hole-forming of the electrical mounting rail, realizes automatic burr removal of the electrical mounting rail, saves labor power, improves working efficiency, is simple in structure, is easy to implementand is convenient to control.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

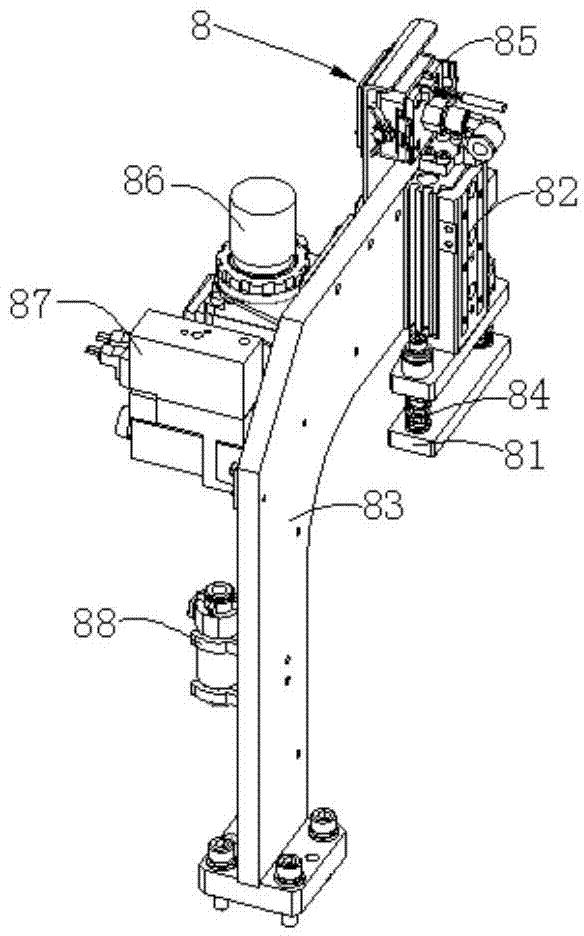

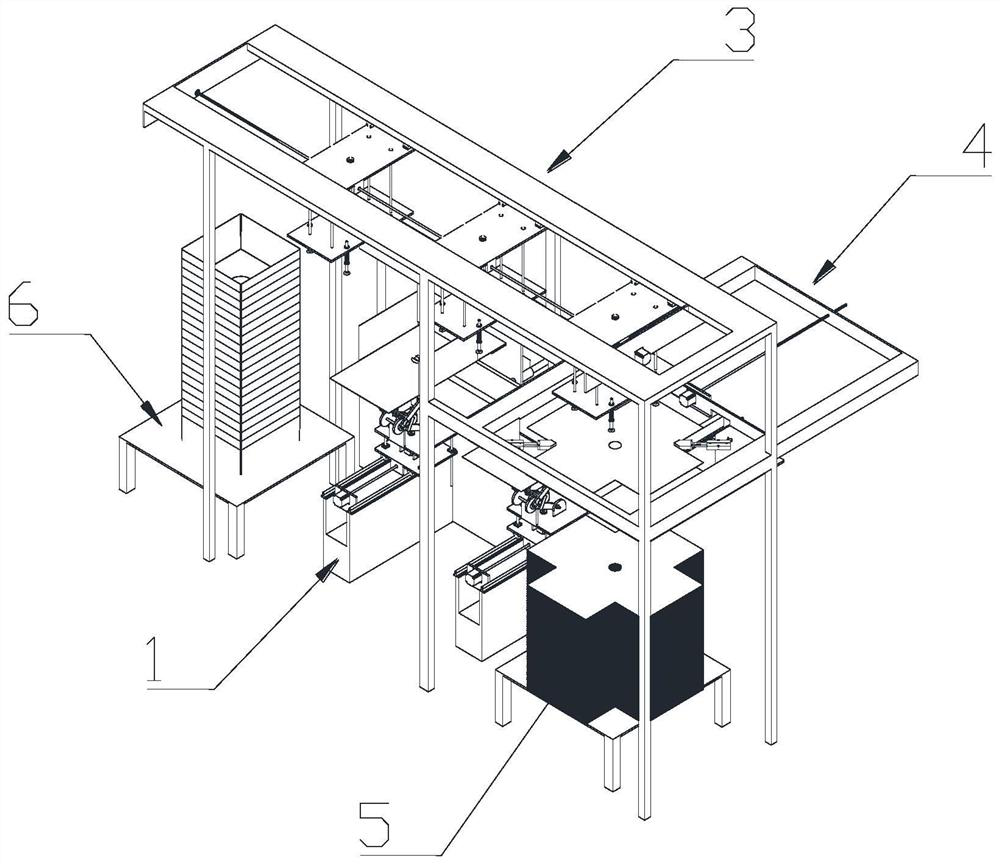

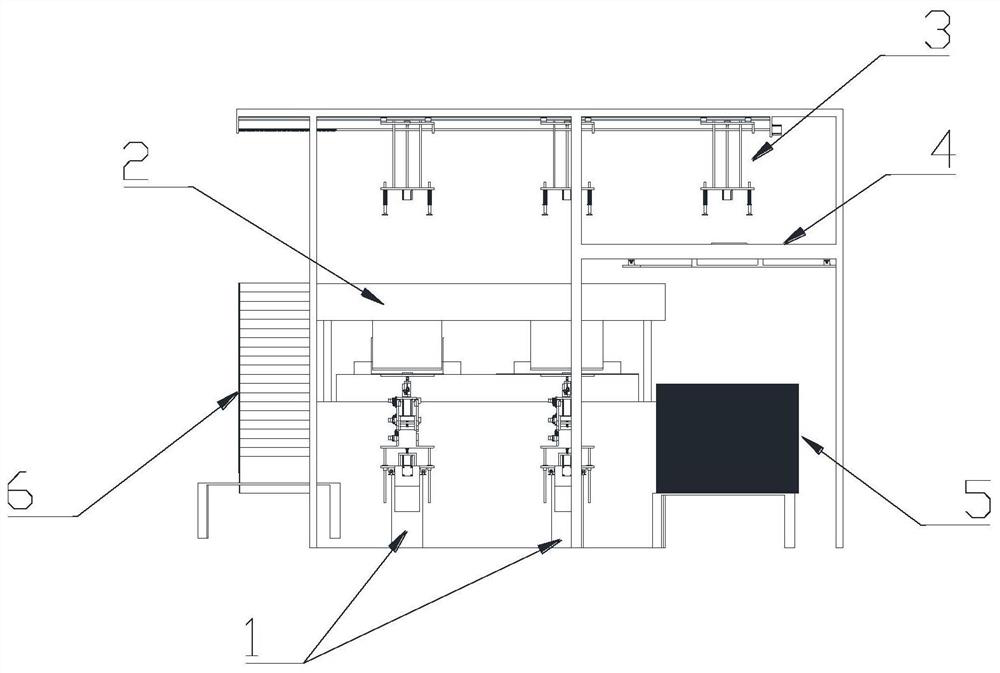

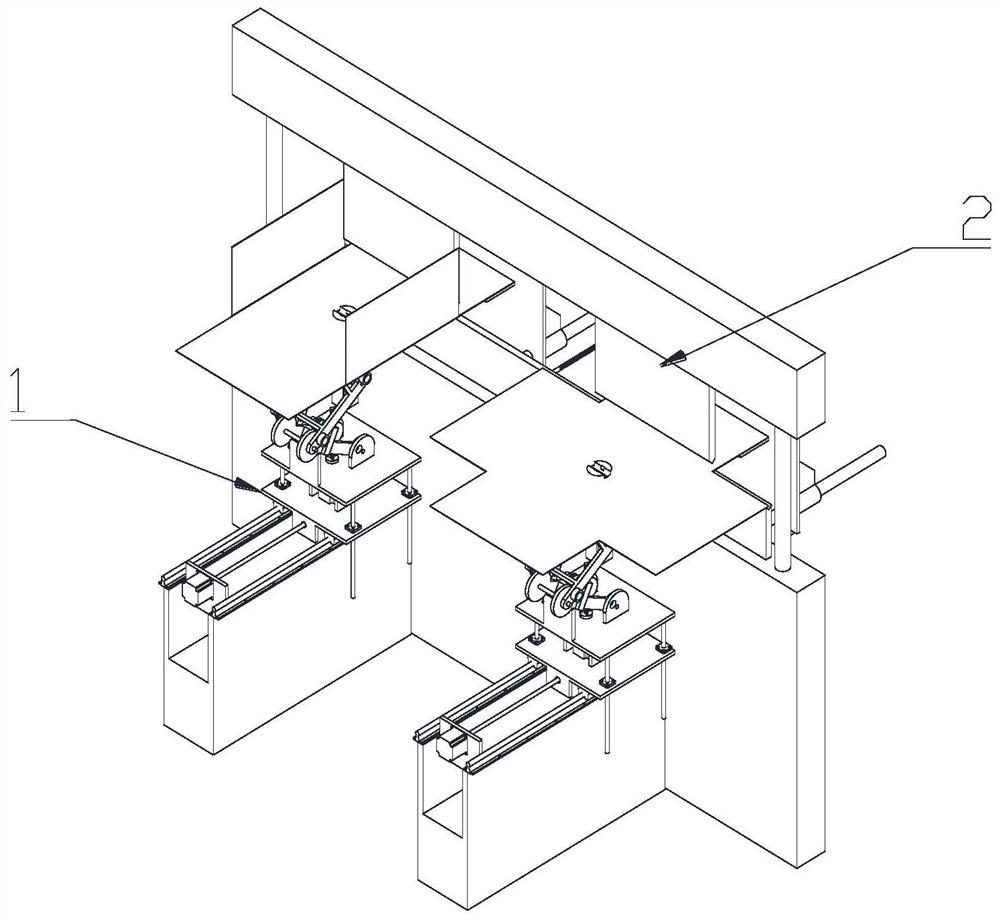

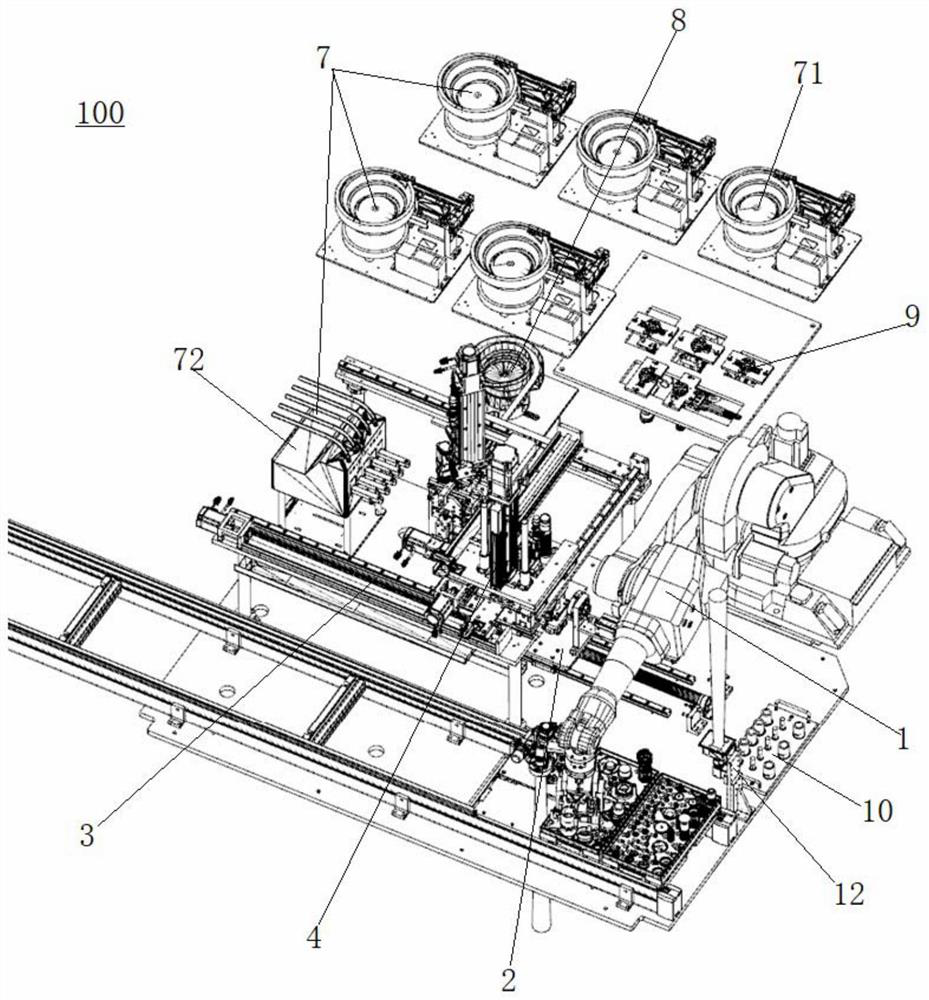

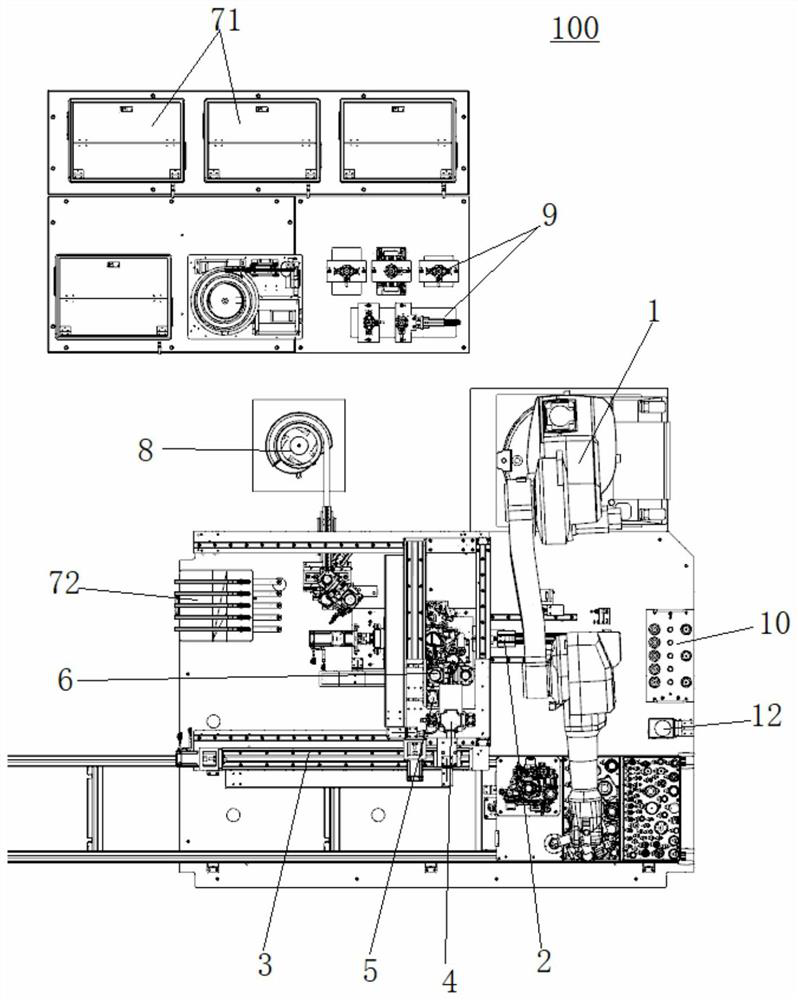

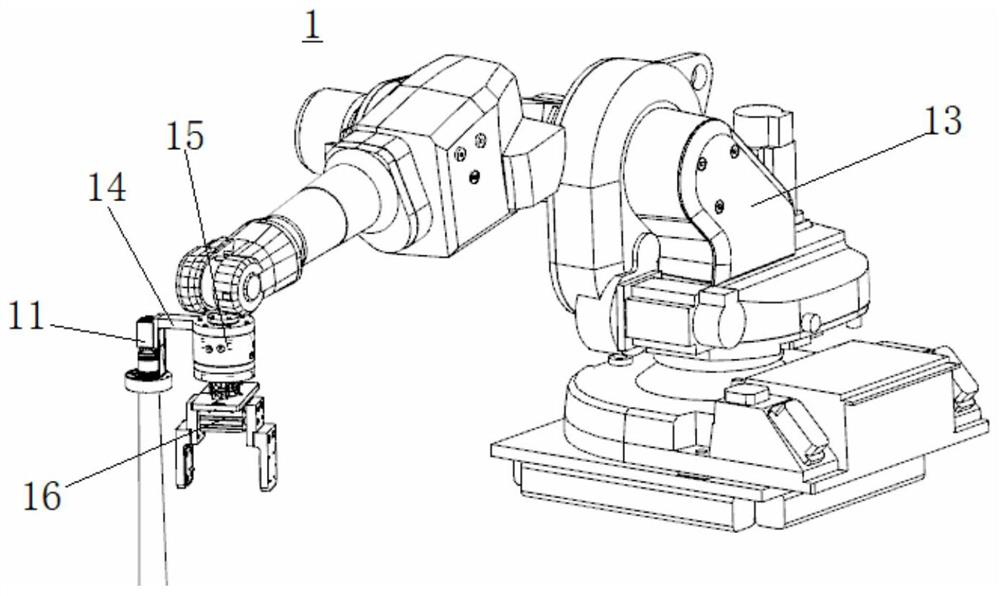

Automatic assembly mechanism and assembly method for engine accessories for aerospace

PendingCN113560882ARealize automatic locking installationRealize automatic bendingAssembly machinesMetal working apparatusEngineeringTransfer mechanism

The invention discloses an automatic assembly mechanism and assembly method for engine accessories for aerospace. The mechanism comprises a rotary fixed transfer unit which is used for bearing and fixing a shell and driving the shell to move between a feeding station and an assembly station, a press-fitting unit, a locking plate and screw mounting unit, a horizontal transfer robot used for driving the press-fitting unit and the locking plate and screw mounting unit to move in the X-axis direction and the Y-axis direction, a gasket feeding unit, a screw feeding unit, a locking plate feeding and bending unit used for feeding and bending locking plates, a robot transfer mechanism, and a robot quick-change clamp unit matched with the robot carrying mechanism to automatically change the clamp at the movable tail end. According to the mechanism, automatic assembly of a plurality of valve assemblies on an engine regulator is achieved, the assembly efficiency and the assembly precision are greatly improved, and the product quality is guaranteed.

Owner:苏州迈智诺智能装备科技有限公司

Fully automatic bending machine

The invention discloses a fully automatic bending machine, which comprises a plurality of bending mechanisms, wherein the bending mechanism are overlapped together, a feeding opening is arranged above the bending mechanism positioned at the topmost end, separation plates are arranged between every two bending mechanisms, a blanking through hole is formed in each separation plate and is matched with the rod body shape of the bending mechanism arranged above the blanking through hole after the bending, each bending mechanism comprises a fixing groove, a rotating rod and a bottom plate, each rotating rod is rotationally connected with each bottom plate, a driving device is connected onto each rotating rod, the driving devices are respectively connected with a control device, each separation plate comprises a separation plate body, a notch is formed in each separation plate body, two sides of each notch are provided with slide rails, a sliding plate matched with the slide rails is arranged in each notch, a first air cylinder is connected onto each sliding plate, and each first air cylinder controls the corresponding sliding plate to slide and is connected with the control device. The fully automatic bending machine has the advantages that the automatic bending can be realized, the labor cost is reduced, and the operation safety is improved.

Owner:NINGBO ZHENHAI SHILI ELECTROMECHANICAL

Intelligent steel pipe bending industrial machine

The invention relates to an intelligent steel pipe bending industrial machine comprising a bottom plate and a bending device installed on the bottom plate. The bending device comprises a bending table, a bending moving mechanism and a filling mechanism. The bending table and the bending moving mechanism are installed on the bottom plate. The filling mechanism is installed on the bending moving mechanism. The problems that the at present, when a steel pipe is bent manually by a tool, the bending effect is not ideal, when the pipe is thick, bending of the steel pipe is difficult for manual power, and the bent position is liable to inner flatness; and the bending radian of the steel pipe is generally fixed at present, bending grinding tools need to be changed manually to change the bending radian of the steel pipe, different bending grinding tools need to be changed manually for different-diameter steel pipes at present, due to manual machine changing, work time is prolonged, and work efficiency is lowered can be solved.

Owner:WENZHOU XINDEDA STAINLESS STEEL MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com