Intelligent vegetable greenhouse framework installing robot

A vegetable greenhouse and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of inconsistent shape of steel pipes, inability to guarantee parallelism, slow work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

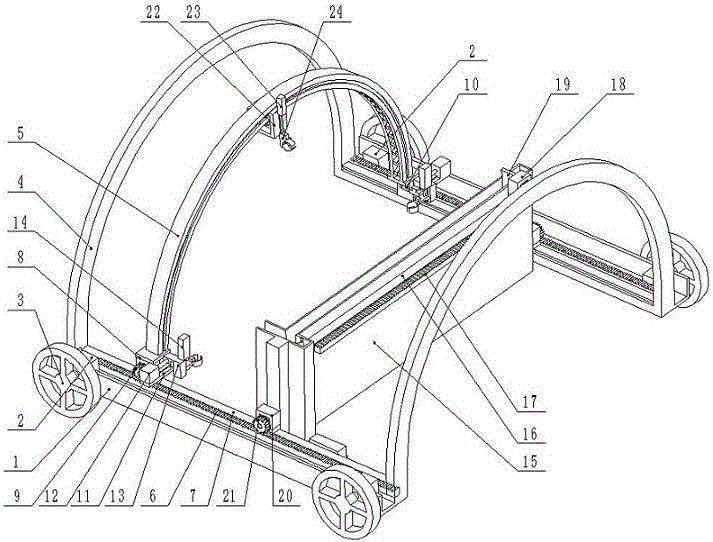

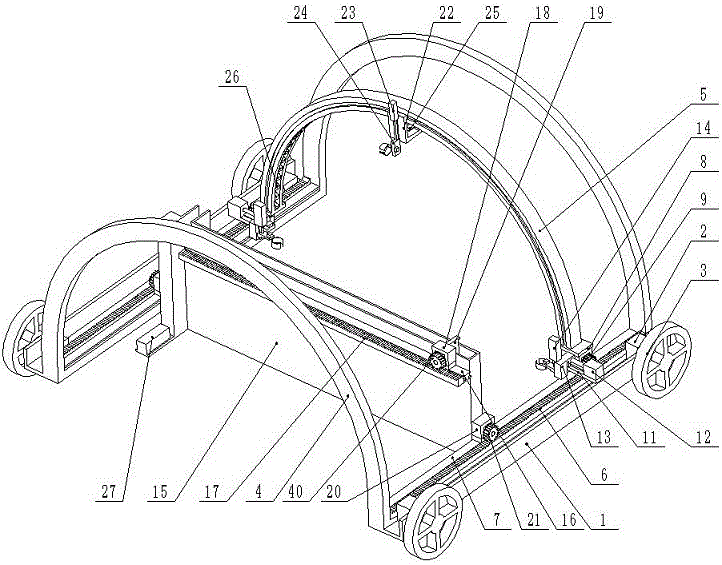

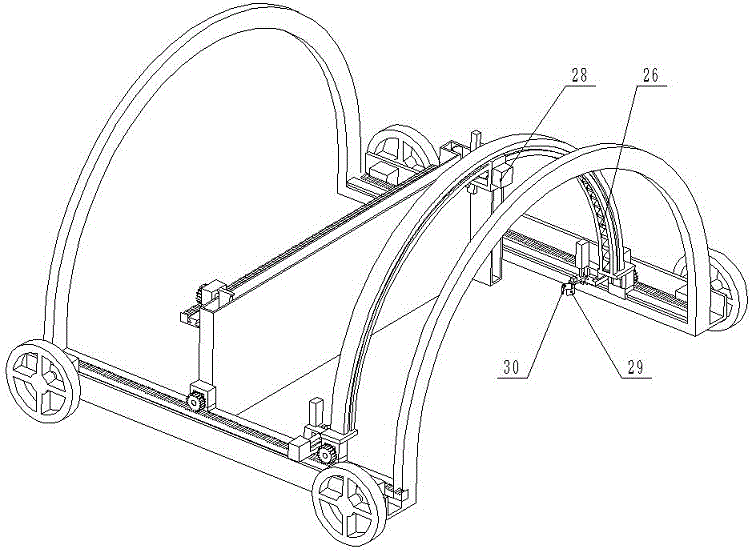

[0027] Example: such as Figure 1 to Figure 13 Shown here is an intelligent installation robot for the vegetable greenhouse framework of the present invention. Two arc fixing frames 4 are semi-arc structures and are respectively installed at the front and rear ends of the base frame 1, and the four corner positions on the outside of the base frame 1 are respectively A traveling wheel 3 is provided for rotation, and four traveling motors 2 are provided at the same time. The main shaft of each traveling motor 2 is coaxially installed with a traveling wheel 3, and the traveling motor 2 drives the traveling wheel 3 to rotate.

[0028] Two moving slide rails 7 are symmetrically provided on the left and right sides of the chassis 1, and a moving rack 6 is respectively provided on the outer side of each moving slide rail 7 in parallel. The arc bending frame 5 is of a semi-arc structure. Both ends of the arc bending frame 5 are respectively provided with a bending frame moving slider 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com