Fully automatic bending machine

A bending machine, fully automatic technology, applied in the field of fully automatic bending machines, can solve the problems of low safety guarantee for workers, high labor cost, easy to clamp hands, etc., to improve operational safety, reduce labor costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

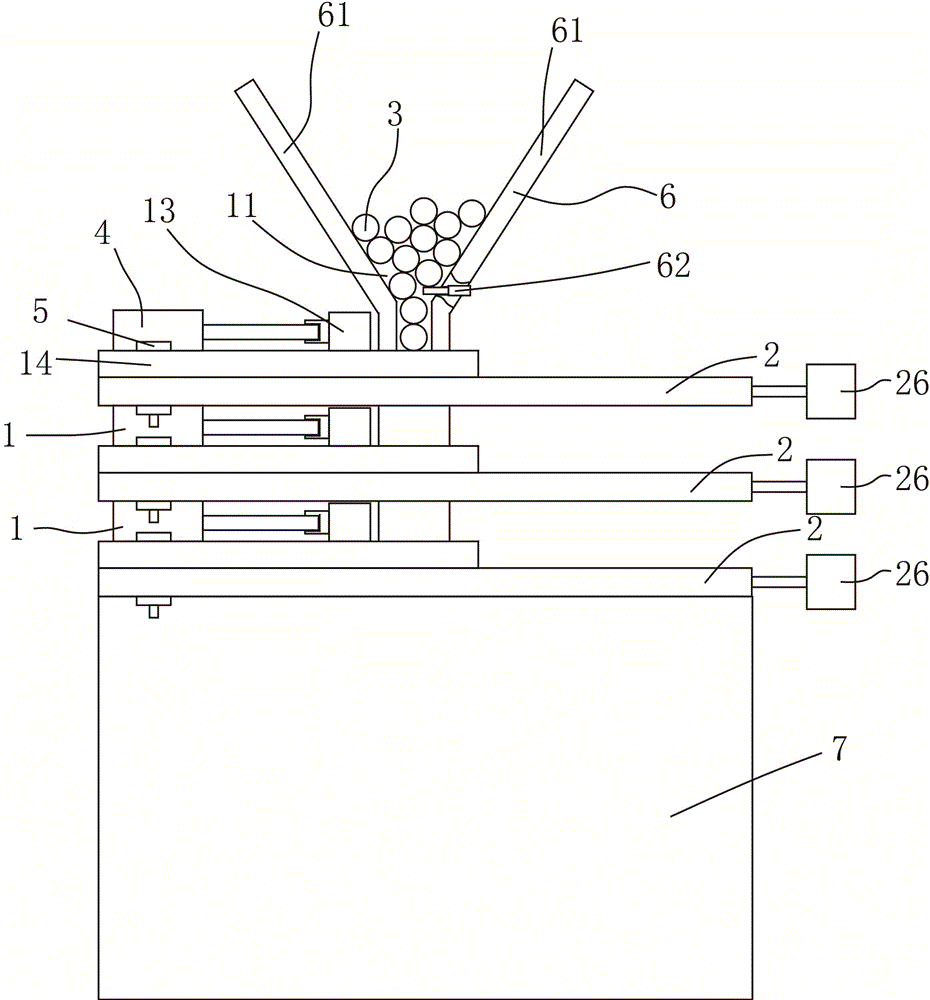

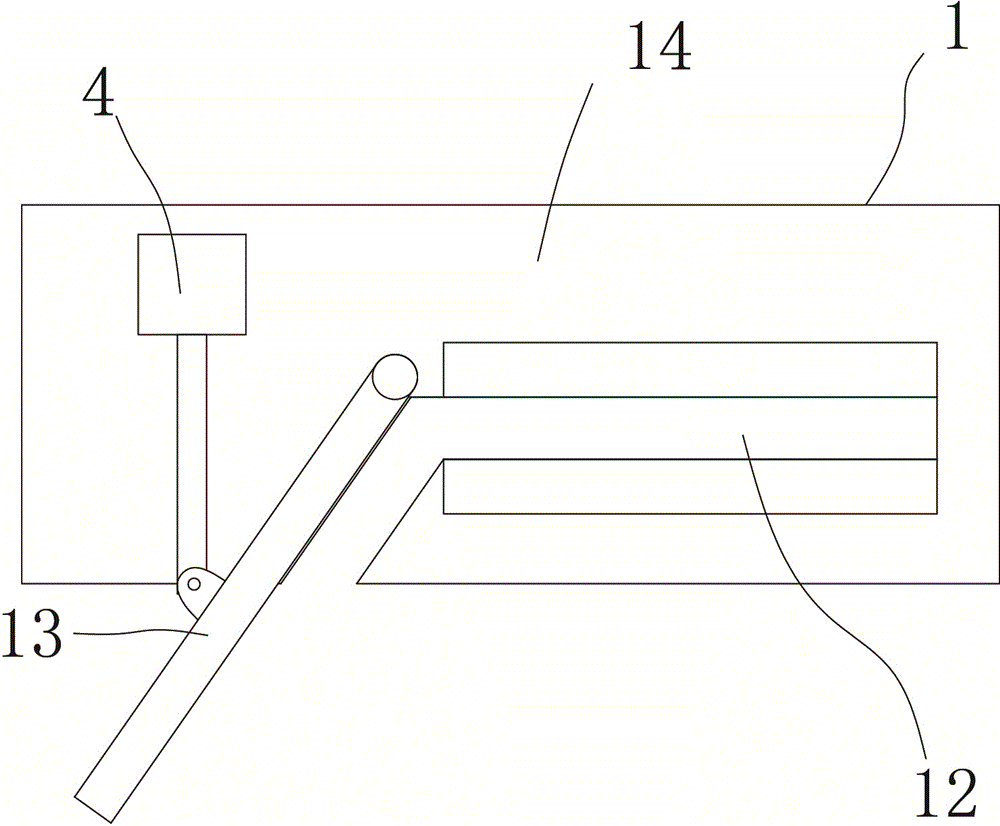

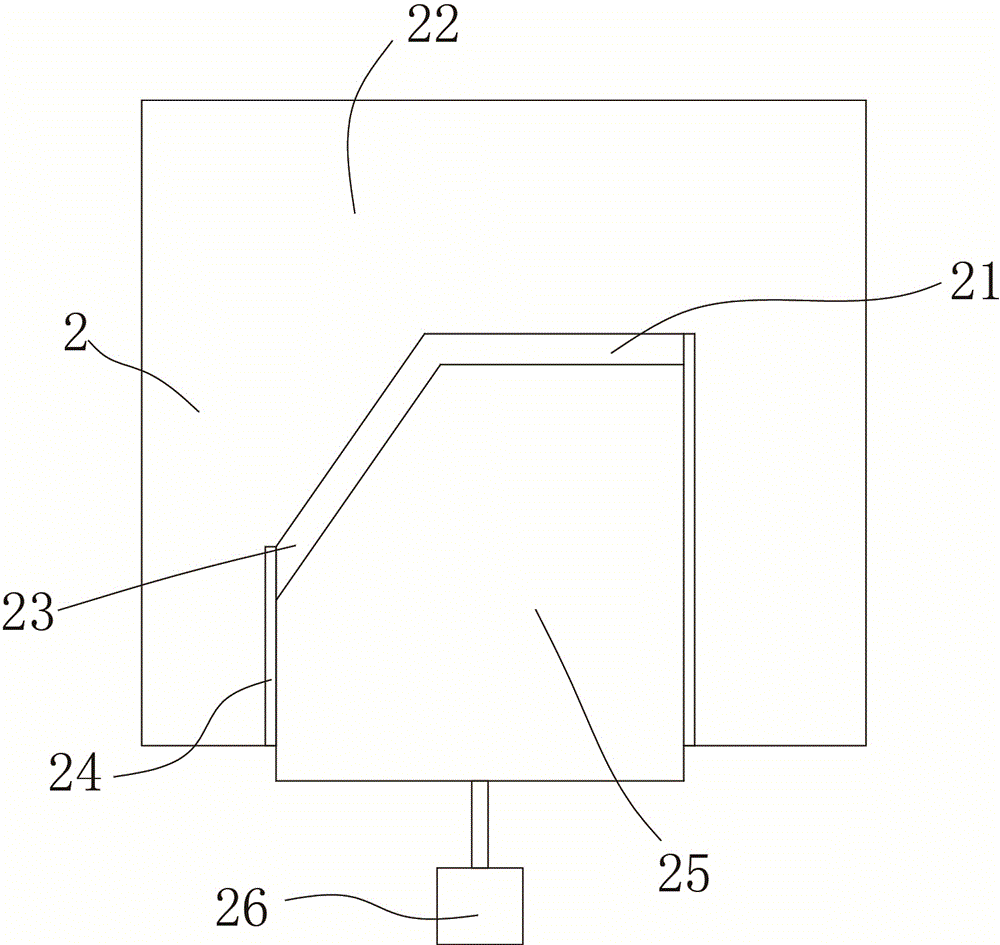

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , a full-automatic bending machine, including several bending mechanisms 1 stacked together, a feeding port 11 is arranged above the bending mechanism 1 at the uppermost end, and a partition is arranged between each bending mechanism 1 2. The partition plate 2 is provided with different blanking through-holes 21, the shape of the blanking through-holes 21 matches with the shape of the rod body 3 (processed material) bent by the bending mechanism 1 above. The bending mechanism 1 comprises a fixing groove 12, a rotating rod 13 and a base plate 14, the rotating rod 13 is rotationally connected with the base plate 14, the rotating rod 13 is connected with a driving device 4, and the driving device 4 is connected with the control device ( (not shown in the figure) are connected. In this embodiment, the driving device 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com